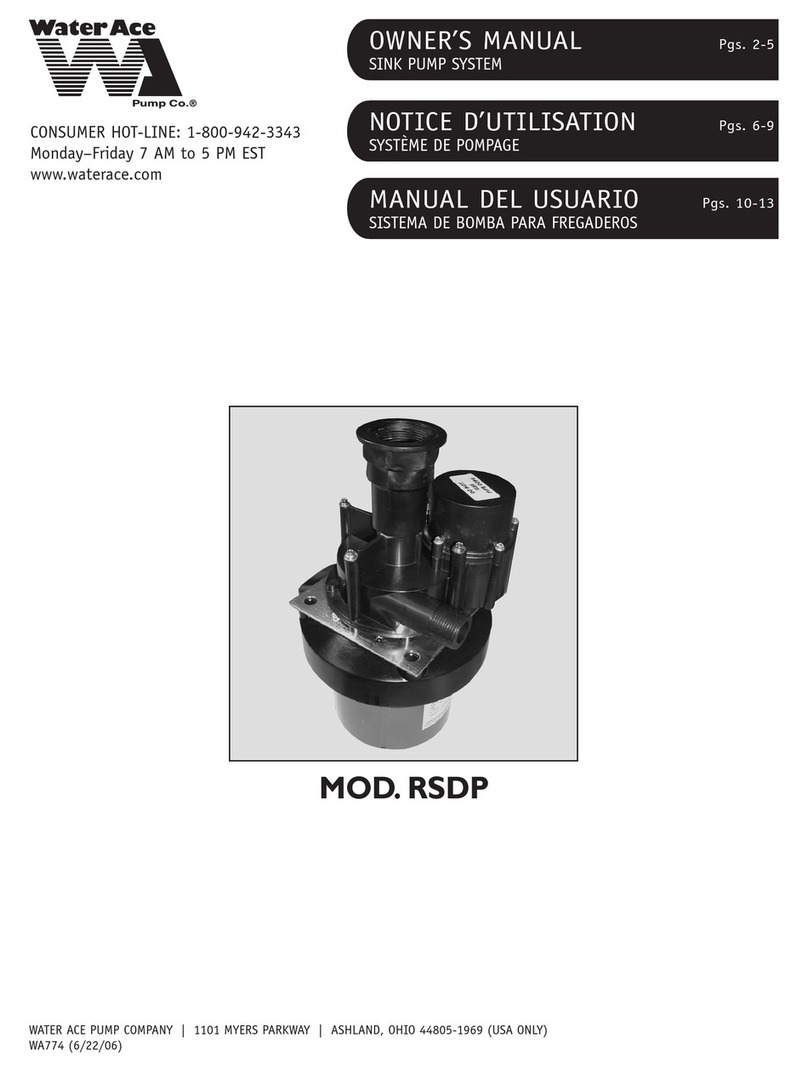

WaterAce WA61DUP User manual

Other WaterAce Water Pump manuals

WaterAce

WaterAce WA62UP User manual

WaterAce

WaterAce RCPH User manual

WaterAce

WaterAce R7L User manual

WaterAce

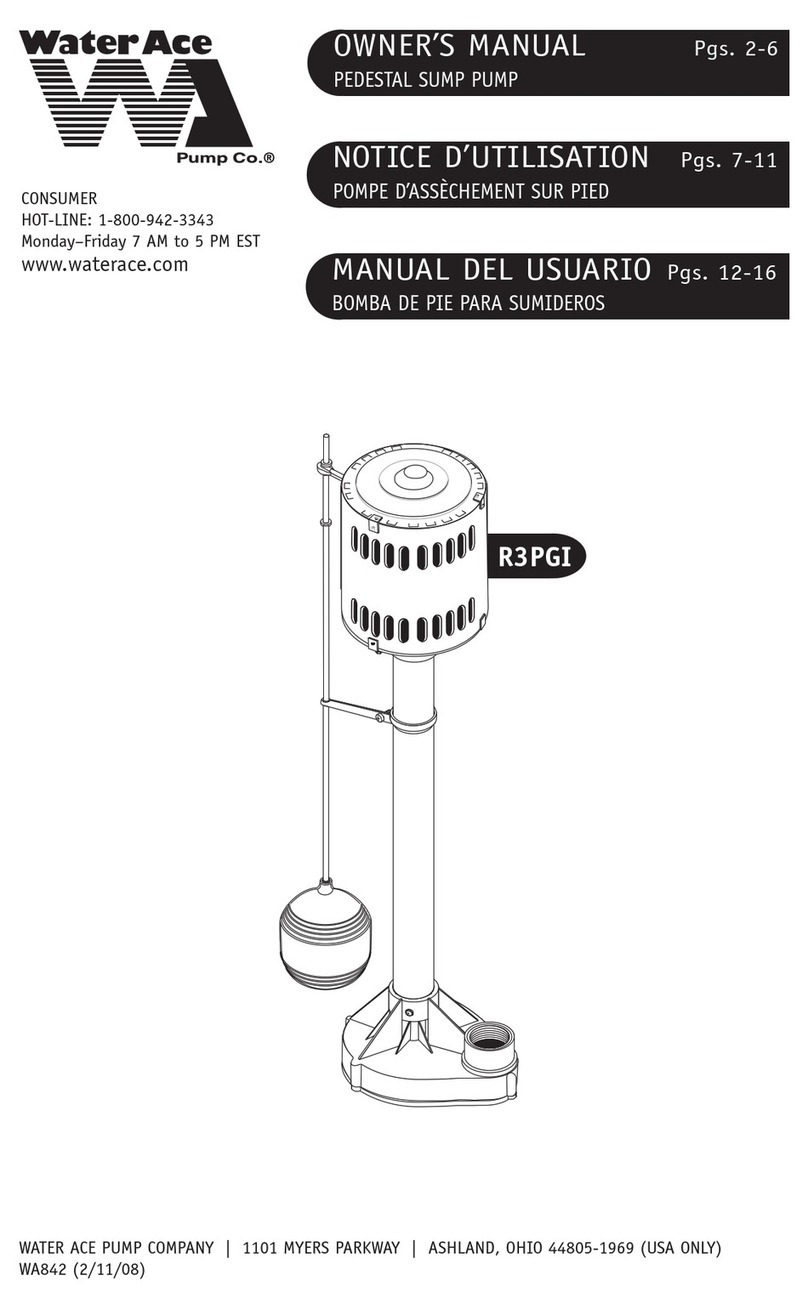

WaterAce R3PGI User manual

WaterAce

WaterAce R4W User manual

WaterAce

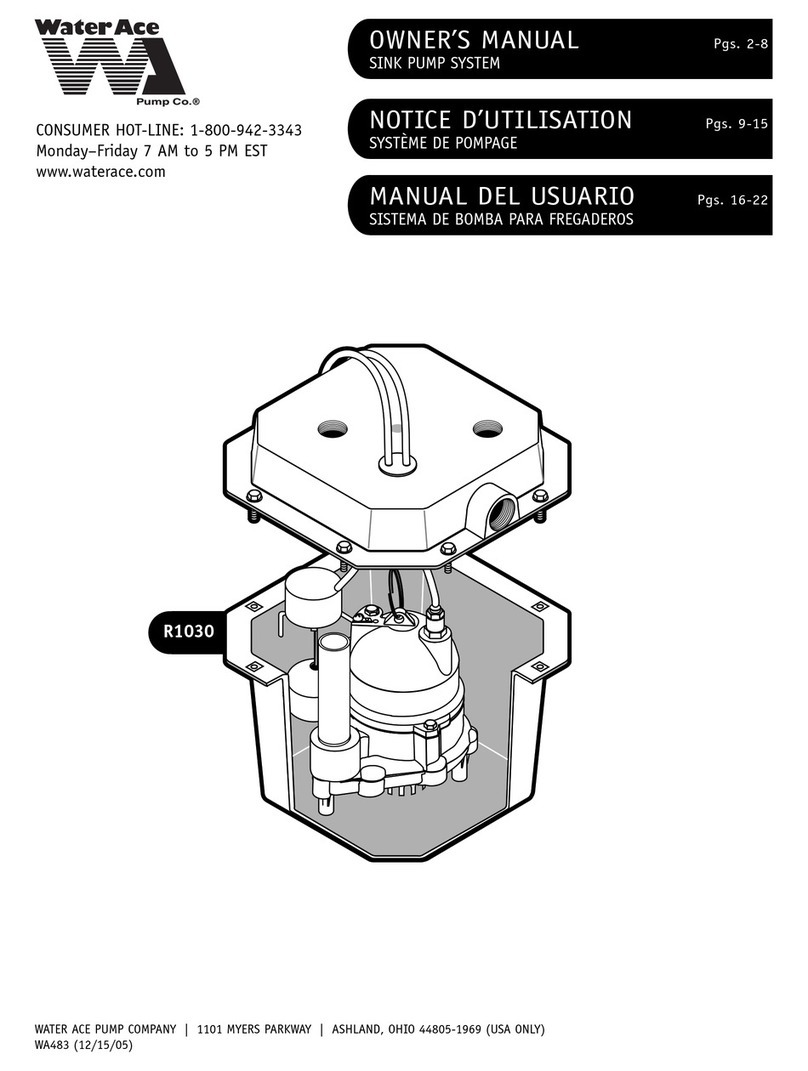

WaterAce R1030 User manual

WaterAce

WaterAce R7PBS User manual

WaterAce

WaterAce R33WU User manual

WaterAce

WaterAce R50VLT User manual

WaterAce

WaterAce R33SU-01 User manual

WaterAce

WaterAce R106 User manual

WaterAce

WaterAce R200A User manual

WaterAce

WaterAce R25SP-01 User manual

WaterAce

WaterAce WAUP Series User manual

WaterAce

WaterAce R106 User manual

WaterAce

WaterAce R106 User manual

WaterAce

WaterAce WACS Series User manual

WaterAce

WaterAce R100U User manual

WaterAce

WaterAce RPT7 User manual

WaterAce

WaterAce R520C-T7-01 User manual

Popular Water Pump manuals by other brands

WITA

WITA ADELINO WQD Installation and operation instruction

Masterflex

Masterflex MFLX77112-10 operating manual

Grundfos

Grundfos DMX 226 Installation and operating instructions

Pentair

Pentair NOCCHI MINIVORT P2-1 Use and maintenance manual

Seko

Seko SAM 5-ME Use and maintenance instruction manual

GÜDE

GÜDE HWW 1300 G Translation of the original instructions

Hi-Force

Hi-Force BPP107 operating instructions

BUSCH

BUSCH WY 4500 C Installation and operating instructions

air&me

air&me PUMP IT UP user manual

NAFFCO

NAFFCO NF-VTP Series Installation operation & maintenance

Grundfos

Grundfos MAGNA3 25-100 (N) Installation and operating instructions

Toku

Toku STRIKER STRIKERMAXX COMPACT quick start guide