Waste King 560C396P01 User manual

Food Waste Disposer

Owner s Guide

IMP RTANT - Read all instructions thoroughly. Keep this guide for

future reference.

CAUTI N - Be sure to review SAFETY INSTRUCTI NS PERTAINING T

A RISK F FIRE, ELECTRICAL SH CK R INJURY T PERS NS before

installing disposer.

CONGRATULATIONS. YOU HAVE PURCHASED THE

#1 PERFORMANCE LEADER IN FOOD WASTE DISPOSERS.

Our food waste disposer is a reliable appliance that will offer your household many years of

trouble free use. This disposer has been uniquely designed to free your kitchen of all organic

food waste left over after the preparation and clean-up of meals. Simply turn on the water,

switch the disposer on, put your food waste in the disposer and it will shred the garbage into

very fine particles that are easily flushed through the sewer system without any problem. For

Batch Feed Operations, please see Section 6 of this manual.

Before installing and operating this disposer:

1. Make sure that the installation of this appliance is allowed by the authorities.

2. Please read and follow all recommendations in this manual to ensure

trouble free operations.

f you have any questions, please contact your distributor.

1MOUNTING ASSEMBLY

2ELECTRICAL CONNECTIONS

3DISHWASHER CONNECTION

4ATTACHING THE DISCHARGE ELBOW

5CONNECTING DISPOSER TO MOUNT ASSEMBLY

6OPERATING INSTRUCTIONS

7TROUBLESHOOTING

8CLEANING AND MAINTENANCE

TABLE OF CONTENTS

560C396P01 REV C

INSTRUCTI NS PERTAINING T RISK F FIRE, ELECTRIC SH CK R INJURY T

PERS NS. SAVE THESE INSTRUCTI NS.

1. Read all instructions before using

the appliance.

2. To reduce the risk of injury, close

supervision is necessary when an

appliance is used near children.

3. Do not put fingers or hands into a

waste disposer while it is functioning.

4. Turn the power switch to the off position

before attempting to clear a jam or

remove an object from the disposer.

5. When attempting to loosen a jam in a

waste disposer, use a long wooden

spoon or a broom handle.

6. When attempting to remove objects

from a disposer, use long-handled

tongs or pliers.

7. To reduce the risk of injury by materials

that might be expelled by a waste

disposer, or damage to it, do not put

the following in the disposer:

a. Clam or oyster shells

b. Drain cleaner

c. Glass, china or plastic

d. Large whole bones

e. Metal, such as bottle caps,

tin cans or aluminum foil

f. Whole corn husks

g. Tea or coffee bags

8. When not operating the disposer, leave

the stopper in place to reduce the risk

of objects falling into the disposer.

9. Do not operate disposer unless

splash guard is in place. Not applicable

to Batch Feed models.

10. For proper earthing instructions

see the ELECTRICAL C NNECTI N

portion of this manual.

11. f you are not familiar with electrical

power and procedures, call a qualified

electrician.

12. The symbol on the product or on its

packaging indicates that this product may

not be treated as household waste.

nstead, it shall be handed over to the

applicable collection point for the recycling

of electrical and electronic equipment. By

ensuring this product is disposed of

correctly, you will help prevent potential

negative consequences for the

environment and human health, which

could otherwise be caused by

inappropriate waste handling of this

product. For more detailed information

about recycling of this product, please

contact your local city office, your

household waste disposal service or the

shop where you purchased the product.

WARNING - When using electrical appliances, basic precautions should always be followed,

including the following:

