Water Factory Systems SQC3 Series User manual

SQC Series

Owner's Manual

This Manual is for the Installation, Operation,

and Maintenance of the

WATER FACTORY SYSTEMS™

SQC3 and SQC4 Series

Reverse Osmosis (RO) Drinking Water Appliance

™

Installer: Leave with homeowner.

SAFETY INFORMATION

Read, understand and follow all safety information contained in these instructions prior to instal-

lation and use of the SQC Series Reverse Osmosis (RO) Drinking Water Appliance. Retain these

instructions for future reference.

Intended use:

The Water Factory Systems™ SQC Series Reverse Osmosis (RO) Drinking Water Appliance is intended to

connect permanently to a home plumbing system and has not been evaluated for other uses.

EXPLANATION OF SIGNAL WORD CONSEQUENCES

WARNING

Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious

injury and/or property damage.

CAUTION

Indicates a potentially hazardous situation, which, if not avoided, may result in property damage.

CAUTION

Indicates a potentially hazardous situation, which, if not avoided, may result in minor or moderate

injury and/or property damage.

To reduce the risk associated with choking:

• Donot allow children under 3 years of age to have access to small parts during the installation of this

product.

To reduce the risk of physical injury:

• Allhydro-pheumaticpressurizedtanksmusthaveanappropriatepressurereliefvalveinstalled.

• Shutoffinletwatersupplyanddepressurizesystemasshowninmanualpriortolterremoval.

To reduce the risk associated with the ingestion of contaminants:

• Donot use with water that is microbiologically unsafe or of unknown quality without adequate disinfection

beforeorafterthesystem.Systemscertiedforcystreductionmaybeusedondisinfectedwaterthatmay

containlterablecysts.EPAEstablishmentNumber070595-CT-001.

•AnapprovedairgapmustexistbetweentheROSystemrejectdrainlineandthedrainlineopeningtomeet

plumbing codes.

To reduce the risk associated with irritation from Sodium Metabisulfite during installation:

• SodiumMetabisulte(CAS07681-57-4)isusedina1%preservativesolutionwithinthereverseosmosis

membrane.

• DonotputthissystemintoservicebeforetheROtankisushedasspeciedintheinstallationinstruc-

tions. Wear eye and face protection during installation.

• TorequestanMSDSrelatingtothisproduct,call203-238-8965orvisitthewebathttp://solutions.3m.

com/wps/portal/3M/en_US/MSDS(clickMSDSsearch).Foremergencies,call800-364-3577or651-737-

6501(24hours).

To reduce the risk associated with eye, skin and respiratory and digestive tract burns from Calcium Hypochlorite

during installation:

• CalciumHypochlorite(CAS7778-54-3)granulesareusedfortanksanitationinthisproduct.

• Duringinstallation,donotgetineyes,onskinorclothing.Donotingest.Weareyeandfaceprotection.

Keep out of reach of children.

• TorequestanMSDSrelatingtothisproduct,call203-238-8965orvisitthewebathttp://solutions.3m.

com/wps/portal/3M/en_US/MSDS(clickMSDSsearch).Foremergencies,call800-364-3577or651-737-

6501(24hours).

To reduce the risk associated with ingestion of water contaminated with sanitizer:

• Sanitizermustbeushedfromthesystembeforeusingasdirectedwithintheinstallationinstructions.

To reduce the risk associated with hazardous voltage due to an installer drilling through existing electric wiring or

water pipes in the area of installation:

• Donot install near electric wiring or piping which may be in path of a drilling tool when selecting the posi-

tiontomountthelterbracket.

To reduce the risk associated with property damage due to water leakage:

• Read and follow UseInstructionsbeforeinstallationanduseofthissystem.

• Installationanduse MUST comply with all state and local plumbing codes.

•

Protect from freezing,removeltercartridgewhentemperaturesareexpectedtodropbelow40°F(4.4°C)

.

•

Donotinstallsystemsinareaswhereambienttemperaturesmaygoabove110°F(43.3°C)

.

• Donotinstallonhotwatersupplylines.Themaximumoperatingwatertemperatureofthisltersystem

is100°F(37.8°C).

• Donotinstallifwaterpressureexceeds100psi(690kPa).Ifyourwaterpressureexceeds80psi(552

kPa),youmustinstallapressurelimitingvalve.Contactaplumbingprofessionalifyouareuncertainhow

to check your water pressure.

•

Donotinstallwherewaterhammerconditionsmayoccur.Ifwaterhammerconditionsexistyoumustinstalla

water hammer arrester. Contact a plumbing professional if you are uncertain how to check for this condition.

•

Wherebackowpreventiondeviceisinstalledonawatersystem,adeviceforcontrollingpressuredueto

thermalexpansionmustbeinstalled.

• Donotuseatorchorotherhightemperaturesourcesnearltersystem,cartridges,plasticttingsor

plastic plumbing.

• Onplasticttings,neverusepipesealantorpipedope.UsePTFEthreadtapeonly, pipe dope properties

may deteriorate plastic.

• Takecarewhenusingpliersorpipewrenchestotightenplasticttings,asdamagemayoccurifovertight-

ening occurs.

• Donotinstall in direct sunlight or outdoors.

• Allhydro-pneumatictanksmusthaveanappropriatepressurereliefvalveinstalled.

• Donot install near water pipes which will be in path of a drilling tool when selecting the position to mount

the bracket.

•

Mountlterinsuchapositionastopreventitfrombeingstruckbyotheritemsusedintheareaofinstallation.

• Ensurethatthelocationandfastenerswillsupporttheweightofthesystemwheninstalled.

• Ensurealltubingandttingsaresecureandfreeofleaks.

•

Donotinstallunitifcolletismissing.ContactWaterFactorySystemsifcolletsaremissingfromanyttings.

• SHUTOFFFUELORELECTRICPOWERSUPPLYTOWATERHEATERafterwaterisshutoff.

• ThedisposableltercartridgeMUST bereplacedevery12months,orsoonerifanoticeablereductionin

owrateoccurs.

• TheROMembranecartridgeMUST bereplacedatleastevery36months.

To reduce the risk of eye injury while drilling counter-tops for faucet installation:

•Safety glasses MUST be worn during the sink hole drilling operations.

To reduce the risk of eye injury while drilling counter-tops for faucet installation:

•Safety glasses MUST be worn during the sink hole drilling operations.

To reduce the risk of injury associated with household bleach:

•Read and follow manufacturers directions and cautions

•Keep out of the reach of children

• DONOTintermixwithotherchemicals

• Failure to install, operate, or maintain your drinking water appliance in accordance with

these use instructions or any other installation or use instructions accompanying this

product may result in product failure and property damage, including water leakage and

will void warranty.

INTRODUCTION

This manual explains the installation, operation and maintenance of the Water Factory

Systems™SQC Series Reverse Osmosis (RO) Drinking Water Appliances. Please read each

section of this manual carefully. The specific model chosen should be appropriate for the

local water conditions and the customer’s needs. Check the Performance Data Sheet for the

performance characteristics and the conditions of use.

The Water Factory Systems undercounter RO drinking water appliances are designed to

connect permanently to a home plumbing system. To ensure that the installation conforms to

your state and local plumbing codes, it is recommended that the installation be performed by a

qualified installation specialist for RO drinking water appliances or a licensed plumber. Failure

to install the system as instructed will VOID the warranty.

TABLE OF CONTENTS

I. Installation Instructions

A. Determine the appliance location................................................................................... 3

B. Prepare the area for installation ..................................................................................... 3

C. Prepare the appliance for installation............................................................................. 4

D. Make the faucet mounting hole ...................................................................................... 4

E. Mount the faucet............................................................................................................. 5

F. Install Stem Adapter With 1/4” Feedwater Tube Outlet ................................................. 6

G. Prefill and sanitize the storage tank ............................................................................... 6

H. Install the drain connection............................................................................................. 7

I. Install the filtration assembly and storage tank .............................................................. 7

J. Make the tubing connections.......................................................................................... 8

K. Install the icemaker hookup (optional) ........................................................................... 8

L. Start up the appliance .................................................................................................... 8

M. Flush the appliance of the preservative and check the operation.................................. 9

N. Cleanup & paperwork..................................................................................................... 9

O. Appendix for basement installations............................................................................... 11

P. Installation troubleshooting............................................................................................. 12

II. Operation & Maintenance Instructions

A. Important water quality assurance requirements ........................................................... 13

B. Replacing the filter cartridges......................................................................................... 13

C. Replacing the RO membrane cartridge.......................................................................... 13

D. Sanitizing the RO appliance........................................................................................... 14

E. Long term non-use ......................................................................................................... 15

