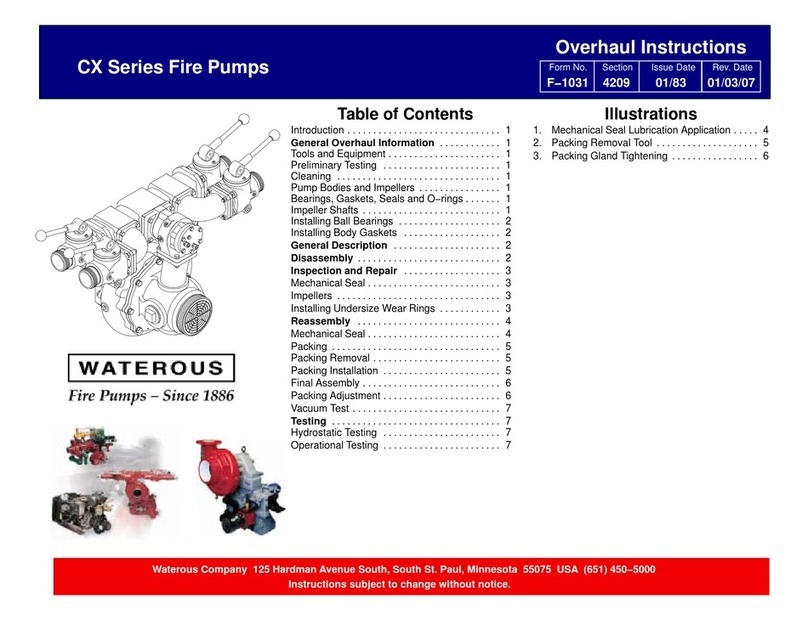

Introduction

This instruction contains the information needed for operation and maintenance of CX Series centrifugal pumps. Since

there are several types of transmissions available for these pumps, they are covered in separate instructions.

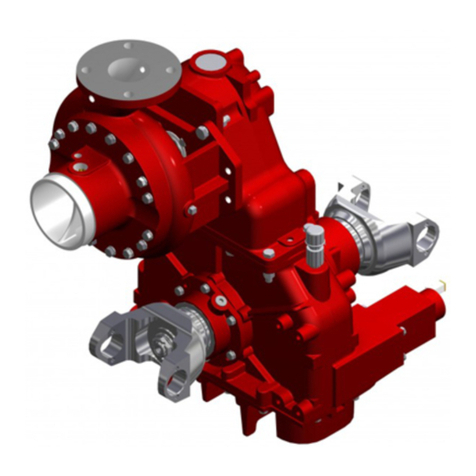

GeneralDescription

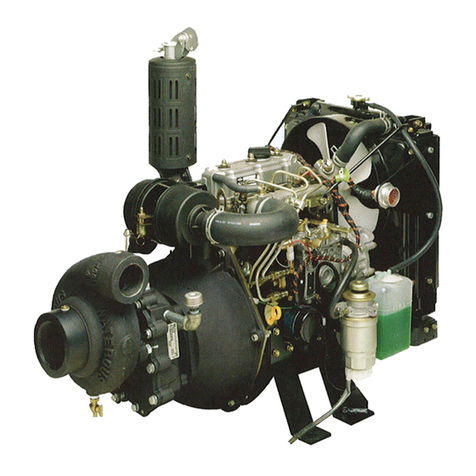

The CX series pumps are single stage centrifugal pumps.

Depending on the type of transmission used, the pump

may be

used as a front-mounted pump (driven from the

engine

crankshaft), power take-off driven, direct-engine

driven

(bellhousing mounted) or midship mounted. They

are available

in capacities up to 1250 gpm (4750 l/m).

OPERATION LIMITS: Do not operate pump beyond max. pressure (350 psi) or max. speed (5200 rpm).

Fail to do that may result in personal injury or premature pump failure.

Body Assembly

Components

Impeller Shaft Assembly

This assembly includes the body, head, intake adapter

and

related parts. The body and adapters are either cast

iron or

bronze.

Heater Jacket (CXR Only)

A heater jacket consists of two 1/2” NPT tapped holes in

the

intake adapter. This allows a piping connection from

the engine

coolant system to connect to the tapped holes.

Engine coolant

then flows through a hollowed out area in

the intake adapter.

