Water Furnace IntelliZone User manual

IntelliZone Installation Manual

Installation Information

Damper Installation

Thermostat Installation

Electrical

Startup Procedures

Wiring Schematic

Comfort Zoning System

Four Zone Capability

™

IM1958 03/09

™

Staging

Effective July 2006, the company introduced a software upgrade to the IntelliZone that allows 4 different comfort

staging options. The available conguration options are Normal, Quicker, Faster and Faster w/Timer. (The Slower stag-

ing option has been removed from the new version of the IntelliZone.)

Normal –

This “as-shipped” mode will upstage the blower and compressor normally and remains unchanged from the

current IntelliZone.

Quicker –

This mode will upstage the blower, compressor and auxiliary electric heat more expediently than Normal

mode for increased comfort.

Faster –

This mode will upstage the blower and auxiliary electric heat slightly faster than Quicker mode. Cooling

operation is same as Quicker mode.

Faster w/ Timer –

This mode allows for a timed element in compressor and electric heat upstaging for situations in

which normal staging is inadequate. Cooling operation is same as Quicker. This staging position should be reserved

for the most demanding and aggressive situations.

Conguring the IntelliZone for Quicker, Faster or Faster w/Timer will give added comfort but will also result in in-

creased system operating costs and should be used only when necessary.

A kit is available for purchase that will include a microchip and instructions for retrotting older IntelliZone systems

with the enhanced operation logic. The kit’s part number is IRC.

Downstaging

Dual stage (E-Series and Envision) units have the ability via DIP switch SW3-2 to satisfy a call normally (Y2 down-

stage to Y1 to nish) or nish on second stage (Y2 runs to nish the call). The units are shipped from the factory with

DIP switch SW3-2 OFF which will enable the unit to nish a call with normal downstaging. When using the Intellizone it

is necessary to ensure that SW3-2 is in the OFF position so that downstaging will work properly.

Minimum Airow Setting

Envision dual capacity units have 70% low capacity, compared to E Series dual capacity and older Premier two

speed units with 50% low capacity. This will change the minimum zone CFM from 25% of nominal (400 CFM/ton) to

40% of nominal. Therefore, when using the IntelliZone with an Envision dual capacity or Synergy3D unit, the zone

branch ducts must be sized to handle MORE airow.

IntelliZone – What’s New?

1

INTELLIZONE INSTALLATION MANUAL

Table of Contents

General Installation Information 2-3

Damper Installation 4-6

Electrical Wiring 7-9

Thermostat Installation 10-11

Blower Motor Wiring Harness Installation 12

DIP Switch Setup 13-15

Blower Data 16-18

System Startup and Checkout 19-20

Wiring Schematic 21

2

INTELLIZONE INSTALLATION MANUAL

General Installation Information

Safety Considerations

Installing and servicing heating and air conditioning equipment can be hazardous due to system electrical components.

Only trained and qualied service personnel should install, repair or service heating and air conditioning equipment. When

working on equipment, observe precautions in the literature, tags and labels attached to the unit, and other safety precau-

tions that may apply.

Follow all safety codes. Wear safety glasses and work gloves.

Delivery Information

When the equipment is received, all items should be carefully checked against the bill of lading to be sure all crates and

cartons have been received. Examine the contents for shipping damage, removing them from the cartons if necessary. If

any damage is noted, the carrier should make the proper notation on the delivery receipt, acknowledging the damage.

General rules to follow when installing a zone system:

Up to four zones with dual capacity units (two with single-speed units).•

All dampers should be located as close to the main trunk as possible to limit the amount of pressurized trunk line and •

thus limit air leakage.

No less than three branch runs in a zone to prevent a single branch obstruction (curtains or clothes etc.) from affect-•

ing unit airow.

Insulate and seal around rectangular dampers to prevent leakage.•

All dampers must be wired with 18-gauge wire.•

Note: Crimp connections should never be used on solid conductor wire.

Insure that the transformer can handle the power requirements of the system.•

No more than three dampers per zone.•

Ductboard-mounted dampers should be supported within six inches of the damper due to the weight and stress on•

the ductboard.

Unit DIP switch #3-3 should be in the NO RPM mode.•

Unit DIP switch #3-2 should be in the OFF position when used with a zone control system.•

Unit DIP switch #2-8 should be in the ON position (continuous ‘L’ signal) when used with a zone control system.•

Installation and Design Steps

Decide which areas of a home or ofce will comprise each of the individual zones. A maximum of four individual zones

1.

(two with single-speed equipment) can be chosen.

Calculate loads using software or other recognized methodology.

2.

Use software to determine the equipment size and performance based on the total heating and cooling demands of the

3.

building, not the sum of the individual zone demands.

Find the peak heating and cooling demands and the peak CFM required for each of the zones.

4.

Note: Dual Capacity Envision has a 70% low capacity output, therefore minimum CFM required per zone is 40% of

nominal CFM, signicantly higher than the E Series with a 50% low capacity output.

Determine zone design air ow and zone size settings using IntelliZone Calculator software.

5.

Lay out and size the supply air ductwork and IntelliZone dampers. Care should be taken to avoid under sizing either the

6.

supply air systems, return air systems, or diffusers.

Decide where to locate the thermostats.

7.

Install the unit and the IntelliZone Comfort Zoning system.

8.

WARNING:

Before performing service or maintenance operations on the system, turn off main power switches to

the indoor unit. Turn off accessory heater power switch if applicable. Electrical shock could cause serious personal

injury.

CAUTION: When installing the IntelliZone in a structure with fossil fuel (oil, gas, propane) appliances, it is impor-

tant that both supply and return dampers are used in each zone to avoid potential back-drafting of fossil-fueled

appliances.

