Water Furnace IntelliZone2 MasterStat Guide

Design Features

Description of Operation

Damper Specifications

System Application and Design

SC1578EW 05/17

IntelliZone2 Specification Catalog and Design Guide

Six Zone Capability

Comfort Zoning System

r

e

s

f

O

p

eration

i

fication

s

c

ation and Des

ig

n

IntelliZone2 Specification

INTELLIZONE2 SPECIFICATION CATALOG

Table of Contents

IntelliZone2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

IntelliZone2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Design Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

IntelliZone2 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

IntelliZone2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-16

Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Blower Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-21

Wiring Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Damper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Zone Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

Special Zoning Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Peak Heating and Cooling Demands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

System Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-29

Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31-32

SAH 5 Speed ECM Blower Performance Data Option A . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-34

Blower Performance Data Option C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35-36

Split Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-39

Revision Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4

INTELLIZONE2 SPECIFICATION CATALOG

The IntelliZone2 Comfort Zoning System is a

residential and/or commercial zone control

system which works with 5 and 7 Series units

(up to 6 tons) to space condition up to six

zones. Each zone is controlled by its own

space thermostat and damper motor(s) using

a maximum 1-inch W.G. inlet static pressure at

zone dampers. The IntelliZone2 monitors the

thermostats, puts the system in the proper mode

of operation, and energizes the correct number of

stages of heating or cooling and airflow.

The IntelliZone2 was designed to solve problems that are inherent with the concept of HVAC zoning by:

• Eliminating the bypass damper;

• Applying the ECM blower motor to zoning;

• Using “Multiple Level” zone calls (Heating 0-3, Cooling 0-2), allowing the controller to better estimate the

demand of each zone and thus condition space most efficiently; and

• Designing a high value control which is both easy to install and service.

• Capable of full communication and control of the variable speed compressor bearing 7 Series

The IntelliZone2 System is a perfect match to 5 and 7 Series geothermal systems, extending comfort and energy savings

farther than ever before. The IntelliZone2 is also compatible with our Symphony/AWL Wi-Fi Smart Comfort System.

WaterFurnace International’s corporate headquarters and manufacturing facility is located in Fort Wayne, IN. A scenic

three-acre pond located in front of the building serves as our geothermal heating and cooling source to comfort-condition

our 110,000 square feet of manufacturing and office space. As a pioneer, and now a leader in the industry, the team of

WaterFurnace engineers, customer support staff and skilled assembly technicians is dedicated to providing the finest

comfort systems available. With Factory ISO 9001 and engineering laboratory ISO 17025 certifications, you are assured of a

quality designed and manufactured product.

By choosing or specifying WaterFurnace IntelliZone2™ Series products, you can be assured that your customer is investing

in an exceptional comfort system and peace of mind for many years to come.

5

INTELLIZONE2 SPECIFICATION CATALOG

Introduction

The IntelliZone2 Comfort Zoning system is to be used only

with heat pumps/air handlers equipped with Aurora AXB

or AHB controls. A package unit must have ABC and AXB

to be compatible with IntelliZone2. A split system with

air handler must have ABC and either AXB or AHB (in

air handler) to be compatible with the IntelliZone2. If the

heat pump or air handler do not have Aurora AXB or AHB

controls you must use IntelliZone2•24V Comfort Zoning

system.

Zoning is a method of ensuring that all areas of a home or

building receive the right amount of heating or cooling.

Zoning allows the occupant to independently control the

temperature in each area of the building. If desired, all

areas can be adjusted for occupancy patterns and uses.

IntelliZone2

Thermostat Zone Damper Supply Register

Geothermal Unit

IntelliZone2 Control

Basement

Zone

Main Living Area Zone

Master Suite Zone

Bedrooms Zone

The above illustration is representational and is not intended

as a guide for IntelliZone2 system installation.

Zoning is particularly useful where normal heat distribution

patterns result in uneven temperature control. For example,

a building that is partly below grade can use zoning

to eliminate uneven temperature control between the

basement and the rest of the building. Large buildings that

might have long, unequal length duct runs can use zoning

to equalize the delivery of conditioned air. Buildings with

many large windows can use zoning to compensate for

solar heat gain and radiation losses at night.

Along with providing comfort, zoning can provide energy

savings by keeping various zones at desired set points

without over-cooling or overheating. In effect, zoning

mandates that the heating/cooling system condition only

the portions (or zones) of the building which need to be

conditioned. This translates into shorter compressor run

times and ultimately lower space conditioning bills.

6

INTELLIZONE2 SPECIFICATION CATALOG

IntelliZone2 Features

IntelliZone2 Features

• Up to 6 zone possible in variable speed systems

(maximum of 4 for dual capacity units and 2 for single

speed units)

• 4.3 in. Color touchscreen master thermostat for ease of use

• TPCC32U01, ZoneStat, SensorStat or SensorStat Remote

Kit options for zones 2-6

• Full communicating system for advanced features:

• Full text Faults/Alarms from IZ2 and 5 or 7 Series heat pump

• Adjust zone setpoints from Masterstat or Zonestat

• Full features of 5 and 7 Series heat pumps are

communicated including faults, energy monitoring,

superboost cooling mode and active dehumidification

- Full zone setback programming from each zone.

- Dealer configuration mode

- Full color touchscreen troubleshooting display

• No bypass damper or dump zone needed.

• 2 (spring) or 3 wire damper options.

• Central Zone option operates all dampers open

on temperature measurement from MasterStat for

construction or service operation.

• Economy/comfort settings for each zone to reduce

operating costs In less important rooms.

• Zones are 'sized' to provide more proper compressor and

blower staging.

• Staging flexibility allows several up/down staging options

for customization to your application.

• Full Aurora controls capability

Flexibility in Zone Comfort Control

The IntelliZone2 allows comfort or economy mode selections

for each zone.

In ‘Comfort Mode’ a single zone call for conditioning will

engage the compressor and allow a minimal set point

variation, thus providing ultimate comfort. However in

‘Economy Mode’ a single zone call for conditioning will be

ignored until either a next level call for that zone or a second

zone call occurs. This will allow slightly greater temperature

fluctuations in these zones allowing lower operating costs

in areas such as rec rooms, unused bedrooms where slightly

higher temperature variation would not be noticeable.

Flexibility in System Staging

(single or dual capacity equipment)

The IntelliZone2 System allows four different staging options

for both heating and cooling. Once the compressor call has

been initiated by a zone, the compressor will be upstaged

using one of four staging options in single, dual, or variable

capacity equipment. The modes are Normal, Quicker, Faster1

and Faster2. More detail is listed later in this document.

Eliminating Bypass Damper

By utilizing the full functionality of the ECM blower motor,

the bypass damper can be eliminated from the zone system.

In effect, the ECM replaces the bypass damper.

In conventional systems, the air handling device can deliver

airflow only at one or two levels, which means a significant

amount of excess air must be “bypassed” to the return. By

looking at which zones are calling, the IntelliZone2 determines

the most efficient compressor and blower speeds. Since the

IntelliZone2, with its six/eight speeds on-line at all times, has

the ability to deliver the correct amount of airflow that the

structure is calling for, there is no need for bypass.

