Waters e-SAT/IN User manual

Waters e-SAT/IN Module

Installation Guide

71500049404/Revision C

Copyright © Waters Corporation 2002−2014

All rights reserved

ii

Copyright notice

© 2002−2014 WATERS CORPORATION. PRINTED IN THE UNITED

STATES OF AMERICA AND IN IRELAND. ALL RIGHTS RESERVED. THIS

DOCUMENT OR PARTS THEREOF MAY NOT BE REPRODUCED IN ANY

FORM WITHOUT THE WRITTEN PERMISSION OF THE PUBLISHER.

The information in this document is subject to change without notice and

should not be construed as a commitment by Waters Corporation. Waters

Corporation assumes no responsibility for any errors that may appear in this

document. This document is believed to be complete and accurate at the time

of publication. In no event shall Waters Corporation be liable for incidental or

consequential damages in connection with, or arising from, its use.

Trademarks

Waters is a registered trademark of Waters Corporation, and e-SAT/IN,

Empower, SAT/IN and “THE SCIENCE OF WHAT’S POSSIBLE.” are

trademarks of Waters Corporation.

Other registered trademarks or trademarks are the sole property of their

owners.

iii

Customer comments

Waters’ Technical Communications department invites you to tell us of any

errors you encounter in this document or to suggest ideas for otherwise

improving it. Please help us better understand what you expect from our

documentation so that we can continuously improve its accuracy and

usability.

We seriously consider every customer comment we receive. You can reach us

Contacting Waters

Contact Waters®with enhancement requests or technical questions regarding

the use, transportation, removal, or disposal of any Waters product. You can

reach us via the Internet, telephone, or conventional mail.

Safety considerations

Some reagents and samples used with Waters instruments and devices can

pose chemical, biological, and radiological hazards. You must know the

potentially hazardous effects of all substances you work with. Always follow

Waters contact information

Contacting medium Information

Internet The Waters Web site includes contact

information for Waters locations worldwide.

Visit www.waters.com.

Telephone and fax From the USA or Canada, phone 800

252-HPLC, or fax 508 872 1990.

For other locations worldwide, phone and fax

numbers appear in the Waters Web site.

Conventional mail Waters Corporation

34 Maple Street

Milford, MA 01757

USA

iv

Good Laboratory Practice, and consult your organization’s safety

representative for guidance.

Safety advisories

Consult Appendix A for a comprehensive list of warning and caution

advisories.

Operating this instrument

When operating this instrument, follow standard quality-control (QC)

procedures and the guidelines presented in this section.

Applicable symbols

Audience and purpose

This document describes the installation of the e-SAT/IN module. It is

intended is intended to be used by qualified operators, installation engineers,

and field service engineers.

Symbol Definition

Manufacturer

Authorized representative of the European

Community

Confirms that a manufactured product complies

with all applicable European Community

directives

Australia C-Tick EMC Compliant

Confirms that a manufactured product complies

with all applicable United States and Canadian

safety requirements

Consult instructions for use

v

Intended use of the Waters e-SAT/IN module

Waters designed the e-SAT/IN module to translate analog signals to digital

signals for data collection. You can operate the device with instruments used

to analyze various types of compounds. The e-SAT/IN module is for research

use only.

Calibrating

To calibrate LC systems, follow acceptable calibration methods using at least

five standards to generate a standard curve. The concentration range for

standards should include the entire range of QC samples, typical specimens,

and atypical specimens.

When calibrating mass spectrometers, consult the calibration section of the

operator’s guide for the instrument you are calibrating. In cases where an

overview and maintenance guide, not operator’s guide, accompanies the

instrument, consult the instrument’s online Help system for calibration

instructions.

Quality-control

Routinely run three QC samples that represent subnormal, normal, and

above-normal levels of a compound. Ensure that QC sample results fall within

an acceptable range, and evaluate precision from day to day and run to run.

Data collected when QC samples are out of range might not be valid. Do not

report these data until you are certain that the instrument performs

satisfactorily.

