5

7. LIFT OUT CARTRIDGES

Carefully rotate and lift out each cartridge, taking

care not to damage the cartridge's pleated material.

CAUTION: Never lay the side of a cartridge on a

rough textured surface such as concrete, asphalt,

gravel, etc.. Damage to the pleated filtering material

may occur. THIS WILL SERIOUSLY REDUCE

FILTERING PERFORMANCE.

8. FLUSH OUT TANK

With a garden hose, flush out tank through the drain

and remove any large debris that may have passed

through the skimmer and/or pump strainer baskets

into the filter.

9. CLEAN CARTRIDGES

Attach the BLASTER NOZZLE to a garden hose.

Position cartridge in an upright position, supporting

with one hand when cleaning. Hold the blaster

nozzle away from the cartridge about 18". Starting

at the top of the cartridge, spray between each

pleat, working downward.

10. SOLUTION CLEAN CARTRIDGES

NOTE: Before solution cleaning the cartridges, be

aware that chlorine and acids kill lawns and plant

life. Clean the cartridges in a suitable area.

Always wear protective clothing such as gloves

and goggles.

If the cartridge becomes impregnated with algae,

pour a mild chlorine solution (1 part chlorine to 4

parts water) over all pleated surfaces and let soak

for 10 minutes. Hose off thoroughly. Then, mix a

solution of warm water and detergent (1 cup per 5

gallons of water). Then add one cup of chlorine or

household bleach to the solution.

Totally submerge and soak the cartridges for 15-30

minutes. Agitate the cartridges vigorously to

dislodge trapped particles.

11. RINSE

Rinse cartridges thoroughly before reinstalling in the

filter. Soapy bubbles will appear on the pool surface

near the return fitting if the cartridges are not rinsed

clean,.

12. HARD WATER

Hard water will eventually coat the cartridges with

calcium deposits that cut off good filtering perfor-

mance. To correct, mix a solution (1 part muriatic

acid to 4 parts water). With the cartridges fully

submerged, soak them for about 15 minutes. Rinse

thoroughly with clean water.

NOTE: Muriatic acid solution will kill lawns and

plant life. Perform this service in a suitable

area.

13. Reverse procedure for re-assembly.

14. RESUME NORMAL OPERATION

Start pump and check for any leaks around cover,

tank drain, and all connections. Correct if neces-

sary.

MAINTENANCE

Preventative maintenance will provide continued smooth

performance and extend the life of your filter for many

years. Neglect will cause parts to wear or bind, leaks to

occur and result in costly repairs. Always keep moving

parts lubricated and maintain a clean environment

around your filter and related components.

LUBRICATION

There are various types of lubricants available.

However, most are intended for moving metal parts.

Unfortunately, these lubricants will harm or degrade

plastics. DO NOT use petroleum based lubricants.

Many people consider “PETROLEUM JELLY” safe for

babies and can be applied to anything. But, it will

DESTROY most plastics and o-rings. Silicone lubri-

cants available at your pool dealer are safe for use on

plastics and o-ring seals.

REPAIRS

Servicing should be performed by a qualified dealer. If

disassembly is attempted, mark each of the parts

assembled position as it relates to its mating parts.

This assures proper alignment when reassembled.

Malfunction will occur if the filter is not properly as-

sembled. See your dealer for original replacement

parts.

CAUTION

BEFORE removing the filter or pump from pool area for

servicing, always disconnect the pump from its electrical

source and prevent the backflow of water from your

skimmer and return fitting ports from flowing out of the

disconnected hoses.

