Water-Loo VENGEN 28 NSHEV Instruction manual

VENGEN28 NSHEV

Installation, operation & maintenance manual

Contents

Health & Safety ........................................... 1

Installation.................................................3

NSHEV Fixing .......................................................3

Installation checks................................................6

Glass installation.................................................. 7

Commissioning............................................8

Actuator xing ....................................................8

Wiring details ......................................................9

Maintenance..............................................10

Operation and visual checks ................................10

Cleaning.............................................................10

Repair / replace................................................... 11

Health & safety

Symbol key

Symbols on the machine

This product complies with

applicable UK directives.

Symbols in this user manual

Warning/Caution!

Risk of crushing

General

Please read this manual carefully in advance

and make it accessible to all persons involved

in a suitable and appropriate place. We point

out that not observing the instructions in this

document may aects the warranty.

It is not permissible to make changes or modify

this product other than those specied in this

document.

Application area

The product is a natural smoke & heat exhaust

ventilator designed for automatic opening in a

vertical external wall.

The product may not be used for anything other

than its intended use.

This product is not suitable for:

• Maintaining compartmentation (e.g smoke

sha)

• Horizontal roof mounted application

• Sloping roof application

Personnel

Work should be carried out by competent site

operatives.

PPE

Appropriate personal protective equipment

should be used. All operatives should follow

guidance for the specic building site.

We recommend the following: Safety shoes

or boots, work gloves, eye protection, helmet,

high viz clothing, hearing protection, face mask.

VENGEN28 NSHEV

2Swegon reserves the right to alter specications.

Electrical safety

Safety extra low voltage V DC!

Do not connect directly to the mains supply!

Connection has to be carried out only by an

authorized electrical specialist.

Actuator rating: IP Protected from limited

dust ingress. Not protected from liquids.

Actuator must be installed on the inside of the

building.

Other Risks

When the product is voltage fed, the ventilator

will be either open or close and there can be a

risk for pinch injuries, for example, on the ngers

if these are placed between the louvred blades.

Danger of crushing hands and ngers!

Initial Checks

Firstly, check the site and ensure that it is safe

and clear of obstacles or hazards before com-

mencing work. Inspect the work area again

checking for potential trip hazards. Ensure that

adequate edge protection is provided if working

from height.

A method statement and risk assessment should

be prepared before any work is carried out.

Suitable access equipment, scaolding or

MEWPs should be used if working at height. All

personnel should be suitably trained in their use.

If working in a high up location, ensure that

there are no walkways or footpaths below the

work area and that no one is working below.

This could put people at risk from falling debris.

Employ a marshal if necessary to keep people-

from going into the area below the work.

Ensure that the xing substrate is structurally

sound and capable of supporting the vent.

Ensure that it is also free of any potentially

hazardous material. Use a detector to ensure

there are no services such as electrical cables or

gas pipes that could pose a potential hazard.

Unloading

The weight of the goods should be assessed

before unloading. Unloading of goods should

be carried using suitable ooading equipment

if required. Manual handling should only be

employed if the weight of the goods is within

safe limitations and the right number of people

should carry out the li.

Goods should be stored in a safe storage area,

as near to the area of work as possible to avoid

unnecessary handling.

Liing and handling

As with ooading, appropriate liing equipment

should be used if required. If NSHEVs are to be

handled manually then the relevant number of

people should be employed for liing.

When NSHEVs have to be moved on site, louvres

must be closed. The NSHEVs can be stored

either on their ends or on their sides. Avoid

placing force on the corners. This may result in

mechanical failure.

Extra care should be taken when handling glass

and every precaution should be taken to avoid

breakages.

All liing should be carried out using best

practice. Suitable hop-ups or access equipment

should be used to avoid stretching or liing

overhead.

The HSE Work at Height Regulations should

be followed at all times.

Installation

Install the product for easy access during

service/maintenance.

Use appropriate tools and the recommended

xings – ensure that the vent is installed safely

and securely. Avoid long periods of drilling.

