Water Factory Systems SQC Owner's manual

Helpful Information

for the

SQC™Owner

© 2001 CUNO Incorporated

INSTR6014 1201

Table of Contents

When to Change Filters of the RO Membrane ........................................................2

How to Sanitize the Storage Tank ............................................................................3

How to Change the Storage Tank Bladder ..............................................................3

How to Service the Storage Tank ............................................................................4

How Much Water Should the Tank Hold?................................................................4

Why Can I Only Get a Quart or Less From My Tank?..............................................5

Why Does My System No Longer Make Water? ....................................................5

Why is Water Leaking From the Hole in My Faucet? ..............................................6

Hey, There’s Something in My Water! ....................................................................7

Why is My System Humming?................................................................................8

Why Do I Hear a Gurgling in My Sink?....................................................................8

How Do I Find an Authorized Dealer for Parts or Service?......................................9

Before You Call ........................................................................................................9

Useful Conversions ................................................................................................10

When to Change Filters or the RO Membrane

Prefilter(s) should be changed at least once every 12 months. The postfilter should be

changed every 12 to 36 months. The RO membrane should be changed when it fails to provide

sufficient water for nomal use, or when the RO water quality drops to an unacceptable level.

Several considerations need to be made regarding what is “acceptable” RO water quality.

Factors such as nitrate or arsenic removal, feed water Total Dissolved Solids (TDS), and

membrane age need to be taken into account. Generally speaking, RO water may be considered

acceptable if the TDS is below 70 ppm (parts per million), the percent rejection is above 70%, and

specific contaminate reduction is acceptable. Your local Water Factory Systems dealer is an excellent

source of information regarding local water quality issues. If you do not know a dealer - visit the CUNO

website at www.waterfactorysystems.com or call CUNO Customer Service at 1-800-733-1199.

Your local dealer can test your water quality. An optional water quality monitor is available

from your dealer. Local water conditions are the primary factor influencing acceptable RO membrane

life. Generally speaking, the RO membrane should last 2 to 4 years.

2

How to Sanitize the Storage Tank

The storage tank should be sanitized yearly. Use of either Water Factory Systems “Tank

Sanitizing Vial” (P/N: 52-34103) or 1/2 teaspoon of unscented bleach is recommended. Contents

of the vial or the bleach can be put into the 3/8” tube connecting the tank to the system. Fill the

tank with either tap water or allow it to fill normally by connecting it to the RO unit. Wait at least

30 minutes after the tank is filled, then drain the tank. This completes the tank sanitizing.

How to Change the Storage Tank Bladder

Disconnect the storage tank from the RO unit. Drain any water out and relieve any air pres-

sure from the Shrader valve. In the case of the white plastic tank, unscrew the large black nut on

the top. In the case of the blue metal tank, remove the 6 bolts. Lift out the old bladder. Install the

new bladder. Wet the sealing surfaces of the new bladder with either glycerine or water.

Reassemble the cap and black nut or the metal plate with the 6 bolts. Add 7-8 psi (48-55 kPa) of

air to the Schrader valve. Wait 5 minutes and recheck the air charge. If OK, sanitize the tank and

reconnect it to the RO system.

3

How to Service the Storage Tank

The storage tank air precharge should be checked yearly. The tank should be disconnected

from the system and air added to the Shrader valve (like the one on a bicycle tire). The ball valve

on the top of the tank should be open. The air charge should be 7-8 psi (48-55 kPa). If the tank

will not hold an air charge, inspect the bladder. If the bladder is OK, replace the Shrader valve. If

the tank still will not hold an air charge, replace the tank.

How Much Water Should the Tank Hold?

The amount of water the storage tank will hold is determined by the air precharge and the

feedwater pressure. The RO system will fill the tank until the pressure in the tank reaches two-

thirds of the feedwater pressure. With an air precharge of 7-8 psi (48-55 kPa), the following chart

lists approximate storage capacities when the tank is full:

Feedwater Pressure Tank Capacity

80 psi (552 kPa) 2.3 gallons (8.7 liters)

60 psi (414 kPa) 2.1 gallons (7.9 liters)

40 psi (276 kPa) 1.5 gallons (5.7 liters)

4

Why Can I Only Get a Quart or Less From My Tank?

and

Why Does My System No Longer Make Water?

Usually, a significant reduction in available water is due to the storage tank losing its air

charge, or possibly the bladder in the tank has failed. You can verify this by moving the tank after

the flow at the faucet declines. If it feels heavy, then the tank needs to be serviced. Refer to the

appropriate sections in this booklet to remedy these conditions.

Your RO system, under most conditions, should produce at least 6 gallons per day (22.7

liters per day). You can check this by closing the ball valve on the top of the tank, opening your

RO faucet, and waiting until the flow of water becomes a constant drip. Using a measuring device,

carefully measure the rate water is being produced, and convert to gallons per day. If the rate is 6

or more gallons per day (22.7 or more liters per day), the reduction in water is not due to prob-

lems with the membrane. If the flow rate is less than 6 gallons per day (less than 22.7 liters per

day), the membrane likely needs to be replaced.

