Installation Guide & Owner’s Manual – Under-the-Counter Reverse Osmosis Drinking Water System

Copyright © 2020 WaterAnywhere

All Rights Reserved.

Page 1

About Your RO Water Treatment System

Thank you for your purchase of the WaterAnywhere home RO reverse osmosis water treatment system. This

drinking water system has been designed for quick and simple installation and maintenance. By carefully

reading this instruction manual and following the operational guidelines you will ensure a successful installation

and reliable operation. Routine maintenance is essential to the longevity and performance of the system.

Filters should be changed every three to six months depending on the quality of the feed water supply.

Notice:

Please read this entire service guide prior to beginning installation.

5 Stages of Water Treatment

Stage1: Sediment Filter Cartridge Replace every 3-6 months

The first filter the water passes through is a five micron filter cartridge. This cartridge removes

sediment including dirt, sand, rust, grit, and other suspended matter from water. This protects the rest

of the filtration stages and equipment from damage and clogging due to buildup of sediment.

Stage 2 & 3: Carbon Block Filter Cartridges Replace every 3-6 months

Next, the water passes through two stages of carbon filters to remove chlorine and objectionable tastes

and odors from water. These filters also protect the membrane from exposure to chlorine, which would

irreparably damage the membrane.

Stage 4: Reverse Osmosis Membrane Replace every 12 months

The fourth stage is the reverse osmosis membrane, which is the heart of the RO system. The RO

membrane substantially reduces the total dissolved solids (TDS) from the water, including arsenic,

barium, cadmium, chromium (hexavalent), chromium (trivalent), copper, turbidity, fluoride, lead, radium

226/228, and selenium, while washing the rejected contaminants down the drain. The treated water is

directed to the storage tank.

Stage 5: Post Carbon Filter Replace every 3-6 months

The last stage of filtration occurs as the water flows from the storage tank directly before being

dispensed from the faucet. The in-line carbon post filter (also known as polishing filter) removes any

remaining tastes or odors from the water, improving the flavor.

Notice:

Replacement frequency varies based upon incoming water quality and use patterns.

Generally speaking, filters should be changed when there is a loss of performance or

after an extended period of non-use.