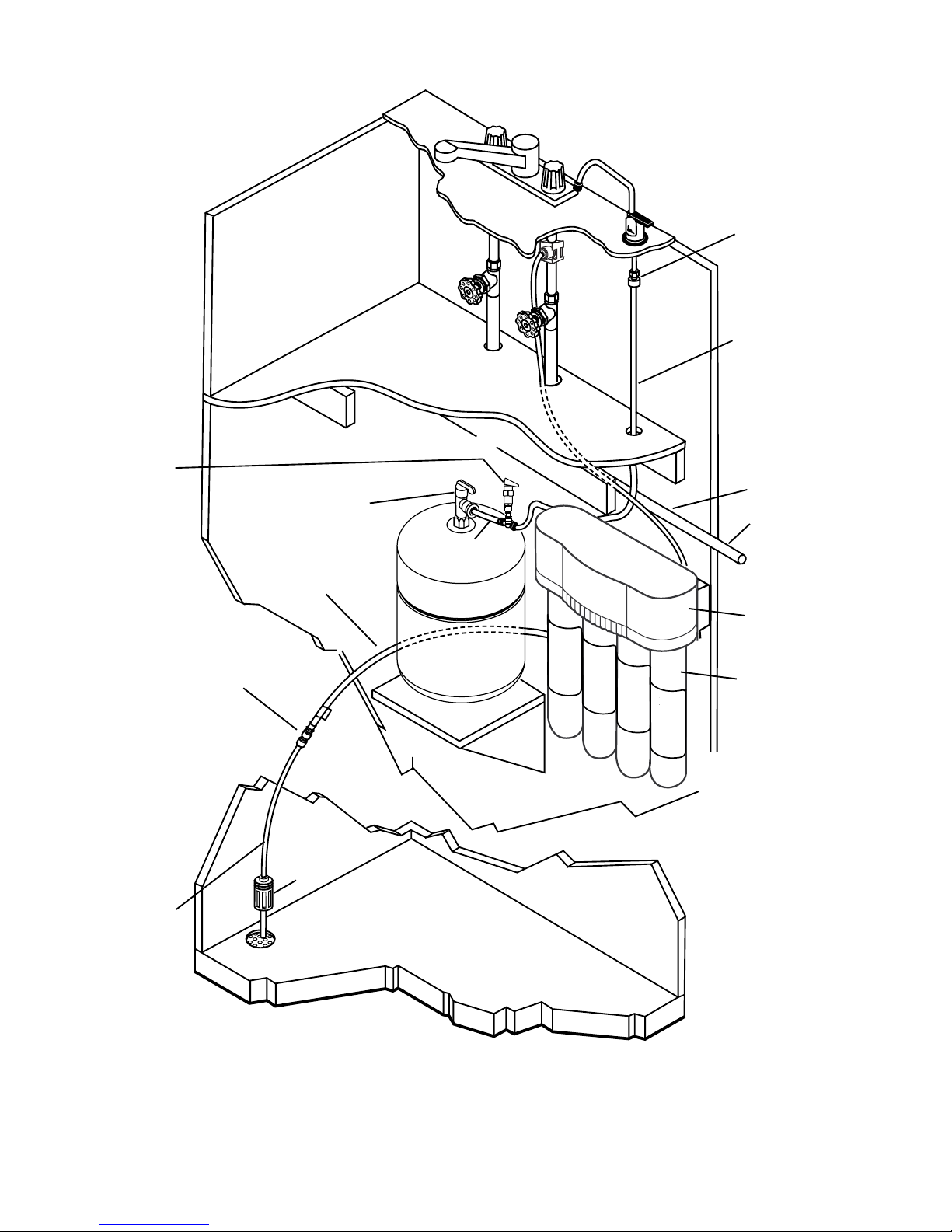

A. DETERMINETHEAPPLIANCELOCATIONS

The appliance can be located under a sink or in a base-

ment depending on space availability and the customer’s

preference. If a basement installation is selected, additional

tubing, hardware and fittings may be needed and a hole will

have to be made from inside the cabinet, through the floor, to

the basement. Never install it in an area of the home where

the temperature may drop below 40

°

C, because damage to the

appliance may occur.

The exact placement of the various components of the

appliance will vary from installation to installation. The install-

er, in conjunction with the customer, must decide on where to

place the faucet, tank and filtration assembly by balancing the

homeowner’s convenience with ease of installation and servic-

ing. (See Fig. 1 & 7)

Considerations for an icemaker or other remote hookup

should be predetermined, including routing and any additional

tools, fittings, and tubing that may be required.

B. PREPARETHEAREAFORINSTALLATION

Remove supplies from under the sink and stack them

neatly away from the working area. Arrange a light for the work

area, if necessary.

If a basement installation is called for, determine where

the components will be located and how they will be mounted.

Special mounting brackets and hardware may be necessary to

secure the appliance to a wall or ceiling joists. (See Figure 7)

Inspect the cold water supply line and determine if any

special fittings, in addition to what is included in the kit, are

required.

NOTE: It is a good idea at this time to check the condition of

the undercounter plumbing for any existing or potential leaks.

Make sure to perform any necessary repairs prior to the instal-

lation of the drinking water device.

I. Installation Instructions

3

Fig. 1

Drain

Saddle

SinkDrain

Storage Tank

Filtration System

1/4"Orange

Tubing

3/8" Yellow

Tubing

Pressure Relief Valve

(required, not included)

Storage Tank Valve

Red SFC Tubing

1/4" Green

Tubing

Feedwater

Connection

Placement

3/8" Blue

Tubing

3/8" Black

Tubing

Reducing

Union

C. PREPARETHEAPPLIANCEFORINSTALLATION

Open the shipping carton and remove the components.

Check to see that all of the installation parts are present. They

should include the filtration assembly, storage tank, faucet,

installation hardware, RO membrane, cartridges and tubing.

Check to see that the air supply in the empty tank is approxi-

mately 7 psi (48 kPa). Adjust it if necessary. To reduce the

risk of cartridge contamination, the RO membrane cartridge

has been shipped separately in a sealed plastic bag. Follow

the steps below to install the RO membrane cartridge.

STEP 1: Cut open the sealed plastic bag and remove the RO

membrane cartridge.

STEP 2: Remove the white plug from the fitting at the bottom

of the cartridge by pushing in the small gray collet and pulling

out the plug simultaneously (see Figure 6).

STEP 3: Connect the red SFC reject tubing by inserting the

open end into the fitting at the bottom of the RO membrane

cartridge as far as it will go. Take note of the tag attached to

the SFC tube which indicates the outlet end.

STEP 4: Remove the red plastic cap from the top of the car-

tridge.

STEP 5: Line up the cartridge ears (Fig. 8), insert the cartridge

and push it into the head until it is fully seated. Twist the

cartridge 1/4 turn counterclockwise to lock it into place. The

final orientation should be such that the cartridge label faces

towards the front and the fitting is located towards the rear.

D. MAKETHEFAUCETMOUNTINGHOLE

A wide variety of RO faucet mounting situations may be

encountered. The most common are stainless steel or ceramic

on metal sinks. Consult your dealer for any other materials

which may be encountered. The faucet should be positioned

so that it empties into the sink and the spout swivels freely for

convenience. If the sink already has a hole provided that can

accommodate the RO faucet, then no drilling is required.

To reduce the risk of eye injury while drilling counter-tops

for faucet installation:

• Safety glasses MUST be worn during the sink hole drilling op-

erations.

IMPORTANT NOTE

• Ifdesired,sprayerscanbedisconnectedtoprovideasuit-

able mounting hole for the RO faucet. A pipe cap or plug

will be required to seal the sprayer connection.

Before drilling the hole, always check underneath the sink to

ensure that nothing will interfere with mounting the faucet such

as reinforcing ribs, support brackets or the cabinet construction.

Stainless steel sink, air gap or non-air gap faucet.

Recommended tools:

• Centerpunch

• Variablespeeddrillandhighspeeddrillbits

• Greenlee7/8”chassispunch(alternate9/16”

may be used for a non-air gap faucet)

• Protectivegloves

Procedure:

1) Center punch a small indent at the center of

the desired faucet location.

2) Slowly drill the required pilot hole for the

chassis punch.

3) Set up the chassis punch per the instructions and

tighten the nut to cut the desired hole size.

4) Clean up all sharp edges with a file if necessary.

Porcelain/Enamel/Ceramic sink on sheet metal or cast iron

base; air gap or non air gap faucet.

Recommended tools:

• Variablespeeddrill

• Relton7/8”porcelaincuttertoolset(alternate9/16”

porcelain bit may be used for a non-air gap faucet)

• Plumber’sputty

It is important to understand what is involved in this proce-

dure. First, the glassy layer of porcelain must be penetrated

through to the base metal. Second, a center disc of porcelain

must be removed while protecting the surrounding porcelain

against chipping or fracturing. Third, the base metal must be

drilled through to complete the hole.

Procedure:

1) Mark the center for the 7/8” hole.

2) Form a shallow putty dam around the hole area and fill it

with enough water to lubricate the carbide drill bit.

3) Carefully drill a pilot hole through the porcelain/enamel and

the base metal using a carbide type pilot drill.

Important: Always operate the drill with light bit pressure

at a slow speed (300-400 rpm).

4) Insert the pilot tip of the spring-loaded porcelain cutter into

the pilot hole.

5) Drill the porcelain/enamel using the spring-loaded porcelain

cutter, making certain a complete ring has been cut through

the porcelain/enamel to the metal base.