3

INTELLIZONE INSTALLATION MANUAL

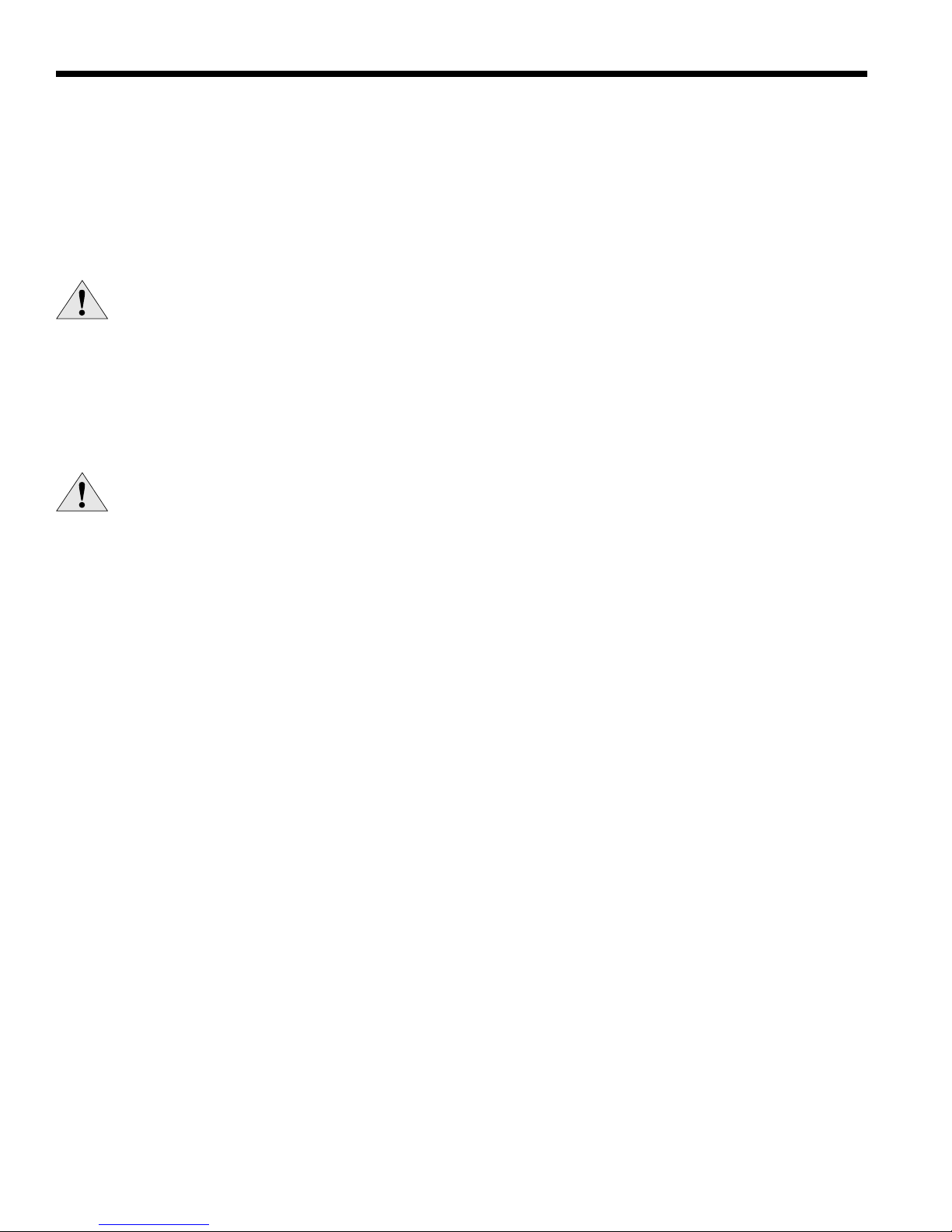

IntelliZone Control Panel

Locate the IntelliZone panel in an indoor area that has enough space for service personnel to perform maintenance or

repair. Provide sufcient room to make electrical connection(s). The IntelliZone is not approved for outdoor installation and,

therefore, must be installed inside the structure being conditioned. Do not locate the control panel in areas where ambient

conditions are not maintained within 45°F to 95°F and are greater than 75% relative humidity. The IntelliZone control panel

should be mounted on or as close to the unit as possible by using the sheet metal screws provided. See Figure 1 for mount-

ing hole locations.

Four Zone System Representational Layout

72

72

72

72

Premier2

9.00” 1.75”

14.50”

13.00”

11.125”

Figure 1: IntelliZone Control Panel Mounting

Notes: Use longer screws (not provided) to

penetrate through drywall into stud.

General Installation Information (cont.)

4

INTELLIZONE INSTALLATION MANUAL

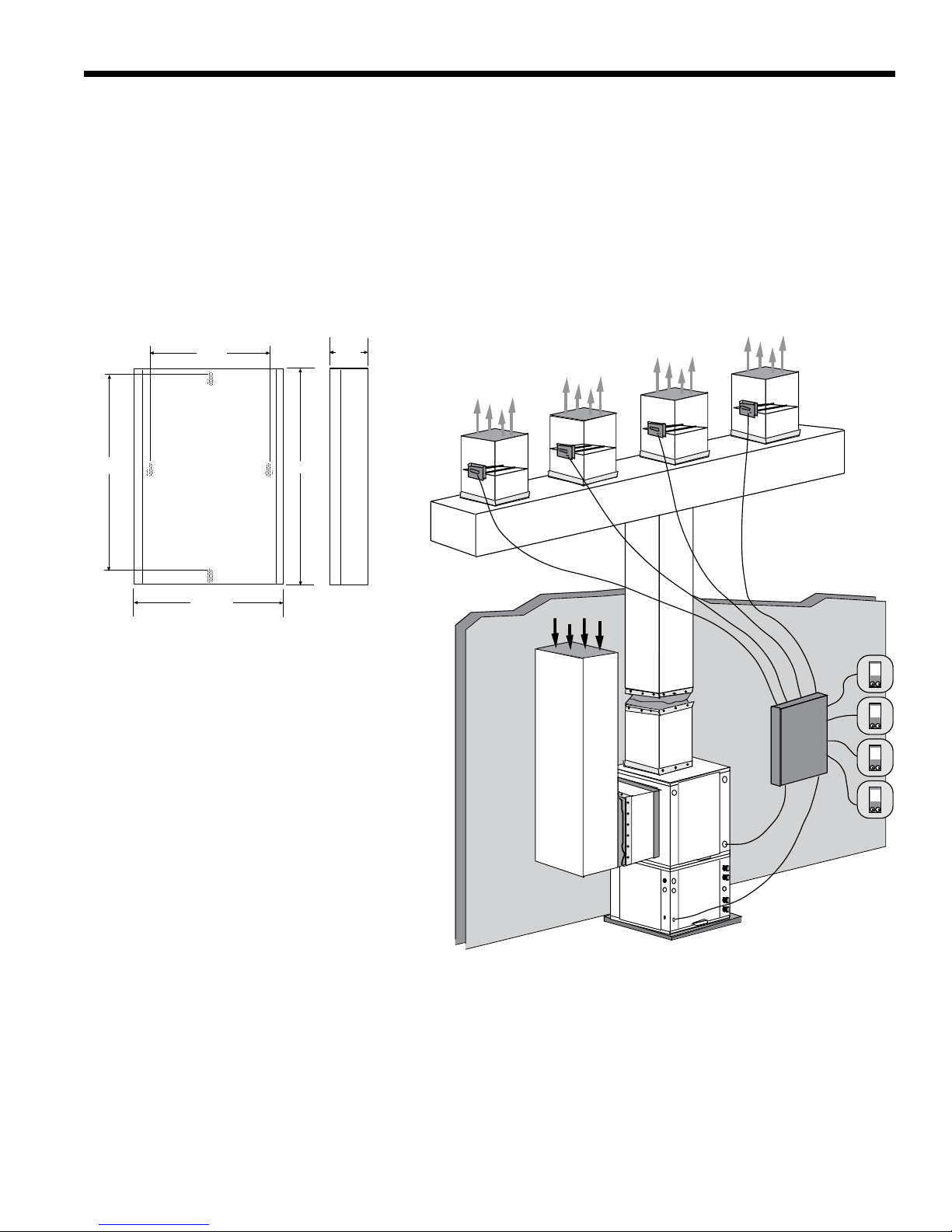

Installing Rectangular Dampers in Metal Ductwork

Cut out dimensions A and B as shown in Figure 2 below by1.

using sheet metal snips.

Note: Dimensions A and B are listed in the table to the right.

Use foam insulation tape on the top and bottom of the zone damp-2.

er to prevent excessive air leakage. Also check the cross emboss

for excessive air leakage (see Figure 2).

Slide the zone damper into the ductwork making sure no obstructions will interfere with damper blade operation.3.

Use the screws provided to mount the damper ange to the ductwork. Four to six mounting holes are provided as 4.

shown in Figure 3 below.

Use drive cleats or regular duct mounting brackets to attach ductwork to joist within six inches on both sides5.

of the damper (see Figure 3).

Check damper blade operation for obstructions by holding the manual release button and rotating the damper shaft6.

CW (Open) and CCW (Closed) 3 Wire only as shown in Figure 4 below.

Damper Installation

Manual release

CCW

Closed

CW

Open

Rotate by hand

Figure 4: Checking Damper Blade for Obstructions

Damper Model H W A B

10"24" 10" 3.75"

8 " 12" 8" 3.75"

ZDR1024

ZDR0812

Dimensional Examples

Cross emboss for

duct stiffness may

cause excessive

air bypass

Foam Seal

Foam Tape

(top and bottom)

A

B

3.75”

Figure 2: Foam Taping Zone Damper Figure 3: Mounting Damper

Mounting Screws

(4 places)

Attach duct/damper

to joist within 6" on

both sides

5

INTELLIZONE INSTALLATION MANUAL

Insulating Rectangular Dampers in Metal Ductwork

Insulate ductwork as shown in Figure 5 below. All metal must be covered. Care must be taken not to obstruct the shaft

from rotating when insulating. Do not insulate the zone damper actuator.

Installing Rectangular Dampers in Ductboard

Cut out dimensions A and B by using a ductboard knife. Note: Dimensions A and B are listed in the Table on page 6.

1.

