2/72

Contents

Safety Precautions………………………….……………………………………….3

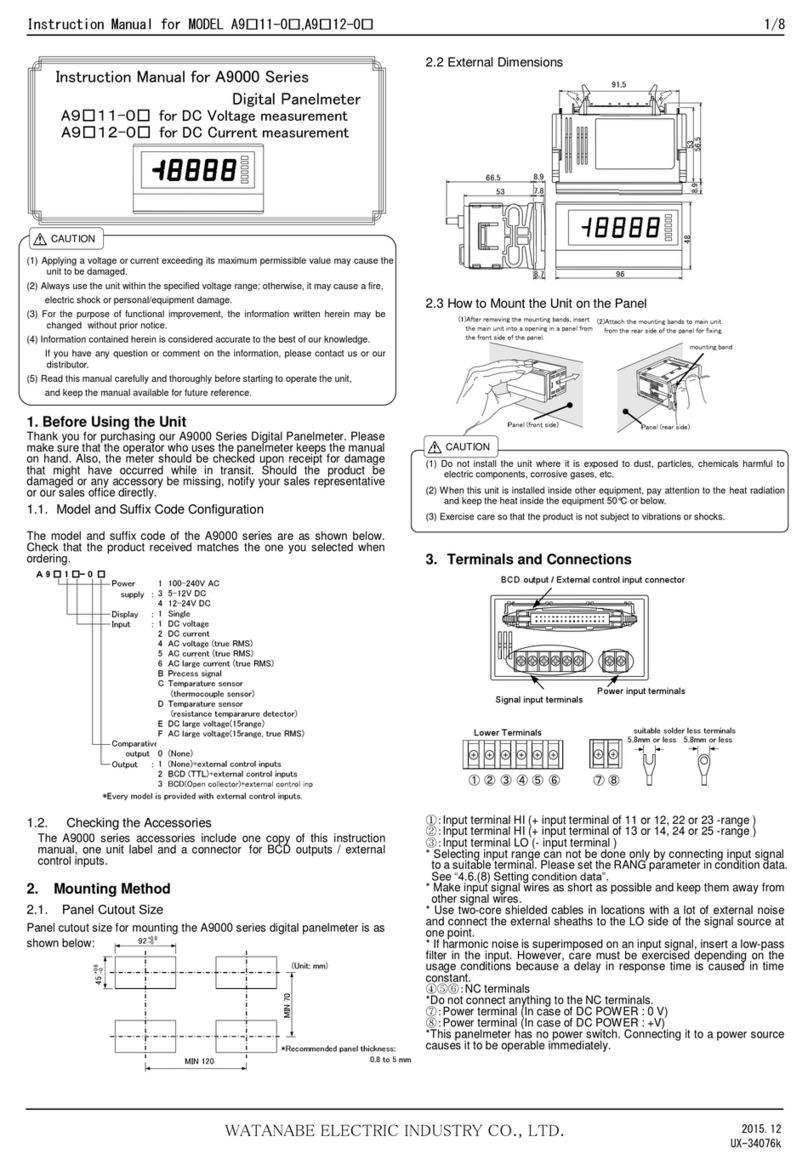

1.Before Using the Product………………………………………………………..4

1.1. Model Codes………………………………………………………………….4

1.2. Checking Each Unit Type and Its Accessories ………………………….5

1.3. Check Before Use……………………………………………………………5

2. About Assembly…………………………………………………………………. 6

2.1. Method Assembly……………………………………………………………6

3. Block Diagram……………………………………………………….……………7

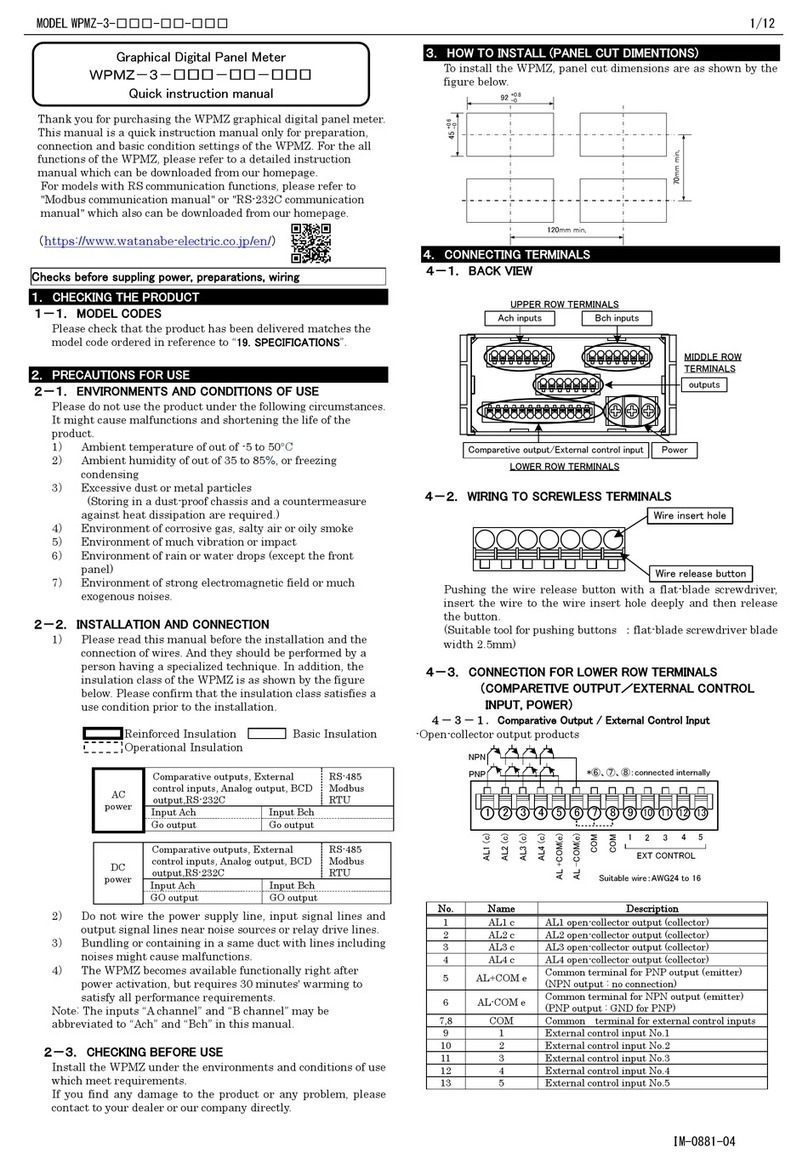

4. Mounting the Product…………………………………………………….……..8

4.1. Mounting the Product to the Panel……………………….………………8

5. Terminal Description and Connection Method…………………….…………9

5.1. Connecting Power……………………………………………………………9

5.2. Connecting Input Signal…………………………………..……………….9

5.3. Connecting External Controls………………………………….………..13

5.4. Connecting Comparison Output……………………….………………..13

5.5. Connecting Analog Output………………………………..…………….. 14

5.6. Connecting Serial Communication………………………..…………….14

6. Components and Their Functions…………………………………..……….15

6.1. Multi Display Unit………………………………………….…………….15

6.2. Single Display Unit…………………………………………….…………16

7. Parameter Setup…………………………………………………….…………17

7.1.Parameter Group………………………………………………….……….17

7.2.LED Display Method………………………………………………………17

7.3.Each Unit and Unit Number………………………………….………….17

7.4. Data lists and Default Settings…………………………………………18

7.5. Differences Between Display Units…………………………………….19

7.6.Operation Flow……………………………………………………………. 20