6) Change to the metal cutter. With a slow speed and light

pressure, cut away the inner porcelain/enamel disc down

to the base metal. Make certain that the cutter does not

touch the outer rim of the cut porcelain/enamel. Continue

with this bit to cut completely through the metal.

IMPORTANT NOTE

• When using a porcelain cutter it is critical that it is always

in a sharpened condition. Dull cutters are known to chip

sinks.

Drilling 7/8” diameter hole through countertop or stainless steel sink:

1. Locate area to be drilled. Mark center of hole with center

punch.

2. Drill hole with 7/8” drill bit suitable for countertop materials or

cast iron/stainless steel.

3. With grinding wheel or file, smooth out any rough edges.

4

E. MOUNTTHEFAUCET

Undercounter installations generally require that the

faucet’s built-in air gap be used. In basement installations,

the built-in air gap does not have to be used if one is provided

elsewhere on the drain line.

For Basement Installations Without An Air Gap Module

See Installation Instructions on page 11.

IMPORTANT NOTE

• The Uniform Plumbing Code dictates that there must be

an air gap between the RO reject line and the waste drain.

An optional non-air gap faucet, which requires a smaller

9/16” mounting hole, is available to make basement in-

stallations easier.

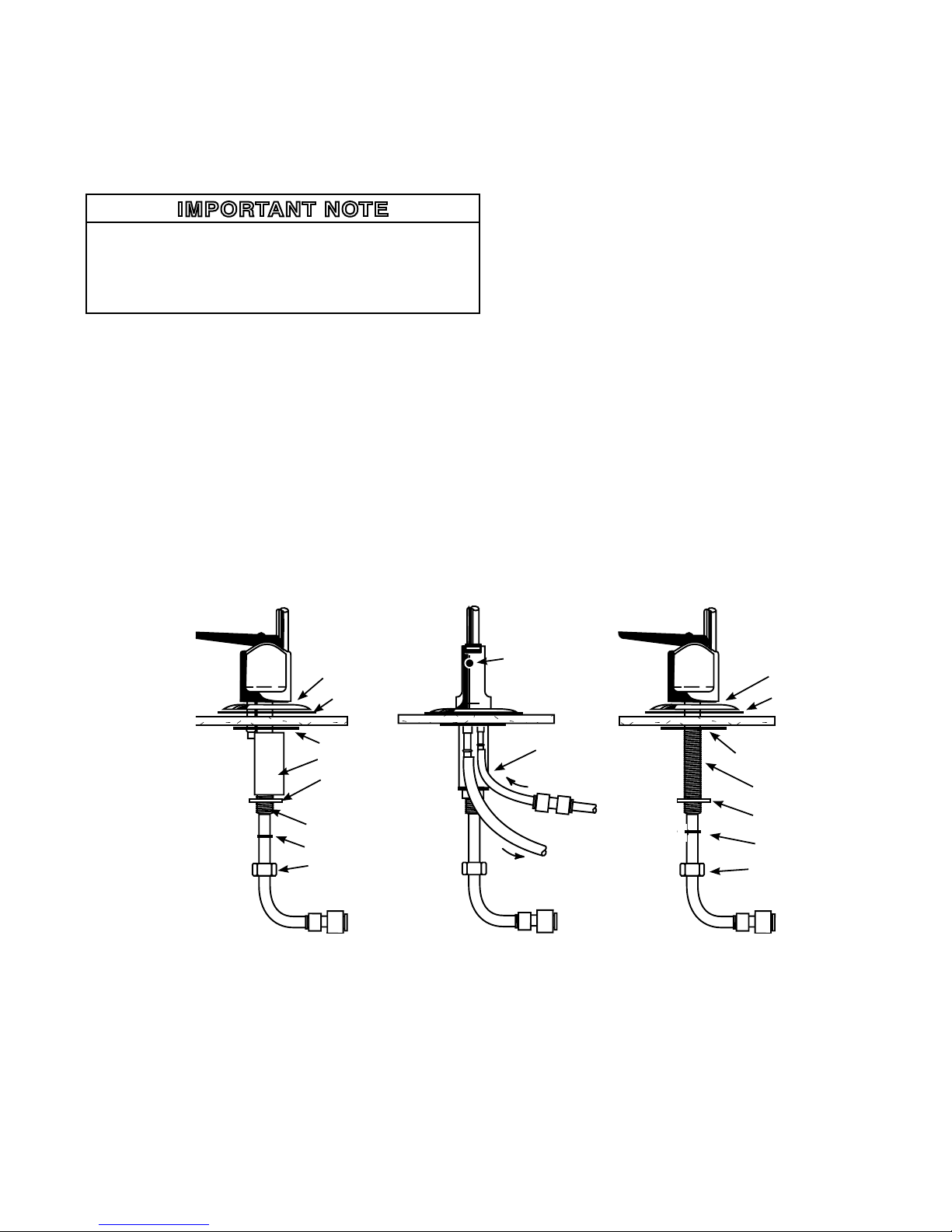

Undercounter Installation With An Air Gap Faucet:

1) Familiarize yourself with all of the components shown in

the air gap faucet diagram. (See Fig. 2)

2) Remove 3/8” tubing in front of the black faucet handle and

discard. Push faucet spout into where the 3/8” tubing was

just removed.

3) Slide the chrome base plate and rubber washer up the

threaded base of faucet.

4) Connect the 1/4” green tubing supplied in the installation kit

to the smaller barb on the air gap faucet. Push it on firmly

until it seats.

5) From above the sink counter-top, feed the air gap tubing

and the threaded nipple through the faucet mounting hole

and position the faucet spout over the sink.

6) From below the sink/countertop, install the white spacer

(open side toward the air gap tubing), flat washer, lock wash

er and hex nut onto the threaded nipple and tighten it by

hand.

7) Back off on the hex nut just enough to slide the slotted

washer (open side toward the air gap tubes) between the

white spacer and the underside of the sink/countertop.

8) After rechecking the faucet orientation, tighten the hex nut

with a 9/16” wrench until the faucet feels secure.

9) From above the sink, make any minor orientation corrections

by turning the faucet on its flats with a padded adjustable

wrench. Use care so as not to mar the chrome finish.

5

C.L.

FaucetwithAirGap FaucetwithoutAirGap

Side View Back View Side View

Chrome base plate

AirGaphole

1/4”Standard

green tubing

Specialred“SFC”

