WaterLink SpinTouch BC User manual

Code 3586

Touch

WaterLink nBC

The Future of

Water Testing

Centrifugal

Fluidics

PhotometryTM

2

3

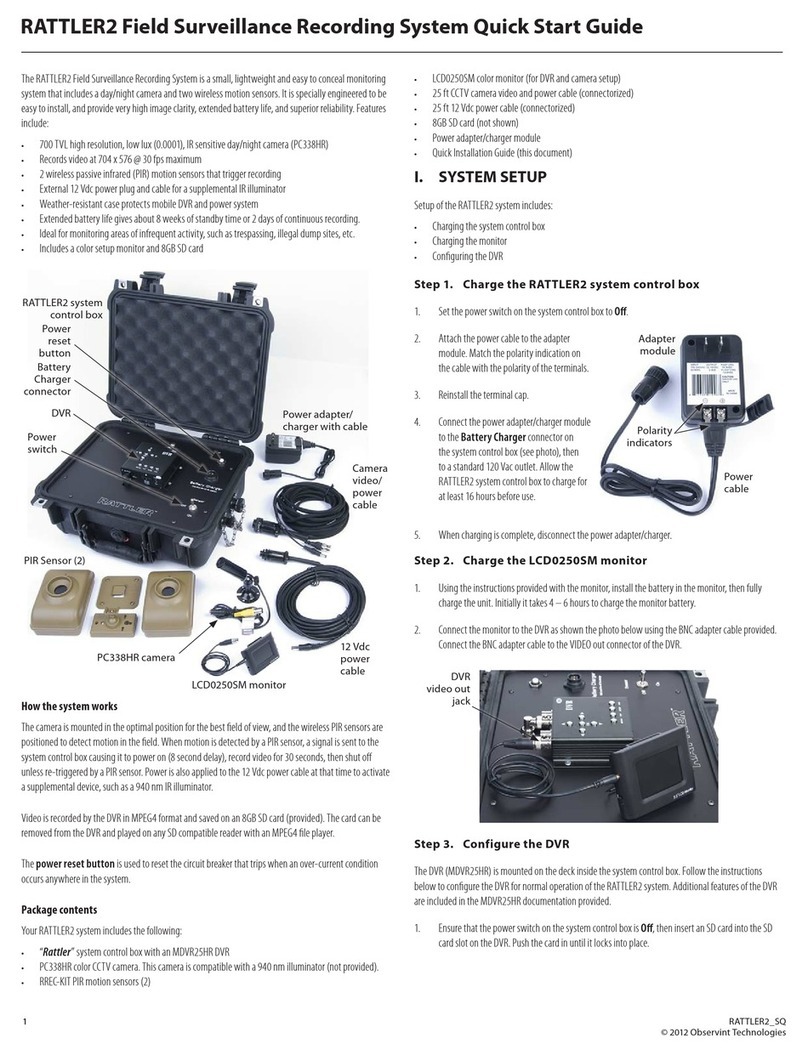

SETUP

BEFORE FIRST USE

¬Fully charge battery using the Spin Touch USB cable and adapter plug in AC

outlet.

¬Ensure your Spin Touch has latest firmware. A USB connection to a Windows®

PC is required:

1. Download and install WaterLink Connect 2 Application for Windows at

http://softwarecenter.lamotte.com/. Select WaterLink Connect 2 Software

for Windows FREE Download.

2. Plug meter into the computer with the provided USB cable and launch

WaterLink Connect 2 Application from the Start Menu.

3. A prompt will appear if firmware updates are available. Select Update.

Testing and data transfer will not be possible until firmware has been

updated.

METER

1. The meter can be powered from an AC outlet, a computer or the internal battery.

2. Use the USB cable and the adapter to plug the meter into an AC outlet.

3. Use the USB cable to connect the meter to the USB port of a computer.

CHARGE THE BATTERY

1. Use the USB cable and the adapter to plug the meter into an AC outlet or use the

USB cable (included) with a car charger (not included) to charge the battery. (Anker

PowerDrive 2, DC 12/24V, 5V = 4.8A, Part Number A2310 recommended.)

2. The battery icon on the screen will show the battery status. Charge the battery until

the battery indicator is full.

FIRMWARE UPDATES

Occasionally, the firmware in the Spin Touch will require updates. A USB connection to a

Windows PC is required. To do so:

1. Visit http://softwarecenter.lamotte.com/ and download the WaterLink Connect 2

application for Windows.

2. Plug the Spin Touch into the computer using the included USB cable.

3. Open the WaterLink Connect 2 desktop application and wait for the update to

complete.

Once the update is complete, it is safe to close WaterLink Connect 2 and unplug the

lab. After updating the firmware, it is recommended that the LED Calibration and Angle

Calibration procedures be performed.

NOTE: When a prompt to update the firmware is received, the options Update Now or

Remind Me Later will be displayed. If Remind Me Later is chosen, the update prompt will

be displayed again in 23 hours. Or, to update the firmware at any time, open WaterLink

Connect 2, go to Settings>Service Settings>Get Updates.

PC CONNECTION

When the WaterLink Spin Touch is connected to a computer via USB, the onboard

touchscreen becomes disabled and operation of the lab is performed using the WaterLink

Connect 2 application for Windows. This application is available for free at http://

softwarecenter.lamotte.com/. Via the WaterLink Connect 2 desktop application, results

SETUP PC CONNECTION

4

from the Spin Touch can be transferred to a water analysis program such as WaterLink

Solutions™.

DEVICE CONNECTION

The Waterlink Spin Touch supports connections to a Windows based PC (over USB) and to

Android and iOS mobile devices (via Bluetooth).

CONNECTING VIA USB

Using the provided USB cable, the Waterlink Spin Touch can be connected to a Windows

based PC. Before connecting a meter via USB, download and install the free WaterLink

Connect 2 Windows application from http://softwarecenter.lamotte.com. When the

Waterlink Spin Touch is connected to the PC via USB, the onboard touch screen controls

will be disabled and operation of the meter is performed using the WaterLink Connect 2

application. LaMotte offers robust water analysis programs as well, such as WaterLink

Solutions, to collect test results and offer detailed treatment recommendations. Learn

more about LaMotte software products at http://softwarecenter.lamotte.com.