A ductboard spacer should be installed on the end of the damper frame as shown in Figure 7 to prevent excessive air

2.

bypass. For example: A one-inch-thick, 8’’x 20’’ ductboard and a 8’’ x 20’’ zone damper would have a one-inch gap at

the end of the frame once it is installed without a ductboard spacer. Use the piece cut out for installation.

Foam insulation tape should be used on the top and bottom of the zone damper to prevent excessive air leakage as

3.

shown in Figure 7.

Slide the zone damper into the ductboard making sure no obstructions will interfere with damper blade operation.

4.

Tape the damper face ange to the ductboard using foil tape mak-

5.

ing sure the damper is secure and air tight as shown in Figure 8

below.

Support the full length of the ductboard underside within six inches

6.

and on both sides of the damper as shown in Figure 8.

Check the damper blade operation for obstructions by holding the

7.

manual release button and rotating the damper shaft CCW and CW

(see Figure 4 on page 6).

Damper Installation (cont.)

Do not insulate zone damper actuator

Duct wrap insulation

A

B

Duct board

Keep spacer clear

of end bushing

Foam tape

(top and bottom)

Insulate between

actuator and damper

spacer

Figure 5: Insulating Rectangular Metal Ductwork

Figure 7: Taping Zone Damper with Foam Tape

Foil tape damper face

to ductboard

Support the full length of ductboard

underside within 6” of damper

Figure 8: Taping Damper Flange to Ductboard

6

INTELLIZONE INSTALLATION MANUAL

Insulating Rectangular Ductboard/Metal Sleeve

Care must be taken not to obstruct the shaft from rotating when insulating. Do not insulate the zone damper actuator.

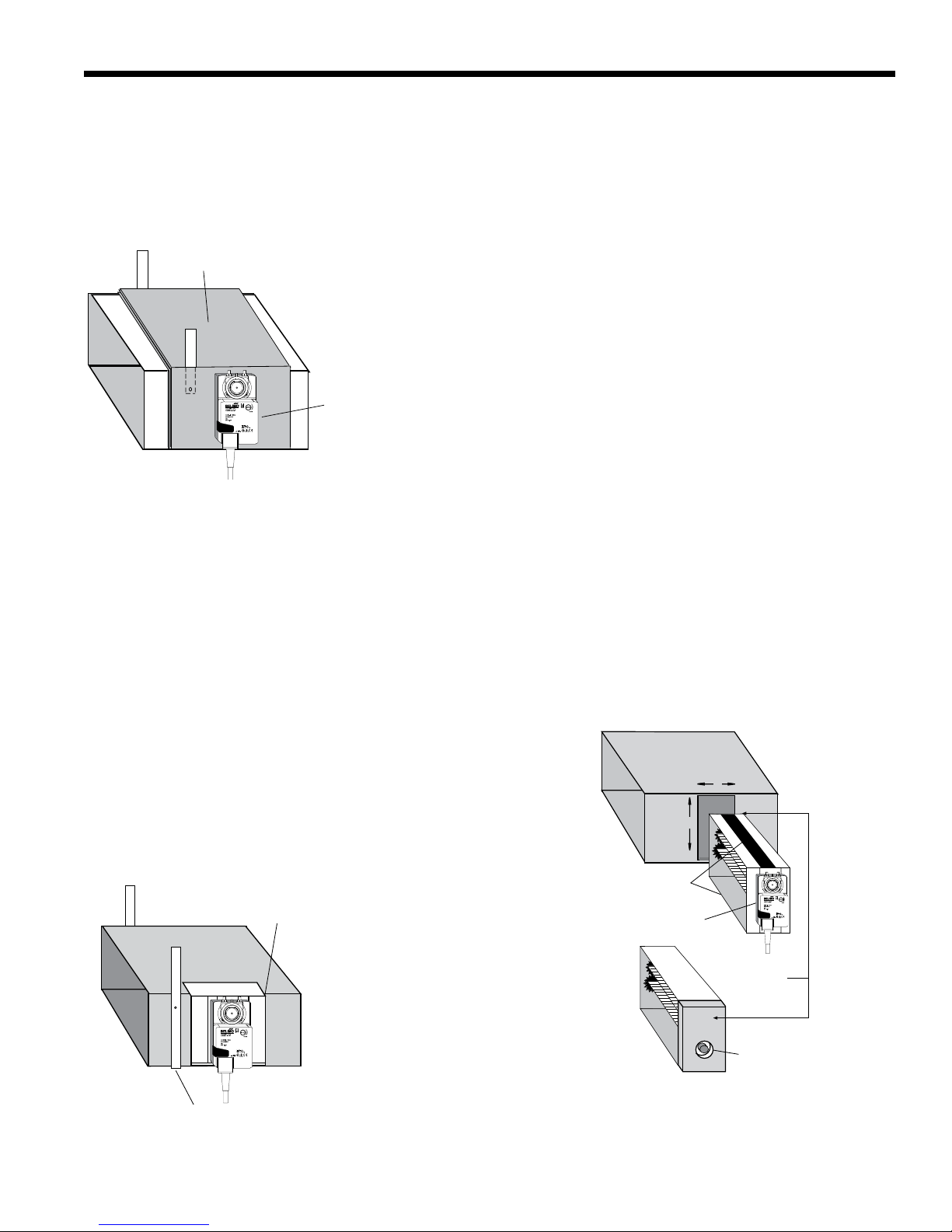

Installing Circular Dampers in Round Metal Duct

Crimp the end of the duct that is the supply air to damper. Insert into circular damper no more than 1.5 inches.

1.

Fasten the duct to the damper with three screws. Screws installed more than one inch from either end may obstruct

2.

damper blade rotation.

Seal completely around the duct with metal duct tape or mastic to prevent air leakage as shown in Figure 10 below.

3.

Check the damper blade operation for obstructions by holding the manual release button and rotating damper shaft

4.

CCW and CW (3 wire only). See Figure 4 on page 6.

Support the duct to joist within six inches of the damper as shown in Figure 9.

5.

Insulating Circular Dampers in Round Metal Duct

Insulate ductwork as shown in Figure 10. All metal must be covered to prevent condensation. Care must be taken not to

obstruct the shaft from rotating when insulating. Do not insulate the zone damper actuator.

Installing Circular Dampers in Flexible Duct

Slide exible duct two to three inches over the damper pipe past the damper rib as shown in Figure 11 below.

1.

Fasten duct to damper with a nylon duct strap, screwing the strap to the pipe to prevent the duct from slipping off.

2.

Screws installed more than one inch from either end may obstruct damper rotation.

Seal completely around the duct with metal duct tape or mastic to prevent any air leakage.

3.

Check the damper blade operation for obstructions by holding the manual release button and rotating damper shaft

4.

CW (Open) and CCW (Closed) - 3 wire only. See Figure 4 on page 6.

Support the damper to joist within six inches on both sides of the damper as shown in Figure 12.

5.

Insulating Damper Actuators

Insulate the damper as shown in Figure 12 below. All metal must be covered to prevent condensation. When insulating,

care must be taken not to obstruct the shaft from rotating. Do not insulate the zone damper actuator.

Damper Installation (cont.)

Flexible duct

Clamp with duct strap. Install screw no farther

than 1” from either end of damper.

Slide duct 2-3’’ past

damper end rib

Air Flow

Support with wide

steel strap

1-1/2’’ or 2’’ if in unconditioned space

Do not insulate

damper actuator

Figure 12: Supporting and Insulating Circular DamperFigure 11: Attaching Flexible Duct to Damper

Three screws sealed

with duct tape or mastic

Manual release button

Air Flow

Figure 9: Taping Round Duct to Circular Damper

Do not insulate

damper actuator

1-1/2" or 2" if in unconditioned space

Support with

wide steel strap

Figure 10: Supporting and Insulating Circular Damper

7

INTELLIZONE INSTALLATION MANUAL

Wiring Damper Actuators

All wiring must comply with local and state codes. Disconnect the power supply before beginning to wire to prevent elec-

trical shock or equipment damage. All wiring should be run back to the control panel. Keep wires a minimum of 12 inches

from any high voltage lines. Follow the damper wiring schematic as shown in Figure 13. Verify that damper rotation direction

is correct. The 3-wire damper rotation direction is reversible with switch on front cover.