When utilized properly, the ECM motor will provide precise

airflow control for a given space. The ECM will operate on up

to six/eight pre-configured airflow levels depending on the

load requirements of the house. All airflow is setup for the 5

or 7 Series in the AID Tool. If the IntelliZone2 is controlling:

• 5 Series single or dual-capacity unit, there will be 6

total airflow levels, two airflow levels for low-speed

compressor operation and two airflow levels for high-

speed compressor operation and one for continuous

blower and one for auxiliary heat.

• 7 Series variable speed unit, there will be 8 total airflow

levels, one airflow level continuous blower and auxiliary

heat settings and six airflow levels for the variable

speed compressor ranging from 25, 40, 55, 70, 85, and

100% airflow depending upon the zone call.

By varying the airflow level per the needed output capacity of

the heat pump, bypass is eliminated and the correct amount

of air is delivered to the house. Consult the 5 and 7 Series

technical literature for more information on airflow setup.

Efficient Space Conditioning

Traditional zone control systems control single-speed

compressors and single-speed blowers and typically

use single heating and cooling calls to determine space

conditioning needs. By operating at only one capacity level,

these traditional systems are seriously handicapped in their

ability to handle the varying load of the structure.

The IntelliZone2 control system controls the dual-capacity

and variable speed compressor as well as the ECM variable-

speed blower, coupling this variable capacity equipment

with multiple level zone calls allows the IntelliZone2 to

exactly match the demands of the space.

One of the goals of the IntelliZone2 system is to minimize

compressor and blower operation by operating at the lowest,

most efficient speed possible. The IntelliZone2 makes logic

decisions which minimize compressor run-times and help

decrease energy cost. For example: If one or more zones

have Y1 demand calls, the thermostat has determined that

the particular zones need conditioning, but the demand is at

a low level. The IntelliZone2 control algorithm will take these

low level calls and determine what compressor capacity with

the proper airflow will satisfy the zone calls. Thus, the system

operates in lower capacity most of the time and intelligently

provides cost-efficient space conditioning control.

Many times, as in any structure, the space conditioning peak

load for each zone can happen at a different time throughout

the day. This may be due to sun, wind, or even the zone use.

This diversity can sometimes allow slightly smaller capacity

equipment to condition one zone during its morning peak and

then condition another during its afternoon peak, whereas

an unzoned structure would have to be sized with larger

capacity equipment to condition both areas at once.

7

INTELLIZONE2 SPECIFICATION CATALOG

Design Features

Full Color Touchscreen Display and

Diagnostic LEDs

With traditional zone control systems, the installer typically

has a difficult time determining the status of the inputs and

outputs of the zone control board. The IntelliZone2 System

employs an LED for each output and the MasterStat color

display shows all inputs and outputs. With just a glance,

the installer is able to quickly determine what inputs the

IntelliZone2 is receiving and what outputs the IntelliZone2

is sending to the unit.

Application Flexibility

• Multiple level zone calls communicate exact zone load

requirements for intelligent equipment control.

• Controls up to six zones with variable speed compressor

(four with dual-capacity and two zones with single-

speed compressor).

• Control of ECM blower motor to match needs of the

space. Six/eight blower speeds are available at all times.

• Zone size as small as 15% of whole house with

variable speed compressor (25% dual-capacity and 50%

single speed).

• Individual zone-selectable economy or comfort modes.

• Four staging options (normal, quicker, faster1 and

faster2) to allow a wide range of comfort and energy

consumption solutions.

• Separate staging options for heating and cooling

provides better comfort.

• Dehumidification mode lowers airflow in cooling for

better dehumidification.

• Simple, reliable thermostat operation; simple

programming for the homeowner.

IntelliZone2's Sophisicated Microprocessor Control

with LEDs to Display Inputs and Outputs

• Individual zone-selectable continuous or

intermittent blower.

• Smart algorithm serves simultaneous heating and

cooling demands.

• Reduces blower power consumption.

• Installation and Service Advantages

• Bypass damper not needed (minimal oversizing of

ductwork may be desired).

• All low voltage wiring (24VAC).

• Central mode control for temporary conditioning of the

whole house using one thermostat.

• Low cost communicating zone thermostats.

• Three-wire or two-wire damper actuators for maximum

performance and reliability.

• Transformer with integrally mounted circuit breaker.

• LED indicators (damper operation, mode, fault) and

troubleshooting screens displayed on MasterStat for

easy diagnostics.

8

INTELLIZONE2 SPECIFICATION CATALOG

IntelliZone2 Components

IntelliZone2 Relay Board (Firmware Version 2.01 or Later)

The IntelliZone2 relay board provides basic relay logic for the damper

operation and serves as a common connection point for all IntelliZone2

thermostats and the heat pump.

IntelliZone2 MasterStat

The IntelliZone2 MasterStat is the master control for the system and has all

of the programming for operation. It is a 4.3 in. communicating color touch

screen device that also functions as a zone thermostat for Zone 1. Optional

remote sensor capability is also available.

IntelliZone2 ZoneStat (Optional)

The IntelliZone2 ZoneStat is a zone thermostat option for any of Zones 2

through 6. It has full setback capability and communicates to the

IntelliZone2 system.

IntelliZone2 SensorStat (Optional)

The IntelliZone2 SensorStat is a zone thermostat option for any of Zones 2

through 6. It has full setback capability (through the MasterStat interface

only) and communicates to the IntelliZone2 system.

IntelliZone2 Outdoor Sensor

The IntelliZone2 Outdoor Sensor measures the outdoor temperature and

communicates to the IntelliZone2 system. This temperature is displayed on

the MasterStat, and also used to balance response as well as auxiliary electric

heat use. The Outdoor Sensor is included in every IntelliZone2 kit.

TPCC32U01 (Optional) (Firmware Version 3.01 or Later)

The TPCC32U01 is a 4.3in communicating color touch screen device that

can be used as a zone thermostat for zones 2 through 6. It has full set back

capability and communicates to the IntelliZone2 System.

SensorStat-Remote-Kit (Optional)

The SensorStat-Remote-Kit is an option for an invisible thermostat installation

and communicates with the IntelliZone2 relay panel. The kit will include

the SensorStat Remote, TSU03 (mud in sensor) and wire nuts. This kit will

monitor the zone temperature in zones 2 through 6. All set point adjustments

are made at the MasterStat.

9

INTELLIZONE2 SPECIFICATION CATALOG

IntelliZone2 Configuration

Aurora System and Communication

Configuration of IntelliZone2

Aurora Communication Basics

The Aurora Control functions around the concept of

modularity and intercommunications between these boards.

The communication is a 4 wire ModBus protocol. ModBus

protocol is an open source protocol becoming more popular

with equipment manufacturers for use in HVAC equipment.

The Aurora has one ‘bus’ for the ABC, AXB, AHB, AWL,

VS Drive, EEV, and thermostats. The AID Tool only plugs

into the ABC AID Tool port, SAH Air Handler AID Tool

port or the AWL (RJ style connector) and will not work

at any other location. The AXB has 3 other independent

ports for differing protocols; for IntelliZone2, ClimateTalk

Components, and Communicating ECM blower motors.