CONNECTING VIA BLUETOOTH

The Waterlink Spin Touch is capable of connecting to a Bluetooth enabled device, such as

a phone or tablet. The Spin Touch is also compatible with a BLE Mobile Printer (5-0067).

Other Bluetooth printers are not supported. It is not necessary to pair the Spin Touch to

the Bluetooth enabled device. Barriers to wireless signals can reduce the range of wireless

devices. The Waterlink Spin Touch will work best if there are no walls between it and the

receiving devices.

Transferring results over Bluetooth to a mobile device requires that a mobile app is

installed on the device and an active account for the associated software program. For

example, with an active WaterLink Solutions account and the WaterLink Solutions mobile

app on a phone or tablet, results can be transferred from the meter into the application.

Mobile apps for LaMotte software products are available on iTunes® (iOS® devices) and

Google Play (for AndroidTM devices). Learn more about LaMotte software products at

http://softwarecenter.lamotte.com.

To transfer results from the Waterlink Spin Touch to a LaMotte software product mobile

app:

1. Log into the LaMotte software product mobile app.

2. Search for a customer or Site record. You may need to create one before you can

begin testing.

3. Start a Water Test in the mobile app.

4. Perform a water test from the Spin Touch onboard touchscreen normally. The Spin

Touch and the Bluetooth enabled mobile device will connect automatically.

5. When the connection is available the will light on the touch screen. When the

is dim, the meter and device are not connected. Tap the to transfer results to the

mobile app.

Whenever the appears on the touch screen the Spin Touch is capable of connecting to

the BLE Mobile Printer (5-0067). The button will be highlighted when connected and

dim when not connected.

The Spin Touch cannot connect to both mobile device and the printer at one time. (See

Save, Print and Send Test Results)

DEVICE CONNECTION

5

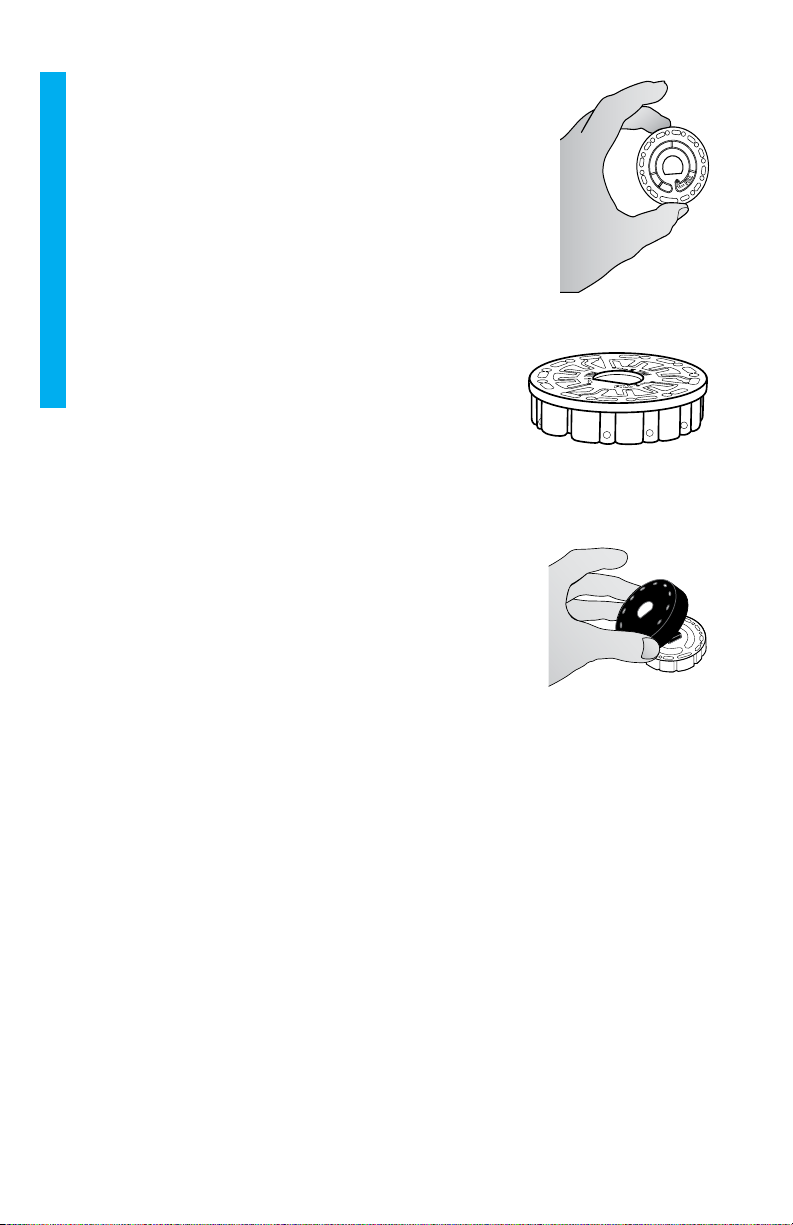

FILLING

When the syringe is placed in the water sample, and the plunger

is pulled all the way up, the syringe will hold more than enough

sample water to adequately fill the disk. The syringe is held

vertically and the tip is inserted into the fill hole on the disk. The

plunger is pressed slowly and smoothly to fill the disk.

1. Fill the disk using slow, even pressure. The

sample water will fill the spaces between

the baffles in a counterclockwise order.

Each space will fill from the bottom to the

top. Sample water should be added until the

sample water in the fourth chamber fills to the

top of the chamber slightly past the embossed

fill line. It is OK to fill slightly past the fill line.

Correct Fill

(Fill line)

2. Do not overfill the disk. If the disk is overfilled,

sample water will flow out of the overflow

hole in the center of the disk. The disk is not

leaking. Dry the disk and run the test.