Damper Actuator Wiring Notes:

Minimum of 18-gauge thermostat wire is recommended.

1.

Use wire nuts to connect the thermostat wire to the actuator wire (solid wire to stranded wire) as shown in Figure 14

2.

below.

The actuator wiring should be secured using a wire tie to prevent the wires from being separated (see Figure 14).

3.

3-Wire Damper

Blk

Red

Grn

COM

CCW

CW

Zone 4

IntelliZone PCB

Com

Open

Close

G

2-Wire Damper

Minimum

18-gauge wire

Zone 4

IntelliZone PCB

Com

Open

Close

G

COM Gray

CCW Yellow

Minimum

18-gauge wire

Note:

1. Each zone must have

dampers that match by

manufacturer and type.

2. Each IntelliZone

System must have

dampers that match,

either 2-wire or 3-wire.

(Indicated rotation direction

is valid for switch position ‘0’ )

Figure 13: Damper Actuator Wiring

Electrical Wiring

Wire Nuts

Figure 14: Actuator Wiring

8

INTELLIZONE INSTALLATION MANUAL

Transformer Sizing

Providing adequate transformer power (VA) to supply the system is an important requirement. Each IntelliZone 3-wire

damper requires 3.0 VA at nominal voltage. Each IntelliZone 2-wire damper requires 7.0 VA at nominal voltage. The stan-

dard transformer available is a 75VA with circuit breaker (Part # ZTK240).

Mount the transformer onto the side of the unit’s control box by inserting and tightening screws (provided) into the pre-

punched holes. Thread all transformer wires through the hole with bushing and follow the wiring schematic for connecting

the transformer primary leads as shown in Figure 15 below.

For 208 volt operation, the red and blue transformer wires must be switched. Follow the wiring schematic in Figure 16 on

page 11 for the secondary side of the transformer. Use wire nuts only for connections to thermostat wire.

Electrical Wiring (cont.)

WARNING:

All wiring must comply with local and state codes. Disconnect the power supply before beginning to

wire to prevent electrical shock or equipment damage.

Figure 15: Mounting Transformer to Control Box (E Series shown)

Transformer 'VA' Calculation (3-wire actuator)

Zone 1 dampers Power to 2 IntelliZone Damper 6.0VA

Zone 2 dampers Power to 1 IntelliZone Damper 3.0VA

Zone 3 dampers Power to 2 IntelliZone Damper 6.0VA

Zone 4 dampers Power to 3 IntelliZone Damper 9.0 VA

Total VA Draw 24 VA

IntelliZone

transformer

(Mount with

wires pointing up)

Wrap end of unused

transformerwirewith

electrical tape and

secure inside the

control box away

from other electrical

terminals

SW 3-2 must be set to OFF

(Zone) on logic board when

used with zone control system.

Connect IntelliZone

transformer primary leads

to “A” and“C” on the

terminal block for proper

operation.

9

INTELLIZONE INSTALLATION MANUAL

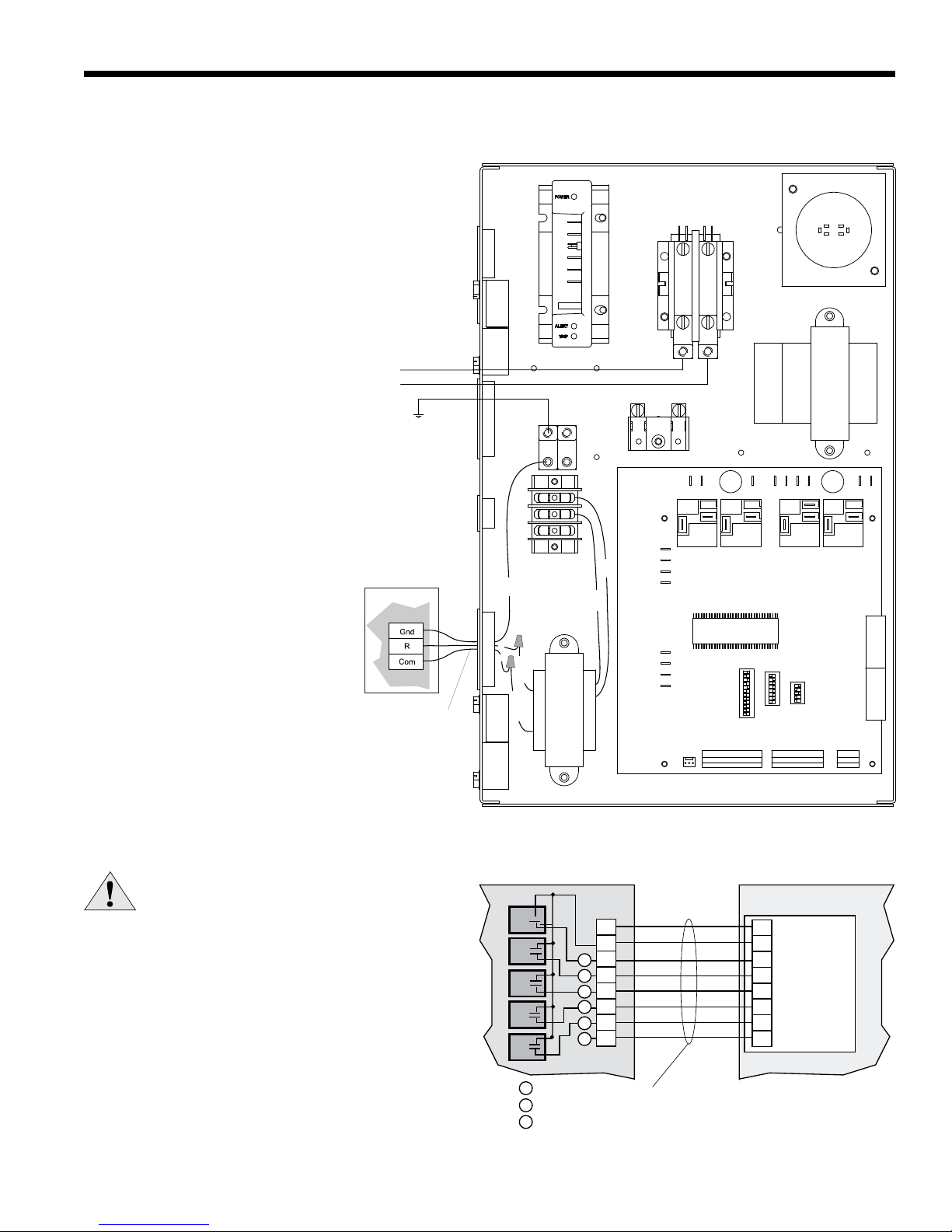

Wiring IntelliZone to the Unit

Follow the wiring schematic in Figure 17 for unit

control connections. Strip the wires back 1/4 inch

(longer strip lengths may cause shorts) and insert the

thermostat wires into the unit’s connector as shown in

Figure 17. Tighten the screws to ensure tight connec-

tions. Use a minimum of 18-gauge thermostat wire for

connections. SW 3-2 must be set to OFF on the logic

board when used with a zone control system. SW 2-8

must be set to ON (continuous ‘L’ signal) when used

with a zone control system.

Electrical Wiring (cont.)

Figure 16: 24 Volt Transformer Wiring (Envision shown)

Note: The IntelliZone control board must be grounded to the

unit to operate properly.

WARNING:

All wiring must comply with local

and state codes. Disconnect the power supply

before beginning to wire to prevent electrical

shock or equipment damage.