IMPORTANT SAFETY INSTRUCTIONS

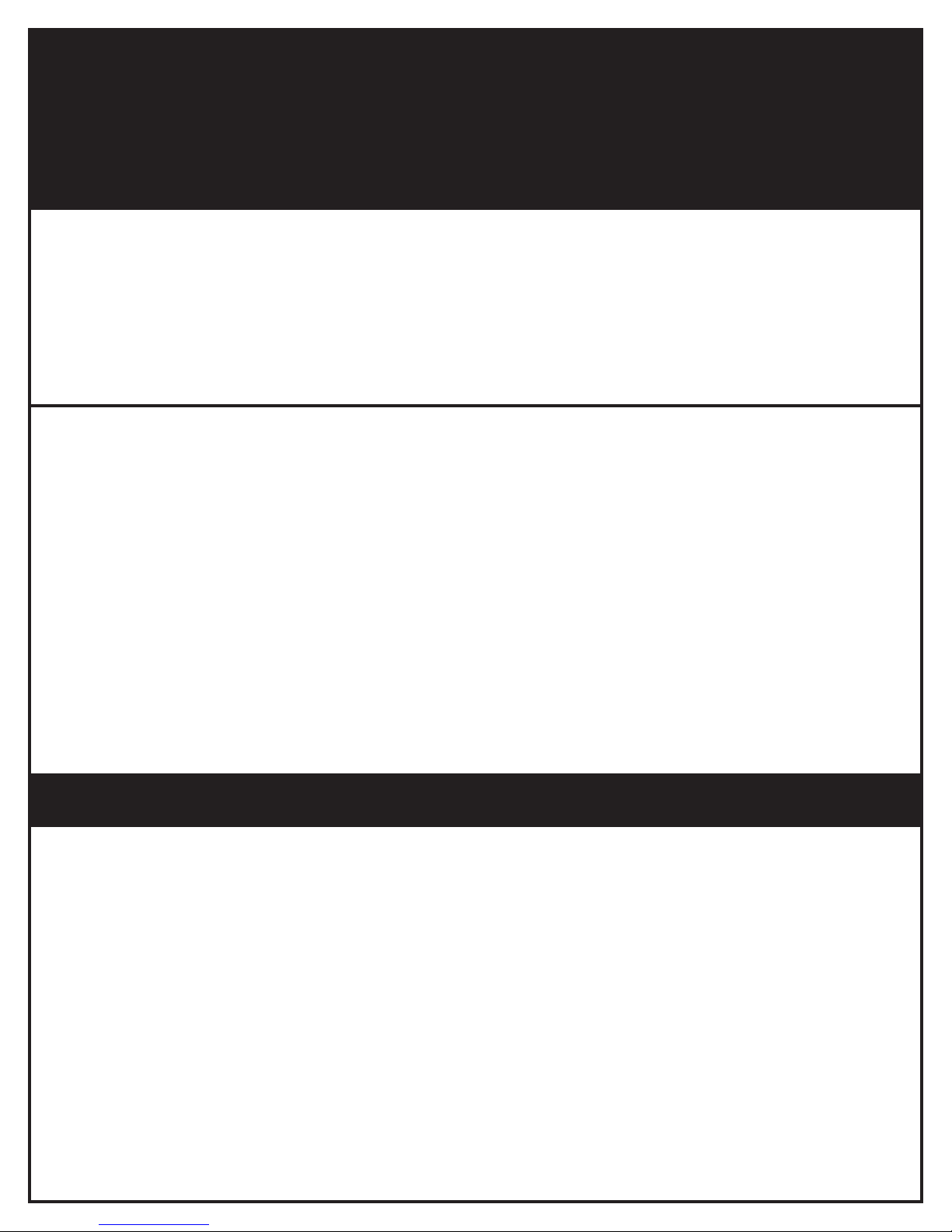

INSTALLATION OF EZ MOUNT ASSEMBLY

STOPPER

REMOVABLE

SPLASH GUARD

S NK FLANGE

RUBBER S NK

FLANGE GASKET

S NK

SUPPORT R NG

NOTE: ARROWS

ND CAT NG UP

CUSH ON MOUNT

GROOVE D SHWASHER

D SCHARGE NLET

HOPPER

ELBOW GASKET

END BELL

(ELECTR CAL

CONNECT ONS)

ELBOW

FLANGE

SCREWS

D SCHARGE

ELBOW

SER AL NUMBER

LOCATED HERE

(Read completely before starting.)

N TE: Pay close attention to the order of mount assembly parts,

as they have been correctly assembled by the factory.

Also, reference the cushion mount detail illustration below for

the proper orientation of the cushion mount.

A. Disassemble mount assembly from disposer by turning mount ring

to the left (clockwise) and remove.

B. Raise mount ring toward top of sink flange. Remove cushion

mount. Remove mount ring. You may want to practice installing

the cushion mount at this point before you are under the sink.

See paragraph "H."

C. Unscrew support ring from sink flange and remove fiber gasket.

You are now left with sink flange and rubber gasket.

D. The rubber gasket is used instead of plumbers putty with

stainless steel sinks. ther sinks may require putty.

E. f no putty is used, insert sink flange through rubber gasket into

sink opening. Do not rotate sink flange once it is seated.

F. f you use putty instead of the gasket, form a ring around

underside of sink flange. nsert flange into sink opening, press

down hard to squeeze out excess putty. From under sink, trim off

excess putty flush with bottom edge of sink opening.

G. From underneath sink, slip fiber gasket onto exposed sink flange.

With arrows pointing up, screw support ring onto the sink flange,

hand tighten until the sink flange will not move (see 1A). At this

point you may want to insert stopper in sink and fill with water to

check sink flange seal and insure there are no leaks.

‡ MOUNT R NG

T GHTEN NG EARS

*Batch feed stopper looks different than stopper

shown here (see Section 6).