Overfilled

(Dry SpinDisk before placing in meter)

3. Do not under fill the disk. If the disk is under

filled, the reagent chambers will not fill entirely

and results will be inaccurate.

Underfilled

4. Do not introduce air bubbles into the disk.

The reagent chambers will not fill entirely

and results will be inaccurate. As soon as a

bubble starts to form, pull back on the plunger

to draw the bubble out of the disk. Begin the

filling process again.

Air

Bubble

5. Wet disks should be dried thoroughly with a

lint free wipe. The disk should be handled by

the edges.

6. Disks should be filled and used within 10

minutes. They cannot be filled ahead of time.

For filling and troubleshooting tips go to: www.lamotte.com/spin_support/

NOTICE! Colored or turbid water samples: The WaterLink Spin Touch uses the blank sample well in

the disk to ratiometrically correct for normal levels of color and turbidity in clean samples. Scatter

will increase in samples with elevated amounts of color or turbidity and the test results will not be

FILLING

6

accurate. The WaterLink Spin Touch is not recommended for analyzing samples that have medium to

high color or medium to high levels of turbidity.

GENERAL OPERATING PROCEDURES

METER

When a filled disk is placed in the chamber and the lid is closed, the meter spins at high

speed to distribute the sample to the test wells. Next the meter slows to maximize the

pumping action of the stainless steel mixing beads as the reagents mix with the sample

water. Each reaction is then read at the proper time and wavelength for that reagent

system.

The button located in the lower center of the top of the meter turns the

instrument on and off.

The Blue indicator light of the on/off button indicates the status of the instrument.

Steady blue light – the blue LED will remain steady to indicate that the meter is on and

ready to run a test.

Blinking blue light (three blinks/second) – a test is in progress and the disk is spinning. Do

not open the lid when the disk is spinning.

Care should be taken when closing the lid. Do not slam the lid. Wiring between the lid and

the body of the photometer passes through the hinge. The meter will not run with the lid

open.

TOUCHSCREEN DISPLAY

When the button is pressed to turn the meter on, the Test Screen will be displayed.

12:14 PM

19-May-20

Source

Disk Series

CL Treated

BC803

Tap to

Start Test

Water Source

Selection

Start

Test

Disk

Type

Power/

Battery

Status

Date &

Time

Test

History

Settings

The display screen is touch-activated. To make a selection, tap the icon or word on the

screen with a fingertip, fingernail, pencil eraser, or stylus.

¬Gently wipe smudges from the screen with the Cloth Wipe (3580-WIPE).

¬Do not touch the screen with a sharp object.

¬Do not place objects on the screen that will scratch or damage it.

GENERAL OPERATING PROCEDURES

7

¬Avoid touching the screen with wet fingers.

TESTING

12:14 PM

19-May-20

Source

Disk Series

CL Treated

BC803

Tap to

Start Test

1. Press and hold until the meter turns on.

2. Tap . Select a Water source. Tap to confirm.

3. Tap . Select a disk series (found on disk packaging). Tap to confirm.

NOTE: Disk Series are limited by Water source selection.

4. Remove a disk from the packaging.

5. Use the syringe (1189) to fill the disk with the water sample.

6. Insert the disk. Cover the disk with the Universal Disk Cover (1719). Close the lid.

7. Tap to start test. Tap to cancel the test. If the test is cancelled discard the

disk.

8. The results will be displayed.

9. Choose an option.

¬Tap to add a tag.

¬Tap the highlighted to save the test results to the test log if Auto Save is

not enabled.

¬Tap the hightlighted to send the results to the enabled Mobile Bluetooth

Printer.

¬Tap the highlighted to send the results to a Bluetooth enabled device.

¬Tap to return to the Test Screen.

10. REMOVE THE DISK FROM THE CHAMBER. DISPOSE OF THE DISK. Disks left in the

chamber can leak and damage the device. Do not store the disk cover on the hub.

11. Press and hold for 2 seconds to turn the meter off.

Allow the sample to cool to 85 °F (20 °C) or below before testing.

The blank well allows the readings to be corrected for small amounts of color and turbidity in the

sample water. For samples with a large amount of solids, allow the solids to settle out and fill the

syringe with the clear liquid above the solids for the best results.

Remove residue daily. Residue will damage the meter and cause inaccurate results. See Cleaning.

GENERAL OPERATING PROCEDURES

8

SAVE, PRINT, AND SEND TEST RESULTS

Test results can be saved, transferred to the WaterLink Connect 2 mobile app via Bluetooth,

and sent to the BLE Mobile Printer (5-0067).

Test Time 05:30:06 19-May-2020

Test Results

Transfer

Results

via

Bluetooth

(Not Available)

Return

to Test

Screen

Save

Results

Print

Results

Tagging

FCL 2.06

TCL 2.06

CCL 0.00

ALK 101

T HARD 650

Ca HARD 0

COPPER 2.2

T IRON 1.1

PHOS 20

SIL 0

Test History Settings

The Spin Touch can log test results for 250 water samples in the Test History. The results

for the most recent sample will be located at the top of the list. All results can be logged

automatically or results for an individual sample can be logged after the sample has been

tested.

To turn on automatic logging, tap on the Test Screen. Tap . Select Auto-Save Tests.

Tap and to return to the test screen. When Auto Save is selected will not be

highlighted on the Test Results screen.

To manually log results for one sample at a time, Auto-Save Tests must be disabled. If

Auto-Save Tests is disabled will be highlighted on the Test Results screen. After the test

has been run, tap to save the results for that water sample to the Test History.

A user defined identification tag can be assigned to an individual sample result. To enable

tagging, tap on the Test Screen. Tap . Select Enable tags. Tap and to return

to the test screen. The tag can be up to 4 hexadecimal characters. It cannot begin with

a zero. To tag a test result, tap on the bottom of the Test Results screen and use the

buttons to enter up to four characters. Tap to erase a character. Tap to save the tag

and return to the Test Results screen. Tap to return to the Test Results screen without

saving the tag. The tagged result will appear on the Test Results screen and the Test

History screen. The tag will be preceded by “T-“.