tube from RO

Black3/8”Reject

tubing to drain

Blue3/8”Product

water tubing connection

Blue3/8”Product

water tubing

Rubber washer

Plasticbottomwasher

Threaded nipple

Flatwasher

Lockwasher

Hexnut

Blue3/8”Product

water tubing

Chrome base plate

Rubber washer

Threaded nipple

Flatwasher

Spacer

Hexnut

Slotted washer

Fig. 2

1/4”x3/8”TubeConnector 1/4”x3/8”TubeConnector 1/4”x3/8”TubeConnector

Lockwasher

F. INSTALLSTEMADAPTERWITH1/4”FEEDWATER

TUBEOUTLET

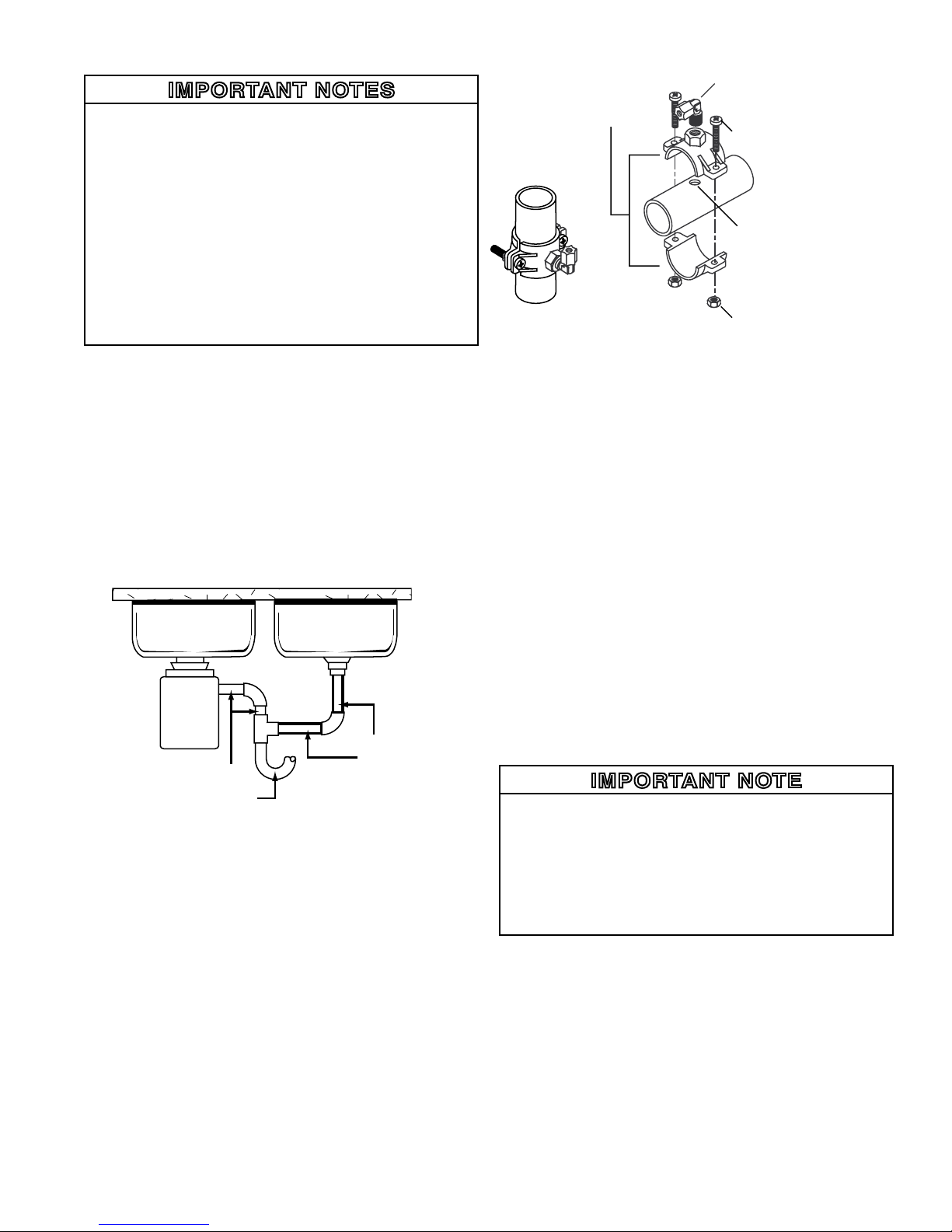

IMPORTANT NOTES

• For basement installations, the existing orange feed

water tubing may have to be longer to reach the faucet

adapter.

1) Open faucet and turn off cold water supply to relieve pres-

sure.

2) Locate the cold water stem on the underside of the faucet

fixture. Unscrew the cold water feed tube from the faucet

stem. Locate the Faucet Adapter that came with your drink-

ing water system. Insert the black gasket into the threaded

adapter and tighten onto the Faucet Cold Water Stem under

the sink, making sure that 1/4” side connection is accessible

and not facing the wall. Make sure not to overtighten.

3) Take the Cold Water Feed Tube and attach to the Faucet

Adapter, making sure not to over tighten.

4) Locate the 1/4” Orange Tubing and insert into the 1/4”

outlet of Faucet Adapter. See Figure 3 and “Using Push-in

Fittings” below.

5) Leave cold water supply off.

G. INSTALLATIONSANITIZING*

PREFILLANDSANITIZETHESTORAGETANK

To reduce the risk associated with eye, skin and respiratory and di-

gestive tract burns from Calcium Hypochlorite during installation:

• CalciumHypochlorite(CAS7778-54-3)granulesare

used for tank sanitation in this product.

• Duringinstallation,donotgetineyes,onskinor

clothing. Do not ingest. Wear eye and face protection.

Keep out of reach of children.

• TorequestanMSDSrelatingtothisproduct,call203-

238-8965orvisitthewebathttp://solutions.3m.com/

wps/portal/3M/en_US/MSDS(clickMSDSsearch).For

emergencies,call800-364-3577or651-737-6501(24

hours).

To reduce the risk associated with ingestion of water contaminated

with sanitizer:

• Sanitizermustbeushedfromthesystembefore

using as directed within the installation instructions.

Prefilling the storage tank is always recommended so that there

is pressure to check for leaks as well as sufficient water to flush

the carbon postfilter. The SQC RO Drinking Water Appliance

is furnished with a container of special sanitizing granules. It is

important to use a sanitizer when prefilling the tank.

1) Remove protective cover from storage tank and discard.

Locate the enclosed container of sanitizing granules, open

it and pour the contents into the end of the tank. Apply PTFE

tape (not included) to threaded tank connection and install

tank valve onto connection. Do not over tighten. Open the

tank valve so that the tank valve handle is parallel to the

valve body.

2) Disconnect the 3/8” yellow tubing from the back of the

filtration assembly and connect one end of it into the tube

fitting located on the tank valve.

3) Connect the other end of the 3/8” yellow tubing to the 3/8”

x 1/4” union connector included in the tank sanitization kit.

4) Connect the free end of the 1/4” orange feed water tubing

to the other end of the 3/8” x 1/4” union connector.

5) Open the cold water supply shut off valve (making sure the

tank valve is still open) and allow the tank to fill (about

3 minutes).

6) Close the cold water supply shut off valve and the tank valve.

Disconnect the 3/8” yellow tubing from the tank valve elbow

fitting and set the tank aside while proceeding with the rest of

the installation (the sanitizatizing solution should be kept in the

tank for at least 15 minutes).

7) Reconnect the 3/8” yellow tubing to the back of the

filtration assembly. Reconnect the 1/4” orange tubing to

the feed water fitting on the filtration assembly.

IMPORTANT NOTES

• If you encounter difficulty in removing the tubing from the

tank, make sure the tank valve is closed and then cut the

yellow tubing approximately 1” away from the tank valve

fitting to relieve the pressure. Remove the 1” piece from

the tank fitting.

• If an alternate storage tank is used, it should be sanitized

with household bleach (5-1/4%). Use 3 ml. (1/2 teaspoon)

of bleach for a 2.5 gallon tank.

• After the installation is complete, it is recommended that

the 3/8” x 1/4” union connector be saved for future use in

tank sanitization.

*ForYearlyOwnerMaintenanceSanitizingInstructions,seepage14

6

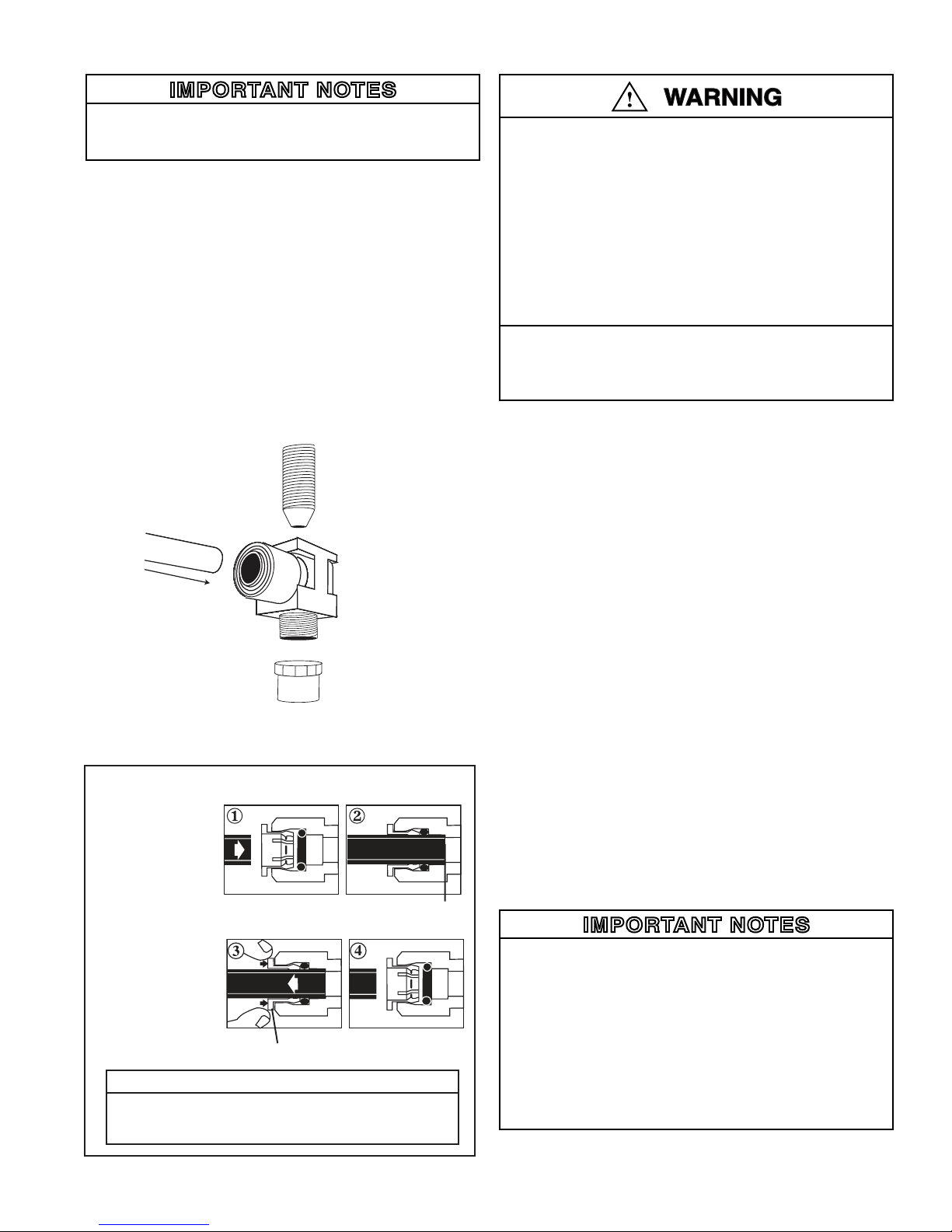

To Release Tubing

Push in grey collet to

release tubing. With

collet held, pull tubing

straight out.