** Not applicable to batch feed models.

‡ Mount ring may look different and may not have

tightening ears.

F BER GASKET

**

*

YOUR DISPOSER COMES WITH ONE OF THE FOLLOWING MOUNT SYSTEMS

Proceed to the in truction for your type of mount y tem.

3-Bolt Mount System

EZ Mount System

SINK FLANGE

SINK FLANGE GASKE

PRO EC OR RING

FIBER GASKE

SINK MOUN RING

MOUN ING SCREWS (3)

SUPPOR RING

MOUN RING

IGH ENING EARS

CUSHION MOUN

SINK FLANGE*

SINK FLANGE GASKE

* An extended sink flange (Item # 3140) is

available for deep-well, cast iron sinks. (For

3-bolt mount only.)

1

INSTALLATION OF MOUNTING ASSEMBLY

INSTALLATION OF EZ MOUNT ASSEMBLY CONT.

SUPPORT R NG

S NK

FBER

GASKET

MOUNT R NG SHOULD BE

FREE TO MOVE UP & DOWN

OPEN AREA, NO

OBSTRUCT ON

S NK FLANGE

BEAD OF

CUSH ON

MOUNT

1A 1B 1C RUBBER GASKET

SNK

FLANGE

H.Place mount ring over sink flange and hold in place

while installing cushion mount (large side down) so

the groove on the

inside of cushion

mount fits over lip on

sink flange, similar to

putting the lid on a

plastic container (see

cushion mount detail

& 1B).

Run fingers around entire cushion mount with

slight pressure. Do not press too hard. When

cushion mount is properly seated, mount ring can

be pulled downward over cushion mount and will

be free to rotate. llustration 1C shows correct

installed position.

TOP

BOTTOM

BEAD

GROOVE

CUSHI N M UNT DETAIL

NOTE: Pay close attention to the order of mount assembly parts,

as they have been correctly assembled by the factory. (See 1D

and 1E.)

A. Disassemble the mounting assembly, as it has been shipped,

by turning the sink flange until the projections align with the

notches in the mount ring and allow you to pull the sink

flange up and out of the remaining mount assembly. Note the

sequence of these parts as they are stacked and refer to 1D

and 3B to identify each part. Unpack the 3 mount screws and

screw them half way through the mount ring (notice “TH S

S DE UP” is imprinted on top of the mount ring).

Next, stack the rubber gasket on top of the protector ring and

sit them on top of the pointed ends of the mount screws.

B. Keep these assembled parts together and set aside. Before

you connect the disposer to the mount assembly under the

sink, you may want to practice engaging the groove of the

Hush Cushion® to the ridge at the bottom of the sink flange.

C. Be sure your sink is clean. Pack the underside rim of the sink

flange with plumberʼs

putty (see 1F).

