01/2015 1

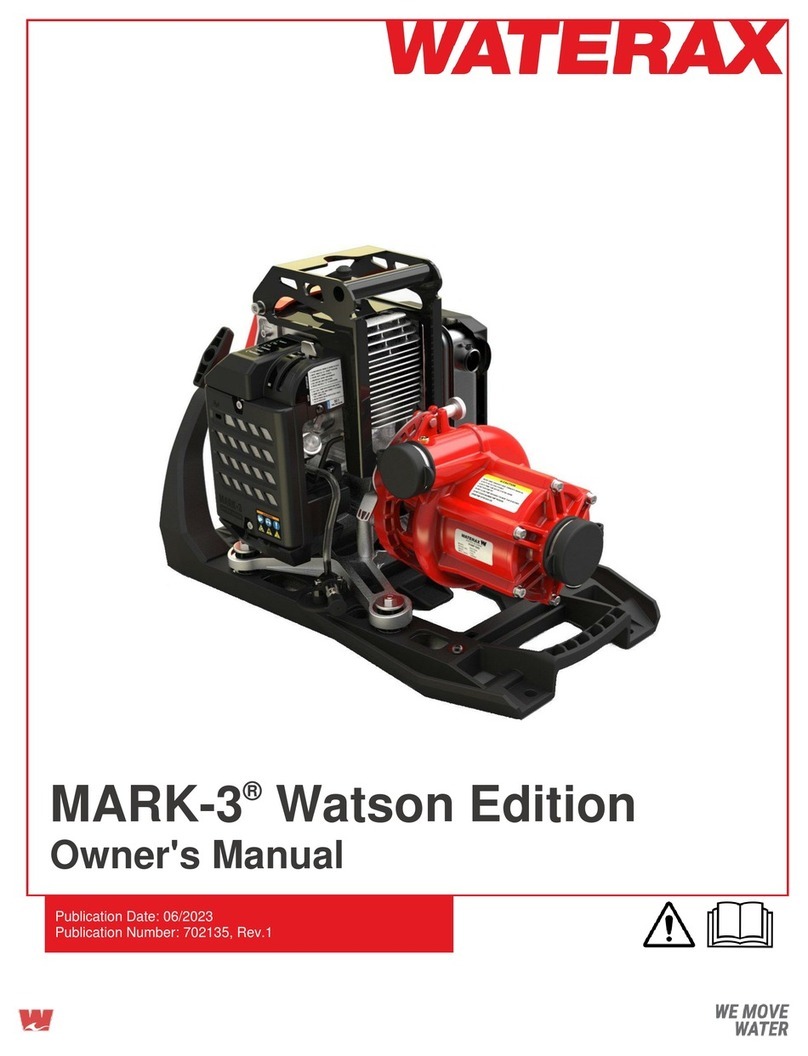

BB-4-18/23 Quick Guide

This Quick Guide shows the basic operation of the

WATERAX BB-4-18/23 4-stage high pressure pump.

The WATERAX BB-4 pump model pairs a WATERAX 4-

stage pump end with a Briggs & Stratton Vanguard 18

HP or 23 HP gasoline engine. For engine instructions,

oil and fuel recommendations, please refer to the engine

manufacturer’s manual.

For detailed instructions on using and troubleshooting

your pump, as well as full service and maintenance

instructions, refer to our website to download the

BB-4 Owner’s Manual.

For full specifications and performance curves, see the

BB-4-18 or BB-4-23 Data Sheets.