Collet

Backstop

“Using Push-In Fittings”

To Attach Tubing

Push tubing in as

far as it will go.

Tubing must be

inserted past o-ring

and hit backstop.

Pull tube to ensure it is secured.

CAUTION

To reduce the risk associated with property damage due to

water leakage:

• Ensure all tubing and fi ttings are secure and free of leaks.

Fig. 3

Orange Tubing

Faucet Stem

Undersink

Feedwater

Tube

H. INSTALLTHEDRAINCONNECTION

IMPORTANT NOTES

• Before starting this procedure, inspect the condition of the

drain piping, especially in older homes where the traps

and tailpieces can be deceptively thin and frail. If they are

in poor condition, it is wise to inform the customer that the

condition should be remedied.

• Some local plumbing codes may prohibit the use of sad-

dle-type valves and/or drain connections. The use of

saddle-type valves are prohibited in Alaska, Delaware,

Idaho, Kentucky, Massachusetts, Michigan, Minnesota,

New Hampshire, North Dakota, Ohio, and South Dakota.

Check your local plumbing codes for any restrictions that

apply. Massachusetts CMR 248 strictly prohibits the use

of saddle-type valves. The feed water connection must

conform to applicable plumbing codes.

Undercounter Installation:

The drain saddle assembly is designed to fit around a

standard 1-1/2” OD drain pipe. For smaller (lavatory type) or

larger (ABS pipe) drains, consult your dealer for special drain

saddles.

The drain saddle should always be installed above (before) the

trap and on the vertical or horizontal tailpiece. Never install the

drain saddle close to the outlet of a garbage disposal because

plugging of the RO drain line may occur. (See Fig. 4)

1) Remove backing on foam seal and place over hole on

threaded half of the drain saddle. Place drain saddle at

the selected location and mark the pipe through the thread

ed opening.

2) Drill a 1/4” hole at the marked location through one side of

the drain tailpiece.

3) Position both halves of the drain saddle on the drain pipe

so that the threaded opening is lined up with the hole in

the drain pipe.

4) Use the screws and nuts to clamp the drain saddle onto

the drain pipe. Make sure that there is equal space

between saddle halves on each side. Do not overtighten.

(See Fig. 5)

5) Orient the elbow in the direction of the RO faucet location.

I. INSTALLTHEFILTRATIONASSEMBLYAND

STORAGETANK

For Basement Installation See Installation Instructions O.

Undercounter Installation:

The filtration assembly is usually mounted to the right or

the left side wall inside of the sink cabinet, taking into consider-

ationthespaceavailableandthetanklocation.Generally,the

storage tank is placed in the rear of the sink cabinet while the

filtration assembly is positioned toward the front for filter car-

tridge accessibility.

To mount the filtration assembly, elevate it at least 2” (5

cm) off of the cabinet floor and, while keeping it level, mark the

location of the mounting holes on the cabinet side wall. Make

small pilot holes with an awl or a drill and screw in the two

mounting screws; leaving just enough protruding to allow the

bracket mounting slots to slide over them.

IMPORTANT NOTE

•If the cabinet side walls are not of solid construction, the

filtration assembly can be set on the cabinet floor and held

against the side wall with the mounting screws. However,

the filtration assembly will then need to be lifted from the

mounting screws in order to remove the filter cartridges.

•It is essential that the filters be installed in the correct

location. Use the icon coded label to match the replacement

filters with their corresponding filter heads.

The storage tank may be oriented either vertically or horizon-

tally. It is generally placed to the rear of the cabinet but can

be set in the front center (between the sink basins) for ease

of access if space permits. For horizontal positioning, care-

fully detach the tank base from the tank bottom and use it as a

cradle.

7

MOUNT

HERE

NEVER

MOUNT

HERE

Fig. 4

Vertical Position Horizontal Position

Nut

Screw

DrainSaddle

Elbow

IMPORTANT:

Hole should be located on

top of the pipe if drain saddle

is positioned horizontally.

DrainSaddle

Halves

Fig. 5

GARBAGE

DISPOSAL

J. MAKETHETUBINGCONNECTIONS

With all of the components in place, the tubing connections

can be made. When routing the tubing between the compo-

nents, several guidelines should be observed.

• Tubingrunsshouldgenerallyfollowthecontourofthe

cabinet rather than interfere with the cabinet storage area.

• Striveforaneatandorderlytubing“flow”byusing

fasteners (e.g. insulated staples) to secure the tubing.

• Arrangethetubingsothattherearenosharpbends.

Leave some “play” in the tubing for ease of servicing, then

cut the tubing to the desired length.

• Trytokeepthetubingfromthefiltrationassemblytothe

tank and faucet as short as practical for good flow.

For Basement Installation See Installation Instructions O.

Undercounter Installation:

The appliance will have the 3/8” yellow and the 3/8” blue

tubing already connected to the filtration assembly.

1) The 1/4” orange tubing should already have been

connected to the cold water supply shut off valve.

Route the other end through the large opening in the “

bottom of the metal bracket and loop it back to the “Feed”

connection on the filtration assembly.

2) Attach the 1/4” x 3/8” union to 1/4” blue tubing on faucet.

3) Connect the 3/8” blue tubing from the filtration

assembly to the other end of 3/8” x 1/4” union.

4) Route the 3/8” black tubing from the faucet air gap to the

drain saddle so that it slopes continuously downward

without any loops or low spots. Cut the tubing to the

proper length and connect it to the drain saddle elbow.

5) Connect the 3/8” yellow tubing from the filtration

assembly to the tank.

6) Remove the plug from the elbow fitting on the RO module

cartridge. Insert the special SFC tube into this elbow fitting.

(Note: The elbow fitting is labeled “drain” on the RO

module.) Route the special red SFC tubing toward the

faucet. Do not cut this special SFC tubing. Its length is

important to maintain proper efficiency and performance.

7) Cut the 1/4” green tubing from the faucet air gap to the

proper length and connect it to the1/4” connector fitting on

the end of the SFC tubing.

K. INSTALLTHEICEMAKERHOOKUP(optional)

The RO drinking water appliance can be connected to any

standard refrigerator icemaker or icemaker/water dispenser. It

should never be connected to a commercial type bar icemaker.

Hooking up an icemaker involves connecting a tee with a

shut off valve into the 3/8” blue faucet tubing and routing the

tubing over to the refrigerator. Hooking up to existing copper

unit is generally not recommended unless it is less than six

months old. If copper tubing must be used, then the installa-

tion of a small in-line carbon filter at the refrigerator connection

is recommended.

Before turning off the existing tap water supply to the refrig-

erator icemaker, always shut off the icemaker first (usually by

lifting the lever arm above the bin to the uppermost position).

The icemaker should only be turned on again after the RO

system has been drained several times and the storage tank

has a full supply of water.

IMPORTANT NOTES

• Before any service is performed on the RO appliance, al-

ways turn off the icemaker valve and the icemaker unit.

Only turn them on when the system is operating and the

tank is full.

L. STARTUPTHEAPPLIANCE

1) Double check to see that all of the connections are secure.

2) Open the cold water supply shut off valve and check the

appliance for leaks. If any leaks are detected, close the

valve and correct the problem before proceeding.

IMPORTANT NOTE

If a leak occurs at a “Push In” plastic fitting, then refer to Fig. 6.

3) Open the storage tank valve and lift the faucet handle until

a steady stream of water flows. Close the faucet, wait at

least 5 minutes and carefully check for leaks. Correct

them as necessary.

IMPORTANT NOTE

When the appliance is first turned on, water may intermittently

“spurt” from the air gap opening at the side of the faucet. This

is perfectly normal, and is caused by air trapped in the sys-

tem. This will usually disappear within a short time.

8

This product is outfitted with user friendly ‘Push In’ connectors. Proper use of the

connectors is shown in Figure 3.

It is most important that the tubing selected for use with these connectors be of

high quality, exact size and roundness, and with no surface nicks or scratches. If it is

necessary to cut the tubing, use a plastic tubing cutter or sharp razor knife. Make a

clean square cut.

Should a leak occur at a ‘Push-In’ connector, the cause is usually defective tubing.

ToFix: •Relieve pressure

•Releasetubing

•Cutoffatleast1/4”fromend.

•Reattachtubing

•Confirmconnectionisleakfree.

‘Push-In’ Tubing Connector

Fig. 6

9

M. FLUSHTHEAPPLIANCEOFTHEPRESERVATIVE

ANDCHECKTHEOPERATION

1) With the tank valve closed (the tank should still contain the

sanitizing solution at this point), open the faucet (set the

faucet handle in the “up” position) and feed water valve.

Water should begin to drip from the faucet within several

minutes. Continue to flush the system for 24 hours. Water

will steadily drip from the faucet at this time. During this

procedure, the tank is being intentionally bypassed in

order to thoroughly sanitize the tank and also flush the

membrane of any preservatives.

To reduce the risk associated with irritation from Sodium Metabi-

sulfite during installation:

• SodiumMetabisulte(CAS07681-57-4)isusedina

1%preservativesolutionwithinthereverseosmosis

membrane.