Position the sink

flange so it is

centered and

readable as you look

into your sink. Push

the sink flange firmly

into the sink opening

READ C MPLETELY BEF RE STARTING

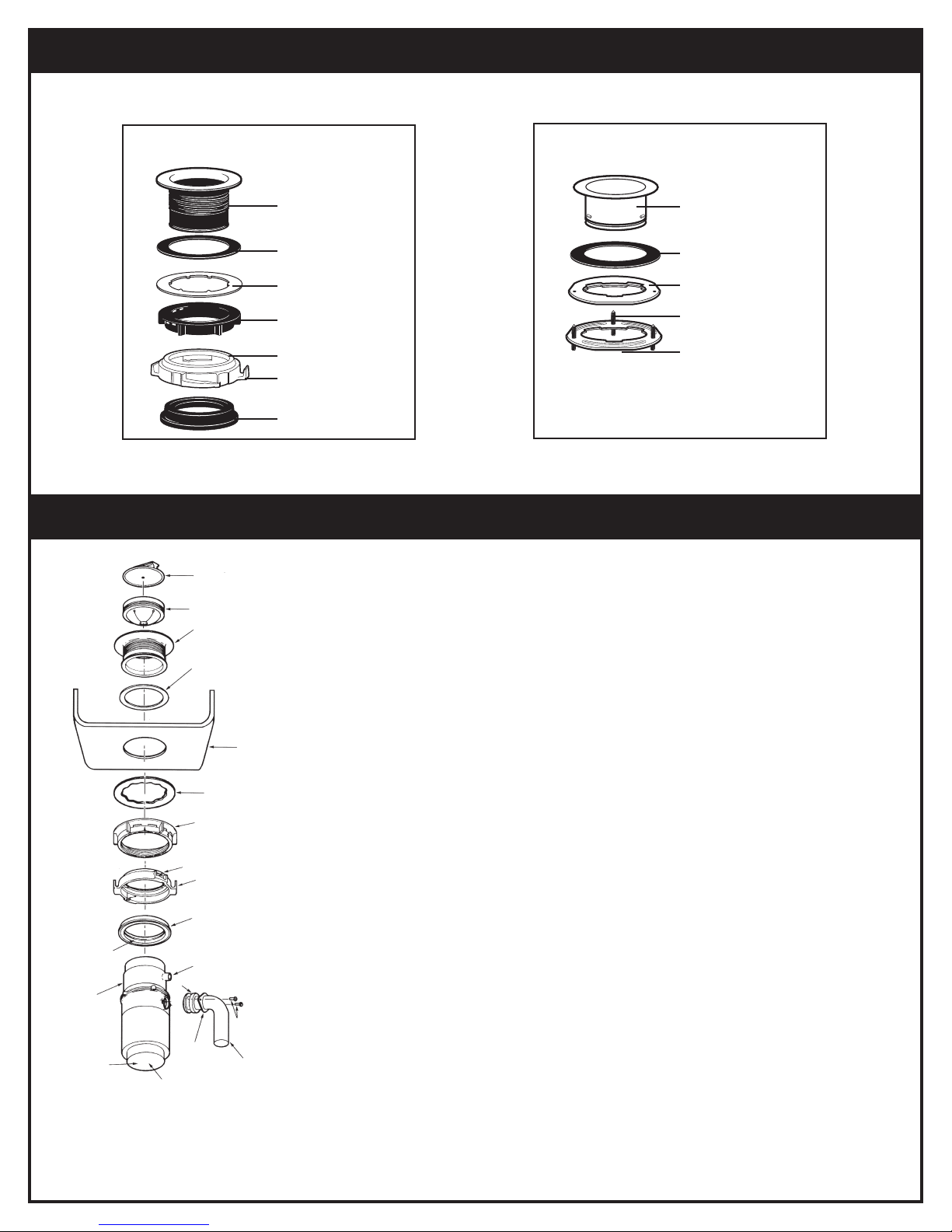

INSTALLATION OF 3-BOLT MOUNT ASSEMBLY

1D

S OPPER*

SINK FLANGE**

SINK

HOPPER

ELBOW

GASKE

SCREWS

SERIAL #- RECORD ON

WARRAN Y CARD

MOUN ING

SCREWS**

SCREW

CLAMP**

PROJEC IONS

RIDGE

RIDGE

DISCHARGE

ELBOW

ELBOW

FLANGE

DISHWASHER

DISCHARGE INLE

HUSH CUSHION®**

RUBBER SINK

FLANGE GASKE **

PRO EC OR RING**

MOUN RING**

PLUMBER’S

PU Y

END BELL

(ELEC RICAL

CONNEC IONS)

MOUN ING

SCREWS

PRO EC OR

RING RUBBER

GASKE

SINK

FLANGE

HUSH CUSHION

1E

SCREW

CLAMP

MOUN ING

RING

Mount Assembly

* Batch Feed Stopper looks different than the stopper illustrated.

** Mount Assembly (see 3B)

to make a good seal. DO NOT move or rotate

the sink flange once seated or the seal may be

broken.

D. Take the remaining portion of the mount assembly,

as it was set aside and make sure that the rubber

gasket is on top of the protector ring. From

under the sink, while holding the sink flange

firmly with one hand, line up the notches in

the mount ring with the projections of the sink

flange. Slide the mount assembly up onto the

sink flange, past the projections and give the

mount assembly a 1/4 turn, so that it will hang by

itself (see 1G).

E. Tighten the 3 mounting screws evenly with a

screwdriver (see 1H). DO NOT OVERT GHTEN!

Trim off excess putty.

ENDBELL RED RESET

BUTTON

EARTH

SCREW

W RE NUTS

REMOVE

COVER PLATE

2

ELECTRICAL CONNECTIONS

INSTALLATION OF 3-BOLT MOUNT ASSEMBLY CONT.

1H

1G

1F

N TE: A qualified electrician is

required. Disconnect electric power

to disposer circuit before installation.

Turn the circuit breaker to the OFF

position or remove the fuse.

For permanently connected

appliances:

EARTHING INSTRUCTI NS

This appliance must be connected

to an earthed, metal permanent

wiring system; or an equipment

earthing conductor must be run with

the circuit conductors and

connected to the equipment -

earthing terminal on the disposer.

A. Connect disposer to AC current

only.

PLEASE N TE: The Food Waste

Disposer in this carton is designed

to operate at the voltage indicated

on the cover plate located at the

bottom of the disposer. This plate

also includes related electrical and

identification information.

B. f you use flexible metal

shrouded cable:

nstall cable connector in hole.