13

Y1

Y2

W

O

G

Unit

Control Board

IntelliZone Control

18-Gauge thermostat wire

G

G

Y

G

R

G

LO

O

W

Y2

G

Y1

C

R

LO

O

W

Y2

G

Y1

C

R

= Green LED

= Red LED

= Yellow LED

G

Y

R

Figure 17: IntelliZone to Premier Control Wiring

L1

L2

2

1

3

BLUE

BLACK

IntelliZone Control

18 gauge

thermostat wire

to IntelliZone

Control

GND

C

R

BLK/WHT

YELLOW

C

10

INTELLIZONE INSTALLATION MANUAL

Locating the Thermostats

The thermostats must be located in the room or zone that each controls. Locate a thermostat about ve feet above the

oor. Do not locate a thermostat where it may be exposed to direct sunlight, drafts or direct supply air. Do not place a ther-

mostat on an outside wall. Follow the same guidelines that apply with standard thermostat installation. If two or more rooms

are on a single zone, locate the thermostat in a hallway or area where it can sense the return air from all rooms.

Thermostat Installation

Figure 18: Four Zone Thermostat Location

Master

Bedroom

Bath

Bath

Bedroom

Bedroom

Kitchen

Living Room

Utility

Room

Dining

Zone 2 Bedrooms

Zone 1 Main Living

Zone 3 Master Suite

Zone 4 Basement

Not

Shown

Family

Room

IntelliZone Thermostat

11

INTELLIZONE INSTALLATION MANUAL

Thermostat Installation (cont.)

Mounting and Wiring the Thermostat

Position the thermostat subbase against the wall so that it is level

and the thermostat wires protrude through the middle of the subbase.

Mark the position of the subbase mounting holes and drill holes with

a 3/16-inch bit. Install supplied anchors and secure base to the wall.

Thermostat wire must be eight-conductor 18 AWG. Strip the wires

back 1/4 inch (longer strip lengths may cause shorts) and insert the

thermostat wires into the IntelliZone connector as shown in Figure

19 at right. Tighten the screws to ensure tight connections. The

thermostat has the same type connectors, requiring the same wiring.

Caulk the hole in the wall where the wires enter the thermostat.

Note: See the instructions enclosed in the thermostat for detailed

installation and operation information.

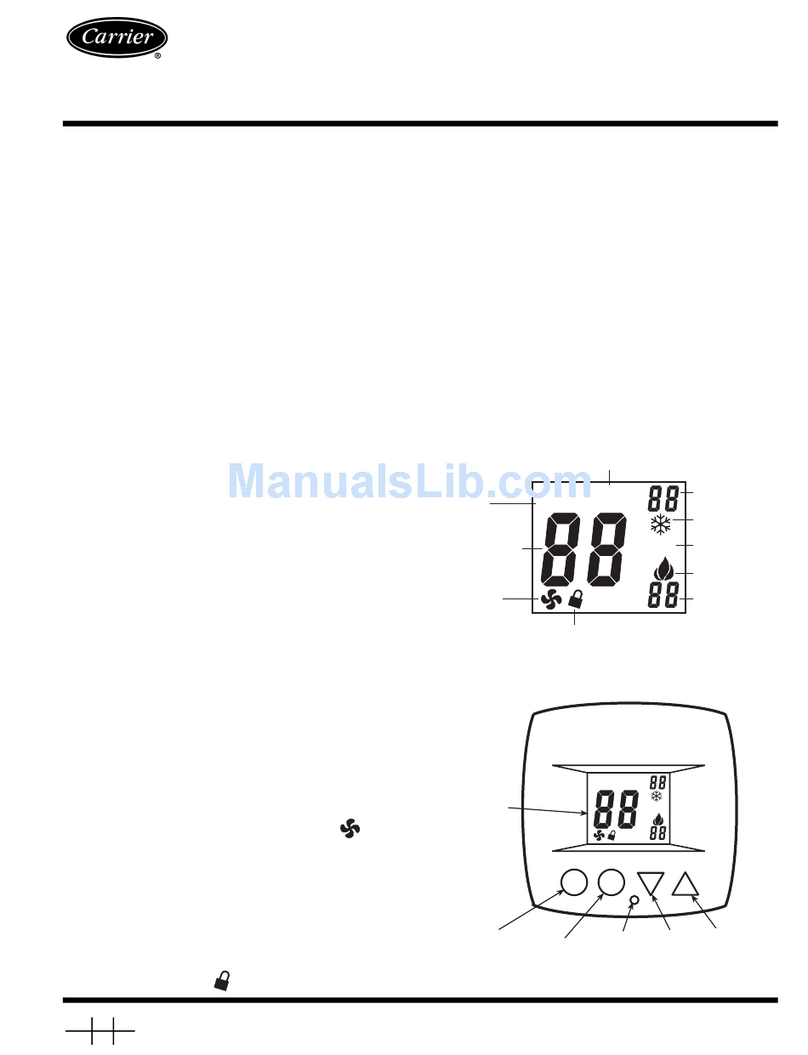

Thermostat Indicator Light Function

“Fault” or “Service Needed” will be displayed on the thermostat.

This text illuminates when a fault condition has occurred. A light on

the front lower panel of the unit will also illuminate to indicate what

condition caused the fault (except airow).

A slowly ashing “fault” light during unit operation indicates a

thermostat wiring problem. A rapidly ashing fault light indicates an

airow fault.

The thermostat may indicate a call for auxiliary heat when a high

heat demand is sensed in a zone. This does not necessarily indicate

that auxiliary heat is being energized in a zone system.

Note: ComforTalk or FaultFlash thermostat features are NOT

available with IntelliZone control boards.

Figure 19: Wiring the Thermostat to the IntelliZone

IntelliZone

Control

Zone One

C

Y1

Y2

R

C

Y1

Y2

Y3

G

O

LO

R

G

G

G

Y

G

P1 through P4

Thermostat

R

IntelliZone Zone Stat

Input

C

Y1

Y2

W

O

G

L1

R

C

Y1

Y2

Y3

O

G

L1

Zone Thermostat

18/8

Wire

1

2

3

Indicator Light Function

Operation Modes IntelliZone Outputs

Y1 Y2 W O G

Heating - 1st Stage ON OFF OFF OFF ON

Heating - 2nd Stage ON ON OFF OFF ON

Heating - 3rd Stage ON ON ON OFF ON

Heating - Emergency OFF OFF ON OFF ON

Cooling - 1st Stage ON OFF OFF ON ON

Cooling - 2nd Stage ON ON OFF ON ON

Constant Fan OFF OFF OFF OFF ON

12

INTELLIZONE INSTALLATION MANUAL

Blower Motor Wiring Harness Installation

Thread the ECM2 motor harness through the knockout in the air handler section of the unit. Use the 3/4-inch romex con-

nector provided for strain relief and to seal the blower compartment from ambient air. Place a section of cork tape from the

inside to the back of the Romex connector for additional sealing. Disconnect the existing blower harness.

Connect the new harness to the blower motor as shown in Figure 20, below. Strap the original harness to the new one

so that it is free of shorting/obstructing the blower wheel.

Thread the IntelliZone end of the harness through the zone cabinet and connect to the IntelliZone printed circuit board

(See Page 22).

WARNING:

Disconnect the power supply before beginning to wire to prevent electrical shock or equipment

damage.

Figure 20: Connecting New Wiring Harness to Blower Motor Wiring Harness

IntelliZone

ECM Motor

Harness

ECM2

Existing

harness from

unit control box

New harness

from IntelliZone

control

Disconnect

Connect

Notes: An ECM motor harness extension (ZBHE is available separately). Switch SW3-3 on the unit must be in the NO RPM

setting.

13

INTELLIZONE INSTALLATION MANUAL

IntelliZone Slide Switch Setup (SW1 Through SW4)

A three-position DIP switch package located on each zone section of the IntelliZone control allows the following eld

selectable zone options.

Zone setting DIP switches are located below each thermostat’s connections as shown in Figure 21 below.

Switch 1: Comfort/Economy Mode

This DIP switch allows the selection in each individual zone for either “Comfort” or “Economy” mode to provide maximum

savings in areas that allow it (such as workshops and basements), but still maintains comfort in the zones where accurate

temperature is most desired (such as bedrooms and baths).

Comfort mode - A single zone call (Y1) for conditioning will engage the compressor and minimize set point variation thus

providing ultimate comfort.