• DonotputthissystemintoservicebeforetheRO

tankisushedasspeciedintheinstallationinstruc-

tions. Wear eye and face protection during installa-

tion.

• TorequestanMSDSrelatingtothisproduct,call203-

238-8965orvisitthewebathttp://solutions.3m.com/

wps/portal/3M/en_US/MSDS(clickMSDSsearch).For

emergencies,call800-364-3577or651-737-6501(24

hours).

2) After flushing for 24 hours, shut off the faucet. Open the tank

valve, lift the faucet handle again and allow the tank to

completely empty. When the tank is empty, the faucet will

drip steadily. Measure and record the rate at which water

drips from the faucet. Use a graduated cylinder (in

milliliters) and a watch with a second hand to calculate the

approximate production in gallons per day (milliliters per

minute x 0.38 = gpd). Proceed to check the reject flow by

disconnecting the tubing at the drain connection and

measuring the drip rate as outlined above. The ratio

should be a minimum of 2.5 (reject) to 1 (product).

Repeat every 5 minutes until the rate is constant. When

the rate is constant, the tank is empty.

3) Allow the system to operate in this condition for 24 hours.

4) Close the faucet and reinspect the appliance for leaks.

Allow the tank to fill completely (it will take approximately

4 hours), then drain the tank again. The water should be

discarded because it may contain some sanitizing solu-

tion.

5) The appliance should be ready to use as soon as the tank

refills. If any objectionable taste is noticed after the

second tankful is drained, instruct the customer to wait

and drain the tank the following day. Only at this time

should an icemaker be turned on if one is connected to

the appliance.

N. CLEANUPANDPAPERWORK

1) Clean up the work area thoroughly.

2) Fill out the warranty card and return it.

For replacement parts and filters, please contact your dealer

or call Water Factory Systems at 1-800-733-1199 or visit our

website at www.waterfactorysystems.com.

This system has been tested for the treatment of water contain-

ingpentavalentarsenic(alsoknownasAs(V),As(+5),orarse-

nate) at concentrations of 0.30 mg/L or less. This system treats

pentavalent arsenic, but may not affect other forms of arsenic.

This system is to be used on water supplies containing a detect-

able free chlorine residual or on water supplies that have been

demonstrated to contain only pentavalent arsenic. Treatment

with chloramine (combined chlorine) is not sufficient to ensure

complete conversion of trivalent arsenic to pentavalent arsenic.

Please see the Arsenic Facts section of the Performance Data

Sheet for further information.

10

Fig. 7

(FLOOR)

Faucetwithout

AirGap

3/8”Blue

Tubing*

Forrefrigera-

tor icemaker or

water dispenser

hookup, tee into

tubing

FaucetAdapter

Cold Water

SupplyPipe

3/8”Yellow

Tubing*

Storage

Tank**

1/4”greentubing

AirGapDevice

(e.g.Gap-A-Flow)

LaundrySink,

Standpipe or

FloorDrain

(BasementFloor)

Storage Tank

Valve

RedSFCTubing

Filtration

assembly

*Forbestflow,keepthetubingasshortaspossible

**Mountthestoragetankonashelforstrapitbetweentwofloorjoists

1/4”Orange

Tubing

SQC3-has3cartridges

SQC 4 (shown)

ReducingUnion

PressureRelief

Valve(Required,

not Included)

11

O. APPENDIXFORBASEMENTINSTALLATIONS

The following variations are generally required for basement

installations:

INSTALL THE DRAIN CONNECTION

For basement installations, the drain saddle is generally

not used. Instead, the RO reject line (SFC tubing) is routed

so that it drains into a laundry sink, floor drain, or standpipe

through an approved air gap.

MOUNT THE FAUCET

If you choose to use the air gap faucet included with the

RO system, follow the faucet installation instructions given ear-

lier in this manual. Do not hook up any air gap tubing to the

faucet since an alternate air gap will be used elsewhere in the

drain line.

If you choose to use the optional non-air gap faucet, follow

the instructions below.

A) Familiarize yourself with all of the components shown in

the diagram of the non-air gap faucet. (See Fig. 2)

B) Install only the chrome base plate and rubber sealing washer

onto the threaded nipple. (Plumbers’ putty may be used in

place of the sealing washer for a neater appearance.)

C) Feed the threaded nipple through the sink/countertop

mounting hole (a 9/16” hole is adequate).

D) From underneath the sink/countertop, install the plastic

bottom washer, flat washer, star washer, and hex nut onto

the threaded nipple. Hand tighten the hex nut until the

faucet feels snug.

E) After rechecking the faucet orientation, tighten the hex nut

with at 9/16” wrench until the faucet feels secure.

F) From above the sink, make any minor orientation

corrections by turning the faucet on its “flats” with a

padded adjustable wrench. Use care so as not to mar the

chrome finish.

INSTALL THE FILTRATION ASSEMBLY AND THE

STORAGE TANK

The filtration assembly is generally mounted to the basement

wall (using wall anchors) or to the wood ceiling supports. To

mount the filtration assembly, keep the bracket level and mark the

location of the mounting holes. Install wall anchors and/or mount-

ing screws as required. Leave the screw heads protruding to

allow the bracket mounting slots to slide over them. (See Fig. 7)

The tank may be oriented either vertically or horizontally and

can be placed on a shelf, on the floor, or suspended from the ceil-

ing supports using brackets.

An effort should be made to minimize the distance between

the tank and filtration assembly in order to ensure an adequate

flow rate to the faucet.

MAKE THE TUBING CONNECTIONS

1) A proper length of the 1/4” orange feed water tubing

should already have been connected to the cold water

supply shut off valve. Route it through the large opening

in the bottom of the metal bracket and loop it back to the

“FEED” connection on the filtration assembly.

2) Connect a longer length of 3/8” blue tubing (not included) to

the faucet adapter. Route the tubing through the floor to the

location of the filtration assembly. Remove the existing

3/8” blue tubing from the filtration assembly. Route the

other end of the longer length of 3/8” blue tubing through the

large opening in the bottom of the metal bracket and connect

it to the “FAUCET” connection on the filtration assembly.

NOTE: Instead of removing the existing 3/8” blue tubing from

the filtration assembly, a 3/8” connector fitting can be used to

join the tubing from the faucet with the tubing from the filtration

assembly.

3) Route the 3/8” yellow tubing from the filtration assembly

to the storage tank.

4) Route 1/4” tubing from an appropriate drain connection

(e.g. laundry sink, floor drain, standpipe) to the location of

the filtration assembly. An air gap must be provided

between the outlet and the drain connection.

5) Connect the red SFC tubing from the filtration assembly

to the 14” tubing from the drain connection using the 1/4”

connector fitting on the end of the SFC tubing.

P. INSTALLATIONTROUBLESHOOTING

Problem: Leak at the drain saddle.

Possible Cause: Drain saddle not clamped tightly enough.

Solution: Tighten the drain saddle screws evenly and firmly.

Problem: Leak at the fittings threaded connection.

Possible Cause: Fitting is improperly taped or not `

tightened sufficiently.

Solution: Retape the threaded portion with PTFE tape and

thread it in firmly. Do not over tighten.

Problem: Leak at the fitting’s push-in connection.

Possible Cause: Tubing is damaged if there is a tubing mis-

assembly.

Solution: Remove the tubing. Squarely cut off 1/4 inch from

the end of the tubing using a sharp razor knife and reinsert it

into the fitting. Make sure that the tubing is pushed in com-

pletely until it seats.

Problem: Leak at the filter cartridge head.

Possible Cause: Damaged or misaligned O-ring.

Solution: Close the cold water supply shut off valve and the

storage tank valve. Lift up on the faucet handle and drain the

tank a minimum of 5 minutes. Remove the filter cartridge and

check the condition of the O-rings. If they are misaligned,

reseal them. If they are damaged, replace them.

Problem: The faucet leaks from the spout with the handle down.

Possible Cause: An obstructed or damaged valve seat in the

faucet mechanism.

Solution: Remove the faucet spout with a twisting/lifting

motion and slide the faucet handle forward over the spout

hole to gain access to the faucet valve. Unscrew the tee-bar

and the slotted bushing to remove the valve. Clean out any

obstruction or replace it with a new valve mechanism if neces-

sary.

Problem: No steady drip from the open faucet after the

tank is drained.

Possible Causes:

• The cold water supply shut off valve is not open.

• A leak from any product water fitting connection.

• The icemaker valve was left open before the start-up

procedure completed.

• Air is still trapped in the system.

Solutions:

• Open the cold water supply shut off valve completely.

• Correct the fitting leak as outlined above.

• Close the icemaker valve and wait until the faucet drips.

• Wait for the air to be purged from the system.

Problem: Water leaks from air gap module opening.

Possible Causes:

• The drain line tubing is looped, kinked, or has a low spot.

• The drain line is blocked or the drain hole is not drilled

through completely.

• Air is locked in the air gap outlet.

• There is excessive RO reject flow.

Solutions:

• Trim any excess tubing to obtain a short, “straight-shot” to

the drain.