None of these ports comply with the ModBus protocol set

up for the rest of the Aurora system.

The ModBus communication is accomplished within the

cabinet using shielded and ground cabling. This shield is

most important in 7 Series applications where the VS Drive

component, by its very nature, emits electro-magnetic

interference and can interfere with ModBus communications.

Round ferrite ‘donuts’ can be observed at various locations

to aid in cleaning the communication lines. Each line is

comprised of an R (+24VAC), C (common) and a ‘+’ and ‘-‘

communication line. At times the ‘R’ and ‘C’ lines may not be

connected or needed. The terminals marked ‘+’ and ‘-‘ should

not be switched, although damage may not occur to the

boards, communication is not possible. The communication

voltage and current are small therefore 24 awg wire is

adequate for these communication lines and a shield is not

required but recommended in high EMI environments.

An extra ‘expansion’ connector is available for connecting

other devices onto the main ABC ModBus.

A small LED is located next to each of the communication

ports to aid in evaluating active communication at that specific

port. This is true for each board. The blinking indicates

transmission or receiving communication activity.

Configuring the Aurora for the IntelliZone2

'Adding' the IntelliZone2 to the Aurora system can be

accomplished using the AID Tool via the 'Config Aurora'

screen and scrolling to IntelliZone2 selecting and adding.

As always a 'Y' in the communication column shows that

communication is OK. This will initiate communication

between the IntelliZone2 system and the Aurora AXB/ABC.

Software Versions

Software versions of the IntelliZone2 MasterStat can be

found in the startup screen or in the AID Tool Aurora

Config screen. Software can be uploaded to the MasterStat

via the USB port on the thermostat. Consult your local

WaterFurnace representative or tech service for details.

Wiring and Configuring the Thermostats/Sensors

The MasterStat and Zone Sensors should be wired using

standard 4-wire thermostat cable (if issues with EMI,

shielded cable should be used and grounded at the ‘–‘

terminal on one end). The other zones should be added

sequentially on the relay board until complete. The dip

switch on the back of each ZoneStat or SensorStat should

be selected for the appropriate zone number; for instance,

Zone 2 stat should be selected using the DIP switch on the

back for ‘off, off, off’.

The TPCC32U01 will auto detect that it is attached to the

IntelliZone2 relay panel and will display the screen below.

Use the up/down arrows▲▼ to select the zone.

If more than one zone is assigned the same zone number

an error will be displayed on the TPCC32U01 and Mas-

terStat. After the initial configuration to change the zone

numbers enter the configuration mode by a finger over the

Zone number in the upper left hand corner for 5 sec. Select

zone number and use the up/down arrow ▲▼ to adjust.

Config Aurora System

Dev Comm Ver

ABC Y X.XX

AXB Y X.XX

Add Device

Remove Device

Back

Option Enter

10

INTELLIZONE2 SPECIFICATION CATALOG

Once added to the Aurora system, the setup and

configuration mode should be entered at the MasterStat

by holding a finger over the IntelliZone2 logo for 5 sec. The

Configuration and Setup mode will appear automatically.

NOTE: These options are intended to be used by the

installer. End users are not advised to change or modify

any of these settings. Doing so may make your equipment

stop working properly and/or may void the warranty of the

zoning system as well as the equipment connected to the

thermostat.

It should be noted that the MasterStat Z2TK troubleshooting

harness can be useful during setup by allowing the temporary

connection of the MasterStat directly at the IntelliZone2 relay

board for ease of configuration or servicing.

Equipment and Number of Zones

The first screen is Equipment and # of Zones. Here the

total number of desired zones and the type of equipment

is selected. Equipment is automatically detected. Press

the up and down arrows until the desired number of

zones appears. The zones should always be installed

sequentially starting with the MasterStat always in Zone 1.

• Single speed equipment is limited to a maximum of

2 zones

• Dual Capacity equipment is limited to a maximum of

4 zones

• Variable speed equipment can have up to the

maximum of 6 zones.

NOTE: If the number of zones selected Is less than 6, the

remaining zones will be disabled.

IntelliZone2 Configuration cont.

ZoneStats/SensorStats PCB

A+

R

C

B-

P14 – Zone 4

A+

R

C

B-

P15 – Zone 5

A+

R

C

B-

Zone 4 Stat

On 3

2

1

Zone 4 code shown

A+

R

C

B-

Zone 5 Stat

On 3

2

1

Zone 5 code shown

ZoneStat

SensorStat

Zone ID must be set for each Zone 2-6. ID can be

confirmed on ZoneStat by pressing cancel button for

5 sec. ID shown on display. See Zone ID Codes.

Zone ID must be set for each Zone 2-6. ID cannot be

confirmed on Zone SensorStat. See Zone ID Codes.

Relay Board

A+

R

C

B-

P11 – Zone 1

MasterStat

DX+

R

C

DX-

Zone 1

MasterStat

MasterStat is

always Zone 1

S1

S2

IntelliZone2

Relay Board

A+

R

C

B-

P16 – Zone 6

DX+

R

C

DX-

S1

S2

Optional

Remote

Sensor

IntelliZone2

Relay Board

MasterStat

TPCC32U01

On 3

2

1

On 3

2

1

On 3

2

1

Zone 4 Zone 5Zone 3

On 3

2

1

Zone 2 On 3

2

1

Zone 6

Zone ID Codes

NOTES:

1) Zone ID must be set for each Zone 2-6. ID can be confirmed on ZoneStat

by pressing cancel button for 5 sec. ID shown on display.

2) Small screw driver can be used to set ID thru protective plastic skin!

3) MasterStat always Zone 1. Zone ID not necessary.

4) TPCC32U01 zone is set through its touchscreen.

(Note 4)

Optional

Remote

Sensor

P3 – Master Stat Local

C

B-

A+

R

Z2TK Kit

IntelliZone2

Relay Panel

Use the Z2TK Harness to temporarily connect the IntelliZone2 MasterStat

directly to the IntelliZone2 Relay Panel for ease of setup or troubleshooting.

11

INTELLIZONE2 SPECIFICATION CATALOG

Damper

The Damper screen allows the selection of either 2 wire

(spring open) or 3 wire (power open/power closed) type.

Staging

Staging allows custom selection of staging for cooling and

heating, independently.

The IntelliZone2 system allows separate staging options

for cooling and heating. There are four options for each

mode which are explained below. As an example, staging

for cooling can be set for ‘Normal’ while staging for heating

is set for ‘Faster2’. Allowing heating and cooling staging to

be independent of each other will provide better comfort

all year long. Once the compressor call has been initiated

by a zone, the compressor will be upstaged using one of

the four staging options.

Single and Dual Staging

Normal - This “as shipped” mode will upstage the blower

and compressor normally.

Quicker - This mode will upstage the blower, compressor

and auxiliary electric heat more expediently than “normal”

mode for increased comfort.

Faster1 - This mode allows for a timed element in

compressor (heating and cooling) and electric heat

(heating) upstaging in 45% and 70% zones for situations in

which ‘Quicker’ upstaging is inadequate. If the heat pump

is already operating in first stage and a 45% or 70% zone

has had a heating or cooling demand for 30 continuous

minutes then second stage will be activated. For heating,

if after another continuous 30 minutes the H3 demand is

still present from a 45% or 70% zone, third stage will be

activated until the zone call is reduced to a H2. Airflow will

increase with compressor staging/EH during this period.