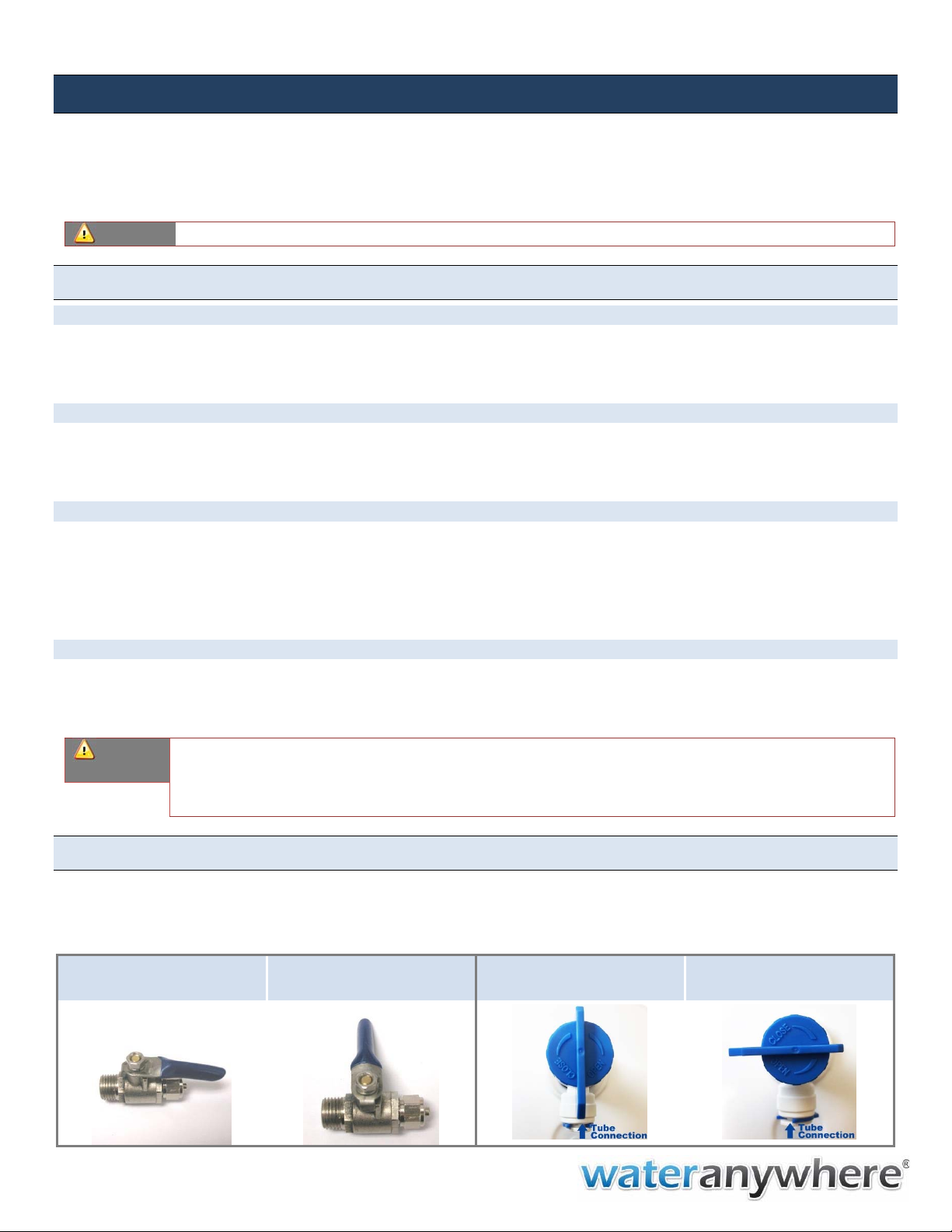

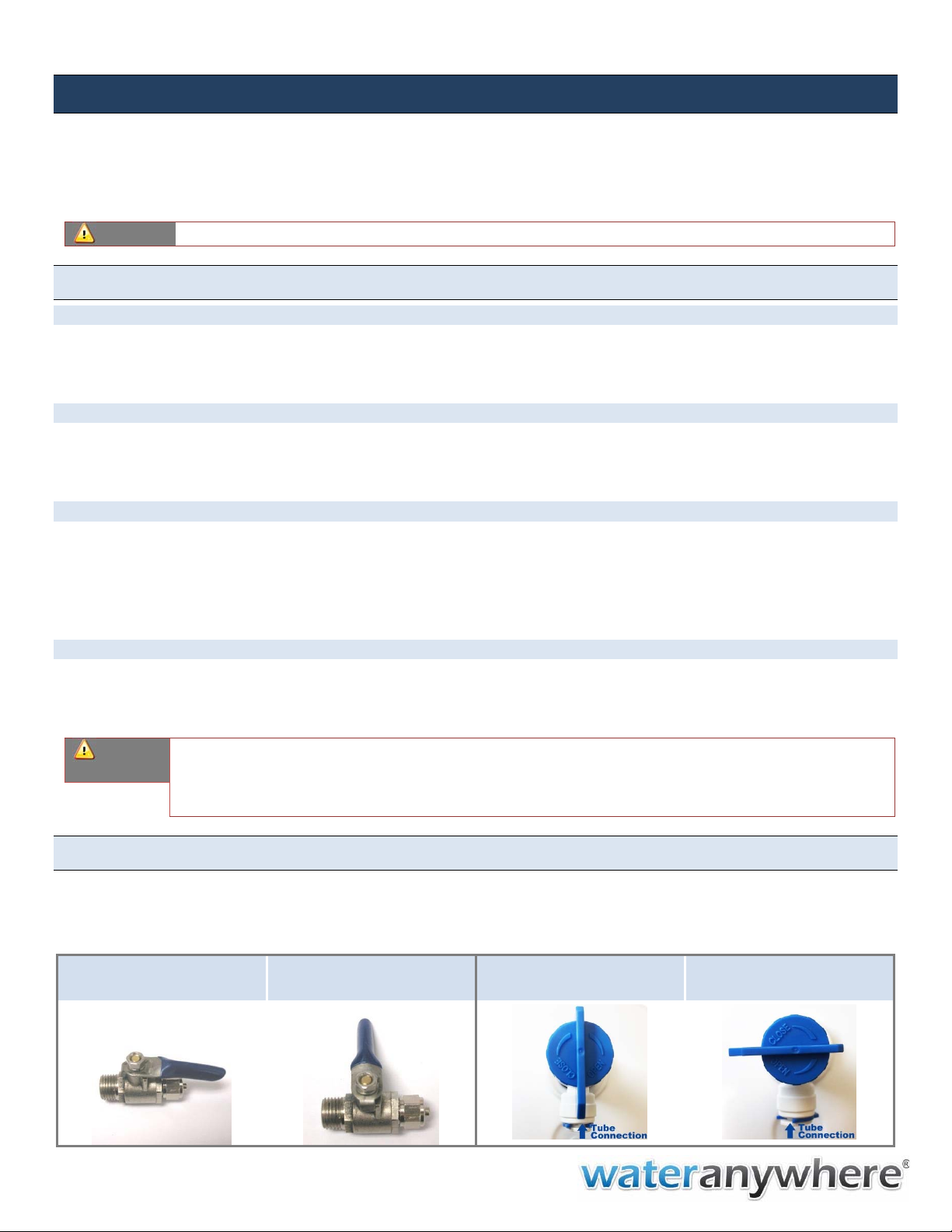

System On/Off Valves

Your RO System is equipped with two on/off ball valves. The system feed valve (to be installed into the cold

water supply line) can be used to turn the water to the system on and off for maintenance without disrupting

the water supply to the sink. The tank valve can also be closed to prevent water in the tank from draining out

during maintenance. Both can be opened by turning counterclockwise, and closed by turning clockwise.

System Feed Valve in

OPEN Position System Feed Valve in

CLOSED Position Tank Valve in

OPEN Position Tank Valve in

CLOSED Position