Contents

1 Features.............................................................................................................................4

2 Safety Symbols used in this Manual..................................................................................5

3 Safety Guidelines...............................................................................................................5

4 Responsibility for Operation or Damage............................................................................6

5 Application..........................................................................................................................6

6 Before Starting...................................................................................................................6

6.1 Transport...............................................................................................................................6

6.2 Installation............................................................................................................................. 7

6.3 Storage..................................................................................................................................7

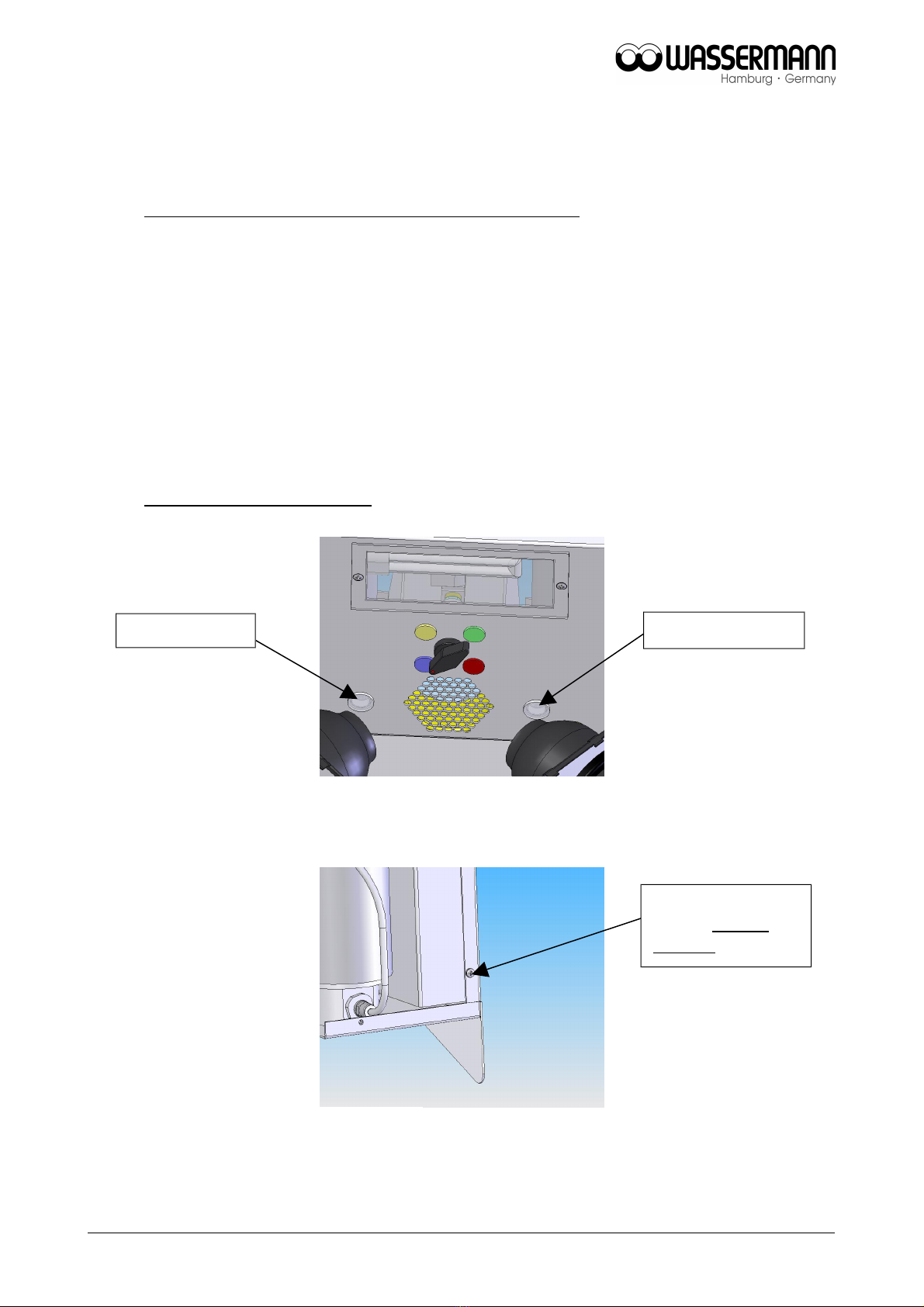

7 Installation/ Start-up...........................................................................................................8

7.1 Assembly Follow-up Kit.......................................................................................................10

8 Operation.........................................................................................................................14

8.1 General Operating Instructions............................................................................................14

9 Troubleshooting...............................................................................................................15

10 Care and Maintenance...................................................................................................16

10.1 Cleaning............................................................................................................................16

10.2 Maintenance...................................................................................................................... 16

10.2.1 Grip-cuff Replacement.........................................................................................................17

10.2.2 Screen Replacement...........................................................................................................17

10.2.3 Conducting Hose Replacement...........................................................................................17

10.2.4 Lamp Replacement..............................................................................................................18

10.2.5 Nozzle Replacement............................................................................................................18

10.2.6 Protection Filter Replacement..............................................................................................19

10.2.7 Water Separator...................................................................................................................19

10.3 Warranty............................................................................................................................ 20

10.4 Scope of Delivery/ Accessories (115 V version)................................................................20

10.5 Spare Parts........................................................................................................................21

10.6 Service Hotline 0049 (0)40 730 926 -20/ -24.....................................................................21

10.7 Repairs..............................................................................................................................21

11 Technical Data...............................................................................................................22

12 Disposing of the Unit......................................................................................................22

12.1 Information on Disposal for Countries within the EU..........................................................22

13 EU Declaration of Conformity........................................................................................23