Economy mode - The economy mode will attempt to satisfy the zone demand without initiating a compressor call. A Y1 call

from a zone in the economy mode position will open the damper to the zone and call for the fan. It will use the return air from

the remaining zones to condition this zone. If the thermostat cannot be satised in this manner, the thermostat will deliver a

Y2 call starting the compressor in low capacity.

Switches 2 & 3: Zone Percentage

These DIP switches allow the eld selection of the zone percentage of the load as shown in Figure 22 below.

If both DIP 2 and 3 are off, the zone is inactive and dampers will be closed. •

If DIP 2 is on and 3 is off, the zone load percentage is 25%.•

If DIP 2 is off and 3 is on, the zone load percentage is 45%.•

If both DIP 2 and 3 are on, the zone load percentage is 70% (25% + 45%=70%).•

DIP Switch Setup

Zone settings DIP SW1 through SW4

IntelliZone

Control

C

Y1

Y2

Y3

G

O

LO

R

G

G

G

Y

G

Thermostat

1-

2-

3-

Priority - Economy/Comfort

Zone Size 25%

(Both on =70% neither on =0%)

Zone Size 45%

(Both on =70% neither on =0%)

Zone One

Figure 21: Setting Zone DIP Switches

Figure 22: Zone Percentage Selection by DIP Switch

Zone

Inactive 25% Zone 45% Zone 70% Zone

On On On On

14

INTELLIZONE INSTALLATION MANUAL

Selecting Zone Priority and Percentages

Selecting the zone percentage should be accomplished by using the Zone Calc Software. This percentage is an approxi-

mation of the maximum heating and cooling load of the zone. The IntelliZone allows 0, 25, 45 and 70% selections. Below

are some general rules to follow when selecting percentages:

Pick a larger percentage for major living areas such as family rooms, etc.•

Pick a smaller percentage for minor living areas such as dens or bedrooms.•

Pick a larger percentage if more branches are required than the load indicates due to large area per load (unnished •

basement).

The total should always add up to over 100%.•

Settings DIP Switch 6 (SW6)

An 8-position DIP switch package on the IntelliZone control allows the following eld selectable options:

1 - Service Test Mode

This DIP switch allows eld selection of “Normal” or “Test” operational modes (Test=OFF / Normal Speed=ON). The test

mode accelerates most timing functions, including the damper timing, 16 times to allow faster troubleshooting.

Note: Three-wire dampers will not have enough time to open in test position.

2 - Central Zone Mode

This DIP switch allows eld selection of “Central” or “Multi-zone” operational modes (Central Zone=OFF /

Multizone=ON). The central mode opens all dampers and operates the control as a central zone using the zone 1 (main)

thermostat inputs. This mode, which operates like a system without zone control, allows simplied operation during testing

or during emergencies. In multi-zone mode, the control allows each active zone to be controlled by its respective thermostat

inputs.

3 - No RPM/RPM Mode

This DIP switch congures the control to monitor the RPM output of the ECM2 blower motor (No RPM=OFF / RPM=ON).

When using a PSC blower motor, the control should be congured for “No RPM” sensing.

4 - Dehumidication Mode

This DIP switch allows eld selection of “Dehumid” or “Normal” operational modes. The “Dehumid” mode uses the logic

of reduced cooling fan speeds 1 and 2 for stage one compressor (Y1 on single-speed), and fan speed 3 and 4 for dual-ca-

pacity compressor (Y2 on single-speed). The “Normal” mode uses the logic of normal cooling fan speeds 2 and 3 for stage

one compressor (Y1 on single-speed), and fan speeds 4 and 5 for stage two compressor (Y2 on single-speed).

5 - Dual capacity/Single-Speed

This DIP switch congures the control for single-speed or dual capacity unit operation (Single-Speed=OFF / Dual Ca-

pacity =ON). Single-speed units are limited to two zones. Dual capacity units can operate up to four zones.

6 & 7 - Staging Options

Normal - This “as shipped” mode will upstage the blower and compressor normally.

Quicker - This mode will upstage the blower, compressor and auxiliary electric heat more expediently than “normal”

mode for increased comfort.

Faster - When heating, this mode will upstage the blower and auxiliary electric heat slightly faster than “quicker” mode.

Cooling operation same as “quicker” mode.

Faster with Timer - This mode allows for a timed element in compressor and electric heat upstaging in 45% and 70%

zones for situations in which normal staging is inadequate when heating. This staging position should be reserved for

the most demanding and aggressive situations. Cooling operation remains the same as “quicker” mode.

Example 1: The heat pump is already operating in rst stage. Second stage will be activated after a 15-minute continu-

ous Y3 zone call from a 45% or 70% zone until the zone call is reduced to a Y2. Airow will be increased to speed tap 3 or 4

during this period.

Example 2: The heat pump is already operating in second stage. Third stage will be activated after a 15-minute Y3

zone call from a 45% or 70% zone until the zone call is reduced to a Y2. Airow will be increased to speed tap 5 during this

period.

DIP Switch Setup (cont.)

15

INTELLIZONE INSTALLATION MANUAL

8 - Damper Timing

This DIP switch congures the control for IntelliZone “3-wire” or

other “2-wire” damper operation (Dampers-Spring [2-wire]=OFF /

Dampers-Intellizone [3 wire]=ON).

“3-wire” dampers require motorized opening and closing. In this

position, opening and closing damper relays energize for 90 sec-

onds allowing plenty of time for complete movement of the damper

to either the open or closed position.

“2-wire” dampers typically use a “stall” motor to close and a

spring to open. In this position, the opening and closing damper

relays are continually energized to power close the dampers for

maximum close off pressure.

SW8 (Jumper)

This is to match the Intellizone with the thermostats being used.

It should be on the center post and “AT” when a TA32E12 thermo-

stat is used. When using a 24 volt AC thermostat, it should be on

the center post and “24V”.

Emergency Heat DIP Switch 7 (SW7)

When conditions call for emergency heat, the unit automatically locks out and the electric heat is energized.

To engage emergency electric heat manually, remove the cover from the IntelliZone board. At the board, push and hold

the black emergency reset button, SW7, located on the middle of the board. Hold for three seconds then release. This will

place the unit into the emergency heat mode.

To turn off emergency heat, push and hold SW7 for three seconds, then release. This will disengage the emergency heat

mode and return the unit into the normal operating mode.

Note: This function cannot be performed from the thermostat.

Selecting Airow DIP Switches (SW5)

A 12-position DIP switch package on the IntelliZone control (shown in Figure 24 below) allows the airow levels to be set.

ECM2 fan motors have 12 different speeds. There are ve airow levels at which the ECM2 will operate depending on the

current load level of the structure. If the IntelliZone is controlling a dual capacity unit, there are two levels each for both low

and high capacity compressor operation. With a single-speed unit, there is one level for Y1 operation and two levels for Y2.

Only ve DIP switches can be in the ON position. The rst ON switch determines the continuous fan operation; the sec-

ond, the low speed; the third, the medium-low speed; the fourth, the medium-high speed and the fth, the high speed.

To change speeds, consult Figure 24 for specic airow and switch information.

DIP Switch Setup (cont.)

