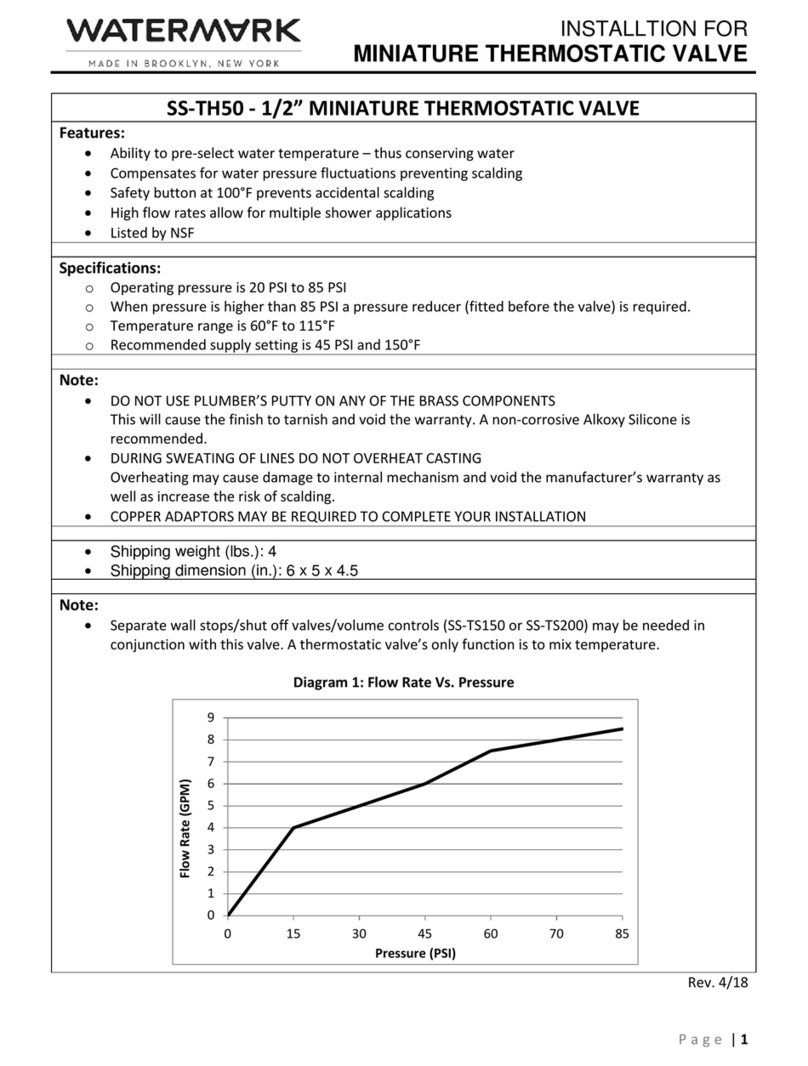

Watermark SS-TH60 User manual

This manual suits for next models

2

Table of contents

Other Watermark Control Unit manuals

Popular Control Unit manuals by other brands

ABB

ABB Relion 615 series installation manual

National Instruments

National Instruments NI 9207E Operating instructions and specifications

Quectel

Quectel FC909A manual

Entron

Entron EN1000 Cascade-FP (SCR) Application note

Crestron

Crestron BiAmp AudiaFlex quick start guide

Honeywell

Honeywell BRAUKMANN SG 162 installation instructions

ASO Safety Solutions

ASO Safety Solutions DRICO slife 150 FU 12 operating manual

DeZurik

DeZurik PEF Installation and operation manual

Pickering

Pickering SYSTEM 10 user manual

Morrison Bros. co.

Morrison Bros. co. 246 Series Installation & maintenance instructions

Emerson

Emerson Fisher 92B installation guide

Fortin

Fortin MS3 install guide

Hi-Link

Hi-Link HLK-LD2410 manual

Heliodyne

Heliodyne Delta T Pro installation guide

Lutron Electronics

Lutron Electronics GRAFIK Eye QS Quick installation and operation guide

Honeywell

Honeywell SmartPAC 2 user manual

Emerson

Emerson Fisher Vee-Ball V150 instruction manual

maxxess

maxxess eMAX-MR51e Installation Guide and Specifications