ISM classification

ISM Classification: ISM Group 1 Class B

This classification has been assigned in accordance with CISPR 11 Industrial

Scientific and Medical (ISM) instruments requirements. Group 1 products

apply to intentionally generated and/or used conductively coupled

radio-frequency energy that is necessary for the internal functioning of the

equipment. Class B products are suitable for use in both commercial and

residential locations and can be directly connected to a low voltage,

power-supply network.

vi

EC authorized representative

Waters Corporation

Stamford Avenue

Altrincham Road

Wilmslow SK9 4AX UK

Telephone: +44-161-946-2400

Fax: +44-161-946-2480

Contact: Quality manager

Table of Contents vii

Copyright notice ................................................................................................... ii

Trademarks ............................................................................................................ ii

Customer comments ............................................................................................ iii

Contacting Waters ............................................................................................... iii

Safety considerations .......................................................................................... iii

Safety advisories................................................................................................. iv

Operating this instrument ................................................................................. iv

Applicable symbols ............................................................................................. iv

Audience and purpose......................................................................................... iv

Intended use of the Waters e-SAT/IN module.................................................... v

Calibrating ........................................................................................................... v

Quality-control ..................................................................................................... v

ISM classification .................................................................................................. v

ISM Classification: ISM Group 1 Class B .......................................................... v

EC authorized representative ........................................................................... vi

1 Introduction ............................................................................................ 1-1

About the e-SAT/IN module ............................................................................ 1-2

Features .............................................................................................................. 1-3

Baseline noise .................................................................................................. 1-3

Sampling rates ................................................................................................. 1-3

Ethernet I/O connection .................................................................................. 1-4

Analog to digital conversion ............................................................................ 1-4

BCD input ........................................................................................................ 1-5

Programmable event outputs.......................................................................... 1-6

Power-on self-tests........................................................................................... 1-6

IP address sequence......................................................................................... 1-6

External power supply..................................................................................... 1-7

Table of Contents

viii Table of Contents

2 Installing the Module ............................................................................ 2-1

Selecting the site ............................................................................................... 2-2

Making electrical connections ....................................................................... 2-2

Installing the network interface card .......................................................... 2-2

Ethernet connections ....................................................................................... 2-3

Single e-SAT/IN module connection ............................................................... 2-3

Multiple e-SAT/IN connections ....................................................................... 2-4

Network installation guidelines...................................................................... 2-4

Integrating an e-SAT/IN module to an existing busSAT/IN system............. 2-6

Connecting analog cables ............................................................................... 2-7

Connecting event cables .................................................................................. 2-8

Event in connections........................................................................................ 2-8

Event out connections...................................................................................... 2-8

Event in and out signal assignments.............................................................. 2-8

Connecting the BCD cable ............................................................................ 2-10

Connecting the power supply ...................................................................... 2-11

3 Using the e-SAT/IN Module .................................................................. 3-1

Powering on the module ................................................................................. 3-2

e-SAT/IN module self-tests.............................................................................. 3-2

Configuring the e-SAT/IN module ................................................................. 3-3

Creating a chromatography system................................................................ 3-3

Configuring Empower software for the e-SAT/IN module............................. 3-3

Smoothing noise in Empower........................................................................ 3-15

Troubleshooting .............................................................................................. 3-17

Power-on problems......................................................................................... 3-18

System troubleshooting ................................................................................. 3-18

When to call Waters technical service .......................................................... 3-19

Error messages .............................................................................................. 3-20

A Safety Advisories .................................................................................. A-1

Table of Contents ix

Warning symbols ............................................................................................... A-2

Task-specific hazard warnings........................................................................ A-2

Specific warnings ............................................................................................. A-3

Caution symbol .................................................................................................. A-5

Warnings that apply to all Waters instruments ......................................... A-6

Electrical and handling symbols ................................................................. A-11

Electrical symbols .......................................................................................... A-11

Handling symbols .......................................................................................... A-12

B Specifications ........................................................................................ B-1

C Spare Parts ............................................................................................ C-1

Index ..................................................................................................... Index-1

x Table of Contents

1-2 Introduction

About the e-SAT/IN module

The Waters e-SAT/IN (Ethernet-SATellite INterface) module is a single-time

base, dual-channel, analog-to-digital (A/D) converter. A data acquisition

system (Empower™) can collect data from either a single channel or both

analog channels. The data start and stop times are identical for both channels.

The e-SAT/IN module uses a dedicated local area network (LAN) to

communicate to the chromatography data acquisition computer. You can

control the e-SAT/IN module using Waters Empower software.