Select All/

De-Select All

00.35 19-May BR Treated BC803

00.22 19-May CL Treated BC803

21.44 19-May CL Treated BC803

21.43 19-May CL Treated BC803

20.41 19-May BR Treated BC803

20.36 19-May BR Treated BC803

Test History

View

Selected

Results

Delete

Selected

Results

History

Settings

Select

Auto Save

Go to Top

Go to Bottom

Scroll up

or down

the test

list by 5

entries

Home

GENERAL OPERATING PROCEDURES

9

Logged results are viewed in Test History. Controls for viewing and managing single or

multiple test records are located on the Test History screen. Tap the checkbox next to a

test record to select it, then tap one of the buttons along the bottom to perform an action

with the selected records.

Print or Send Results to a Bluetooth Phone or Tablet

The Spin Touch can print to the Mobile Bluetooth Printer or send test results to a

Bluetooth-enabled device such as a phone or a tablet. The highlighted or will show

which function is active. The Spin Touch cannot connect to the printer and connect to a

phone or tablet at the same time.

There are two modes of operation for connecting to the printer and a phone or tablet – Fast

Printer Connect ON and Fast Printer Connect OFF. The default mode is Fast Printer Connect

ON. Fast Printer Connect can be turned on or off from the Bluetooth Menu that is located in

the Settings Menu.

If Fast Printer Connect is ON, the meter will connect immediately to the printer upon

recognizing it. It will also connect to a phone or tablet but priority is given to the printer

connection. The printer will start printing immediately when is tapped. The will dim

in intensity while the printer is printing. Fast Printer Connect should be ON if results will

be printed more frequently than results will be sent to a phone or tablet. It can remain

selected if results will only be sent to a phone or tablet. If Fast Print Connect is ON, and the

printer is on, the printer will have to be turned off before results can be sent to a phone or

tablet.

If Fast Printer Connect is OFF, the meter has the opportunity to connect to a phone or

tablet at all times other than when the printer is actually printing a test. The meter will

connect to the printer only after has been tapped so printing will be delayed a few

seconds while the connection to the printer is being established. The will dim in

intensity while the printer is printing. After printing, the meter will automatically reconnect

to the phone or tablet. Fast Printer Connect should be OFF if results will be sent to a phone

or tablet most frequently and printed less often.

SYRINGE

A plastic 3 mL syringe (Code 1189) is used to fill the disks. A

precision tip on the syringe fits into the fill hole on the disk. The

syringe tip should not be removed from the syringe. Syringes should

be cleaned between water samples. Pump air in and out of the

syringe a few times to clear the previous sample or rinse the syringe

with a small amount of the next water sample before filling it with the

next sample. Replace the syringes when the tips become worn, or the

plungers don’t move smoothly. See Accessories and Replacement

Parts.

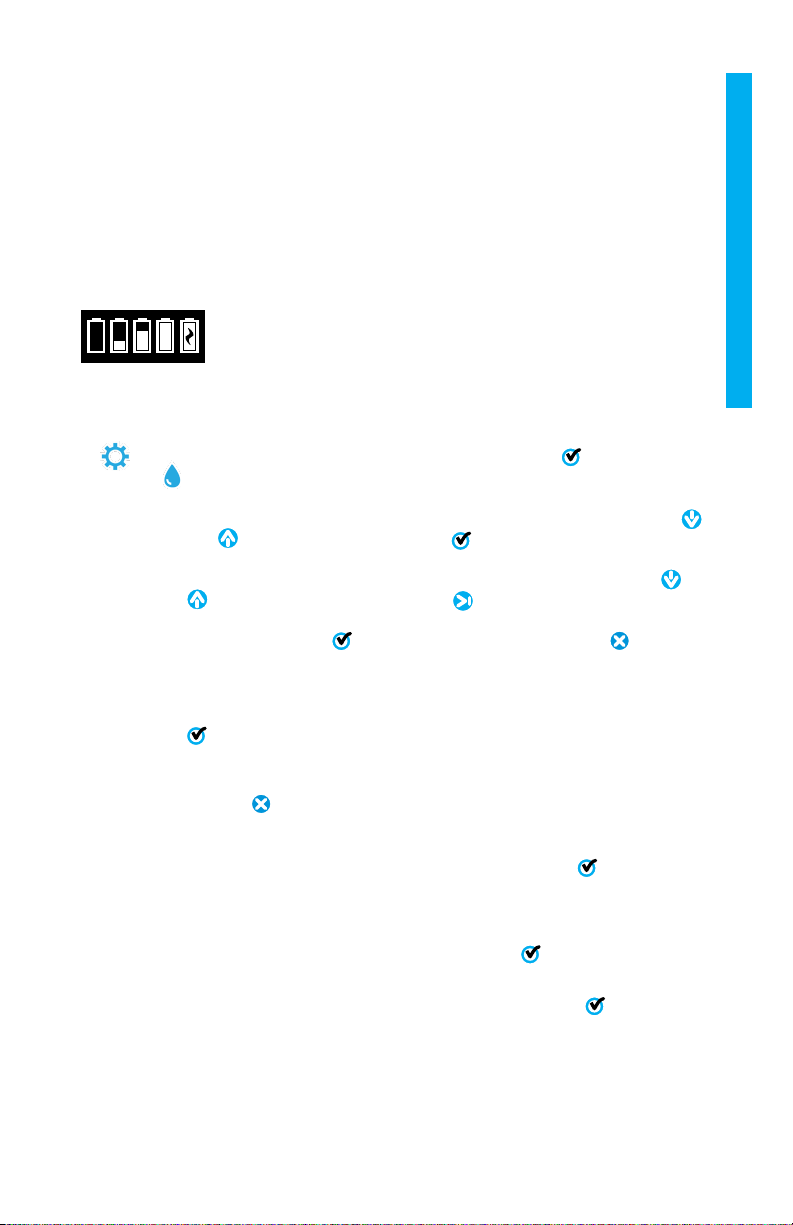

REAGENT DISK

The Waterlink Spin Touch uses a SpinDisk™reagent system. The dried

reagents are packaged in single test amounts in a sealed, polystyrene

disk. Stainless steel mixing beads in the reaction chambers mix the

sample water and the dried reagents. Tests for all factors in the series

are performed at one time. It is not possible to isolate the well for a

single factor and perform a test for one test factor only. Single-use

disks contain reagents for a single series. Disks should not be filled in

the meter chamber.