When opening and closing the NSHEV ensure

that hands are held away from any moving

parts to avoid the possibility of trapping/

crushing.

Once installed the NSHEV should be le in a

safe manner, ideally with the blades closed

ensuring that no parts of the NSHEV are

protruding into a walkway area.

3

Swegon reserves the right to alter specications.

VENGEN28 NSHEV

Installation

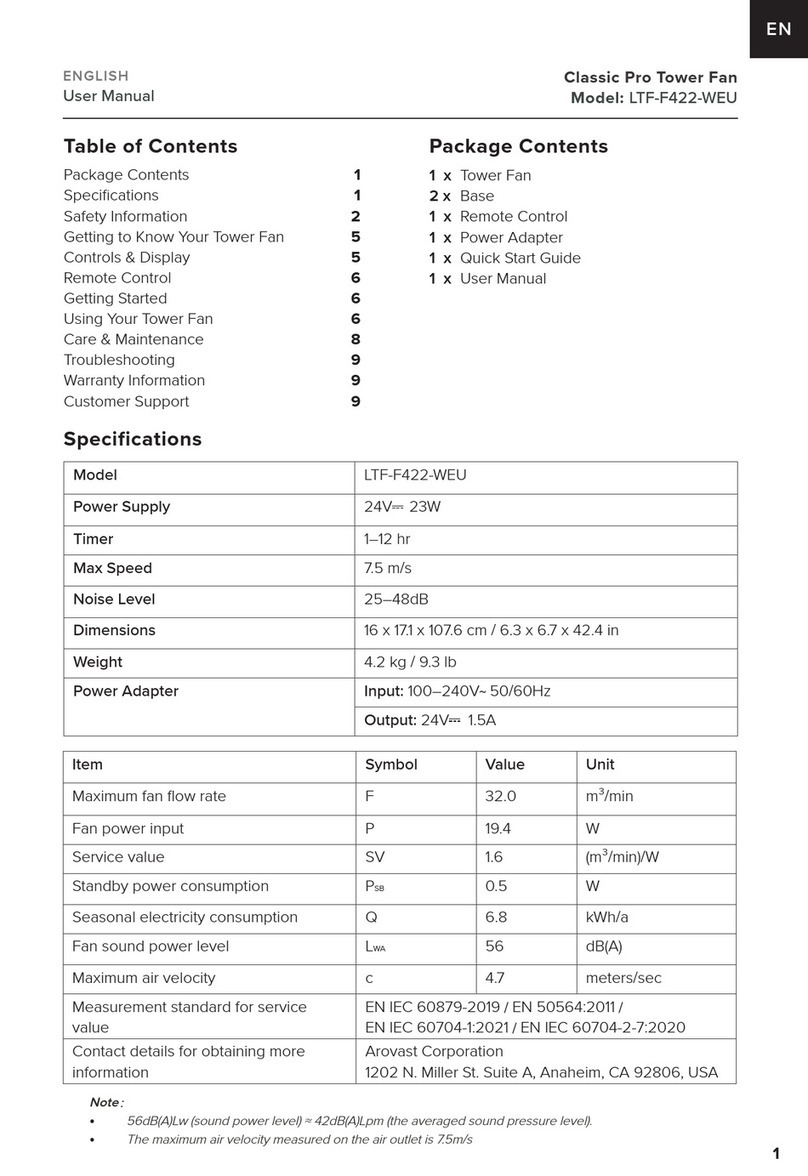

Builders clear opening

Use the below graph to check the opening

sizes meet the minimum requirements

For the horizontal clearance apply the width

of the VENGEN28 NSHEV to obtain minimum

clearance values to be applied to each side of

the NSHEV.

For the vertical clearance apply the height of

the VENGEN28 NSHEV to obtain minimum

clearance values to be applied to the top &

bottom of the NSHEV.

