WPE DIESEL GENERATORS WPE DIESEL GENERATORS

PREPARATION BEFORE START OPERATION

4 5

Batteries generate hydrogen gas, which can flames or

sparks near a battery, especially during charging.

Charge the battery in a fully ventilated area.

WARNING

Know how to stop the generator quickly, and

understand how to operate all of the controls. Never

permit anyone to operate the generator without

proper instruction.

Always wear a helmet, safety shoes and proper

clothing. Keep pets and children away from the

generator when it is in operation.

PREPARATION BEFORE START

Selection and handling of fuel

– Only light diesel fuel can be used.

– The fuel must be filtered .

– Fuel should be free of water or dust because these

can contaminate the fuel injection system.

– Do not overfill the tank beyond the top of the red plug

inside the fuel tank filter, use fuel gauge on top of tank.

– Do not smoke and allow sparks in the area where the

engine is refueled or where gasoline is stored.

– Do not spill fuel when refueling, make sure the filter

cap is securely closed.

Selection and handling of oil

– Set the generator on a level surface.

– Fill the engine oil into the inlet.

– To check the oil level, simply dip the dipstick into the

pan. Do not screw in the dipstick when checking.

NOTICE

Nothing effects the performance and durability of

the generator more than the oil you use. If inferior oil

is used or if your engine oil is not changed regularly,

the risk of piston seizure, piston ring sticking and

accelerated wear of the cylinder liner, bearings and

other moving components increase significantly.

– Make sure to check the oil level and to refill with oil to

the specified level before starting the generator, even

though it is equipped with a low oil pressure warning

system.

– If your generator doesn’t start by the 5th attempted or

starts and cuts out, your oil level is to low and needs to

topped up.

NOTICE

Oil should be changed after the first 20 hours (or 1

month) of use and then every 3 months or 100 hours

of use.

Be sure to drain the oil while the engine is warm but

not hot . It is difficult to drain the oil completely after

cooling.

WARNING

NEVER add or attempt to change oil into the

generator while the engine is running.

Check air filter

– Loosen the wing nut, detach the cover of air cleaner

and remove the element. Do not wash air cleaner

element with detergent . Use water or petrol (MUST

allow to dry before replacing).

– The air cleaner element must be changed when the

output of engine decreases or the color of exhaust is

abnormal.

– Never run the generator without the air cleaner

element. This may cause rapid engine wear.

– Reattach the cover of air cleaner and tighten the wing

nut.

Ensure no load on generator

– Turn off the main circuit breaker and any other loads.

– Be sure to turn off the main circuit breaker before

starting the generator. If the switch is not on the “OFF“

position, sudden application of load could be very

dangerous, when the diesel engine is started.

– The generator should be earthed to prevent electric

shocks. (Recommended).

Handling of dual voltage type generator

– Operation of change over switch: The AC circuit

breaker on the control panel must be set to ‘OFF’

position before running the machine. After starting

the generator, allow the speed to reach rated RPM

and then turn the AC circuit breaker to the “ON”

position, so that the receptical sockets can be used

for operating equipment.

– NEVER try to switch between voltages when the AC

circuit breaker is ON and equipment plugged IN.

– Set the main AC circuit breaker to the “OFF” position

when using the 12v DC power supply.

Check for Airlock

WARNING

The FUEL and engine OIL are drained off by factory

prior to transportation. Generators are dry for

storage.

– Check for airlock in fuel pipeline, and find whether

there is air mixed into the pipeline, if yes, drain away

the air from the pipeline before refuel and start the

diesel engine.

– Fuel filter should be minimum 75% full, if not then air

may be present in system.

– The method to remove is, loosen the 17mm gland

nut connection between injecting pump and high

pressure brass pipeline, put run lever to “RUN”

position and turn over the engine until fuel starts to jet

out.

– Replace and re-tighten 17mm gland and repeat the

process if engine still does not start.

OPERATION

Low oil warning system

– Device works to stop the engine automatically when

the oil pressure falls below the regulatory level and

will prevent engine seizure when the engine oil is

running low or engine pressure is lost.

– The oil temperature will rise high if the engine is

operated with insufficient engine oil. On the other

hand, too much oil is dangerous because the oil may

combust and cause a sudden and excessive rise in

engine rpm, so before operating the machine each

day be sure to check the oil and fill oil to the specified

level if necessary.

Opening the cabinet door and cover.

Opening the cabinet door and raise the door and check

daily.

1. Turn the handle anticlockwise to open cabinet door.

2. Turn the handle clockwise to lock cabinet door.

Break-in operation

While your generator is still new, application of heavy

loads may shorten the life of the engine. Follow the break-

in procedures during the first 20 hours.

1. Avoid applying any heavy load during the break-in

period.

2. Change engine oil regularly. Change the engine oil

every 20 hours or one month after the initial use, and

every 3 months or 100 hours thereafter.

Starting the generator

Recoil start (Open Frame Type Only)

1. Open the fuel cock (at the “ON” position).

2. Put the engine speed lever in the “RUN” position.

3. Pull out the recoil starting handle.

4. Pull out the handle to the point where your hands

feel strong resistant and then return it to the initial

position.