GENERAL OPERATING PROCEDURES

10

DISK HANDLING

The disk should be handled only by the edges. Avoid touching the

top or bottom of the disk. The light passes through the non-frosted

areas of the disk so these areas must be kept free of smudges and

fingerprints. Wet disks should never be placed in the meter. Wet

disks should be dried with a lint free cloth before placing them into

the chamber.

The disk is positioned in the chamber by aligning the D-shaped hole

in the center of the disk over the D-shaped hub in the photometer

chamber. The disk should be placed gently on the hub. There is no

need to firmly press the disk down onto the hub.

DISK STORAGE

Disks are sensitive to moisture. Avoid opening more packs

than are needed. Disks have a limited shelf life and should not

be exposed to the humidity in the air more than necessary.

For the most accurate results, store and use disks at room

temperature (68 – 75 °F/20 – 24 °C)..

DISK COVER

The black disk cover is placed over the disk in the photometer

chamber to reduce interference from stray light. The disk cover

is positioned over the disk by aligning the D-shaped hole in the

center of the disk over the D-shaped hub in the photometer

chamber. The disk cover should be placed gently on the hub.

There is no need to firmly press the disk cover down onto the hub.

The test will be aborted if the disk cover is not used. Do not store

the disk cover on the hub.

METER CHECK DISK

The Meter Check Disk (Code 1705/1705-EU) is used to evaluate the meter calibration and

calibrate the meter if the calibration check fails.

IMPORTANT!!

Do not attempt to separate the components of the Meter Check Disk (Code 1705/1705-

EU). The Meter Check Disk consists of a disk with a permanently attached cover. Do not

fill the Meter Check Disk with water. Water is not used in the Meter Check Disk.

For use of the Meter Check Disk see TROUBLESHOOTING WITH THE METER CHECK DISK.

USB CABLE

A USB cable connects the Waterlink Spin Touch to a Windows-based PC. When used with

the AC Power Adapter, it connects the meter to an AC outlet.

WARNING: only use the USB cable and wall adapter that are supplied with the kit. Make no

substitutions.

BATTERY

A fully charged battery will last for approximately 150 tests under average conditions. The

battery life will vary based on usage patterns. The meter should be turned off after testing

to prolong the battery life. The standard life cycle of a lithium ion battery is 500 cycles. The

GENERAL OPERATING PROCEDURES

11

battery will fully charge in approximately 6 hours. The battery is designed to be charged

overnight and should be charged indoors only. The battery is rated at 12 V and 8.1 AH

capacity. Power the meter from the battery pack or from AC power. The USB cable and AC

adapter are used to plug the meter into an AC outlet. WARNING: only use the AC adapter

supplied with this equipment. Do not substitute.

The battery charge status is indicated by the battery icon on the display. The battery icon

will indicate when the battery charge is full, partial, low, empty or charging. The empty

battery icon will flash to indicate that meter should be connected to AC power source. If the

meter continues to be used at low battery power without connecting it an AC power source,

the meter will go into an auto-shutdown mode. In this mode the meter will be locked until

meter is connected to an AC source and the battery is charged to a sufficient voltage. While

charging, the charging battery icon will be displayed. The meter should

remain plugged in until the battery is fully charged. When the battery is

completely charged, the charging icon will change to the full battery

icon.

SETTINGS

Tap to enter the SETTINGS menu. After changing a setting press confirm the

change. Tap to return to the test screen at any time.

Brightness The brightness level of the display can be adjusted from 00 to 10. Tap

and to adjust the brightness. Tap to exit to the Settings menu.

Date/Time The Year, Month, Day, Format, Hour, Minute, AM/PM can be set. Tap or

to adjust the displayed value. Tap to move to the next value. After

the last value has been chosen (minutes for 24 hour format, AM/PM for

12 hour format) tap to return to the Settings menu. Tap to exit to

the Settings menu at any time.

Set

Language

There are ten language options – English, French, Spanish, German,

Dutch, Swedish, Portuguese, Italian, Turkish, Chinese. Tap selection. Tap

to exit to the Settings menu.

Calibration Tap to run an angle calibration to evaluate the alignment of the hub and

disk. Tap to exit to the Settings menu.

Power

Options

There are three power options: Auto Dim Time, Auto Off Time, and Power.

Tap the options then tap a selection. Tap selection. Tap to exit to the

Settings menu.

Bluetooth There are two Bluetooth options: Bluetooth Enabled and Fast Printer

Connect that are used to print test results. Tap to exit to the Settings

menu.

Market

Type

Tap to select the market type. Select Boiler/Cooling. Tap to exit to the

Settings menu.

GENERAL OPERATING PROCEDURES

12

Other

Settings

About… lists the Serial Number, Firmware Version, Bluetooth MAC address,

Bluetooth Version and Test Count. The Test Count shows the number of

complete tests that have been performed over the lifetime of the meter.

Tap to return to the Settings menu.

Ranges Enabled allows the option of having test results that are out of the

range of the reagent system displayed in red. The default setting is on.

When Show Market Type is selected, the market type will be displayed

on the Testing Screen. The default setting is OFF. Tap to return to the

Settings menu.

RANGES

Test Factor Range Display Abbreviation

Alkalinity, Total 0–250 ppm ALK

Bromine 0.00-33.00 ppm BR

Chlorine, Free 0.00–15.00 ppm FCL

Chlorine, Total 0.00–15.00 ppm TCL

Chlorine, Combined 0.00–15.00 ppm CCL

Copper 0.00-6.00 ppm COPPER

Hardness, Calcium 0-800 ppm Ca HARD

Hardness, Total 0-1200 ppm T HARD

Iron, Total 0.0-6.0 ppm T IRON

Phosphate 0-50 ppm PHOS

Silica/Silicon Dioxide 0-100 ppm SIL

Test results that are out of range of the reagent system wil be RED. RED test results may

not be accurate. Go SETTINGS>Other Settings to turn the Ranges Enabled feature OFF.