Example:

Unit 1000 (W) x 1300 (H)

Horizontal Clearance : 9.7mm ----

Vertical Clearance : 12.5mm ----

Builders Clear Opening: 1020mm (W) x 1325mm (H)

9.7

12.5

0

5

10

15

20

25

2 00 4 00 6 00 8 00 1000 1200 1400 1600 1800 2000 2200

MINIMUM CLEARANCE [mm]

WIDTH / HEIGHT [mm]

NSHEV CLEARANCE REQUIREMENTS

VENGEN28 NSHEV

4Swegon reserves the right to alter specications.

NSHEV xing

Direct xing

• Fix cill clips to the cill structure with suitable

packing to meet clearance requirements

• Place NSHEV into opening & position over cill

clips & secure.

• Open the blades of the unit to reveal pre-

drilled xing holes

• Drill pilot holes in the building structure

located through pre-drilled frame holes

• For brick & blockwork remove louvre to drill

holes & t suitable wall plug for building

material (not provided) Note: Allow suitable

edge distance for xing.

• Place NSHEV back into opening. Sucient

packing shims should be placed around

direct xings to avoid distortion of the

window frame when xings are tightened.

• Important! Refer to installation checks

(page 6) to ensure NSHEV is true/square/

level & plumb. If not remove xing and

adjust

• Fit backing rod between NSHEV & opening

Sealant application should be in accordance

with good practice for xing commercial

window systems.

5

Swegon reserves the right to alter specications.

VENGEN28 NSHEV

Lug Fixing

• Fix lugs to side of frame with a maximum

spacing of 600mm between centres and

150mm from each edge.

• Place NSHEV into opening & secure window

• Drill pilot holes in the building structure

located through bracket xing holes

• Remove NSHEV to drill holes & t suitable

wall plug for building material (not provided)

• Note: Allow suitable edge distance for xing

• Place NSHEV back into opening. Sucient

packing shims should be placed around

direct xings to avoid distortion of the

NSHEV frame when xings are tightened.

• Important! Refer to installation checks

(page 6) to ensure NSHEV is true/square/

level & plumb. If not remove xing and

adjust

• Fit backing rod between NSHEV & opening

• Sealant application should be in accordance

with good practice for xing commercial

window systems.

VENGEN28 NSHEV

6Swegon reserves the right to alter specications.

Glazing system

• VENGEN28 NSHEV can be provided with a

28mm glazing edge for installation into a

façade.

• Compare glazing edge thickness to façade

glazing opening.

• Place NSHEV into glazing system with

suitable packing pieces and secure.

• Important!! Refer to installation checks

(page 6).

• Fix in accordance with façade suppliers

instructions applying the following

guidelines:

Installation checks

Important!! Please ensure the following installation steps are adhered to:

• Post installation make the below checks:

• Ensure unit is square by measuring the corners are at 90° angle and corner to corner measurements

are equal as per g. 1

• Ensure the louvre window frames are exactly parallel to each other

• Ensure blades move freely without motor attached

• Check blades open to at least 86°

7

Swegon reserves the right to alter specications.

VENGEN28 NSHEV

Glass Installation

• Glass is typically supplied loose for onsite

glazing

• Glazing should be carried out aer NSHEV is

xed to the structure and prior to actuator

tting.