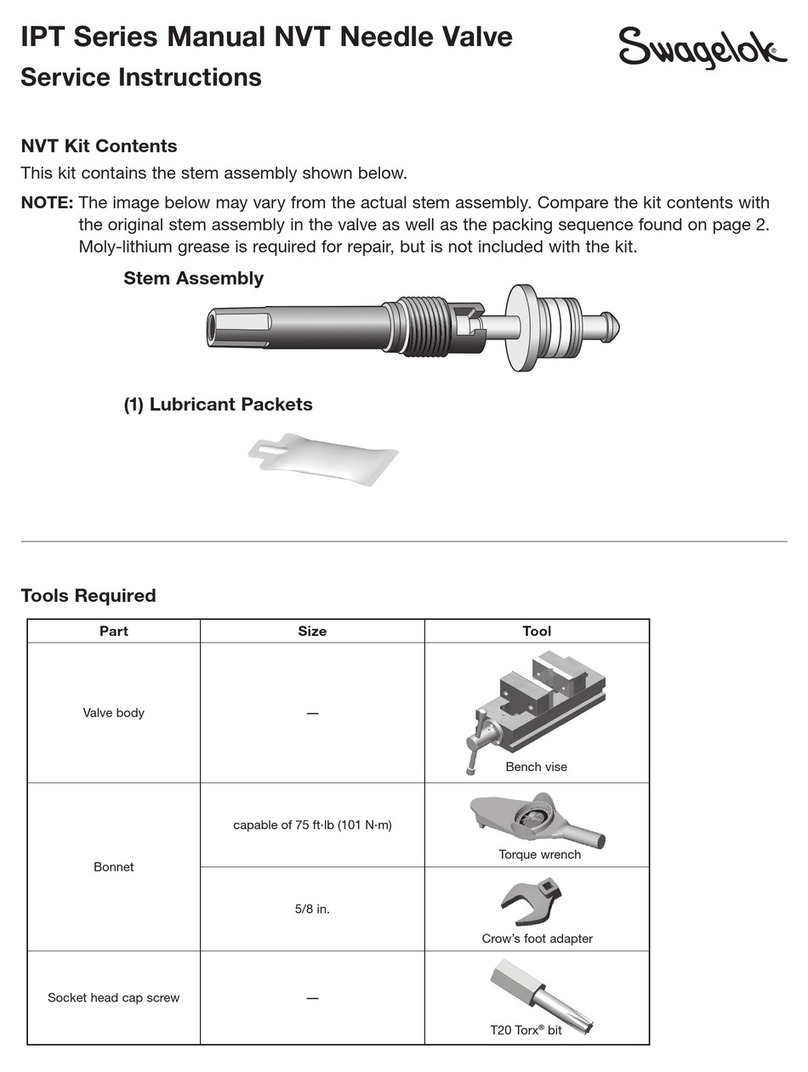

e-SAT/IN module, front view

The e-SAT/IN module provides the following:

• Software-selectable setting for local power line input frequency (50 or 60

Hz).

• Fixed data acquisition rates at 50 or 60 Hz from 2 to 480 samples per

second (Hz). Refer to the table titled “AC line frequency sampling rates”

on page 1-4 for specific sampling rates.

• Up to 24-bits of A/D conversion, depending on the sampling rate.

CHANNEL2

POWER

DATA

10

Waters

e-SAT/IN

CHANNEL1

Power

switch

LEDsAnalog

inputs

I/O connector

RELAY

TTL1

TTL2

INJ

START

Features 1-3

• Internal storage buffer (225 K) with a capacity of 1 minute of data when

both channels are operating at a data rate of 100 samples per second.

• One Ethernet 10 base-T connector for communication.

• Two analog data input channels.

• One BCD input port.

• Three programmable event outputs. Two use TTL and one uses relay

event output.

• Self-test and internal calibration at power-on.

• Power-on self-test status indicator (LED).

• Data status indicator (LED).

• Dedicated external voltage autosensing power supply.

Features

This section describes the features of the e-SAT/IN module.

Baseline noise

As analysis times decrease, higher data sampling rates are required to

accommodate narrower peaks. The e-SAT/IN module features new technology

and a design that reduces chromatographic baseline noise at all its sampling

rates.

Chromatography data requirements have advanced allowing shorter run

times, higher data rates, and lower limits of detection. Technological advances

with the latest A/D converters and surface-mounted device design have shown

that noise can be significantly reduced at higher data rates if the data

sampling rate is synchronized to the “local” power line input frequency. For

optimum performance, you must select a line frequency, then select a data

rate from a list of values appropriate to the line frequency.

Sampling rates

To minimize baseline noise, you can optimize sampling rates to the frequency

of the local power line environment, either 50 or 60 Hz.

The Instrument Method Editor contains a field to select the power line

frequency. This value does not affect the actual power (line frequency)

1-4 Introduction

supplied to the instrument, but will allow you to select optimum sampling

rates that are set to the selected frequency.

When using data rates above 10 samples per second, a method developed for

use throughout global locations where power source frequencies differ can be

optimized so that either:

• The method is the same in all geographies, but may have slightly higher

baseline noise in some areas.

• The method has the lowest baseline noise in all geographies, but will

require different sampling rates.

Ethernet I/O connection

The Waters e-SAT/IN module connects to a chromatography data system

using a 10 base-T Ethernet interface to a dedicated local area network (LAN).