7.7. Condition Data……………………………………………………………..21

Peak Hold………………………………………………………………….21

Measurement Range………………………………..…………………..22

Number of Averaging Times………………………………………..….24

Number of Moving Averaging Times……………………….…………25

Step Wide……………………………………………………….………...26

Display Blank……………………………………………………….……27

Baud Rate(RS232C/RS485)……………………………………………28

Data Length(RS232C/RS485)………..………………………………. 29

Parity Bit(RS232C/RS485)……………………………………………..30

Stop Bid(RS232C/RS485)………………………………..…………….31

Delimiter(RS232C/RS485)…………………………..………………..32

Equipment ID(RS485)……………………………..………………….33

Analog Output Type……………………………………..…………….34

Digital Zero Back up……………………………….………………….35

Linearization Function………………………….……………………36

Input Selection(input board 15)…………………….……………….37

Tracking Zero Time…………………………………….………………38

Tracking Zero Width…………………………………….…………….39

Sensor Power(input board 17)………………………….…………….40

Power –ON Delay Time………………………………….…………….41

Protect Function…………………………………………….………….42

Unit Number Display……………………………………….………….43

7.8. Comparator Data………………………………………………….………..44

7.9. Scaling Data…………………………………………………….………..46

7.10. Linearization Data…………………………………………..…………51

7.11. Calibration Data………………………………………………..………52

8. Other Functions……………………………………………………..………..54

8.1. The Display Shift Function………………………………….…………54

8.2. Monitor Mode………………………………………….…………………54

9. Control Functions………………………………………………….………….55

9.1. About Control Function…………………………………………….……55