• If actuator is tted remove plastic cap,

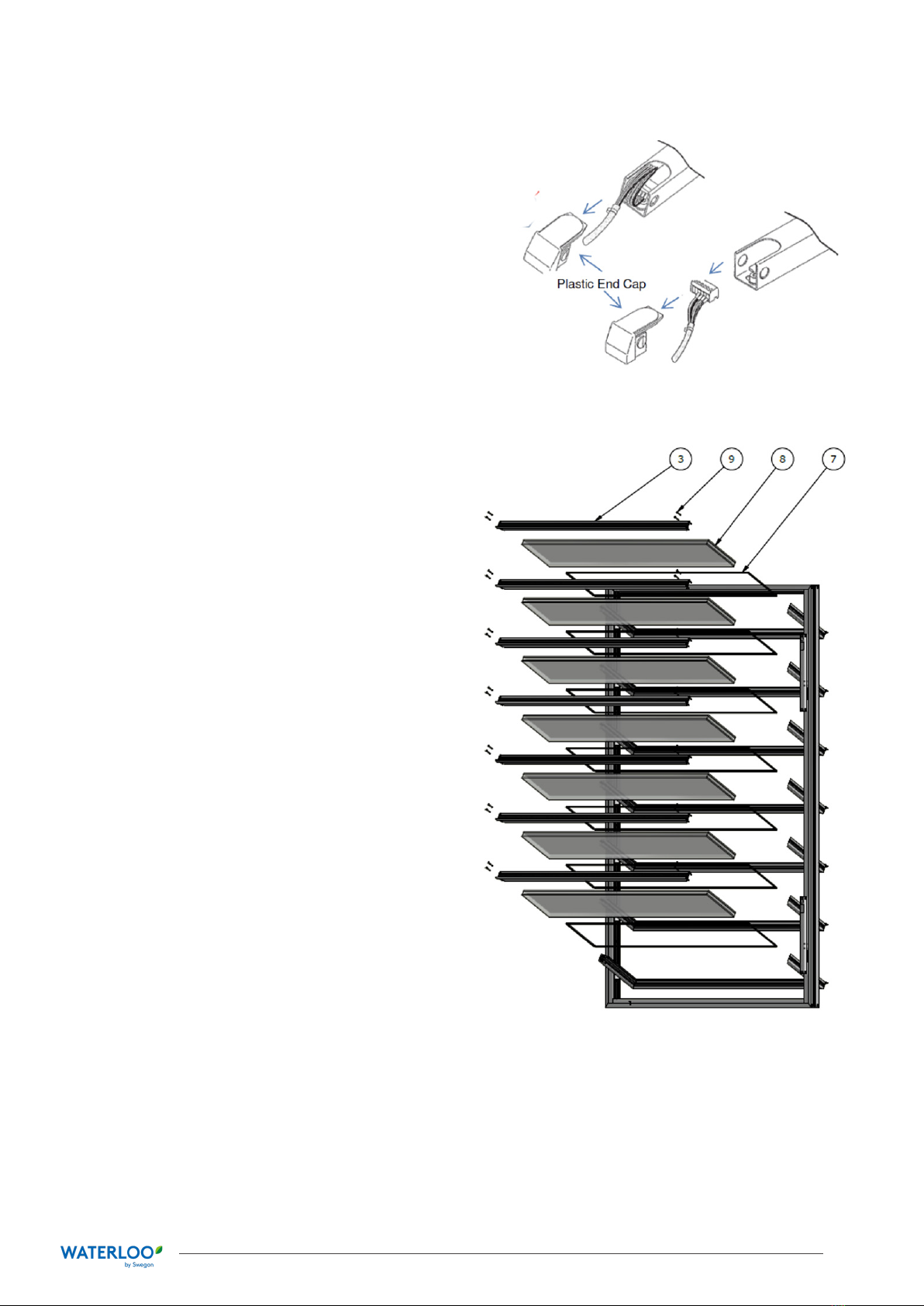

disconnect cable (gure 1) and undo screws

top & bottom.