Ethernet allows for the use of long cables (when required) and eliminates the

need for proprietary interface hardware beyond the dedicated Ethernet card

(network interface card) within the acquisition computer.

Analog to digital conversion

Most detectors provide an analog output that must be converted to digital

format to be read by a chromatography data acquisition system. Analog

signals from different detectors can vary in size, shape, and rate. The

AC line frequency sampling rates

50−Hz AC Line Frequency 60−Hz AC Line Frequency

400 (samples per second) 480 (samples per second)

200 240

100 120

50 60

25 30

12.5 15

10 10

55

22

Features 1-5

e-SAT/IN module provides up to 24-bits of A/D conversion (depending on the

sampling rate).

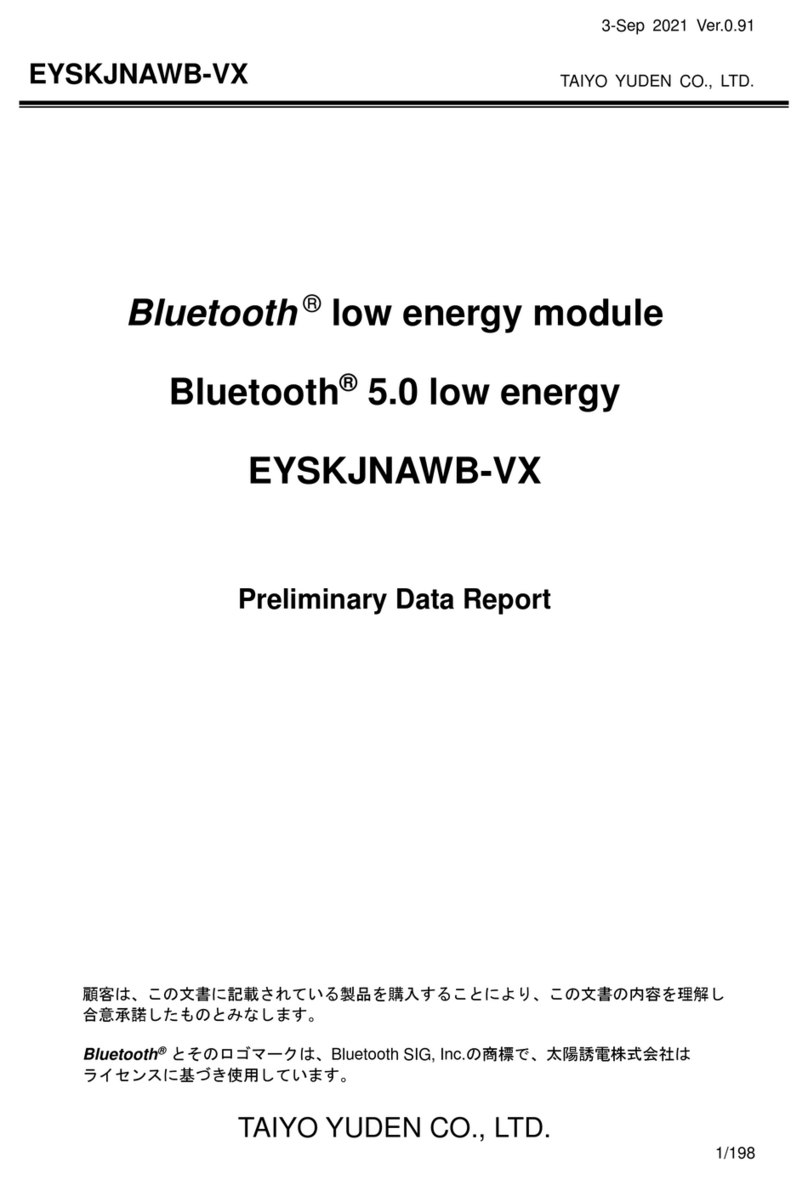

Analog input channels

The analog input channels of the e-SAT/IN module receive analog signals from

the detector. This analog signal is converted to digital data. The digital data

signal is bundled into a data packet and sent using Ethernet to the acquisition

computer as shown in the figure below.

Signal flow

BCD input

The BCD (binary coded decimal) input records the BCD output from

chromatography autosamplers. Many chromatography autosamplers have

BCD output capability to document the vial number of the injection that was

made. Binary coded decimal input signals numbered 0 to 99 are bundled into

the data packet and sent using Ethernet to the acquisition computer. The

autosampler output should be compatible with the e-SAT/IN BCD input

configuration. Refer to page 2-10, and the table titled “BCD connection

assignments” on page 2-11.