PLEASE N TE:

Black or brown wire of disposer

- L VE

White or blue wire of disposer

- NEUTRAL

Green or yellow/green wire

and earth screw of disposer

- EARTH

Connect wires according to the

color code indicated on the

endbell illustration.

See diagram below.

f flexible metal shrouded cable

is not used, provide a separate

earth wire to the nearest cold

water metal pipe or other

suitable earth, using screw in

bottom endbell for the earth

wire.

C. f plug-in cord is used, it should

have an earthed plug or a plug

with an earth wire attached for

connection to the earth screw at

the bottom of the endbell.

D. Use a cable clamp strain-relief

connector similar to the one

shown, at the point where the

power cord enters the disposer

(see 2A).

E. f your power supply does not

include an earth wire, you must

supply one unless metal cable is

used. Attach a copper wire

securely to disposer earth screw

and attach other end of wire to a

metal cold water pipe. f plastic

pipe is used in your home, a

qualified electrician should

install a proper earth.

STRA N

REL EF

NUT

2A

•The appliance in this carton is

designed to operate at voltages

between 220-240 volts, 50/60Hz.

•For electrical rating please refer to

the serial number label located on

the bottom of the disposer.

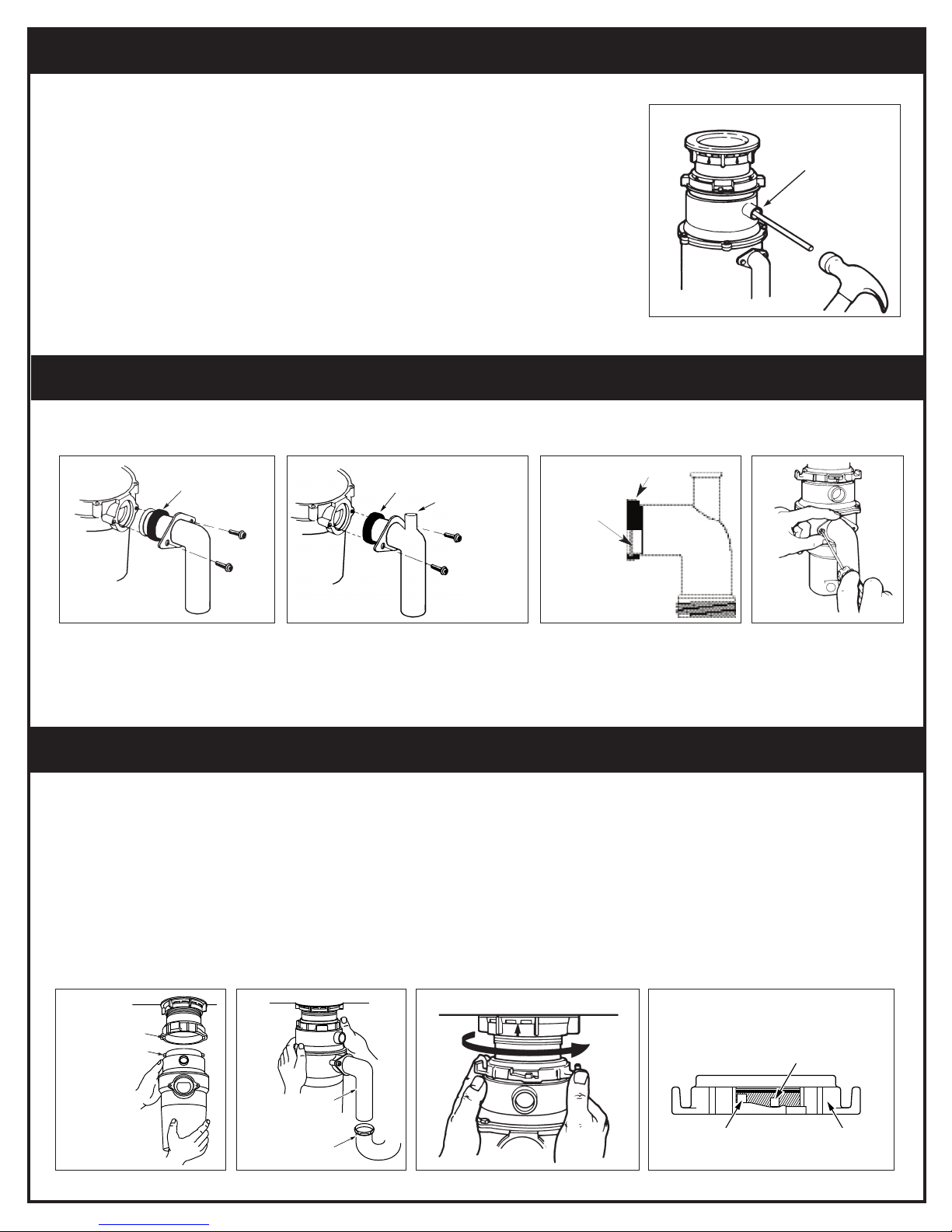

A. Connect waste elbow to disposer (see 4A or 4B), proceed to step 5 and then connect bottom of elbow

by tightening slip nut.