Figure 23: DIP Switch System Settings

System Settings

SW6

1 - Test/Normal Speed

2 - Central Zone/Multizone

3 - NO RPM/RPM

4 - Dehumid/Normal

5 - Single-Speed/Dual Capacity

6 - Staging Options (See Configuration Table)

7 - Staging Options (See Configuration Table)

8 - Dampers—Spring (2-wire)/IntelliZone (3-wire)

Off On

IntelliZone Control Unit

On

ECM2

Airflow Settings

ECM2 Motor

Gnd

Enab

RPM

PWM

NU

RGnd

Yel

Blk

Gray

Violet

Blue

1

2

3

4

5

6

Airflow

1

2

3

4

5

6

7

8

9

10

11

12

“G” only = 1 speed

First five

switches

in the “On”

position

determine

fan speed

SW5

P10

2 Speed

G

3 Speed

G

4 Speed

G

5 Speed

G

Gnd

Enab

RPM

PWM

RGnd

Figure 24: IntelliZone Control Board DIP Switches Fan Settings

Description SW6-6 SW6-7

Normal ON ON

Quicker OFF ON

Faster ON OFF

Faster w/Timer OFF OFF

Staging Conguration

16

INTELLIZONE INSTALLATION MANUAL

MAX AIRFLOW DIP SWITCH SETTINGS

MODEL ESP 1 2 3 4 5 6 7 8 9 10 11 12

600 700 800 900 1000 1100 1150 1225 1300

1 2 3 4 5

650 750 850 950 1050 1150 1250 1325 1375 1475

1 2 3 4 5

650 750 850 950 1050 1150 1250 1325 1375 1475 1550 1600

1 2 3 4 5

E040, P040 750 900 1000 1200 1400

w/1hp* 1 2 3 4 5

E047, P046 750 900 1000 1200 1400 1600 1700

w/1hp* 1 2 3 4 5

0.75 750 900 1000 1200 1400 1600 1700 1850 2000 2200 2300 2400

1 2 3 4 5

750 900 1000 1200 1400 1600 1700 1850 2000 2200 2300 2400

1 2 3 4 5

—— — — —

—

— — — — — — —

———

—

E066, P066

E035, P034

E040, P040

E047, P046

E058, P056

0.50

0.50

0.50

0.75

0.75

0.75

MAX AIRFLOW DIP SWITCH SETTINGS

MODEL ESP 1 2 3 4 5 6 7 8 9 10 11 12

600 700 800 900 1000 1100 1200 1300 1400 1500 1550 1600

123 4 5

600 700 800 900 1000 1100 1200 1300 1400 1500 1550 1600

1 2 3 4 5

E048 750 900 1000 1200 1400 1600 1700 1850 2000 2200 2300 2400

w/1hp* 1 2 3 4 5

0.75 750 900 1000 1200 1400 1600 1700 1850 2000 2200 2300 2400

1 2 3 4 5

750 900 1000 1200 1400 1600 1700 1850 2000 2200 2300 2400

1 2 3 4 5

0.50

0.50

0.75

0.75E072

E036

E048

E060

Premier and E Series Single-Speed Blower

Premier E Series Dual Capacity Blower

Notes: Factory settings are at recommended 1-2-3-4-5 DIP switch locations. Factory 1 setting is minimum allowed for cooling.

Settings 2-5 must be located within boldface CFM range. CFM is controlled within ± 5% up to the maximum ESP. Max ESP

includes allowance for wet coil and standard lter. Highest 5 DIP switch settings are assumed to be 1, 2, 3, 4, and 5. * With

optional one horsepower fan motor.

Notes: Factory settings are at recommended 1-2-3-4-5 DIP switch locations. CFM is controlled within ± 5% up to the maximum

ESP. Max ESP includes allowance for wet coil and standard lter. * With optional one horsepower fan motor.

Blower Data

17

INTELLIZONE INSTALLATION MANUAL

Blower Data (cont.)

Envision Single Speed ECM

Rev. 5/30/06Notes: Factory settings are at recommended 1-2-3-4-5 DIP switch locations. Factory 1 setting is minimum

allowed for cooling. Settings 2-5 MUST be located within boldface CFM range. CFM is controlled within ±5%

up to the maximum ESP. Max ESP includes allowance for wet coil and standard lter. Highest ve DIP switch

settings are assumed to be 1, 2, 3, 4 and 5. Factory L-M-H settings shown for comparison purposes only.

*With optional 1 horse power fan motor.

MODEL MAX

ESP

AIR FLOW DIP SWITCH SETTINGS

1234567891011 12

036 0.50 650 750 850 1000 1100 1200 1300 1400 1500

1 L 2 3 M 4 5 H

036

w/1hp* 0.75 800 1000 1100 1300 1500 1600 1800

12 L 3 M 4 H 5

042 0.50 650 800 900 1050 1150 1250 1350 1450 1550

1 L 2 M 3 4 5 H

042

w/1hp* 0.75 800 900 1000 1200 1400 1600 1700 1850 2000 2200 2300 2400

1 L 2 3 M 4 H 5

048 0.50 650 800 900 1050 1150 1250 1350 1450 1550

1 L 2 3 M 4 5 H

048

w/1hp* 0.75 800 900 1000 1200 1400 1600 1700 1850 2000 2200 2300 2400

1 L 2 M 3 H 4 5

060 0.75 800 950 1100 1300 1500 1750 1950 2100 2300

1 L 2 M 3 4 H 5

070 0.75 800 950 1100 1300 1500 1750 1950 2100 2300

1 L 2 M 3 4 H 5

MODEL MAX

ESP

AIR FLOW DIP SWITCH SETTINGS

1234567891011 12

038 0.50 650 750 850 1000 1100 1200 1300 1400 1500

1 L 2 3 4 M 5 H

038

w/1hp* 0.75 800 1000 1100 1300 1500 1600 1800

1 L 2 3 M 4 H 5

049 0.50 650 800 900 1050 1150 1250 1350 1450 1550

1 L 2 3 4 M 5 H

049

w/1hp* 0.75 800 900 1000 1200 1400 1600 1700 1850 2000 2200 2300 2400

1 L 2 3 4 M H 5

064 0.75 800 950 1100 1300 1500 1750 1950 2100 2300

1 L 2 3 M 4 H 5

072 0.75 800 950 1100 1300 1500 1750 1950 2100 2300

1 L 2 3 M 4 H 5

Envision Dual Capacity ECM

Rev. 5/30/06Notes: Factory settings are at recommended 1-2-3-4-5 DIP switch locations. Factory 1 setting is

minimum allowed for cooling. Settings 2-5 MUST be located within boldface CFM range. CFM is

controlled within ±5% up to the maximum ESP. Max ESP includes allowance for wet coil and standard

lter. Highest ve DIP switch settings are assumed to be 1, 2, 3, 4 and 5. Factory L-M-H settings shown

for comparison purposes only. *With optional 1 horse power fan motor.

Note: Dual Capacity Envision has a 70% low capacity output, therefore minimum CFM required per zone is

40% of nominal CFM, signicantly higher than the E Series with a 50% low capacity output.

18

INTELLIZONE INSTALLATION MANUAL

Envision Air Handler ECM with Envision Split Single Speed

Blower Data (cont.)

AIR HANDLER

MODEL

MAX

ESP

SPLIT

MODEL

AIR FLOW DIP SWITCH SETTINGS

1234567891011 12

NAH036 0.50 036 300 400 600 800 900 1000 1100 1200 1400

12345

NAH042 0.75 042 650 850 1100 1300 1500 1700 1850 1950 2100

12345

NAH048 0.75 048 650 850 1100 1300 1500 1700 1850 1950 2100

12345

NAH060 0.75 060 650 850 1100 1300 1500 1700 1850 1950 2100

12345

NAH060 0.75 070 650 850 1100 1300 1500 1700 1850 1950 2100

12345

10/27/08

NOTES: Factory settings are at recommended 1-2-3-4-5 DIP switch locations. Factory 1 setting is minimum allowed for cooling. Settings 2-5

MUST be located within boldface CFM range. CFM is controlled within +5% up to the maximum ESP. Max ESP includes allowance for wet coil

and standard lter. Highest ve DIP switch settings are assumed to be 1, 2, 3, 4, and 5.

Envision Air Handler ECM with Envision Split Dual Capacity

AIR HANDLER

MODEL

MAX

ESP

SPLIT

MODEL

AIR FLOW DIP SWITCH SETTINGS

1234567891011 12

NAH036 0.50 038 300 400 600 800 900 1000 1100 1200 1400

12 3 4 5

NAH048 0.75 049 650 850 1100 1300 1500 1700 1850 1950 2100

12345

NAH060 0.75 064 650 850 1100 1300 1500 1700 1850 1950 2100

12 3 4 5

NAH060 0.75 072 650 850 1100 1300 1500 1700 1850 1950 2100

12 3 4 5

10/27/08

NOTES: Factory settings are at recommended 1-2-3-4-5 DIP switch locations. Factory 1 setting is minimum allowed for cooling. Settings 2-5

MUST be located within boldface CFM range. CFM is controlled within +5% up to the maximum ESP. Max ESP includes allowance for wet coil

and standard lter. Highest ve DIP switch settings are assumed to be 1, 2, 3, 4, and 5.