Detector

e-SAT/IN

A / D

Acquisition

module

Ethernet

Digital data

D

computer

Analog

Waters 2487

Dual l Absorbance Detector

Detector

signal

Keyboard

Monitor Mouse

CPU

packet

1-6 Introduction

Programmable event outputs

The e-SAT/IN module provides three programmable event outputs as shown

in the table below

Each event channel can be programmed to one of the following states:

•On

•Off

• Pulse (a single pulse during run time)

• Repetitive pulse (repeated pulses with a programmable frequency

during run time)

Tip: The default pulse interval is .02 minutes. When Pulse or Repetitive pulse

is selected, the interval can be set from .02 to 100 minutes.

Power-on self-tests

After powering on the e-SAT/IN module, it performs self-tests to determine

that the unit is functional. When the power-on self-test sequence is completed

successfully, the green LED indicator shows that the unit is requesting an IP

address. Refer to page 3-2 for indicator details.

IP address sequence

The green LED indicator shows that the e-SAT/IN module is requesting IP

configuration information by blinking. After the module receives its IP

configuration information, the LED remains on and the e-SAT/IN module is

ready for use. Refer to page 3-2 for indicator details.

Programmable event channels

Programmable

event channel Trigger methods

Reference voltage

High (ON) Low (OFF)

Relay Solid-state relay N/A N/A

TTL1 TTL >3.5 Vdc <0.8 Vdc

TTL2 TTL >3.5 Vdc <0.8 Vdc

Features 1-7

External power supply

The Waters e-SAT/IN module uses an external power supply that is provided

with the device. The power supply automatically adjusts to the AC input line

voltage, and provides the proper DC voltage to the e-SAT/IN module. A

separate AC power supply cable is provided for the country in which it will be

installed.

The DC power cable connector is designed with a locking mechanism that

latches to the power input connector in the e-SAT/IN module. This eliminates

accidental disconnection of the power cable during operation. You must

mechanically unlatch the connector when disconnecting it. Refer to the figure

“e-SAT/IN module and power supply kit” on page 2-12.

Caution:

• Failure to unlatch the DC power connector before disconnecting can

damage the connector.

• Use only a Waters e-SAT/IN power supply module to power your

e-SAT/IN module. Substitute power supplies can damage the

e-SAT/IN module and void your warranty.

1-8 Introduction

2-1

2Installing the Module

This chapter provides information you need to install a single e-SAT/IN

module or a multiple e-SAT/IN system.

Contents

Topic Page

Selecting the site 2-2

Making electrical connections 2-2

Installing the network interface card 2-2

Connecting analog cables 2-7

Connecting event cables 2-8

Connecting the BCD cable 2-10

Connecting the power supply 2-11

2-2 Installing the Module

Selecting the site

Install the e-SAT/IN module in a laboratory location that meets the following

conditions:

• Install the e-SAT/IN module up to 100 meters (320 feet) from the

acquisition computer or the Ethernet switch.

• Locate the e-SAT/IN module within 2 meters (6.6 feet) (maximum

analog cable length) from the detector(s) to which it is to be connected.

• Locate the e-SAT/IN module within 1.5 meters (4.9 feet) (maximum BCD

cable length) from the autosampler to which it is to be connected.

• Do not install the e-SAT/IN module and the associated network

components where they can be subjected to fluidic leaks.

• Do not install the e-SAT/IN module close to devices that emit high levels

of electromagnetic interference (EMI) or radio frequency

interference (RFI).

• Use only grounded AC power receptacles to turn on the e-SAT/IN

module power supply.

• When using an Ethernet switch (multiple-connection terminal) in a

multiple-module system configuration, set the Ethernet switch in a

central physical location within the system.

• Install the e-SAT/IN modules in an equipment rack using DIN rails.

Making electrical connections

For proper operation, system instrumentation always requires a properly

grounded AC power supply with no abrupt voltage fluctuations. A power

conditioning device may be required for microprocessor-controlled devices

when the voltage source is unstable. Contact your Waters Technical

Representative for advice.

Installing the network interface card

The network interface card (NIC) is used to communicate with the e-SAT/IN

module. The card must be addressed properly to allow communications to

become established between the acquisition computer and the e-SAT/IN

module.

Table of contents

Other Waters Control Unit manuals

Popular Control Unit manuals by other brands

YASKAWA

YASKAWA DO-A3 installation manual

Crow

Crow CRRSI01 Installation & user guide

herdstar

herdstar Bintrac Installation and operation manual

PR electronics

PR electronics 9410 Series manual

Balluff

Balluff BNI IOL-302-S02-Z012-C11 user guide

Tectronix Systems

Tectronix Systems Genius operating instructions