For heating, if the heat pump is already operating in second

stage and a 45% or 70% zone has had a demand for 30

continuous minutes then third stage will be activated until

the demand is reduced to H2. Airflow will be increased to

EH selection during this period.

Faster2 - This mode allows for a timed element in

compressor (heating and cooling) and electric heat

(heating) upstaging in 45% and 70% zones for situations in

which Faster 1 upstaging is inadequate. If the heat pump

is already operating in first stage and a 45% or 70% zone

has had a heating or cooling demand for 15 continuous

minutes then second stage will be activated. For heating,

if after another continuous 15 minutes the H3 demand is

still present from a 45% or 70% zone, third stage will be

activated until the zone call is reduced to a H2. Airflow

will increase with compressor staging/EH during this

period. For heating, if the heat pump is already operating

in second stage and a 45% or 70% zone has had a demand

for 15 continuous minutes then third stage will be activated

until the demand is reduced to H2. Airflow will be

increased to EH selection during this period.

Variable Speed Staging

For heating in all the staging options below, the total of

the zone demands will determine when auxiliary heat is

energized which could be anywhere from compressor

speed 9 to speed 12. If auxiliary heat is energized while on

compressor speed 9-11 the compressor speed automatically

increases to speed 12. Airflow will increase with

compressor speed/EH during this period.

Normal - This “as shipped” mode will upstage the blower

and variable speed compressor normally.

Quicker - This mode will upstage the blower, compressor

and auxiliary electric heat more expediently than “normal”

mode for increased comfort. Generally the compressor will

be upstaged 1 extra speed more than normal.

Faster1 - This mode allows for a timed element in

compressor and electric heat upstaging in 45% and

70% zones for situations in which quicker staging is not

meeting demand. When an H3 (heating) or C2 (cooling)

demand is initially received the compressor will upstage

two speeds more than normal. After 15 continuous minutes

of an H3 or C2 demand the compressor will upstage one

more compressor speed and will continue to upstage one

compressor speed with every 15 minutes of a continuous

H3 or C2 demand until auxiliary electric heat is energized

for heating or maximum compressor speed for cooling.

Faster2 - This mode also allows for a timed element

in compressor and electric heat upstaging in 45% and

70% zones for situations in which Faster1 is not meeting

demand. When an H3 (heating) or C2 (cooling) demand is

initially received the compressor will upstage two speeds

more than normal. After 15 continuous minutes of an H3

or C2 demand the compressor will upstage two more

compressor speeds and will continue to upstage two

compressor speeds with every 15 minutes of a continuous

H3 or C2 demand until auxiliary electric heat is energized

for heating or maximum compressor speed for cooling.

IntelliZone2 Configuration cont.

12

INTELLIZONE2 SPECIFICATION CATALOG

Zone Configuration

Zone configuration allows the selection of the zone size and

the zone priority. The zone can be selected by touching the

upper right screen text noting the zone. In this way you can

cycle thru all of the active zones to view the configuration.

Zone Percentage

Selecting the zone percentage can also be calculated by

using the IntelliZone2 Calculator software. This percentage

represents an approximation of the maximum heating or

cooling load percentage of the zone and thus to a certain

extent volume of airflow. The IntelliZone2 allows 0, 25, 45,

and 70% selections. Some general rules to follow in this

selection procedure are as follows:

• Pick the larger percentage for major living areas such

as family rooms, etc.

• Pick the smaller percentage for minor living areas such

as dens or bedrooms.

• Pick a larger percentage if more branches are required

than the load indicates due to large area per load (i.e.

unfinished insulated basement).

• The IntelliZone2 Design software should be used to aid

in the selection and calculation of design cfm.

• The IntelliZone2 determines modes as a proportion of

the total demand. A simple example of this to begin

with is a two-zone system in the cooling mode. If each

zone is set at 70% we have the following scenario:

Zone 1 = 50%

Zone 2 = 50%

NOTE: All Zone % calculations are ‘normalized using

the following process: We now must determine what

percentage of the total load each zone represents. To

perform this operation, add the two zones together 70 + 70

= 140. One zone would then be 70/140 or 50%.

The IntelliZone2 then reduces the total demand based

upon thermostat demand. A “Y1” call in the above example

will result in one half of the zone demand in this case 1/2

of 50% for a 25% system demand. A common complaint

is insufficient cooling when only one zone is calling for

cooling. The IntelliZone2 will not initiate a “Y2” output to

the unit until it senses a 51% total system demand (This is

when the IntelliZone2 is set for normal upstaging). If the

IntelliZone2 is set for quicker upstaging it drops to the total

system demand required 41% to initiate a Y2 output. By this

example, it will require a “Y2” call from one zone (50%) and

a “Y1” call from the second zone (25%). This will give us a

total system demand of 50% + 25% = 75%. System demand

for three- and four-zone systems are computed in the same

manner.

Heating demand is determined in the same manner, but

we now have a third stage instead of two for cooling. The

IntelliZone2 assigns values as follows:

Y1 = 40%

Y2 = 80%

Y3 = 100%

We know from the previous example that the IntelliZone2

will initiate a “Y2” output to the compressor when it is set to

normal upstaging and 51% of total demand is needed. It will

issue a “W” call to the unit when there is a 90% total demand.

It is a common assumption that if you have a house with

two zones equally divided each zone should be set at an

equal amount, usually 70%. As can be seen in the above

example, it will take a “Y3” call from one zone as well as a

“Y2” call from the second zone to obtain auxiliary heat.

This is a simple example, but three- and four-zone systems

are calculated in the same manner. Blower speeds are also

assigned upon the percentage of system demand and a

complete understanding of this process is not necessary

for day-to-day decisions. As a serviceman, the temptation

arises, in some instances, to influence the logic of the board

by jumping “Y1” and “Y2”. While this will create a quicker

response, the ductwork of that zone must be capable of

handling the cfm delivered by the unit (i.e., if a “Y2” signal

is given to the unit, can the ductwork handle the total cfm

of the unit).

When setting up a new system remember that if you have

unused zones they must be set to zero. If they are not, the

setting that they have will be included in the total demand

preventing the other zones from operating correctly, as

there will be no inputs on those zones.

The IntelliZone2 allows the selection of either comfort

or economy mode in each individual zone to provide

maximum savings in areas that allow it (such as workshops

and basements), while maintaining perfect comfort in the

zones where accurate temperature is most desired (such as

bedrooms and baths)

IntelliZone2 Configuration cont.

13

INTELLIZONE2 SPECIFICATION CATALOG

IntelliZone2 Configuration cont.

Zone Priority

Comfort Mode - A single zone call (Y1) for conditioning

will engage the compressor and allow a minimal set point

variation, thus providing ultimate comfort.