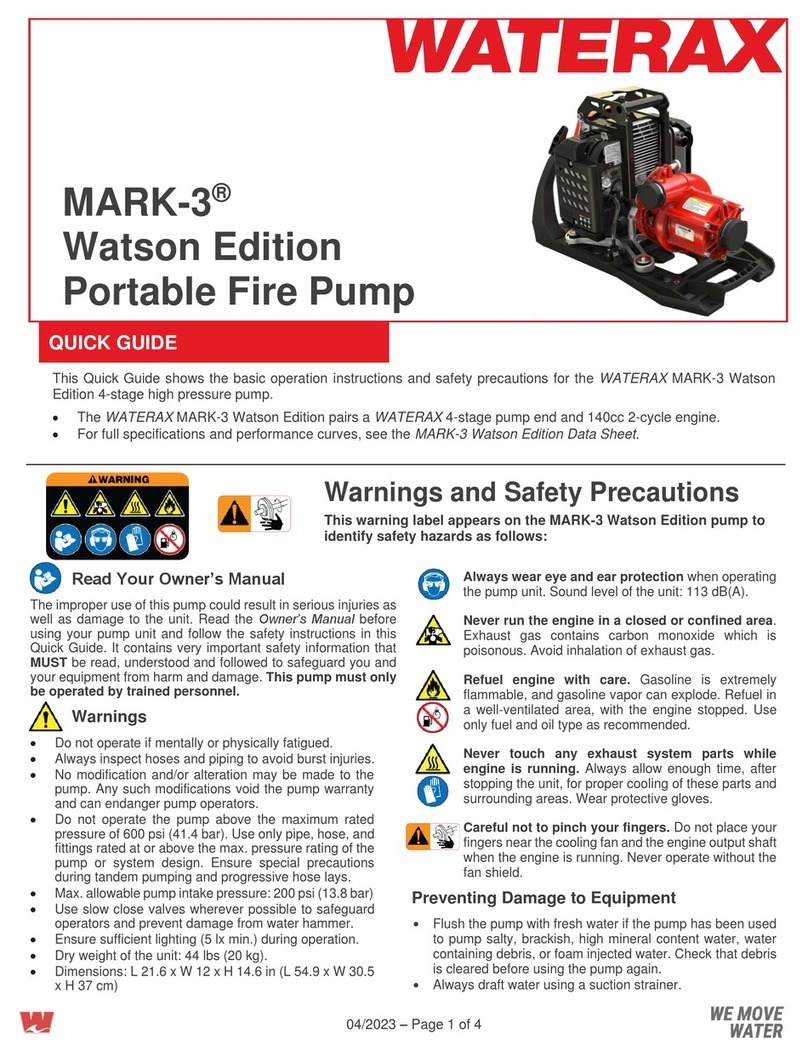

Warnings and Safety Precautions

This warning label appears on all WATERAX pumps to identify safety

hazards as follows:

READ YOUR ENGINE MANUAL!

Before proceeding further, locate and read the engine

manufacturer’s manual. It contains very important safety

information that MUST be read, understood and followed to

safeguard you and your equipment from harm, as well as for

the proper use and care of your engine. Use only fuel and oil

type recommended in the engine manufacturer’s manual.

Always check oil level in crankcase before use.

WEAR EAR AND EYE PROTECTION.

Always wear eye and ear protection when operating the

pump unit. Sound level of the unit: 99 dB(A).

GENERAL WARNINGS:

Do not operate if mentally/physically fatigued.

Inspect hoses and piping to avoid burst injuries.

No modifications and/or alterations may be made to the

pump. Any such modifications void the pump warranty

and can endanger pump operators.

Do not operate the pump above the maximum rated

pressure. Use only pipe, hose, and fittings rated at or

above the maximum pressure rating of the pump or

system design.

Slowly close valves. Use slow close valves wherever

possible to safeguard operators and prevent damage

from water hammer.

Dry weight of the unit: 164 lbs (will vary depending on

options).

READ THE PUMP OWNER’S MANUAL!

The improper use of this pump could result in serious injuries

as well as damage to the unit. Read the BB-4 Owner’s

Manual before using your BB-4 pump unit and follow the

safety instructions in this Quick Guide.

NEVER RUN THE ENGINE IN A CLOSED

OR CONFINED AREA.Exhaust gas contains

carbon monoxide which is poisonous to humans.

Avoid inhalation of exhaust gas.

REFUEL ENGINE WITH CARE. Gasoline is

extremely flammable, and gasoline vapor can

explode. Refuel in a well-ventilated area, with the

engine stopped.

NEVER TOUCH ANY EXHAUST SYSTEM

PARTS WHILE ENGINE IS RUNNING. Always

allow enough time, after stopping the unit, for proper

cooling of the muffler and surrounding parts.

EQUIPMENT DAMAGE PREVENTION:

Flush the pump with fresh water if the pump has been

used to pump salty, brackish, high mineral content

water, water containing debris, or foam injected water.

Check that debris is cleared before using the pump

again.

Always draft water using a suction hose strainer.