B. Make sure all plumbing connections are tight.

A. Line up disposer under mount assembly. Guide hopper projections into mount ring slots (see 5A).

Turn mount ring about 6mm to right so that disposer is temporarily supported.

B. Turn mount ring and disposer until waste elbow lines up with outlet pipe (see 5B).

C. Turn mount ring to the right until it locks up tight (see 5C). Hopper projections must be to extreme

left of mounting slots (see 5D).

D. f mount ring is hard to turn, you may add a small amount of petroleum jelly or liquid soap to hopper

projection. Run water and check for leaks.

f you are utilizing a dishwasher, complete the following procedure.

f dishwasher is not to be connected go on to step 4.

A. Using a blunt instrument (steel punch or wooden dowel), knock

out entire plug (see 3A). Do not use a screwdriver or sharp

instrument. When knockout plug falls into disposer, you may

remove it or simply grind it up when the disposer is used. This

will not damage the disposer in any way, but may take some time

to grind, over the course of several uses.

B. Connect dishwasher hose using hose clamp. f hose size is

different, you will need a stepped rubber adapter.

L CKING DETAIL

RUBBER GASKET

KNOCK

OUT

PLUG

HOPPER PROJECT ON N

“SUPPORTED” POS T ON

HOPPER PROJECT ON

N “LOCK” POS T ON

MOUNT

R NG

3

DISHWASHER CONNECTION (IF REQUIRED)

4

ATTACHING DISCHARGE ELBOW (IF REQUIRED)

5

CONNECTING DISPOSER TO EZ MOUNT ASSEMBLY

3A

5C5B5A 5D

4C

4A RUBBER

GASKET OVERFLOW

NLET

4B

SLOT

PROJECT ON

ELBOW

OUTLET

P PE

Your disposer comes with a discharge elbow of either configuration 4A or 4B.

GASKET

ENGAGE

NNER

GROOVE

OF

GASKET

W TH

FLANGE

OF

ELBOW

THIS DISP SER UTILIZES ANTI-JAM SWIVEL IMPELLERS THAT MAKE A CLICKING S UND AS THEY

SWING INT PLACE. THIS INDICATES N RMAL PERATI N.

BATCH FEED MODELS:

LARGE

SMALL

MED UM

6

OPERATING INSTRUCTIONS

6A 6B 6C 6D

CONNECTING DISPOSER TO 3-BOLT MOUNT ASSEMBLY

A. Remove sink stopper. Turn on

cold water using a medium flow.

B. Turn switch to ON position; your

motor is turning at full speed

and ready to use.

C. Scrape in food waste. Down the

drain go table scraps, peelings,

cobs, rinds, seeds, pits, bones

and coffee grounds. To speed up

food waste disposal, cut or

break up large bones, rinds and

cobs. Large bones and fibrous

husks require considerable

grinding time and are more

easily thrown away with other

trash. Do not be alarmed that

the disposer slows down while

grinding. The disposer is actually

increasing torque (grinding

power) and is operating under

normal conditions.

D. Before turning disposer off, let

water and disposer run for

approximately 25 seconds after

shredding stops. This assures

that all waste is thoroughly

flushed through trap and drain.

E. t is not recommended to use

hot water while running

disposer. Cold water will keep

food waste and fats solid so dis-

poser can flush away particles.

F. PM4 model is designed for

intermittent usage only and is

not rated for continuous

commercial usage.

A. Remove sink stopper and turn

on a medium flow of cold

water (see 6A).

B. Scrape in food waste. Down

the drain go table scraps,

vegetable peelings, cobs, rinds,

pits, bones and coffee grounds

(see 6B).

C. nsert stopper to start disposer

(see 6C). One of the two

small slots in stopper base

must line up with switch plunger

inside the neck of the disposer.

Push down firmly. Lift stopper to

shut disposer off.

D. Run disposer for 25 seconds

after shredding stops.

This assures that all waste is

thoroughly flushed through trap

and drain.

E. To fill sink, insert stopper so that

largest slot lines up with switch

plunger (see 6D). Stopper can

now be pushed down to seal

sink without actuating disposer.

When medium sized slot (see 6C)

in stopper base is lined up with

the switch plunger, water can

drain, but tableware, etc.,

cannot be accidentally dropped

into disposer.