• Fully open NSHEV

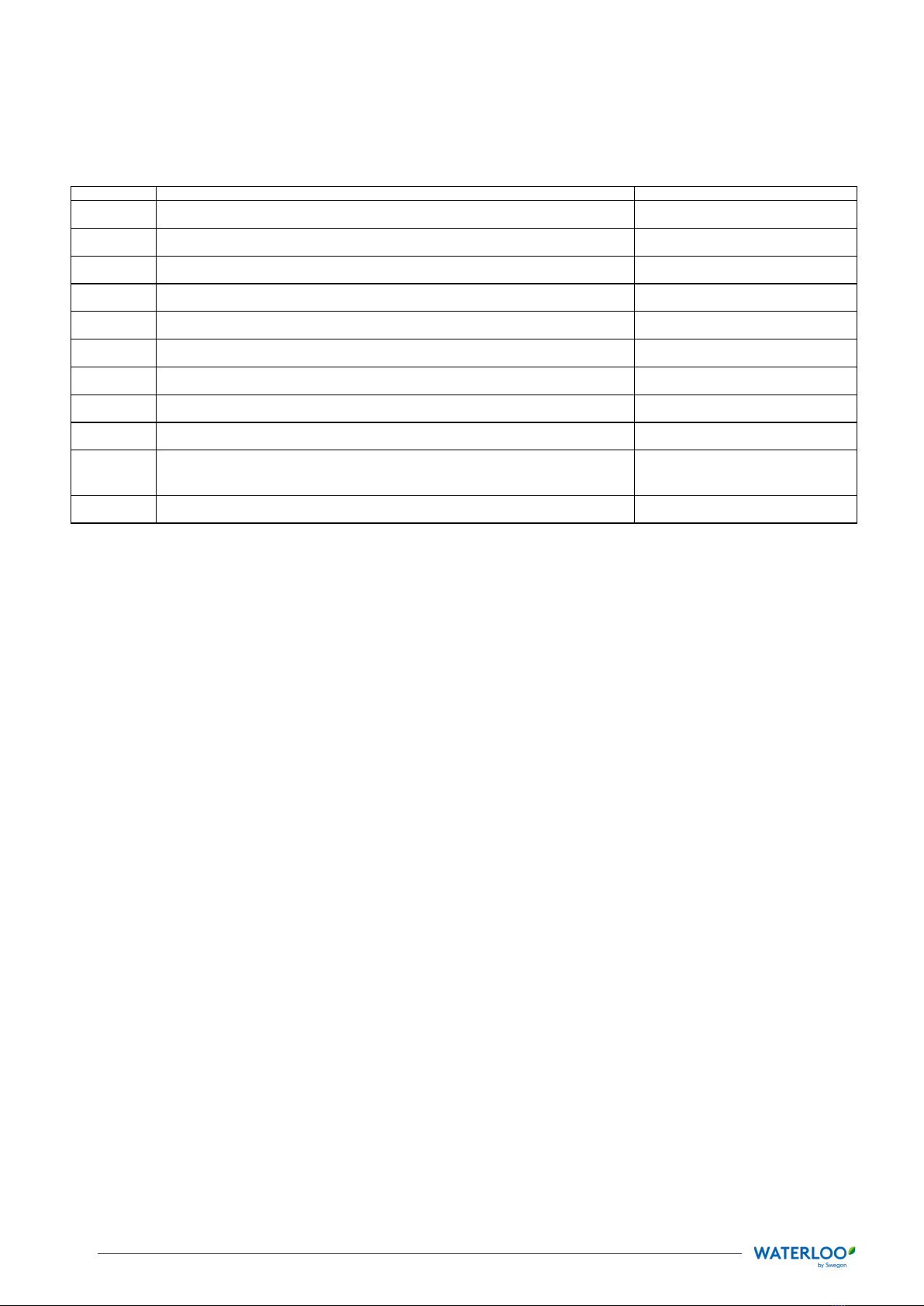

• Remove 2no. screws (9) from each end of

the louvre head rail (3) & remove horizontal

head rail.

• Slide glass unit (8) into ‘goal post’ frame &

re-t horizontal head rail (3).

• Close the NSHEV to t the internal glazing

wedges (7).

Note; Wedges are supplied in

reels for site cutting

• Fit head & Cill rail wedges rst followed by

side rail wedges

• Repeat for each louvre blade.

• Aer glazing it may be necessary to re-level

and square the head & cill rails. To do this

apply pressure at centre points of rail.

• Check & seal frame corners at junctions of

head, cill & side rails with small joint sealant.

VENGEN28 NSHEV

8Swegon reserves the right to alter specications.