Economy Mode - A single zone call (Y1) for conditioning

will be ignored by the IntelliZone2 until either a Y2 call

is initiated from the same zone or another zone calls for

conditioning (Y1). This allows a slightly greater set point

variation than in comfort mode. This setting prevents

less important zones from energizing the compressor

unless it is really needed, thus saving money. As a bonus

in this mode, upon a Y1 call, the IntelliZone2 may try to

precondition the zone with return air from other zones

already satisfied and, in some cases, can preclude the need

for energizing the compressor.

Variable Speed Fan Staging - Variable Speed Fan Staging

allows the ability to expand the blower levels. Options

are Normal and Expanded. There are three airflow speeds

assigned to a compressor speed and the airflow level is

determined by the fan demand total zone %. Normal is

the recommended airflow level. Selecting Expanded will

increase the highest airflow level by one level and decrease

the lowest airflow level by one level from Normal. Not

available for single speed or dual capacity models.

Zones - Displays the inputs that the IntelliZone2 is

receiving.

Status - Displays the outputs that the IntelliZone2 is

sending to the equipment.

Test Mode - In Test mode ‘Central Zone’ mode can be

selected. In Central mode all dampers are opened and

thermostat readings are taken ONLY from the Zone 1

MasterStat. This will approximate operation without a zone

system (all dampers open and IntelliZone2 MasterStat

temperature control) and can be useful during initial

construction of the home or during service etc.

Also in ‘Central Zone’ mode each damper can be

individually cycled off/on to verify operation during

Installation or service. It should be noted that the

MasterStat Z2TK troubleshooting harness can be useful

here by allowing the temporary connection of the

MasterStat directly at the IntelliZone2 relay board for ease

of configuration or servicing.

Thermostat Type

NORMAL/DUAL FUEL

Normal - used for normal operation

Dual Fuel - used on dual fuel systems; needs

outdoor sensor to lockout dual fuel

14

INTELLIZONE2 SPECIFICATION CATALOG

IntelliZone2 Configuration cont.

Dual Fuel (Single Speed/Dual Capacity) - When Dual Fuel

is selected for 'Thermostat Type' and a 'W' call is present

operation will be as follows:

1. The temperature will be controlled by the MasterStat

while other zones are ignored.

2. All zone dampers will open, Y1, Y2, G, W outputs shall

run for 60 seconds. After 60 seconds Y1 and Y2 will be

dropped and output only W and G (if Fan with Heat

Option is selected otherwise G will be dropped).

3. There will be a two minute minimum run time once

Dual Fuel operation has been entered, regardless if

MasterStat heat call has been satisfied.

4. Once the two minute minimum run time expires and

the 'W' call is satisfied at the MasterStat then Dual Fuel

operation will be terminated. There will be no down

staging.

5. Once Dual Fuel operation is terminated all zone

dampers will close.

6. There will be a 4 minute time delay once Dual Fuel

operation is terminated before compressor operation

for cooling or heating may begin.

Dual Fuel (Variable Speed) - When Dual Fuel is selected

for 'Thermostat Type' and a 'W' call is present operation

will be as follows.

1. The temperature will be controlled by the MasterStat

while other zones are ignored.

2. All zone dampers will open, the current compressor

speed, G and W outputs shall run for 60 seconds. After

60 seconds the compressor will be stopped and output

only W and G (if Fan with Heat Option is selected

otherwise G will be dropped).

3. There will be a two minute minimum run time once

Dual Fuel operation has been entered, regardless if

MasterStat heat call has been satisfied.

4. Once the two minute minimum run time expires and

the 'W' call is satisfied at the MasterStat then Dual Fuel

operation will be terminated. There will be no down

staging.

5. Once Dual Fuel operation is terminated all zone

dampers will close.

6. There will be a 4 minute time delay once Dual Fuel

operation is terminated before compressor operation

for cooling or heating may begin.

Fan with Heat Option (Dual Fuel Applications) - Options

are ON or OFF. This selection determines whether G (fan)

output is to be ON or OFF when W (auxiliary heat) output

is ON.

Aux Heat Lockout - Allows the configuration to lockout

electric heat above a selected outdoor temperature.

The outdoor sensor (OAT) must be installed on the

IntelliZone2 Relay Board. This setting is adjustable in 5°F

increments from NONE to 40°F. This will provide full heat

pump capacity without electric heat above the selected

temperature. When the outdoor temperature drops

below the selected temperature, then electric heat will be

energized when the demand is present.

Differential

This adjustment will vary the number of degrees, from

the set point, before a call for heating or cooling is made.

Adjustments can range between 0.2° and 4° differential.

Default is 0.5° differential. (If your set point is 70°F in

heating, your thermostat will not call for heat until the room

temperature is 69.5°F, when using a 0.5° differential setting.

Offsets

Temperature Offsets – This option allows calibration

(or deliberate miscalibration) of the room

temperature sensor(s). The Offset function

only works on the MasterStat. There are various

reasons why the displayed temperature would be

adjusted to a higher or lower value. NOTE: Do not

adjust for 30 minutes after installation because

board may be heated by handling. The selected

number is the number of degrees, plus or minus,

which will be added to actual temperature. The

numbers can range between -5˚ and +5˚. Default

values are set to 0˚ offset.

Indoor Offset (MasterStat internal sensor)

Remote Indoor Offset (if sensor is attached)

Outdoor Offset (if sensor is attached)

Humidity Offset – This option allows calibration of the

humidity sensor. Adjustments can range between

-10% and +10%. Default is 0% offset.

15

INTELLIZONE2 SPECIFICATION CATALOG

IntelliZone2 Configuration cont.

Humidity

Humidify - Turns on the H output when the room

humidity is below the set point and there is an

active heating call

Dehumidify – Turns on the DH output when the room

humidity is above the set point and the MODE

is set to COOL or AUTO when Cool was the last

mode run.

-Turns on Active Dehumidification (VS Systems)

Both – HUMIDIFY operates in the HEAT mode and

DEHUMIDIFY operates in COOL mode.

NONE – Neither is active.

Temperature Sensors - Allows selection of the remote

sensor to determine outdoor or indoor temperature.

Because IntelliZone2 ships standard with an outdoor

sensor, this option needs to be selected.

NOTE: LAS = OAT on IntelliZone2 relay board.

Accessories -

Each of these options has settings for Cumulative Run Time

and Calendar Time. Messages will flash at the top of the

Main screen when these events are met to alert the owner

that it is time service these options.

Air Filter - Cumulative Run Time default is 1000 hours

and Calendar Time is 3 months. Values can range

from NONE-2500 hours for Cumulative Run Time

(in 100 hour increments), or Calendar Time can be

set to NONE to 12 months (in 3 month increments).

Humidifier - Cumulative Run Time default is NONE

hours (OFF) and Calendar Time is NONE. Values

can range from NONE, 400-2500 hours for

Cumulative Run Time (in 100 hour increments), or

Calendar Time can be set to NONE to 12 months

(in 3 month increments).

UV Lamp - Cumulative Run Time default is NONE

hours (OFF) and Calendar Time is NONE. Values

can range from NONE, or 400-3600 hours for

Cumulative Run Time (in 100 hour increments), or

Calendar Time can be set to NONE to 48 months

(in 3 month increments).