• Check to see that the drain line is clear of any obstruction

and remove the drain saddle fitting to verify that the hole is

drilled through completely.

• Blow air into the air gap outlet using a short length of tubing.

• Disconnect the red SFC reject tubing from the faucet air

gap inlet tubing and check the reject flow rate. It should

be less than 5.9 ounces/min. If it is greater than 5.9 ounc

es/min, replace the red SFC reject tubing with the new one

of proper length.

Problem: Too little or no reject flow.

Possible Causes:

• Red SFC reject tubing is plugged or damaged.

• An obstruction in the faucet air gap module.

Solutions:

• Replace the SFC reject tubing with one of proper length.

• Remove the air gap module and inspect the internal flow

path. Replace the air gap module if necessary.

Problem: Chlorine or other unpleasant taste/odor is evi-

dent after the initial tank filling.

Possible Cause: Residual preservative/sanitizer is still in the

water.

Solution: Drain and fill the storage tank several times if

necessary.

Problem: Noise in the drain (gurgling or

dribbling sound).

Possible Cause: The reject water is dripping into the standing

water in the drain trap.

Solutions:

• Make sure that the 3/8” black drain tubing from the faucet

air gap module slopes continuously downward to the drain

saddle without any loops or low spots.

• Angle the drain piping so that the reject water runs down

the side of the drain pipe.

• Change the location of the drain saddle to the horizontal

drain pipe or any alternate vertical drain pipe which is

farther from the trap. Properly plug the original hole.

• Drill larger hole in drain pipe.

Caution: Make sure the drain saddle is always installed

above (before) the trap.

12

A. IMPORTANTWATERQUALITYASSURANCE

REQUIREMENTS

Reverse Osmosis drinking water appliances contain treat-

ment components that are critical for the effective reduction of

Total Dissolved Solids (TDS) as well as inorganic chemical con-

taminants. Water Factory Systems™strongly recommends that

the user test the water periodically (every six to twelve months

minimum) to verify that the appliance is performing satisfac-

torily. Your dealer may offer a water testing service. Routine

maintenance is necessary in the form of prefilter, postfilter, and

membrane replacement, based on the following guidelines:

• Sediment,Carbon,orSediment/CarbonPrefilters,and

Carbon Postfilters: Change every 12 months or sooner

depending on the feed water quality.

• RO Membrane: Change it as required based on Percent

Rejection. A testing service may be offered by your dealer

every 36 months or sooner.

B. REPLACINGTHEFILTERCARTRIDGES

The life of the prefilter cartridge generally depends on

the local water conditions (i.e., dirt, rust and/or chlorine

levels) while the life of the postfilter cartridge(s) is generally

determined by the length of service.

When to Replace the Sediment Replacement Filter

• Every twelve (12) months or sooner depending on local water

conditions.

• Anoticeabledecreaseinwaterproductionisanindication

that the filter requires changing.

When to Replace the Granulated Carbon Replacement

Filter

The granulated carbon replacement filter reduces free chlorine

in the feed water supply to protect the TFCM membrane from

chlorine attack. To find out the chlorine level in a water supply,

call the public water supplier.

When to Replace the Carbon Block Replacement

Post-Filter

• If the filter is being used to control tastes and odors, replace it

every twelve (12) months or sooner depending on local water

conditions.

When to Replace the Carbon Postfilter Cartridge

Change at a minimum of 12 months or sooner, depending

on feed water quality.

How to Replace the Prefilter and

Postfilter Cartridges

1) Lift up on the faucet handle to drain the tank. Close the

cold water supply valve. Wait five (5) minutes for the

filtration assembly to completely depressurize.

2) Remove cover and twist the filter cartridge 1/4 turn

clockwise so that the

ears on the cartridge are able to disengage from the

head. Firmly pull the cartridge from the head. It may

be necessary to twist the cartridge slightly from side to

side to help free it. (See Fig. 8)

3) Remove the new filter cartridge from its sanitary sealed

wrapper. (Double check to see that it is the correct

replacement by comparing the labels.)

4) Using tap water, wet the o-ring seals to make cartridge

insertion easier.

5) Line up the cartridge ears, insert the cartridge and push

it into the head until it is fully seated. Twist the

cartridge 1/4 turn counterclockwise to lock it into place.

6) Open the cold water supply valve and carefully check

for leaks.

7) RO System Flush Instructions:

Prefilter: Flush at least 2 gallons of water through filter

before use.

Postfilter: Flush at least 2 gallons of water through fil-

ter before use.

RO Membrane Cartridge: Run product water to drain for

24 hours.

C. REPLACINGTHEROMEMBRANECARTRIDGE

The life of the RO membrane cartridge depends on the

local water conditions and proper maintenance, e.g., regular

filter changes. The maximum recommended service life is

36 months. Unlike the filter cartridges, the RO membrane

cartridge life is not determined by the amount of water used

because of its self-cleaning feature.

II. Operation & Maintenance Instructions

13

To reduce the risk associated with property damage due to water leakage:

• Read and follow UseInstructionsbeforeinstallationanduseofthissystem.

• Installationanduse MUST comply with all state and local plumbing codes.

• Protect from freezing,removeltercartridgewhentemperaturesareexpectedtodropbelow40°F(4.4°C).

• Donotinstallifwaterpressureexceeds100psi(690kPa).Ifyourwaterpressureexceeds80psi(552kPa),youmust

install a pressure limiting valve. Contact a plumbing professional if you are uncertain how to check your water pressure.

• Donotinstallwherewaterhammerconditionsmayoccur.Ifwaterhammerconditionsexistyoumustinstalla

water hammer arrester. Contact a plumbing professional if you are uncertain how to check for this condition.

• ThedisposableltercartridgeMUST bereplacedevery12months,attheratedcapacityorsoonerifanoticeable

reductioninowrateoccurs.

• TheROMembranecartridgeMUST bereplacedatleastevery36months.

How to Replace the RO Membrane Cartridge

1) Close the cold water supply shut off valve. Lift up on the

faucet handle to drain the tank. Wait five (5) minutes for

the filtration assembly to completely depressurize.

2) Make sure that there is some slack in the red SFC tubing

connected to the fitting at the bottom of the RO membrane

cartridge. Twist the cartridge 1/4 turn clockwise so that

the tubing connection is accessible. (See Fig. 8)

3) Remove the red SFC tubing by depressing the small gray

collet and pulling the tubing away from the fitting.

Note: It is advisable to check the end of the red SFC tubing

for nicks or scratches. If any are observed, cut off 1/4” from

the end of the tubing with a sharp razor knife.

4) Firmly pull the cartridge away from the head. (It may be

necessary to twist the cartridge slightly from side to side.)

5) Remove the new RO membrane cartridge from its sanitary

sealed wrapper. (Double check to see that it is the correct

replacement by comparing the labels.) Rinse it with tap

water and dry it off.

6) Remove the white plug from the fitting at the bottom of the

cartridge by pushing in the small gray collet and pulling out

the plug.

7) Remove the red plastic cap from the top of the cartridge.

8) Using tap water, food grade silicone lubricant or glycerin,

wet the O-ring seals to make cartridge insertion easier.

9) Reconnect the red SFC reject tubing by inserting it into the

fitting at the bottom of the new RO membrane cartridge as far

as it will go. Line up the cartridge ears, insert the cartridge

and push it into the head until it is fully seated. Twist the

cartridge 1/4 turn counterclockwise to lock it into place.

10) Open

cold water supply valve

and carefully check for

leaks. Carefully inspect the fitting at the bottom of the new

RO membrane cartridge.

11) Follow the sanitizing procedure for the storage tank and

the filtration assembly outlined below.

D. YEARLYMAINTENANCESANITIZATION*

SANITIZINGTHEROAPPLIANCE

To assure the highest quality water from your RO Drinking

Water Appliance, it is important to routinely sanitize both the

storage tank and the filtration assembly.

IMPORTANT: These procedures are only intended to be

part of a routine maintenance program only and are not

designed to sanitize systems that have become highly

contaminated from misuse.

When to Sanitize the Storage Tank

• Upon start-up as described in the beginning of this manual.

• Afteranyservicingorroutinemaintenancethatinvolves

replacing the RO membrane cartridge, the postfilter(s), ser-

vicing the storage tank, or replacing the RO faucet.

When to Sanitize the Filtration Assembly

• Afteranyservicingorroutinemaintenancethatinvolves

replacing the RO membrane cartridge, the postfilter(s), ser-

vicing the storage tank, or replacing the RO faucet.

• Afteranyextendedperiodofnon-use(over30days)unless

the cartridges are stored inside a sealed plastic bag in the

refrigerator.

Remove the red SFC tubing from

the fitting before completely

removing the RO membrane modul

e

O

N

O

F

F

Fig. 8

14

* Initial sanitization to be performed using instructions on page 6.

How to Sanitize the Storage Tank and Filtration System

Sanitizing the storage tank generally requires:

• Common household bleach (5.25% non-scented)

• Eye dropper or plastic oral syringe

1) Close the cold water feed valve and lift up on the faucet

handle to empty the water in the storage tank. It should

feel light when empty.