A. Press firmly around the Hush Cushion® to ensure

it is engaged with the neck of the disposer.

B. Lubricate the top inside lip of the rubber Hush

Cushion® with a liquid soap.

C. Line up discharge elbow of disposer with trap

under mounting assembly. Guide disposer up and

engage the groove of the Hush Cushion® around

the ridge at the bottom of the sink flange (see 5E

& refer back to 3B). While still supporting the dis-

poser, tighten the screw-clamp around Hush

Cushion®. The disposer will now hang by itself.

D. f you need to turn the disposer make sure the sink

flange does not turn. t will break the seal created

when installed. Go back to steps 5A and 5B.

IMP RTANT – PLEASE READ

Do not remove clamp from Hush Cushion® or

Hush Cushion® from hopper. Both parts are factory

installed and installation ready.

Lubricate top angled surface of

rubber Hush Cushion® with liquid

soap prior to engaging disposer

to sink flange. Fit Hush Cushion®

lip into sink flange groove using a

slight rocking motion. Tighten

clamp (see 5F).

5F

SINK FLANGE

CLAMP

HUSH CUSHION®

OP ANGLED

SURFACE

HUSH

CUSHION®

5E

SINK

FLANGE

GROOVE

CLAMP

HOPPER

Before seeking repair or replacement, we recommend that you review the following:

L UD N ISES (Other than those during grinding of bones and fruit pits): These are usually caused by

accidental entry of a spoon, bottle cap or other foreign object. To correct this, turn off disposer and water. After

disposer has stopped, remove *splash guard, remove object with long handled tongs, and replace *splash guard.

UNIT D ES N T START: Unplug power cord or turn either the wall switch or breaker box switch to “off”

position, depending on your model and wiring configuration. With *splash guard removed, check to see if

turntable will rotate freely using a broom handle. f turntable rotates freely, replace *splash guard and check

reset button to see if it has been tripped. Reset button is red and located opposite discharge elbow, near the

bottom (see 7A). Push button in until it clicks and remains depressed.

f reset button has not been tripped, check for shorted or broken wire connecting to disposer. Check

electrical power switch, fuse box or circuit breaker. f wiring and electrical components are intact, the unit may

have internal problems that require service or replacement.

IF TURNTABLE D ES N T R TATE FREELY: Check for foreign object lodged between the turntable and grind

ring. Dislodge object by rotating table with a broom handle and remove object (see 7B). f no foreign object is

present, there may be internal problems.

LEAKS: f the unit leaks at the top, it may be due to:

1. mproper seating of sink flange (gasket choice, putty or tightening.)

2. Support ring not tightened properly.

3. Defective cushion mount.

f unit leaks at the waste elbow, leak may be due to improper tightening of elbow flange screws.

*Splash guard is not used with Batch Feed units.

RESET

BUTTON

SER AL NO.

REMOVE

SPLASH GUARD

TURNTABLE

7

TROUBLESHOOTING

7B7A

TIPS - Helpful Hints

1.Be sure disposer is empty

before using your dishwasher so

it may drain properly.

2. You may want to leave the stop-

per in the drain when not in use

to prevent utensils and foreign

objects from falling into the dis-

poser.

3. Use it wisely! Your disposer is

ruggedly built to give you years

and years of trouble-free serv-

ice. t will handle all normal food

wastes–BUT it will not grind and

dispose such items as tin cans,

bottles and bottle caps, glass,

china, leather, cloth, rubber,

string, feathers, clam or oyster

shells, or stringy or fibrous food

waste. These are waste materi-

als and belong in the trash can

or trash compactor – not inside

your food waste disposer.

4. Use your disposer “before”

and “after” meals! While

preparing food, turn on your

disposer and the cold water,

clearing your sink of vegetable

peelings, or salad trimmings.

When the meal is over, scrape

food scraps directly into the

disposer.

5. TO SPEED UP FOOD WASTE

D SPOSAL... Cut or break up

large bones, melon rinds,

grapefruit skins, corn cobs.

tems such as large bones,

fibrous husks like lima bean

pods and corn husks require

considerable cutting time. For

this reason, you may prefer to

place them in the trash can or

trash compactor.

OPERATING INSTRUCTIONS CONTINUED

8CLEANING AND MAINTENANCE

The motor is permanently lubricated for life. D N T ATTEMPT T LUBRICATE Y UR DISP SER!

The disposer is self cleaning and scours itself with each use.

Your disposer is equipped with a removable **splash guard for ease of cleaning or replacement. Remove splash guard by pulling it out

from the top. To replace, simply insert into sink flange and push down until properly seated.

NEVER put lye or chemical drain cleaners into the disposer, as they cause serious corrosion of metal parts. f used, resulting damage can

be easily detected and all warranties are void.