5

Why is Water Leaking From the Hole in My Faucet?

Most installations utilize a faucet with a built-in air gap. The reject water from your RO system

flows through a small chamber in the faucet and then down the larger 3/8” tube to your drain. This

3/8” tube needs to be straight down and over to the drain pipe. There should not be any excess

tubing, upward bends, kinks, or sags in the tubing. Correct if necessary.

Sometimes blowing air into the hole with a straw will eliminate the problem; or remove the

elbow fitting on the drain clamp and clear the hole with a pipe cleaner. A slight blockage caused by

food matter in your drain pipe may be to blame.

Occasionally, over time, a gradual accumulation of organic material in the 3/8” tube is sufficient

to restrict the flow to the drain. Replacing the 3/8” tube is recommended in these cases. The existing

tube can be cut several inches below the faucet, a 3/8” union connector installed, and a new length

of 3/8” tubing installed. Remember the comments made above about the route this tube needs to

take when replacing.

6

Hey, There’s Something In My Water!

The most common substance seen in your RO water is dissolved oxygen and carbon dioxide.

Some feedwater supplies are high in these dissolved gases and they can cause the RO water to

appear cloudy. If this cloudiness goes away after allowing the water to stand in a clear glass for

30 minutes, then you can be sure the cloudiness is dissolved oxygen and carbon dioxide. In many

locations, this cloudiness is a seasonal event and will stop after a few weeks. Changing filters may

also introduce air into the system, but any cloudiness that results will be eliminated after several days.

Occasionally, after changing the post-filter, black specks may be observed in the RO water.

These are carbon fines (extremely small particles of carbon). They are not harmful and should dis-

appear after a few days. Try emptying the storage tank every night to more rapidly flush these fines

from the system. If this problem persists, contact your local Water Factory Systems dealer and

arrange to have the post-filter cartridge replaced.

7

Why is My System Humming?

Occasionally, systems may produce a “humming” sound. This is caused by air in the system’s

automatic shut off valve. This generally occurs immediately after the system has been installed, or

after prefilter changes. This “humming” sound almost always stops after a couple of days. If it does

not, contact your local Water Factory Systems dealer.

Why Do I Hear a Gurgling in My Sink?

A very faint “gurgling” sound may sometimes be heard coming from the RO faucet. This is

normal. A more pronounced “gurgling” sound coming from the sink area may be the result of the

RO reject water dropping into a pool of standing water in the drain line. Either reorienting the drain

pipe, or relocating the RO drain clamp so that the reject water runs down the side of the drain pipe

should eliminate this problem.

8

How Do I Find an Authorized Dealer for Parts or Service?

Visit us at www.waterfactorysystems.com or call Customer Service at (800) 733-1199.

Before You Call

If you are experiencing a problem or have a question, the following information will be most

helpful to have on hand before you call.

Model of System: SQC1 _____ SQC2 _____ SQC3 _____ SQC4 _____

Date Installed: ____________________________________________________________

Serial Number of Unit: _____________________________________________________

(eg: WxA-xxx or 6xxxxx1 or 6xxxxx2 located on label on the underside of the shroud)

Date of Last Service: _____________________________________________________

Service Performed: _______________________________________________________

9

Useful Conversions

1 Cup = 8 Fluid Ounces

1 Quart = 32 Fluid Ounces

1 Gallon = 128 Fluid Ounces

1 Fluid Ounce = 29.6 Milliliters

1 Fluid Ounce per Minute = 11 Gallons per Day

CUNO Incorporated, 400 Research Parkway, Meriden, CT 06450, U.S.A.

