FACET FILTER-SEPARATOR SERVICE MANUAL

©2018 Facet has a policy of continuous product research and development and reserves the right to change design and specifications without notice.

www.processtechnologies.filtrationgroup.com 1-(800) 223-9910 1-(918) 272-8700

Sep-19 Setting the Standard for Aviation Fueling TM 2

For Installing, Operating & Servicing Filter-Separators

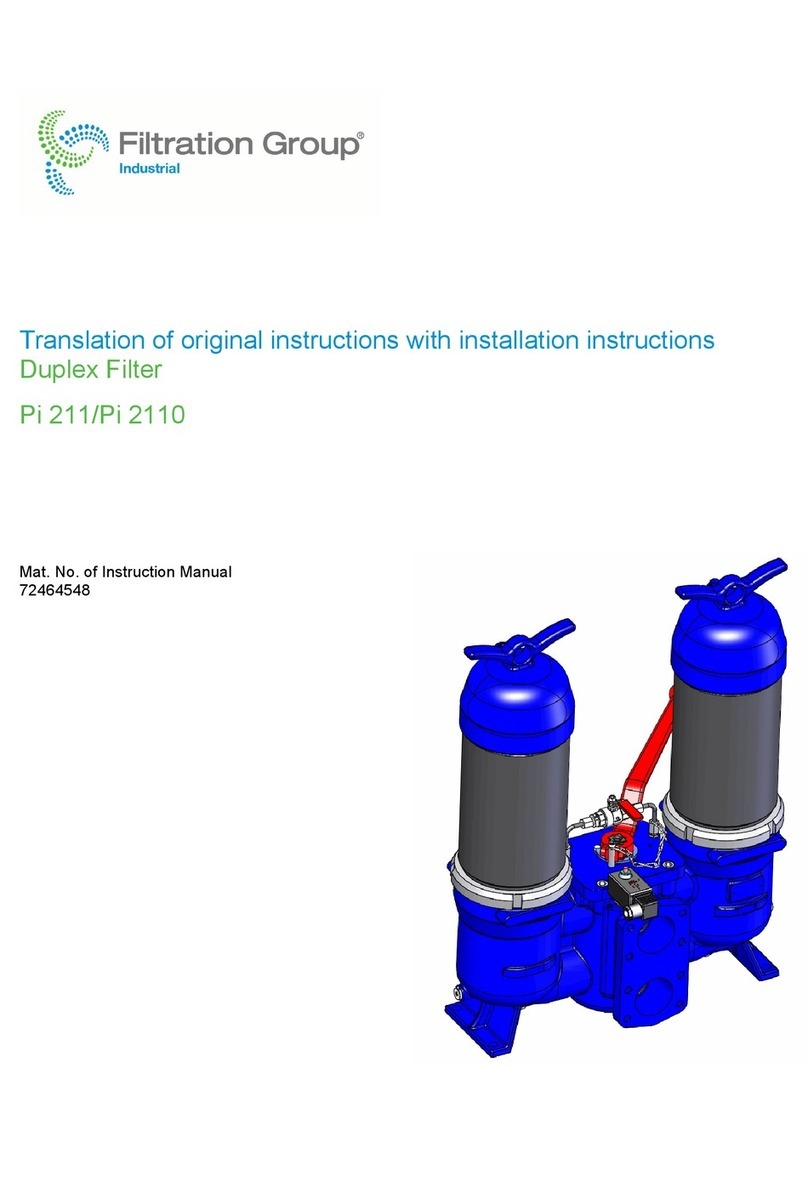

This Facet filter-separator is basically a cylindrically shaped

pressure vessel designed specifically to remove solid

contaminants such as dirt, rust, scale, sand and metal

particles as well as remove emulsified, free and entrained

water from liquid and air/gas product streams.

Removable access opening covers are provided to facilitate

the replacement of the filter elements contained inside the

main body of the unit and to permit cleaning the interior of

the vessel.

Suitable mounting supports are provided for anchoring the

unit. Inlet, outlet, vent and drain connections are provided on

all units. The size, type and location of the connections are as

specified to suit the installation requirement.

The nameplate attached to each unit contains important

information such as model number, serial number, operating

pressure, flow rate, filter element type and change-out

pressure. Be sure to send nameplate information to the

nearest representative of Facet or to the Tulsa office when

ordering replacement parts or for additional information

regarding technical problems related to the Facet equipment.

Remove filter-separator from shipping crate and discard all

protective wrapping and packing material. Remove flange

face and thread protectors from all connections.

Remove access covers and inspect interior components for

possible damage during shipment. Replace any damaged

NOTE: Units shipped without filter elements installed will be

tagged with a notice calling attention to this fact.

Check hex nuts on element mounting rods to be sure that

elements are securely mounted. Tighten nuts with torque

wrench to 60 in-lbs (5 ft-lbs) for separators and 360 in-lbs

(30 ft-lbs) for coalescers.

If no damage is found to exist in the unit, be sure to place

cover seal in proper location before bolting covers. Tighten all

bolting evenly and securely.

Provide suitable level concrete slab or metal platform and

anchor bolts of adequate size and bolt unit in place securely

before proceeding with connecting piping. It is recommended

that the filter-separator be installed into the system with a

minimum number of turns and fittings to minimize any

additional turbulence in the inlet connecting piping. This will

eliminate any further emulsification of the product and water

in the incoming product line, as well as minimize total system

pressure loss.

Be sure to correctly identify the inlet and outlet connections

of the filter-separator before connecting the unit in the

system. The unit will not perform correctly if the

connections are reversed.

All piping leading to and from the filter-separator must be

aligned as closely as possible with the connections on the unit

to avoid over stressing the body connections or flanges. Be

sure to use the correct gaskets between flanged connections.

Tighten all connection bolting evenly and securely.

If a positive displacement pump and/or automatic product

discharge control valve is used in the system, it is imperative

that adequate bypass piping around the filter-separator be

provided or a relief valve be installed on the filter-separator

in order to prevent excessive pressure which can develop

when the discharge control valve is closed.

Provide suitable vent and drain lines to conduct the fumes

and separated water away from the operating area.

Shutoff valves should be provided in all pipe lines leading to

and from the filter-separator to isolate the unit from the

piping system for servicing the unit or complete removal of

the unit from the process system.

Normally, all accessory items such as pressure gauges,

automatic air eliminators, liquid level gauges, relief valves,

automatic control valves and electric heaters are factory

installed before shipment. When such items are shipped in

separate containers, be sure to inspect all items for possible

damage before installing them to the filter-separator.

All tubing lines should be formed with care to prevent kinking

or flattening of the tubing.

After all piping connections have been made and all accessory

items installed, a check should be conducted before

submitting the unit to a fluid test. The following suggestions

and recommendations should be observed before conducting

the fluid test.

1. Make certain that all anchor bolts are tightened

securely.

2. Inspect all flanged connections to be sure that the

proper gaskets have been placed between flanges.