Commissioning

Actuator xing

VENGEN28 NSHEV is provided with a 24v DC

programmable linear actuators. The drive allows

variable opening and closing for daily use, whilst

also being suitable for smoke ventilation.

• Close NSHEV to allow actuator tting

• Lubricate the linkage drive plate

• Place D+H Mechantronic 24V LDN actuator

on jamb and align the slot on the back with

the drive plate.

• Using screws & anti-shake washers secure

the actuator to VENGEN28 NSHEV via top &

bottom holes.

Note : Actuator is to be tted

inside the building

• Connect the motor lead by sliding the cable

connection block rmly over the motor pins.

• Connect the live and neutral wires to a 24v

power pack.

• Connect to D&H soware and program the

stroke length to achieve minimum 86 degree

blade angle.

• Activate the motor – open fully then close

the window. Repeat a second cycle.

• If the unit is functional place the cover caps

on the motor.

Pin Assignment

1.

2.

3.

9

Swegon reserves the right to alter specications.

VENGEN28 NSHEV

Wiring details

Standard

Optional Signals

* protect against short circuit

** Cable acc. to DH table for layout of

cables (see instructions for use of control

panel)

VENGEN28 NSHEV

10 Swegon reserves the right to alter specications.

Maintenance

Operational and visual checks

FFrreeqquueennccyyAAccttiioonnPPuurrppoossee

Weekly

To prevent water ingress

Weekly

Check window opening edges are clear of obstruction

To ensure window can actuate in

accordance with EN12101-2

3 Months

Check actuator screws are secured tightly

To ensure window can actuate in

accordance with EN12101-2

Weekly

Check whether the glass louvre or actuator has any visible damage or corrosion

To ensure window can actuate in

accordance with EN12101-2

Weekly

Actuation of the system should be simulated, ensuring NSHEV opens as intended

To meet guidance for BS 9999

Weekly

Check Louvre is left in normal operational position after inspection

To ensure window can actuate in

accordance with EN12101-2

Observe windows are running parallel on opening & closing

To ensure window can actuate in

accordance with EN12101-2

Yearly

The operating hardware should be lubricated.

To ensure window can actuate in

accordance with EN12101-2

3 Months

Actuation of all smoke control systems . All zones should be separately tested and it should be

ensured that the NSHEV operates correctly

To meet guidance for BS 9999

Yearly

Arrangements should be made for annual inspections and performance tests of the following to

be carried out by a competent persons, for any defects to be logged and the necessary action

taken, and for certificates of testing to be obtained

To meet guidance for BS 9999

3 Months

Check actuator wiring for damage

To ensure window can actuate in

accordance with EN12101-2

3 Months

Check condition of seals & brush seals

Cleaning

External surface

Cleaning should start at the time the products

are installed, ensuring that construction

materials such as concrete, plaster and paint

splashes are removed before they have a

chance to dry. Failure to remove these materials

at this early stage will require the use of

aggressive cleaning materials and techniques

with potential damage to the powder coated

surface.

The best method of cleaning is by regular

washing of the coating using a solution of warm

water and non-abrasive, pH neutral detergent

solution. Surfaces should be thoroughly rinsed

aer cleaning to remove all residues. All surfaces

should be cleaned using a so cloth or sponge

or nothing harsher than a so natural bristle

brush. Cleaning of powder coated sections can

be conveniently carried out at the same time

as window cleaning. If the project is subject to

any hazardous unusual environmental factors,

or is close to salt water an estuary or marine

environments then swegon must be consulted

on an individual project basis.

The frequency of cleaning depends in part on

the standard of appearance that is required and

also the requirements to remove deposits, which

could cause damage. For frequency please refer

to Interpon D series Cleaning and Maintenance

Guidelines.

11

Swegon reserves the right to alter specications.

VENGEN28 NSHEV

Internal surface

Repairing/ Replacements

• Any malfunction or damage should be

immediately reported to Swegon.

• Repairs are to be carried out exclusively by a

Swegon approved installer.