Air Cleaner - Cumulative Run Time default is NONE

(OFF) and Calendar Time is NONE. Values can

range from NONE, 400-2500 hours for Cumulative

Run Time (in 100 hour increments), or Calendar

Time can be set to NONE to 12 months (in 3 month

increments)

Dealer Information - Allows the input of the dealer

name, phone, address, e-mail and website. Simply press

the screen segment where you want to enter information

and a keypad will appear.

Fault Status - Shows the last 10 IntelliZone2 system Faults

(heat pump fault history is displayed at the heat pump on

the AID Tool). The faults can be cleared or refreshed from

this screen.

Restore Defaults - This will allow you to revert to the

factory default settings.

Restart Thermostat/Upgrade Software - This allows a

convenient way to restart the thermostat or upload the

latest software using the USB port without killing power to

the whole system.

USB - Allows the import and export of data using the USB port.

Importation of: Installer settings, User Settings, Program,

Dealer Details

Exportation of: Installer settings, User Settings, Program,

Dealer Details

Data Logging - Allows the USB thumb drive to record the data

every 5 seconds. Data should not be collected for more than

a one week period. Collecting data more than one week will

create a file too large to read.

F°/C° - Allows selection of either Fahrenheit or Celsius

temperature scale.

Residential, Commercial - Future Use

Energy Demo - These screens allow a dealer to show

the end user an example of the information that will be

displayed on daily and monthly screens once their system

is operating. This is only an example and not actual data

from their system.

Photo Upload - The Intellizone2 will allow personal photo

upload to be displayed once the thermostat goes into

sleep mode. The MasterStat can only accept photos that

are TCI format. Common photo formats can be converted

to the TCI format, which is used by the thermostat, by

using our photo converter software. Once the photos

have been converted and uploaded to the MasterStat they

will be displayed as a slide show when the thermostat

goes into sleep mode. Sleep mode occurs after 5 minutes

of inactivity (no screen touches). The photo conversion

software and instructions for uploading the photos can be

found at www.auroracontrols.com.

16

INTELLIZONE2 SPECIFICATION CATALOG

IntelliZone2 Configuration cont.

AWL Status (If Installed)

This screen displays the AWL firmware revision and

provides the current AWL communication status relating to

an Aurora WebLink (AWL) device. This screen is available

whether an AWL is installed on the system or not.

AWL Time Synchronization - When enabled the AWL

will synchronize the thermostat’s date and time

with internet time servers. This option by default is

disabled. NOTE: setting the proper time zone in the

Symphony Portal is necessary for correct operation.

Monitor AWL Status - When enabled, the thermostat will

monitor the AWL’s RS485, INTERNET, and SERVER

status. The thermostat will display “AWL Comm

Err” when the AWL is not communicating properly

with the Aurora Modbus Network, “AWL Internet

Err” when the AWL is unable to communicate to the

symphony Servers. This option by default is disabled.

SuperBoost (Variable Speed Heat Pumps ONLY) -

SuperBoost can be found under the main menu settings of

the thermostat. The SuperBoost option temporarily enables

a larger cooling capacity range. Normal cooling mode is

limited to compressor speeds 1-9 and SuperBoost allows

compressor speeds 10-12 if needed. This screen will allow the

homeowner to turn the SuperBoost option ON or OFF. The

SuperBoost option will be enabled, by default, for a 24-hour

period of time then will automatically be disabled. NOTE:

Continuous use of SuperBoost could result in overheating

the ground loop.

Dehumidification – Active (Variable Speed Heat Pumps

ONLY) - Active dehumidification will only activate during

cooling operation, when cooling demand from the

IntelliZone2 MasterStat is compressor speed 4 or lower

and the humidity setpoint of the MasterStat is at least 5%

below the actual relative humidity. The green status LED

will flash code 2 when active. The compressor will ramp up

and airflow will begin at a low level. Airflow is then reduced

periodically until air coil temperature setpoint is reached. If

coil temperature continues to drop, the airflow is increased

until air coil setpoint is maintained. After 20 minutes of

operation in the Active Dehumidification mode normal

cooling operation will resume for 5 minutes. This cycle

continues until the dehumidification setpoint is reached or

room temperature is more than 1.5°F below the cooling set

point or IntelliZone2 MasterStat cooling demand requires

greater than compressor speed 4 (normal cooling takes

over). In IntelliZone2 systems, the main zone will remain

open during active dehumidification.

17

INTELLIZONE2 SPECIFICATION CATALOG

IntelliZone2 Operation

Upon a call (or calls) from the zones, the IntelliZone2

“weighs” each zone based upon two components: 1) the

level of call (Y1, Y2, Y3) coming from the zone; and 2)

the size of the zone (zone % selected). This gives a very

accurate picture of not only overall heating or cooling

requirements (as in other control methods), but also

how much heating or cooling is really required for each

separate zone.

This, in turn, defines how much compressor (1st or 2nd

stage), blower (speeds 2 thru 5), and auxiliary heat should

be engaged for each particular situation. The result is a

system that utilizes lower compressor and blower speeds

more often for improved comfort and energy savings,

while relying upon auxiliary heat less often for more energy

savings than non-zoned systems.

Heating, Unit 1st stage

(Single/Dual Capacity Compressor and Variable Speed ECM)

Operation as stated above with separate zone call levels of

YI, Y2, and W being translated into unit call 1st stage (Y1).

Blower speed will be the ‘L’ setting of the ECM which is set

up at the heat pump control.

Heating, Unit 1st stage

(Single/Dual Capacity Compressor and 5-Speed ECM)

Operation as stated above with separate zone call levels of

YI, Y2, and W being translated into unit call 1st stage (Y1).

Blower speed will be the ‘Y1’ setting of the 5-Speed ECM

which is set at the motor.

Heating, Unit 2nd stage

(Single/Dual Capacity Compressor and Variable Speed ECM)

Operation as stated above with separate zone call levels of

YI, Y2, and W being translated into unit call 2nd stage (Y1,

Y2). Blower speed will be the ‘H’ setting of the ECM which

is set up at the heat pump control.

Description of Operation - Package Unit

Heating, Unit 2nd stage

(Single/Dual Capacity Compressor and 5-Speed ECM)

Operation as stated above with separate zone call levels of

YI, Y2, and W being translated into unit call 2nd stage (Y1,

Y2). Blower speed will be the ‘Y2’ setting of the 5-Speed

ECM which is set at the motor.

Heating, Unit 3rd Stage

(Single/Dual Capacity Compressor and Variable Speed ECM)

Operation as stated above with separate zone call levels of

YI, Y2, and W being translated into unit call 3rd stage (Y1,

Y2, W). Blower speed will be the ‘H’ (Premier control) or

‘Aux’ (ABC control) setting of the ECM which is set up at

the heat pump control.

Heating, Unit 3rd Stage

(Single/Dual Capacity Compressor and 5-Speed ECM)

Operation as stated above with separate zone call levels of

YI, Y2, and W being translated into unit call 3rd stage (Y1,

Y2, W). Blower speed will be the ‘W’ setting of the 5-Speed

ECM which is set at the motor.

Heating

(Variable Speed Compressor)

The unit will operate based upon demand as calculated by

the IntelliZone2. The resulting compressor speed (1-12) will

also select an appropriate blower speed for the selected

compressor speed. Auxiliary heat will be available on

compressor speeds 9-12, depending on the zone inputs.