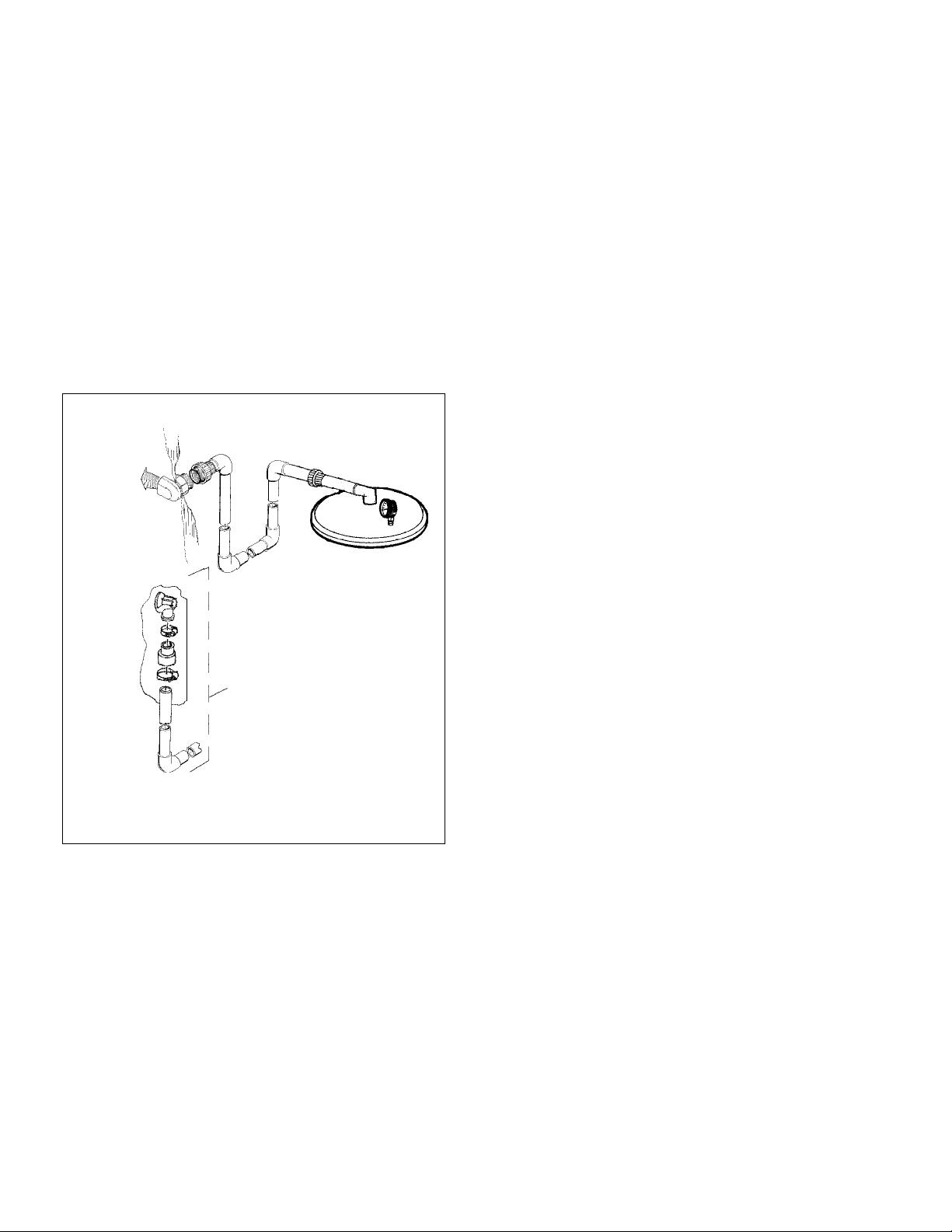

1. Remove skimmer cover and basket and plug the

port at the bottom of the skimmer with a rag.

2. Referring to the instructions for your return fitting,

install the Shutoff disc. Option: stuff a rag into the

return fitting opening.

3. Disconnect hoses on the filter or pump as neces-

sary when removing for service or repairs.

DRAIN TANK

See Caution Above

1. Remove tank drain cap to drain.

2. Remove v-clamp, cover, and large o-ring from tank.

3. After servicing, reassemble and install in reverse.

Make sure tank's o-ring and sealing areas are free

of any dirt or grit, and that the o-ring is lubricated

with silicone lubricant. Be sure that the o-ring is

evenly seated in the cover groove before replacing

the cover and v-clamp.

WINTERIZING FILTER

In areas subject to freezing damage, it is mandatory

that the filter, pump and any related components be

removed from the pool area and stored indoors. (Refer

to the individual components owner's guide such as

pump, skimmer, chlorinator, etc., for specific winterizing

instructions.)

1. Siphon water level down below skimmer opening by

using your vacuum hose and allow the water to flow

to an area that can accept a thousand gallons or

more.

2. Drain the tank completely.

3. Disconnect all line connections.

4. Remove v-clamp from the filter and remove the

cover and gasket.

5. Remove cartridges, flush out tank, clean the car-

tridges thoroughly and allow to dry completely. Turn

the tank upside down to allow the water to drain

out of the manifold assembly.

6. Reinstall the cartridges only after they have dried

completely. Replace the cover and drain cap.

7. Store all components in a warm dry area indoors.

DAMAGE CAUSED BY FREEZING TEMPERATURES

IS NOT COVERED BY PRODUCT WARRANTY.