• In the event of a life safety actuation the

NSHEV should be assessed by a Swegon

approved installer. Any signs of re damage

the unit should be replaced.

• Any attempt to repair the NSHEV or

actuator would void the warranty.

• Only Swegon parts can be used for repair/

replacement.

• For the actuator only DH parts can be used

Technical le at:

Swegon Ltd, Unit D Vantage Point, Snodland , ME SL Kent

Table of contents

Other Water-Loo Fan manuals

Popular Fan manuals by other brands

Vornado

Vornado Zippi user guide

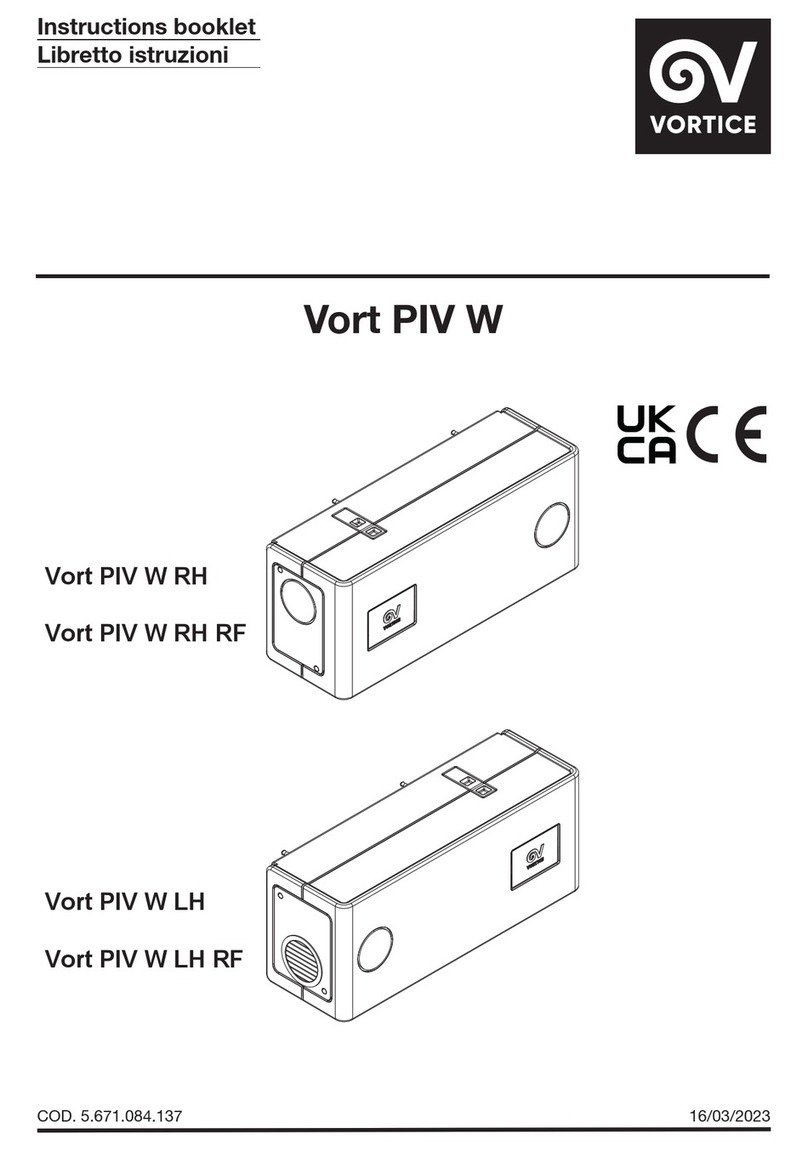

Vortice

Vortice Vort PIV W Series Instruction booklet

TZS First AUSTRIA

TZS First AUSTRIA FA-5553-1 instruction manual

Ellington

Ellington OP42BC5 installation guide

Kendal Lighting

Kendal Lighting AC-19544 installation instructions

NuAire

NuAire xboxer xbx+ installation manual