If the concentration for one test factor is significantly out of the range for the reagent

system, the accuracy of the results for the other test factors may be affected.

Copper concentrations over 10 ppm will result in high phosphate results.

Dissolved iron concentrations over 10 ppm will result in low phosphate results.

Polyquats over 100 ppm will result in high phosphate results.

Polyquats will cause a significant positive interference with silica results.

GENERAL OPERATING PROCEDURES

13

DISK DESCRIPTIONS

Cooling Water Disk CW801 (Code 4339)

Bromine

Calcium Hardness

Combined Chlorine

Copper

Free Chlorine

Total Alkalinity

Total Chlorine

Total Hardness

Total Iron

Free Chlorine

(Bromine)

Total

Chlorine

High Range

Total Hardness

Total

Alkalinity

Blank

Low Range

Total Hardness

Copper

Calcium

Hardness

Total

Iron

Empty

Empty

Cooling Water Disk CW802 (Code 4339)

Bromine

Calcium Hardness

Combined Chlorine

Copper

Free Chlorine

Iron

Total Alkalinity

Total Chlorine

Total Hardness

Free Chlorine

(Bromine)

High Range

Total Hardness

Total

Alkalinity

Blank

Low Range

Total Hardness

Total

Chlorine Calcium

Hardness

Total

Iron Copper

Empty

Empty

Boiler/Cooling Water Disk BC803

(Code 4339)

Bromine

Calcium Hardness

Combined Chlorine

Copper

Free Chlorine

Iron

Phosphate

Total Alkalinity

Total Chlorine

Total Hardness

Silica/Silicon Dioxide

L

ore

m

Free Chlorine

(Bromine)

High Range

Total Hardness

Total

Alkalinity

Blank

Low Range

Total Hardness

Total

Chlorine Calcium

Hardness

Total

Iron Copper

Silica/Silicon Dioxide

Phosphate

NOTE: Colored reagents may be visible in the disk before adding sample water.

For the most accurate results, store and use disks at room temperature (68 – 75 °F/20 –

24 °C).

14

ACCESSORIES AND REPLACEMENT PARTS

Description Code

Waterlink Spin Touch Meter

Water Sample Bottle (60 mL) 0688

Plastic Beaker, 50 mL 0944

Syringe with tips (3) 1189-3

Syringe tips (3) 1189-TIP

Cleaning Tissues 0669

Meter Check Disk (North America) 1705

Meter Check Disk (Europe) 1705-EU

Universal Disk Cover 1719

USB Cable 1712

AC Adapter (North America) 1715

AC Adapter (Europe) 1715-EU

Cloth Wipe 3580-WIPE

BLE Mobile Printer 5-0067

Waterlink Spin Touch Counter Mat 3580-MAT

Waterlink Spin Touch Manual 3586-MN

Waterlink Spin Touch Quick Guide 3586-QG

For available reagent disks, see Disk Descriptions.

WARNING: only use the USB cable and wall adapter that are supplied with the kit. Make no

substitutions.

SPECIFICATIONS

Instrument Type Centrifugal Fluidics Photometer

Wavelengths

(interference filters)

390 nm, 428 nm, 470 nm, 525 nm, 568 nm, 635 nm

Display Color Capacitive Touchscreen, 3.5 in, 320 x 240 pixel resolution

Wavelength Accuracy ±2 nm

Wavelength Bandwidth 10 typical

Photometric Range -2 to 2 AU

Photometric Precision ±0.01 AU at 1.0 AU

Photometric Accuracy ±0.01 AU at 1.0 AU

Sample Chamber Accepts prefilled disk

Light Source 6 LEDS

Detectors 6 silicon photodiodes

Pre-Programmed Tests Yes, with automatic wavelength selection

Languages English, French, Spanish, German, Dutch, Swedish, Portuguese,

Italian, Chinese, Turkish

15

Temperature Operation: 0-50 °C; storage – 40-60 °C

Operation Humidity Range 0- 90 % RH, non-condensing

Communication USB-C, Bluetooth low energy technology (BLE)

Calibration Factory set, field calibration via internet connection

Firmware Internet updateable (New Test, New Test Calibrations, etc.).

Requires a USB connection to Windows PC

Software WaterLink Solutions (Web, Android, iOS), DataMate Web (Web,

Android, iOS), WaterLink Connect 2 (Windows)

Power Requirements USB wall adapter, USB computer connection or internal lithium

ion rechargeable battery

Battery Type Lithium ion

Minimum Capacity 12 V/2.6 AH

Charge Life Approximately 150 tests

Battery Life Approximately 500 charges

Full Charge 6 hours

Water Resistance Rubber over-molded base, rubber USB Port Plug, gasketed

display and hinge.

Electrical Rating Rated voltage

5V

, Rated power of input current (1.6 A)

at USB C

Auto Off Yes, default 15 (only with battery power)

Power Save Yes, default OFF

Data Logger 250 test results stored for download to PC or transfer by

Bluetooth

Certifications EZ-BLE™PRoC™

Module,

CYBLE-022001-00

RF Radio:

FCC (USA):

Industry

Canada (IC)

Certification:

FCC ID:

WAP2001

License IC:

7922A-2001

CE (Europe): Complies with

Directive

1999/5/EC

MIC (Japan): 005-101007

KC (Korea): MSIP-CRM-

Cyp-2001

EMC: EU: ETSI EN 301489-1

US: FCC PART 15 B

CAN ICES-3 (B)/NMB-3(B)

AS/NZS: CSPR 22

Safety: EU: EN61010-1:2010

AS/NZS: national differences

Dimensions 21.6 X 12.4 X 10.4 cm (L X W X H)

8.5 X 4.9 X 4.2 in

Weight 0.79 Kg, 1.74 lb

16

TROUBLESHOOTING

TROUBLESHOOTING GUIDE

Problem Reason Solution

Meter Check Disk Meter Check Disk in chamber

instead of reagent disk

Select “Continue” to go to Test

Results screen. Select “Abort” to

go to Testing screen and run test

with reagent disk.