Toll Free: 1-800-733-1199, Worldwide: 203-237-5541, Fax: 203-238-8701

www.waterfactorysystems.com • www.cuno.com

10

Table of contents

Other Water Factory Systems Water Filtration System manuals

Popular Water Filtration System manuals by other brands

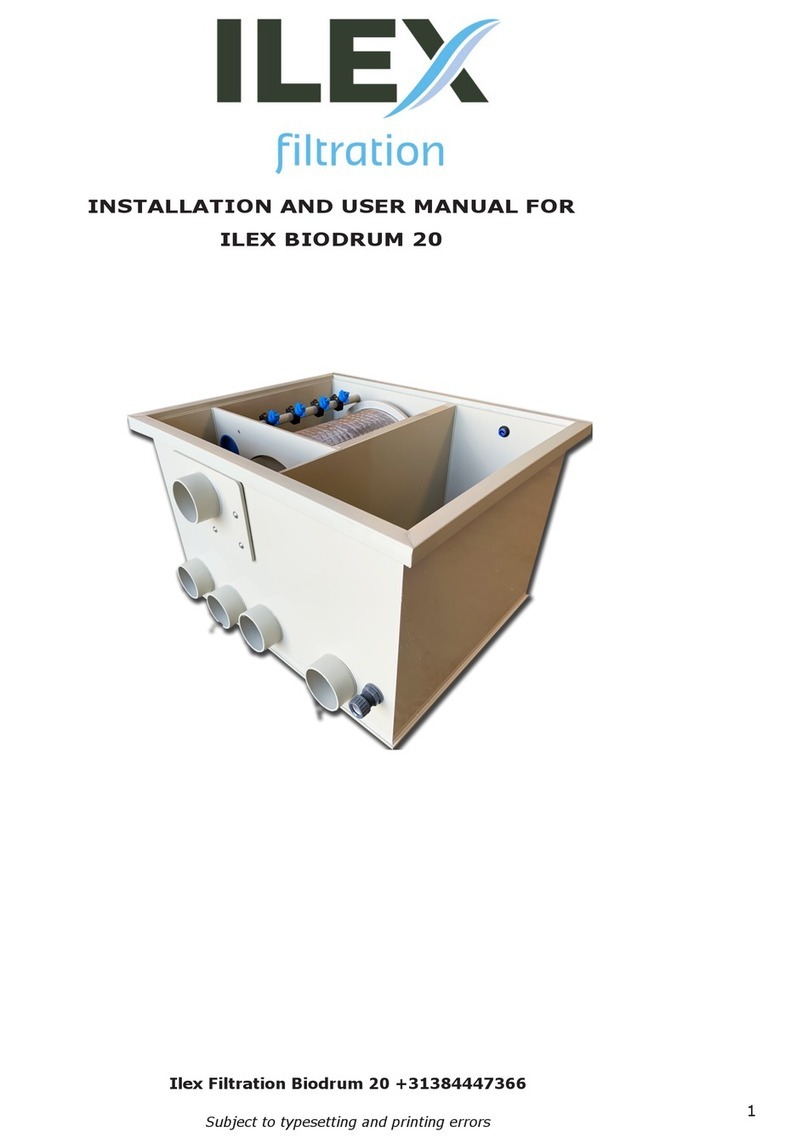

Ilex

Ilex BIODRUM 20 Installation and user manual

Filtration Group

Filtration Group Facet HCS-222-1324 Installation operation & maintenance

Whole House

Whole House iSpring WSP-J user manual

Clean Water Systems

Clean Water Systems Upflow Carbon Series Installation & start?up guide

BWT

BWT AQA Detector quick guide

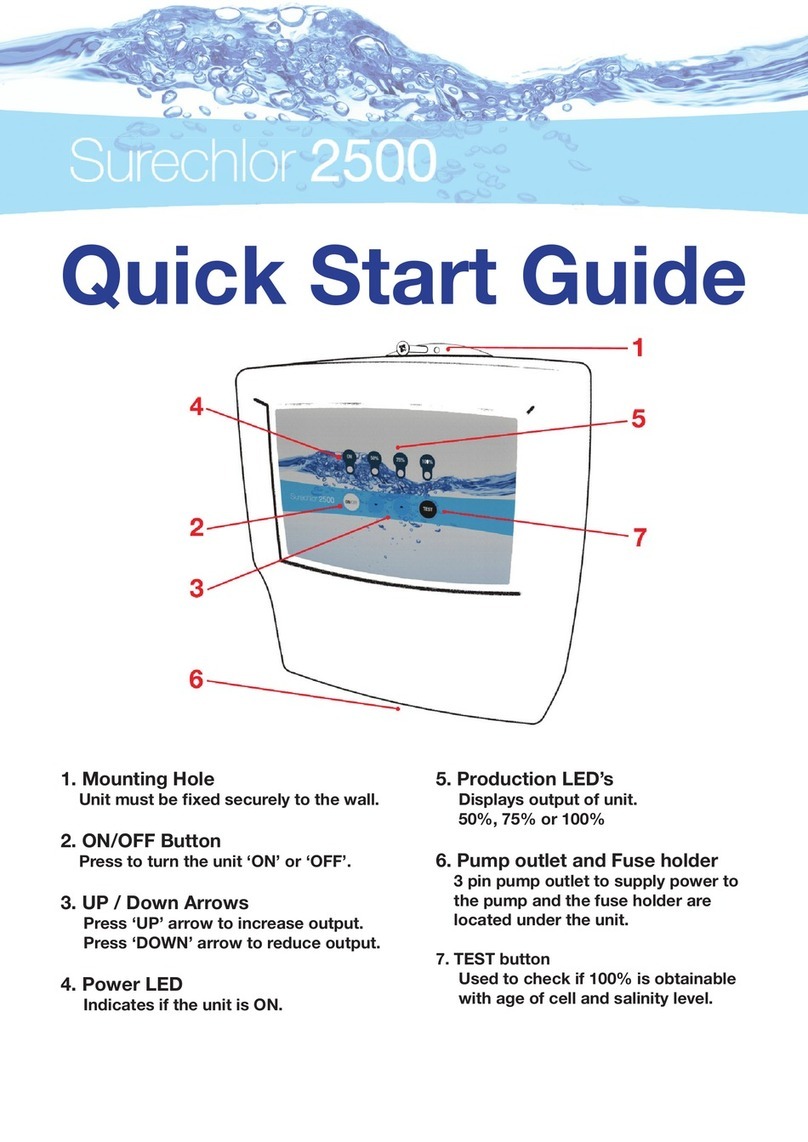

APS Chlorinators

APS Chlorinators Surechlor 2500 quick start guide