Introduction

This instruction contains the information needed for operation and maintenance of CZ Series centrifugal pumps.

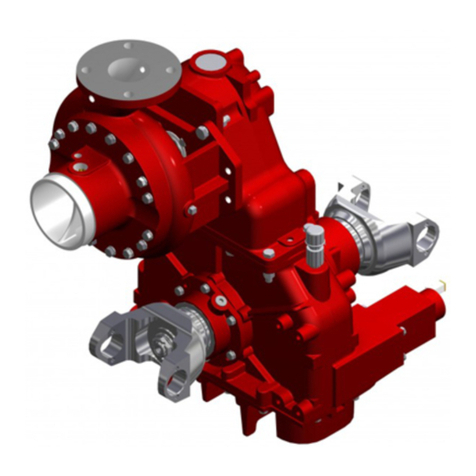

General Description

The CZ Series centrifugal fire pumps are direct−drive, single stage, vertically−split and designed to operate from a water tank,

hydrant or from draft. CZ Series pumps are equipped with a 5” intake and are capable of pumping 950 gpm at 260 psi (3600

l/m @ 18 bar). CZU Series pumps are equipped with a 6” intake and are capable of pumping 1500 gpm at 250 psi (5675 l/m

@ 17.3 bar).

OPERATION LIMITS: Do not operate pump beyond max. pressure (350 psi) or max. speed (4000 rpm for CZ; 4200

rpm for CZU).

Fail to do that may result in personal injury or premature pump failure.

Body Assembly Components

tates with the impeller shaft. It presses against a highly

polished (lapped), silicone carbide, stationary ring that is

This assembly includes the body, intake and discharge

adapters, bearing housing and related parts. The body

and adapters are either cast iron or bronze.

Impeller Shaft Assembly

This assembly consists of a bronze impeller mounted on a

stainless steel shaft with wear rings, mechanical seal and

related parts. The impellers are balanced and the impeller

shaft is supported by ball bearings.

Mechanical Seals

CZ

The mechanical seal consists of a flat, highly polished

(lapped), spring−fed carbon ring that is sealed to and ro-

sealed in the pump body. This seals the shaft and pre-

vents air from entering and water from leaving. A mechan-

ical seal does not leak or drip water, even when pumping.

CZU

The mechanical seal consists of a flat, highly polished

(lapped), spring−fed carbon ring that is seated in the pump

volute. It presses against a highly polished (lapped),

stainless steel ring that is seated in and rotates with the

impeller. This seals the shaft and prevents air from enter-

ing and water from leaving. Additional O−rings around the

washer help keep the shaft dry during pump operation. A

mechanical seal does not leak or drip water, even when

pumping.

Intake Screens Options

Anodes

Zinc die cast screens are normally used in the intake fit-

tings, with brass screens available optionally. Although the

screens are chemically treated (coated) to inhibit corro-

sion, the water being pumped may still corrode the

screens. Such corrosion is ‘‘sacrificial’’; that is, it will help

prevent corrosion in the rest of the pump the same way

the magnesium anodes protect the metal parts of a water

heater.

As additional corrosion protection for iron body pumps,

Waterous has anodes available to fit any unused opening

in the intake fitting. Anodes provide an additional sacrificial

surface to the water to supplement the intake screens.

Overheat Protection Manager (OPM)

The Overheat Protection Manager (OPM) acts as a safety

device by releasing hot water to the ground or back to the

water tank from the discharge area of the pump.

Figure 1. CZ Series Fire Pumps Figure 2. CZU Series Fire Pumps

IL 1624 IL 1625