“Sanitizer” appears on

test screen instead of

“Source”

Wrong Market Type was chosen Go to Settings. Change Market

Type to Boiler/Cooling

!

On Test Results and

Test History screens

Problem with default blank due

to under filled disk or air bubble.

Test results are questionable.

Fill disk correctly (see FILLING).

On Test Results screen tap ! for

details.

Range Error Raw data out of range Contact Support

Output Error Decreased light intensity.

Possibly dirty lens

Clean lens (see CLEANING).

Follow Range Check Procedure. If

error message persists, contact

Support.

Consistently unexpected

high results for metals

Metals may actually be present Repeat test with distilled water. If

the results still show that metals

are present, contact Support.

Alkalinity result of 0 ppm Usually due to an underfilled disk. Review the disk filling procedures

and test again. If problem persists,

contact Support.

Unexpected results Dirty disk cover Gently clean disk cover apertures

with pipe cleaner or lint free cloth.

Disk type is not an option

in Disk Series

Software or meter firmware is

out of date.

Update WaterLink Connect 2 at

softwarecenter.lamotte.com

High pH results Water sample temperature above

100 °F (38 °C) interferes with pH

reagent

For water samples over 100 °F

(38 °C) subtract 0.1 from pH result

or, for the most accurate result,

wait until water sample is below 90

°F (32 °C) to test

Disc not spinning Lid open, meter not powered on,

low battery, disk or disk cover

pressed down too tightly on hub

Close lid, power on meter, charge

the battery or plug meter into a

stable power source, remove the

disk/disk cover and place back in

the meter more gently

Fast electrical transients may

disrupt operation of the Spin

Touch meter

Restart the test to resume normal

operation

Test result value on the

display is red

Results are out of range of

reagent system

Dilute sample. Retest for out of

range test factor. (All factors

except pH.)

17

Trouble connecting to

Bluetooth device

Bluetooth not enabled

Too many Bluetooth devices near

the meter

Printer power is ON and Fast

Printer Connection is ON

Enable Bluetooth

Have only one device near the

meter

Turn printer power OFF. Or turn

Past Printer Connection OFF.

Trouble connecting to

computer by USB

Broken connection Press and hold power button for

1 second.

Results not printing Printer not on

The Waterlink Spin Touch will only

print to the BLE Mobile Printer

(5-0067)

Turn printer on

Connect to BLE Mobile Printer

(5-0067)

TROUBLESHOOTING WITH THE METER CHECK DISK

IMPORTANT!!

Do not attempt to separate the components of the Meter Check Disk (Code 1705/1705-

EU). The Meter Check Disk consists of a disk with a permanently attached cover. Do not

fill the Meter Check Disk with water. Water is not used in the Meter Check Disk.

CALIBRATION OPERATIONS

The Meter Check Disk (MCD) is used to perform two calibration operations – Check

Calibration and Start Calibration. The Start Calibration procedure should only be performed

if the meter fails the Check Calibration procedure.

Check Calibration

Meters are calibrated at the time of manufacture. However, it is possible for the calibration

settings to be lost due to power anomalies or other circumstances. The Meter Check Disk

is used in the Check Calibration procedure to determine whether the alignment of the hub

and disk are correct. For some meters, it also evaluates the brightness of the individual

LEDs.

1. Follow the CLEANING procedure to clean the light chamber and optic lenses.

2. From the main test page, tap to select Settings.

3. Tap Calibration.

4. Tap Check Calibration.

5. Remove the Meter Check Disk (Code 1705/1705-EU) from the foil pouch. DO NOT

remove the black cover from the disk. Insert the Meter Check Disk (MCD) into the

meter and close the lid.

6. Tap Start.

7. The meter will briefly spin. When it is complete, six channel values will be displayed.

Compare the displayed channel values to those printed on the MCD pouch. If the

displayed channel values are within the ranges provided on the Meter Check Disk

pouch, the meter is calibrated and performing normally. If the displayed channel

values are not within the ranges provided on the Meter Check Disk pouch, perform the

Start Calibration procedure.

NOTE: Range specifications are specific to the disk identified by the serial number

on the pouch. The range specifications will vary from disk to disk. The exact readings

from a specific disk may vary from meter to meter.

8. Tap to return to the test screen.

9. Remove the MCD from the meter and return to the foil pouch for storage.

18

Start Calibration

The Start Calibration procedure calibrates the alignment of the hub and disk for all meters

and sets the brightness of the individual LEDs for compatible meters. Before performing

this calibration procedure, run the Check Calibration procedure to determine whether the

meter is calibrated and operating normally. The Start Calibration procedure should only be

completed if the meter fails the Check Calibration procedure.

1. Follow the CLEANING procedure to clean the light chamber and optic lenses.

2. From the main test screen, tap to select Settings.

3. Tap Calibration.

4. Tap Start Calibration.

5. Remove the Meter Check Disk (Code 1705) from the foil pouch. DO NOT remove the

black cover from the disk. Insert the Meter Check Disk. Close the lid.

6. Tap Start.

7. When the calibration is complete the message “Angle Calibration Successful” will

appear. Meters that can also perform an LED calibration will display “LED Calibration

Successful”.

8. Tap to return to the test screen.

Angle Calibration checks the alignment of the hub and disk. The LED Calibration sets

the brightness of the individual LEDs. The results are reported as pass or fail. If the

measurements pass, the settings will be saved, and the meter is calibrated. If the analysis

fails, contact Support.

email: [email protected]

phone: 800-344-3100 option 3 | Mon-Fri 9am-5pm EST

HELPFUL HINTS

¬Do not touch top or bottom of disk. Handle disk by the edge.

¬Do not fill disk while in the meter. Fill disk on clean, dry surface.

¬Fill the disk on a dark surface to more easily see the sample water.