When auxiliary heat is engaged with compressor speed

9-11, the compressor speed automatically increases to

speed 12 for maximum output.

Cooling, Unit 1st stage

(Single/Dual Capacity Compressor and Variable Speed ECM)

Operation as stated above with separate zone call levels of

YI, Y2, and O being translated into unit call 1st stage (Y1, O).

Blower speed will be the ‘L’ setting of the ECM which is set

up at the heat pump control.

18

INTELLIZONE2 SPECIFICATION CATALOG

Description of Operation - Package Unit cont.

Cooling, Unit 1st stage

(Single/Dual Capacity Compressor and 5-Speed ECM)

Operation as stated above with separate zone call levels of

YI, Y2, and O being translated into unit call 1st stage (Y1, O).

Blower speed will be the ‘Y1’ setting of the 5-Speed ECM

which is set at the motor.

Cooling, Unit 2nd stage

(Single/Dual Capacity Compressor and Variable Speed ECM)

Operation as stated above with separate zone call levels

of YI, Y2, and O being translated into unit call 2nd stage

(Y1, Y2, O). Blower speed will be the ‘H’ setting of the ECM

which is set up at the heat pump control.

Cooling, Unit 2nd stage

(Single/Dual Capacity Compressor and 5-Speed ECM)

Operation as stated above with separate zone call levels of

YI, Y2, and O being translated into unit call 2nd stage (Y1,

Y2, O). Blower speed will be the ‘Y2’ setting of the 5-Speed

ECM which is set at the motor.

Cooling

(Variable Speed Compressor)

The unit will operate based upon demand as calculated by

the IntelliZone2. The resulting compressor speed, speeds

1-9, (speeds 10-12 are reserved for SuperBoost mode only)

will also select an appropriate blower speed.

Emergency Heat

Emergency heat mode may be engaged by selecting at

the MasterStat. All zone thermostat fault LED's begin to

flash two quick flashes, followed by a pause, indicating

that emergency heat mode has been activated. The

temperature of the structure will be controlled by the

zone 1 MasterStat while other zones are ignored. When

a demand for heat occurs at the MasterStat all zone

dampers are opened and emergency heat is energized.

Emergency heat will continue to operate until the

MasterStat demand is satisfied.

Emergency heat mode may be exited by selecting OFF (or

one of the other mode selections) at the MasterStat, as well

as all zone thermostat fault LED's stop flashing, indicating

emergency heat mode has been deactivated and normal

IntelliZone2 operation may resume.

Continuous Blower

The unit's blower will be operated on blower speed 1

(G-LED) while heating or cooling is suspended for any

zone(s) selected for continuous blower operation at the

zone thermostat. Upon any heating or cooling call to the

unit, all continuous blower operation ceases.

Lockout Mode

(Single/Dual Speed Compressor)

During the unit lockout mode, the appropriate Fault code

will be communicated to the IntelliZone2 MasterStat.

The blower will continue to operate on blower speed 1. If

the collective zones translate into a > 24% heating call,

emergency heat operation will occur and all zone dampers

will open. Blower speed will be Aux Heat speed setting.

Lockout Mode

(Variable Speed Compressor)

During lockout mode the appropriate Fault code will

be communicated to the IntelliZone2 MasterStat. The

blower will continue to operate on blower speed 'G'. If the

collective zones translate into > 40%, all zone dampers will

open and emergency heat operation will occur until the

demand is < 24%.

19

INTELLIZONE2 SPECIFICATION CATALOG

Blower Data - Package Unit

Airflow Selection (Single or Dual Capacity)

When equipped with a Variable Speed ECM airflow from

the Intellizone2 is communicated to the Aurora via a

'Blower Level %'. These blower levels are 55, 70, 85, and

100%. The Aurora will dictate actual airflow based upon

these percentages. Below is a graphic showing how the

IntelliZone2 would signal for a 55-100% blower level percent

and the resulting airflow based upon the ABC setpoints of

speed 5 for med and speed 8 for high in the example AID

Tool setting. Notice that a blower level of 85% would result

in a blower speed of 7 with these settings. All airflows are

rounded to the nearest 1-12 blower speeds. Continuous

blower and aux heat blower speeds are set Independently

of the compressor blower speeds.

In cooling a similar procedure occurs with the exception

that when dehumidification reduces airflow it is a reduction

as shown below. Therefore in dehumidification mode, if

blower speed 5 is selected the resulting airflow will be

blower speed 5, less 15%. If cooling airflow is configured to

be 15% less than heating airflow then there is no difference

between cooling and dehumidification cooling airflow.

Heating Airflow Selection (Single or Dual Capacity)

Selected in AID Tool

From IZ2

Air Level %

Blower

Speed

Cont

Blower Low High Aux

Heat

1

2

3

4

Comp Stage Low 55% 5 --->

Comp Stage Low 70% 6

Comp Stage High 85% 7

Comp Stage High 100% 8 ---> --->

9

10

11 --->

12

NOTES:

1) Continuous Blower activated by G only call from IntelliZone2

(selection can be anywhere)

2) Aux Heat Airflow activated by Aux or Emergency heat call (selection

must be greater than high and allow proper airflow for the installed

electric heat/heat pump model)

Airflow Selection (Variable Speed)

Airflow from the IntelliZone2 is communicated to the

Aurora via a blower Level %. These blower levels are 25, 40,

55, 70, 85, and 100%. The Aurora will dictate actual airflow

based upon these percentages. Below is a graphic showing

how the IntelliZone2 would signal for a 25-100% blower

level percent and the resulting airflow based upon the ABC

setpoints of speed 3 for low and speed 8 for high in the

example AID Tool setting. Notice that a Blower level of 85%

would result in a blower speed of 7 with these settings.

All airflows are rounded to the nearest 1-12 blower speeds.

Continuous blower and aux heat blower speeds are set

Independently of the compressor blower speeds.

Continued on the next page.

Cooling Airflow Selection (Single or Dual Capacity)

Selected in AID Tool

From IZ2

Air Level %

Actual

Blwr Spd*

Blwr

Speed

Cont

Blwr Low High Aux

Heat

1

2

3

4

Comp

Stage Low 55% Blwr Spd

5 - 15% 5 --->

Comp

Stage Low 70% Blwr Spd

6 - 15% 6

Comp

Stage High 85% Blwr Spd

7 - 15% 7

Comp

Stage High 100% Blwr Spd

8 - 15% 8 ---> --->

9

10

11 --->

12

NOTES:

1) Continuous Blower activated by G only call from IntelliZone2

(selection can be anywhere)

2) Aux Heat Airflow activated by Aux or Emergency heat call (selection

must be greater than high and allow proper airflow for the installed

electric heat/heat pump model)

Heating Airflow Selection (Variable Speed)

Selected in AID Tool

From IZ2

Air Level %

Blwr

Speed

Cont

Blwr

Low

Comp

Hi

Comp

Aux

Heat

1

2

Comp Speeds

1 & 2

Low

Selection 25% 3 --->

Comp Speeds

3 & 4 40% 4

Comp Speeds

5 & 6 55% 5

Comp Speeds

7 & 8 70% 6

Comp Speeds

9 & 10 85% 7

Comp Speeds

11 & 12

High

Selection 100% 8 ---> --->

9

10

11 --->

12

20

INTELLIZONE2 SPECIFICATION CATALOG

Blower Data - Package Unit cont.