Synergy3D Dual Capacity

MODEL MAX

ESP

AIR FLOW DIP SWITCH SETTINGS

1234567891011 12

038 0.50 650 750 850 1000 1100 1200 1300 1400 1500

1 L 2 3 4 M 5 H

038

w/1hp* 0.75 800 1000 1100 1300 1500 1600 1800

1 L 2 3 M 4 H 5

049 0.50 650 800 900 1050 1150 1250 1350 1450 1550

1 L 2 3 4 M 5 H

049

w/1hp* 0.75 800 900 1000 1200 1400 1600 1700 1850 2000 2200 2300 2400

1 L 2 3 4 M H 5

064 0.75 800 950 1100 1300 1500 1750 1950 2100 2300

1 L 2 3 M 4 H 5

072 0.75 800 950 1100 1300 1500 1750 1950 2100 2300

1 L 2 3 M 4 H 5

3/18/08

NOTES: Factory settings are at recommended 1-2-3-4-5 DIP switch locations. Factory 1 setting is minimum allowed for cooling. Settings 2-5

MUST be located within boldface CFM range. CFM is controlled within +5% up to the maximum ESP. Max ESP includes allowance for wet coil

and standard lter. Highest ve DIP switch settings are assumed to be 1, 2, 3, 4, and 5.

Dual Capacity Envision has a 70% low capacity output, therefore minimum CFM required per zone is 40% of nominal CFM,

signicantly higher than the E Series with a 50% low capacity output.

Table of contents

Other Water Furnace Thermostat manuals

Water Furnace

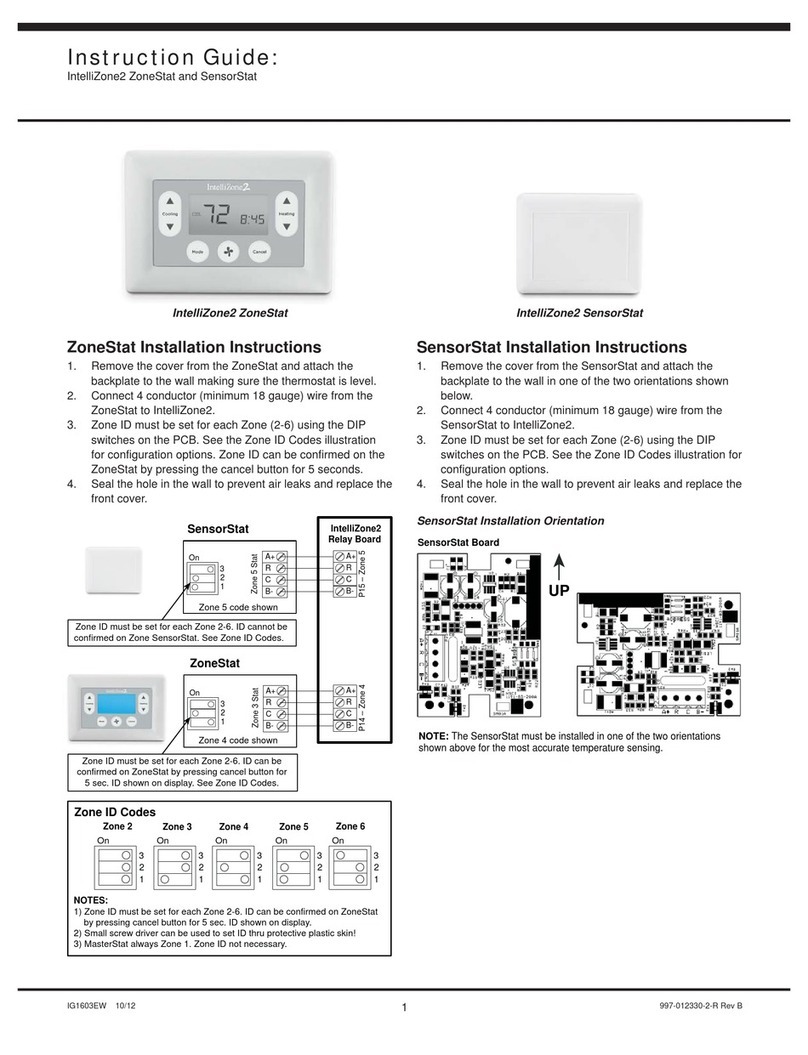

Water Furnace IntelliZone2 ZoneStat User manual

Water Furnace

Water Furnace IntelliZone2 MasterStat Operation manual

Water Furnace

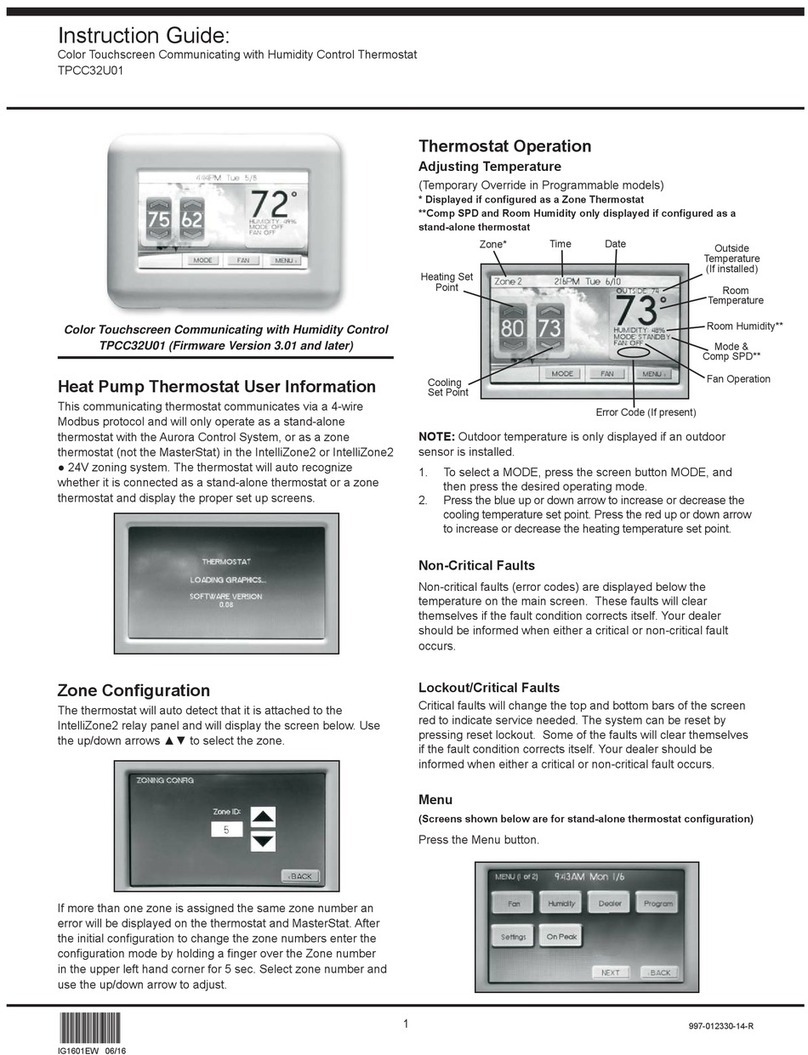

Water Furnace TPCC32U01 Manual

Water Furnace

Water Furnace TPCM32U03 Manual

Water Furnace

Water Furnace IntelliZone2 ZoneStat Manual

Water Furnace

Water Furnace TP32U03 User manual

Water Furnace

Water Furnace IntelliZone2 MasterStat User manual

Water Furnace

Water Furnace TP32W03 User manual

Water Furnace

Water Furnace IntelliZone2 MasterStat User manual

Water Furnace

Water Furnace TPCC32U01 Manual