5. Push down the decompression lever. (It will return

automatically when the recoil starter is pulled).

6. Pull out the recoil starting handle briskly with both

hands.

7. Do not allow the handle grip to snap back against

the engine. Return it gently to prevent damage to the

starter.

WARNING

NEVER pull out or touch the recoil when the diesel

engine is running, otherwise it will damage the

engine.

8. In cold weather, when diesel engine is difficult to

start, remove the plug from the rocker arm cover and

add 2 cc of engine oil.

9. Replace the plug before starting.

10. Always keep the red plug in the cover except

when adding oil, otherwise rain , dirt and other

contaminants may enter the engine and cause

accelerated wear of internal engine parts. This in

turn can cause serious problems.

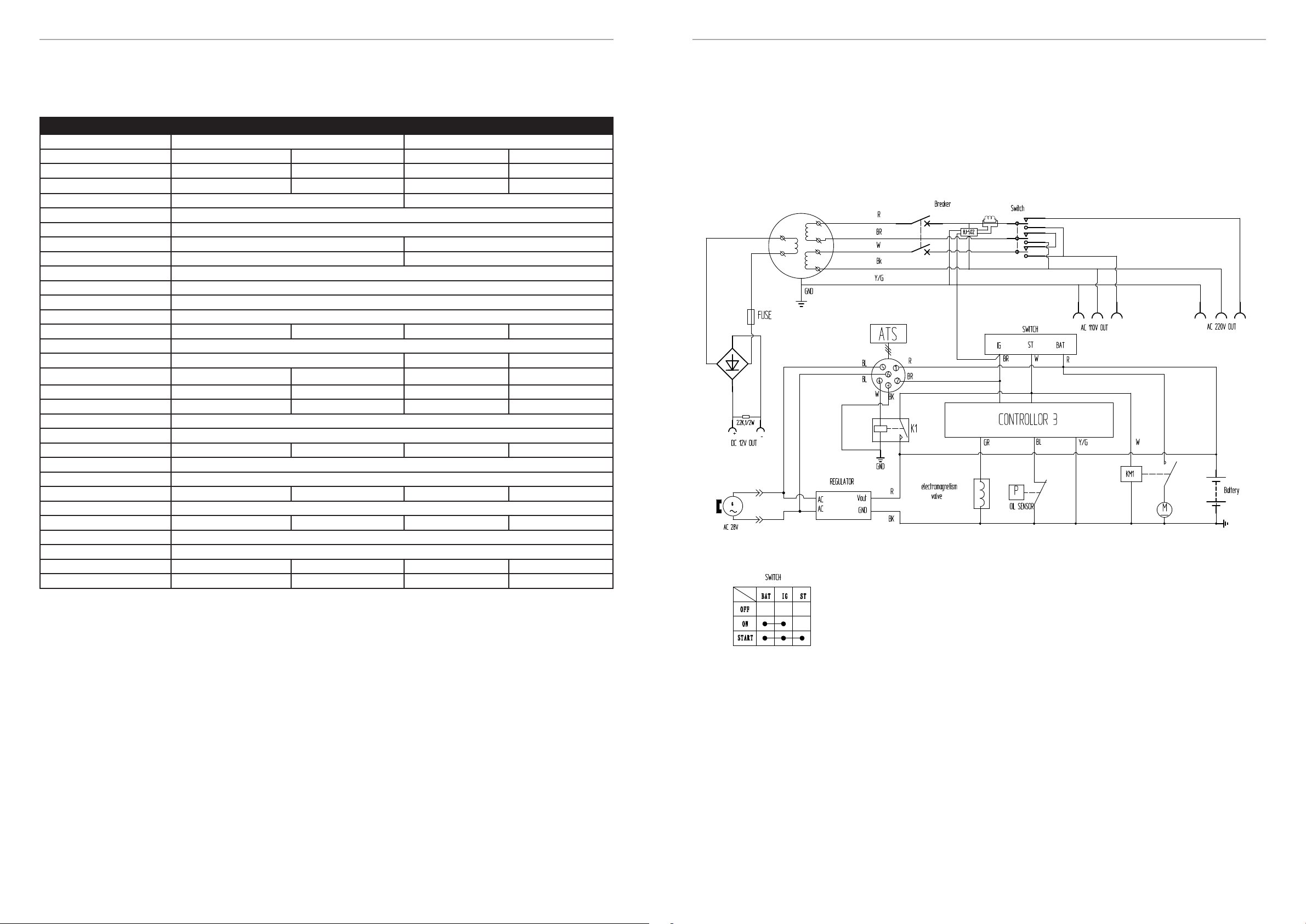

Electric Start

1. Turn ignition key clockwise to ‘ON’ position.

2. Put the engine speed lever in the “RUN” position.

3. Turn the ignition key clockwise to “Start” position.

4. Release your hand from the key as soon as the

engine starts and let the key return automatically to

initial ‘ON’ position.