Cooling Airflow Selection (Variable Speed)

Selected in AID Tool

From IZ2

Air Level %

Actual

Blower Speed*

AID Reported

Blower Speed Cont Blower Low Comp Hi Comp Aux Heat

1

2

Comp Speeds

1 & 2 Low Selection 25% Blower Spd 3 - 15% 3 --->

Comp Speeds

3 & 4 40% Blower Spd 4 - 15% 4

Comp Speeds

5 & 6 55% Blower Spd 5 - 15% 5

Comp Speeds

7 & 8 70% Blower Spd 6 - 15% 6

Comp Speeds

9 &10 Cooling Max 85% Blower Spd 7 - 15% 7

Comp Speeds

11 & 12 SuperBoost Only 100% Blower Spd 8 - 15% 8 ---> --->

9

10

11 --->

12

NOTE: * Denotes default cooling airflow setting of 15% less than heating mode airflow.

Dual or Single Capacity

Heating Unit

Call

Blower Level Call

(Norm)

Blower Level Call

(Dehumid)

H1 55 or 70% na

H2 85 or 100% na

H2, W Aux Blower na

W Aux Blower na

G G Only (cont Blower) na

Cooling Unit

Call

Blower Level Call

(Norm)

Blower Level Call

(Dehumid)

C1 55 or 70% 55 or 70% less 15% cfm

C2 85 or 100% 85 or 100% less 15% cfm

G G Only (cont Blower) G Only (cont Blower)

Variable Speed Capacity

Heating Unit

Call

Blower Level Call

(Normal Staging

Shown)

Blower Level Call

(Dehumid)

H1 or H2 25% or 40% na

H3 or H4 25% or 40% or 55% na

H5 or H6 40% or 55% or 70% na

H7 or H8 55% or 70% or 85% na

H9 or H10 70% or 85% or 100% na

H11 or H12 85% or 100% na

H9-H12, W Aux Blower na

W Aux Blower na

G G Only (cont Blower) na

Cooling Unit

Call

Blower Level Call

(norm)

Blower Level Call

(Dehumid)

C1 or C2 25% or 40% Norm less 15% cfm

C3 or C4 25% or 40% or 55% Norm less 15% cfm

C5 or C6 40% or 55% or 70% Norm less 15% cfm

C7 or C8 55% or 70% or 85% Norm less 15% cfm

C9 or C10 70% or 85% or 100% Norm less 15% cfm

C11 or C12 85% or 100% Norm less 15% cfm

G G Only (cont Blower) G Only (cont Blower)

NOTE: C10-C12 are only available in SuperBoost mode.

In cooling a similar procedure occurs with the exception

that compressor speed is limited to a maximum of speed

9. However compressor speed 10-12 is available for a

short period of time and the resulting airflow during the

‘SuperBoost’ mode is shown below. Another exception is

when dehumidification reduces airflow; it is a reduction

as shown below. Therefore, in dehumidification mode, if

blower speed 3 is selected, the resulting airflow will be

blower speed 3, less 15%.

Other manuals for IntelliZone2 MasterStat

2

Table of contents

Popular Control System manuals by other brands

Openpath

Openpath ACCESS CONTROL SYSTEM installation guide

Lathem

Lathem PC600 Series quick start guide

Burkert

Burkert 8644 AirLINE operating instructions

Vex Robotics

Vex Robotics VEX IQ user guide

Crestron

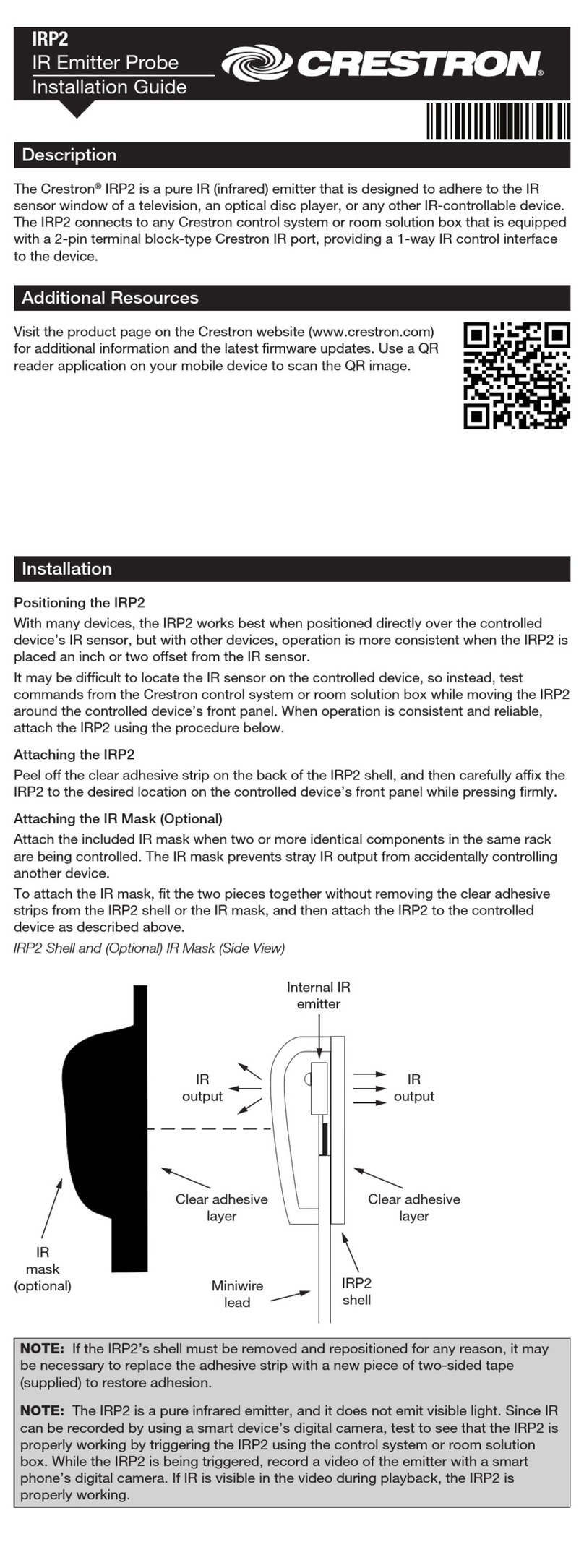

Crestron IRP2 installation guide

Stuart Turner

Stuart Turner STUART SPU 135 Midi Installation, operation & maintenance instructions

Addonics Technologies

Addonics Technologies DGC7 quick guide

Trio

Trio MC403 quick start guide

SILENT KNIGHT

SILENT KNIGHT INTELLIKNIGHT 5820XL Sales guide

2VV

2VV FINESSE Assembly, installation and operation instructions

Intermatic

Intermatic RC2263BE Installation, operation & service manual

Pentair

Pentair SunTouch Quick reference guide