The engine coolant helps prevent the

water flowing into the

pump from freezing.

This assembly consists of a bronze impeller mounted on a

stainless steel shaft, wear rings, mechanical seal or pack-

ing

and related parts. The impeller is balanced and the im-

peller

shaft is supported by ball bearings.

Mechanical Seal

The mechanical seal consists of a flat, highly polished

(lapped), spring-fed carbon ring that is sealed to and ro-

tates

with the impeller shaft. It presses against a highly

polished

(lapped) stainless steel, stationary ring that is

sealed in the

pump head. This seals the shaft and pre-

vents air from

entering and water from leaving. A me-

chanical seal does

not leak or drip water, even when

pumping.

Intake Screens

Options

consistently outwear hard chrome plating, tool steel and

solid

tungsten carbide.

Zinc die cast screens are normally used in the intake fit-

tings, with brass screens available optionally. Although

the

screens are chemically treated (coated) to inhibit cor-

rosion,

the water being pumped may still corrode the

screens. Such

corrosion is ‘‘sacrificial’’; that is, it will help

prevent corrosion in

the rest of the pump the same way

the magnesium anodes

protect the metal parts of a water

heater.

Anodes

As additional corrosion protection for iron body pumps,

Waterous has anodes available to fit any unused opening in the

intake fitting.. Anodes provide an additional

sacrificial surface to

the water to supplement the intakescreens.

Flame Plated Impellers

Approximately 75% of the pump wear due to pumping

sand,

occurs on the impeller hubs. For this reason, the

Waterous

Company adopted the policy of offering a flame

plated impeller

as an option. The flame plating process

consists of adding

tungsten carbide to the surfaces to be

protected from wear.

This unique process produces ex-

tremely hard, well bonded,

wear resistant coatings which

Overheat Protection Manager (OPM)

The Overheat Protection Manager (OPM) acts as a safety

device by releasing hot water to the ground or back to the

water

tank from the discharge area of the pump.

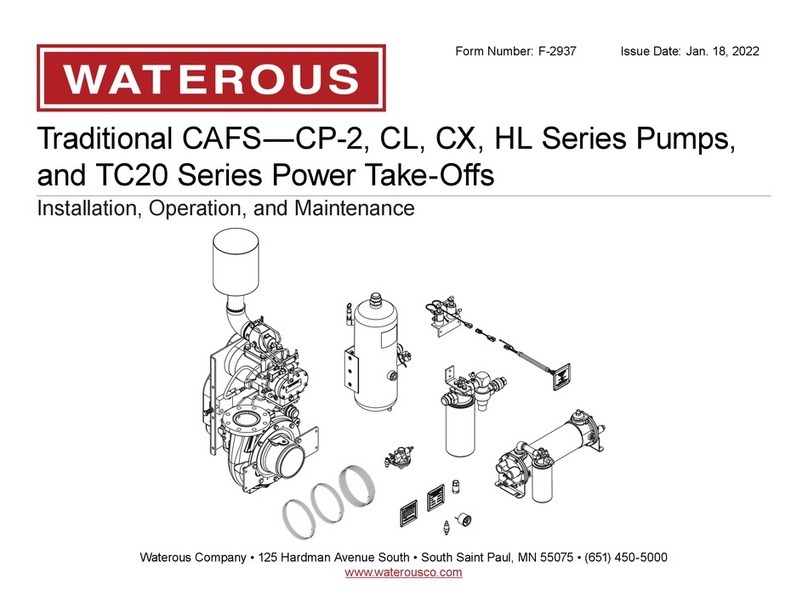

Monarch Intake Valve

The Monarch intake valve is a package including an extra

short

intake fitting, an intake butterfly valve and an intake

nipple with

integral relief valve mounting pad, all designed

to fit behind the

pump panel. The Monarch intake valve

also features a provision

for a pre-valve relief valve and

choice of manual worm gear or

pneumatic actuator. For

operation and maintenance instructions

for the Monarch

intake valve, see the following instructions:

•

F-1031, Section 2318, Operation, Maintenance and

Installation Instructions for Butterfly Valves

•

F-1031, Section 2319, Operation, Maintenance and

Installation Instructions for Butterfly Valve Pneumatic

Actuator