2) Disconnect the 3/8” yellow tubing (system tank) from the

ball valve on top of the storage tank.

3) Insert into the yellow tubing 1/2 teaspoon (3 ml) of house-

hold bleach. (See Fig 9)

4) Reconnect the yellow tube to the tank ball valve.

5) Close the RO faucet and open the cold water feed valve.

6) Wait 4-5 hours.

7) Lift up the handle of the RO faucet and allow contents of

tank to drain completely into the sink.

8) Sanitizing is now complete.

9) If there is any residual chlorine/bleach taste in the next tank

full, drain tank completely a second time.

E. LONG TERM NON-USE

If the RO appliance is to be left unused for a long period of

time (greater than 30 days), follow this procedure:

1) Lift up on the faucet handle to drain the storage tank and

close the cold water supply shut off valve. Wait five min-

utes for the filtration assembly to depressurize.

2) Remove all of the filter cartridges. Turn the cartridges

upside down in the sink to drain out as much water from

them as possible.

3) Place the cartridges in an air tight plastic bag and store

them in the refrigerator.

IMPORTANT NOTE:

The cartridges must be not be allowed to freeze because

permanent damage may occur, which may result in property

damage due to water leakage.

4) When the RO appliance is ready to be put back into ser-

vice, reinstall the filter cartridges by matching the symbols

on the top of the cartridge labels with the ones on the

filtration assembly heads. Sanitize the storage tank as

described in the previous section. The filtration assembly

can be sanitized at this time if so desired.

5) Follow the start up procedure outlined in the previous

section.

15

Eyedropper

with Bleach

Prefilter

Cartridge

Cartridge Ear

1/2 Tsp.

5.25%

Unscented

Bleach

Eyedropper

with Bleach

Storage Tank

Fig. 9

To reduce the risk associated with ingestion of water contaminated with sanitizer:

• Sanitizermustbeushedfromthesystembeforeusingasdirectedwithintheinstallationinstructions.

To reduce the risk of injury associated with household bleach:

• Readandfollow manufacturers directions and cautions

• Keepoutofthereachofchildren

• DONOTintermixwithotherchemicals

3M Purification Inc.

400 Research Parkway

Meriden, CT 06450, U.S.A.

Tel (800) 733-1199

(203) 237-5541

Fax (203) 203-8701

www.3Mpurification.com

www.waterfactorysystems.com

Please recycle. Printed in U.S.A.

Water Factory System is a trademark of 3M Company used under license.

3M is a trademark of 3M Company.

© 2010 3M Company. All rights reserved.

98-880040 0210

Limited Warranty: 3MPuricationInc.warrantsthisProductwillbefreefromdefectsinmaterialandmanufactureforthefollowingperiodsfromthedateof

purchase:Ten(10)yearsfortheProduct,exceptforthereplacementltercartridgeandmembrane,whicharewarrantedforone(1)year.Thiswarrantydoes

notcoverfailuresresultingfromabuse,misuse,alterationordamagenotcausedby3Morfailuretofollowinstallationanduseinstructions.Nowarrantyis

givenastotheservicelifeofanyltercartridgeormembraneasitwillvarywithlocalwaterconditionsandwaterconsumption.IftheProductfailstosatisfy

thisLimitedWarrantyduringthewarrantyperiod,3MwillreplacetheProductorrefundyourProductpurchaseprice.Thiswarrantydoesnotcoverlabor.The

remedystatedinthisparagraphisCustomer’ssoleremedyand3M’sexclusiveobligation.

Thiswarrantygivesyouspeciclegalrights,andyoumayhaveotherrightswhichmayvaryfromstatetostate,orcountrytocountry.Foranywarranty

questions,pleasecall1-866-990-9785ormailyourrequestto:WarrantyClaims,3MPuricationInc.,400ResearchParkway,Meriden,CT06450.Proofof

purchase(originalsalesreceipt)mustaccompanythewarrantyclaim,alongwithacompletedescriptionoftheProduct,modelnumberandallegeddefect.

Limitation of Liability: 3M will not be liable for any loss or damage arising from this 3M product, whether direct, indirect, special, incidental, or consequen-

tial,regardlessofthelegaltheoryasserted,includingwarranty,contract,negligenceorstrictliability.Somestatesandcountriesdonotallowtheexclusionof

limitationofincidentalorconsequentialdamages,sotheabovelimitationorexclusionmaynotapplytoyou.

This manual suits for next models

1

Table of contents

Other Water Factory Systems Water Filtration System manuals

Popular Water Filtration System manuals by other brands

AquaMaster

AquaMaster AMS700 Owner's manual and installation guide

US Water Systems

US Water Systems Flexx Oxi-Gen FX-150 owner's manual

Pentair

Pentair Logix 762 user guide

Penguin Water

Penguin Water 200-PWRO Series manual

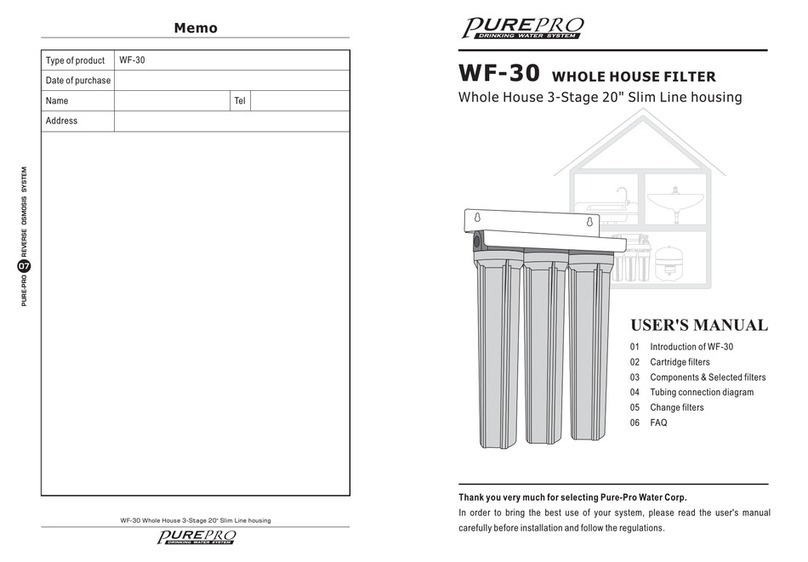

Pure-Pro

Pure-Pro WF-30 user manual

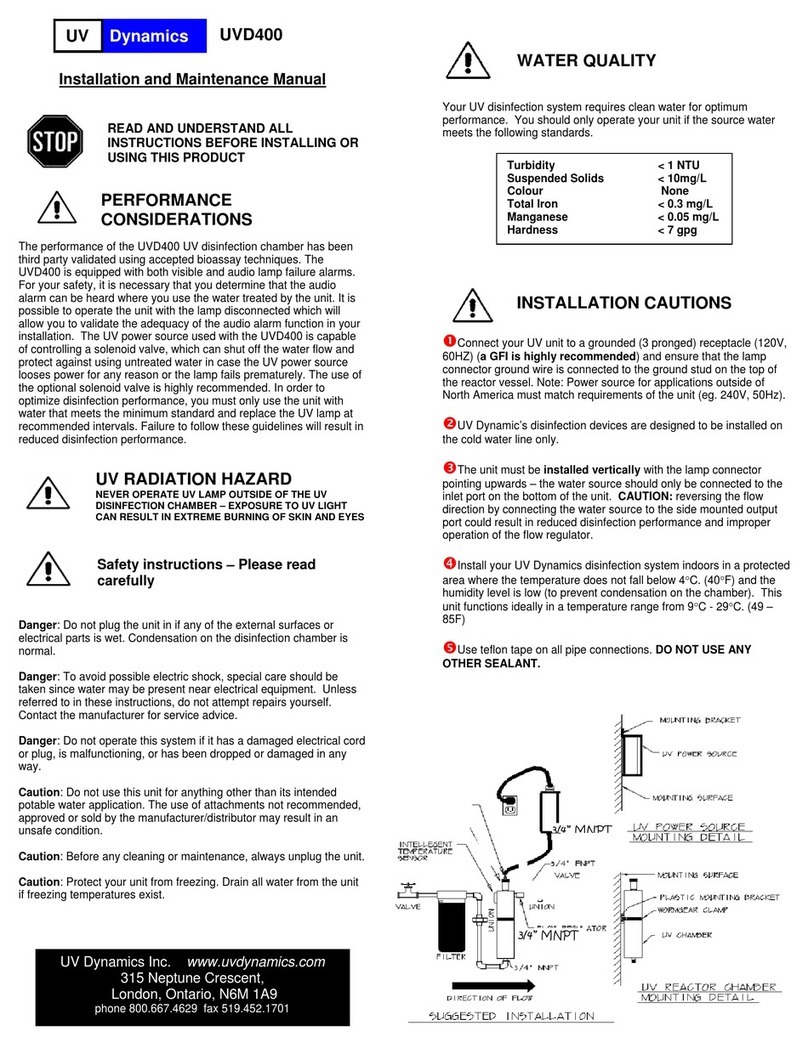

UV Dynamics

UV Dynamics UVD400 Installation and maintenance manual