¬The disk should not contain any large air bubbles. Air bubbles will result in erroneous

results.

¬Only the Universal Disk Cover (Code 1719) can be used with the Waterlink Spin

Touch.

¬Empty syringe of old sample before filling with next sample.

¬Remove filled disk from meter after testing. Do not travel with filled disks in meter.

They may leak.

¬Keep the chamber clean and dry. Gently swab LED and photodiode lenses located

around the hub with a cotton swab dampened with streak-free window cleaner. Do

not use alcohol. It will leave a thin film over the lenses when dry.

¬Hold syringe vertically when filling disks.

¬Store disks at 70°-80°F/21°-27°C.

MAINTENANCE

CLEANING

The optical system of the Waterlink Spin Touch must be kept clean and dry for optimal

performance. Dry the disk with a lint-free wipe before placing it into the chamber to avoid

introducing moisture. For best results, store the instrument in an area that is dry and free

19

from aggressive chemical vapors. Clean the exterior housing with a damp, lint-free cloth.

Do not allow water to enter the light chamber or any other parts of the meter. To clean the

light chamber and optic lenses, point a can of compressed air into the light chamber and

the lid and blow the pressurized air into the light chamber and lid. Focus the pressurized

air around the LEDs which are the small round lenses positioned at 2:00, 4:00, 6:00, 8:00,

10:00 and 12:00 in the lid. The photodiodes are located on the bottom of the chamber

around the hub. This area must be kept clean and dry. Use a cotton swab dampened with

streak-free window cleaner to gently swab the LED and photodiode lenses. Do not use

alcohol; it will leave a thin residue over the optics when dry.

Remove smudges due to routine use from the touchscreen with the Cloth Wipe (Code

3580-WIPE). Use a cloth dampened with alcohol for more thorough cleaning when

necessary. Do not use Windex®window cleaner, or similar cleaners, on the touchscreen.

RETURNS

Should it be necessary to return the meter, pack the meter carefully in a suitable container

with adequate packing material. A return authorization number must be obtained from

LaMotte Company by calling 800- 344-3100, ext. 3 (US only) or 410-778-3100, ext. 3,

be resolved over the phone or by email. If a return of the meter is necessary, attach a letter

with the return authorization number, meter serial number, a brief description of problem

and contact information including phone and FAX numbers to the shipping carton.

METER DISPOSAL

Waste Electrical and Electronic Equipment (WEEE)

Natural resources were used in the production of this equipment. This equipment may

contain materials that are hazardous to health and the environment. To avoid harm to

the environment and natural resources, the use of appropriate take-back systems is

recommended. The crossed out wheeled bin symbol on the meter encourages the use of

these systems when disposing of this equipment.

Take-back systems will allow the materials to be reused or recycled in a way

that will not harm the environment. For more information on approved

collection, reuse, and recycling systems contact local or regional waste

administration or recycling services. Do not incinerate the equipment.

DISK DISPOSAL

The disks cannot be reused. Over time, the water in reacted disks will evaporate. Disks

can be recycled. Warning: Recyclers should check with the local authorities. Some states

may require that no chemical residue remains on the plastic or may not be able to accept

plastic waste with stainless steel mixing beads. Used disks may be returned, at the

customer’s expense, to LaMotte for recycling.

GENERAL INFORMATION

PACKAGING AND RETURNS

Experienced packaging personnel at LaMotte Company assure adequate protection

against normal hazards encountered in transportation of shipments. After the product

leaves the manufacturer, all responsibility for its safe delivery is assured by the

transportation company. Damage claims must be filed immediately with the transportation

company to receive compensation for damaged goods. Should it be necessary to return

the instrument, pack the instrument carefully in a suitable container with adequate

packing material. A return authorization number must be obtained from LaMotte Company

20

by calling 1-800-344-3100 or 1-410-778-3100, ext. 3 or emailing softwaresupport@

lamotte.com. Attach a letter with the authorization number to the shipping carton which

describes the kind of trouble experienced.

GENERAL PRECAUTIONS

Read the instruction manual before attempting to set up or use the instrument. Failure

to do so could result in personal injury or damage to the meter. The Waterlink Spin Touch

should not be stored or used in a damp or excessively corrosive environment. Care should

be taken to prevent water or reagents from entering the photometer chamber. Wet disks

should never be put into the photometer chamber.

SAFETY PRECAUTIONS

Read the safety precautions on the labels of all reagent containers and packaging prior to

use. Safety Data Sheets (SDS) can be found at www.lamotte.com. Additional emergency

information for all LaMotte reagents is available 24 hours a day from the National Poison

Control Center at 1-800-222-1222 or by contacting the 24 hour emergency line for

ChemTel at 1-800-255-3924 (USA, Canada, Puerto Rico). For locations outside of the

North American continent call 813-248-0585 collect.

Ensure that the protection provided by this equipment is not impaired. Do not install or use

this equipment in a manner that is not indicated in this manual.

LIMITS OF LIABILITY

Under no circumstances shall LaMotte Company be liable for loss of life, property, profits,

or other damages incurred through the use or misuse of its products.

CE MARK

The WaterLink Spin Touch meter has been independently tested and has earned the

European CE Mark of compliance for electromagnetic compatibility and safety. To view

certificates, go to the LaMotte website at www.lamotte.com.

This device complies with Part 15 of the FCC rules. Operation is subject to the following

two conditions (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

Note: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

residential environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

¬Reorient or relocate the receiving antenna.

¬Increase the separation between the equipment and receiver.

¬Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

¬Consult the dealer or an experienced radio/TV technician for help.

Other manuals for SpinTouch BC

1

This manual suits for next models

1

Table of contents

Other WaterLink Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Larson Davis

Larson Davis 820 Technical reference manual

Hanna Instruments

Hanna Instruments HI706 instruction manual

Klein Tools

Klein Tools RT390 instruction manual

HK Instruments

HK Instruments DPG Series installation instructions

Teledyne Lecroy

Teledyne Lecroy Frontline SD quick start guide

GREISINGER

GREISINGER GIR 230 FR manual