Mineral deposits from your water can form on the stainless steel turntable of your disposer, giving the appearance of rust. D N T BE

ALARMED, the stainless steel turntables used on PM2S2, PM2L7, PM2A, PM3, PM4, and Batch Feed models will not corrode.

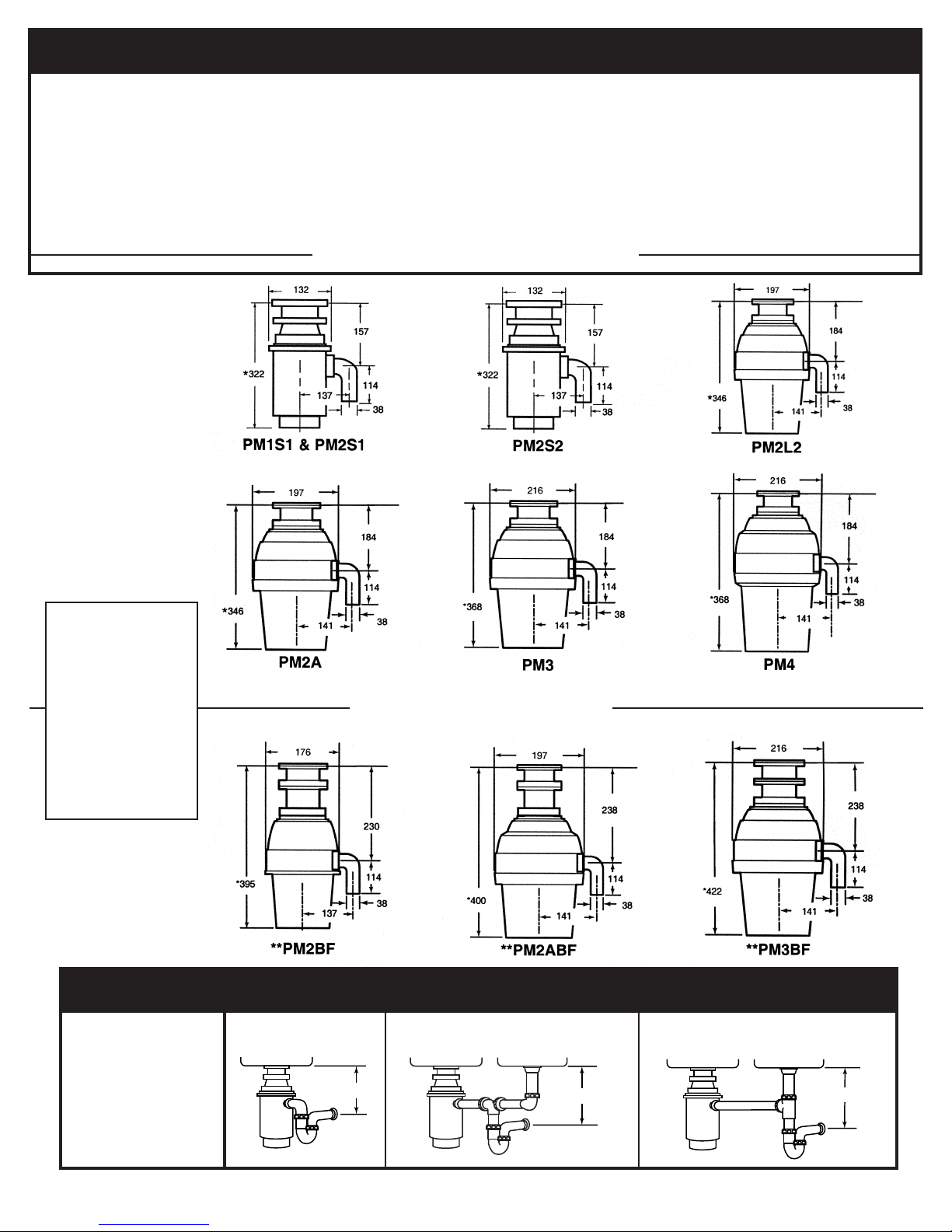

TYPICAL INSTALLATIONS

560C396P01 REV B

SINGLE B WL D UBLE B WL

CENTER UTLET D UBLE B WL

END UTLET

* Approx. * Approx. * Approx.

*229 for models PM2S1

and PM2S2

*254 for models PM2L2,

PM2A, PM3 and PM4

*305 for batch feed

models PM2BF, PM2ABF

and PM3BF.

Choice of trap is optional.

BATCH FEED M DELS

C NTINU US FEED M DELS

N TE:

All dimensions

are in mm.

* Add 16mm for

RF filter.

** Batch Feed

does not use

splash guard.

Table of contents