Waters Alliance e2695 Manual

Waters Alliance e2695

Separations Module

Operator’s Guide

715003794

Revision C

Copyright © Waters Corporation 2018

All rights reserved.

February 27, 2018, 715003794 Rev. C

Page ii

February 27, 2018, 715003794 Rev. C

Page iii

General Information

Copyright notice

© 2008 – 2018 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF AMERICA

AND IN IRELAND. ALL RIGHTS RESERVED. THIS DOCUMENT OR PARTS THEREOF MAY

NOT BE REPRODUCED IN ANY FORM WITHOUT THE WRITTEN PERMISSION OF THE

PUBLISHER.

The information in this document is subject to change without notice and should not be construed

as a commitment by Waters Corporation. Waters Corporation assumes no responsibility for any

errors that may appear in this document. This document is believed to be complete and accurate

at the time of publication. In no event shall Waters Corporation be liable for incidental or

consequential damages in connection with, or arising from, its use. For the most recent revision of

this document, consult the Waters Web site (www.waters.com).

Trademarks

Waters, “THE SCIENCE OF WHAT’S POSSIBLE.”, Alliance, Empower, and Waters Quality Parts

are registered trademarks of Waters Corporation, and LACE/E, PerformancePLUS, and SAT/IN

are trademarks of Waters Corporation.

Fluorinert is a registered trademark of Solvay S.A.

Fluoroloy is a registered trademark of Saint-Gobain S.A.

Fomblin is a registered trademark of Solvay S.A.

Galden is a registered trademark of Solvay S.A.

Tefzel is a registered trademark of E. I. du Pont de Nemours and Company or its affiliates.

SealTight is a trademark of Upchurch Scientific, Inc. (IDEX Corporation).

Teflon is a trademark of The Chemours Company.

Triton is a trademark of Sigma-Aldrich Corporation.

Other registered trademarks or trademarks are the sole property of their owners.

February 27, 2018, 715003794 Rev. C

Page iv

Customer comments

Waters’ Technical Communications organization invites you to report any errors that you

encounter in this document or to suggest ideas for otherwise improving it. Help us better

understand what you expect from our documentation so that we can continuously improve its

accuracy and usability.

We seriously consider every customer comment we receive. You can reach us at

Contacting Waters

Contact Waters with enhancement requests or technical questions regarding the use,

transportation, removal, or disposal of any Waters product. You can reach us via the Internet,

telephone, or conventional mail.

Safety considerations

Some reagents and samples used with Waters instruments and devices can pose chemical,

biological, or radiological hazards (or any combination thereof). You must know the potentially

hazardous effects of all substances you work with. Always follow Good Laboratory Practice, and

consult your organization’s standard operating procedures.

Safety hazard symbol notice

Documentation needs to be consulted in all cases where the symbol is used to find out the

nature of the potential hazard and any actions which have to be taken.

Waters contact information

Contacting medium Information

Internet The Waters Web site includes contact information for Waters

locations worldwide. Visit www.waters.com.

Telephone and fax From the USA or Canada, phone 800-252-4752, or

fax 508-872-1990.

For other locations worldwide, phone and fax numbers appear in

the Waters Web site.

Conventional mail Waters Corporation

Global Support Services

34 Maple Street

Milford, MA 01757

USA

February 27, 2018, 715003794 Rev. C

Page v

Considerations specific to the Waters Alliance e2695

Separations Module

Power cord replacement hazard

Solvent leakage hazard

The source exhaust system is designed to be robust and leak-tight. Waters recommends you

perform a hazard analysis, assuming a maximum leak into the laboratory atmosphere of 10% LC

eluate.

Flammable solvents hazard

When using flammable solvents, ensure that a stream of nitrogen continuously flushes the

instrument’s source, and the nitrogen supply pressure remains above 690 kPa (6.9 bar, 100 psi).

You must also install a gas-fail device that interrupts the solvent flowing from the LC system in the

event the supply of nitrogen fails.

Hand crush hazard

High temperature hazard

Warning: To avoid electric shock, use the SVT-type power cord in the United States and

HAR-type (or better) cord in Europe. The main power cord must be replaced only with one

of adequate rating. For information regarding what cord to use in other countries, contact

your local Waters distributor.

Warning:

• To confirm the integrity of the source exhaust system, renew the source O-rings at

intervals not exceeding one year.

• To avoid chemical degradation of the source O-rings, which can withstand

exposure only to certain solvents,determine whether any solvents you use that

are not listed are chemically compatible with the composition of the O-rings.

Warning: To prevent ignition of flammable solvent vapors in the enclosed space of a mass

spectrometer’s ion source, ensure that nitrogen flows continuously through the source. The

nitrogen supply pressure must not fall below 690 kPa (6.9 bar, 100 psi) during an analysis

requiring the use of flammable solvents. Also a gas-fail device must be installed, to interrupt

the flow of LC solvent should the nitrogen supply fail.

Warning: To avoid hazards associated with the reciprocating or rotating parts in the source,

keep hand clear of the regions marked with yellow and gray labels.

Warning: To avoid burn injuries, avoid touching the source enclosure when operating or

servicing the instrument.

February 27, 2018, 715003794 Rev. C

Page vi

High voltage hazard

Bottle placement prohibition

FCC radiation emissions notice

Changes or modifications not expressly approved by the party responsible for compliance, could

void the users authority to operate the equipment. This device complies with Part 15 of the FCC

Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation.

Electrical power safety notice

Do not position the instrument so that it is difficult to disconnect the power cord.

Equipment misuse notice

If equipment is used in a manner not specified by its manufacturer, protections against personal

injury inherent in the equipment’s design can be rendered ineffective.

Safety advisories

Consult Appendix A for a comprehensive list of warning advisories and notices.

Warning: To avoid electric shock, observe these precautions:

• Do not remove the mass spectrometer’s protective panels. The components they cover

are not user-serviceable.

• When the instrument is in Operate mode, avoid touching the areas marked with the high

voltage warning symbol. To touch external areas marked with the symbol, first put the

instrument in Standby mode.

Warning: To avoid injury from electrical shock or fire, and damage to the equipment, do not place

vessels containing liquid atop the workstation or ancillary equipment or otherwise expose those

units to dripping or splashing liquids.

Prohibited: Do not place vessels containing liquid—such as solvent bottles—atop the

workstation or ancillary equipment or otherwise expose those units to dripping or splashing

liquids.

February 27, 2018, 715003794 Rev. C

Page vii

Operating this instrument

When operating this instrument, follow standard quality-control (QC) procedures and the

guidelines presented in this section.

Applicable symbols

Symbol Definition

Manufacturer

Date of manufacture

Authorized representative of the European Community

Confirms that a manufactured product complies with all applicable

European Community directives

or

Australia EMC compliant

Confirms that a manufactured product complies with all applicable

United States and Canadian safety requirements

Consult instructions for use

Alternating current

Electrical and electronic equipment with this symbol may contain

hazardous substances and should not be disposed of as general

waste.

For compliance with the Waste Electrical and Electronic Equipment

Directive (WEEE) 2012/19/EU, contact Waters Corporation for the

correct disposal and recycling instructions.

Serial number

Part number catalog number

5()

February 27, 2018, 715003794 Rev. C

Page viii

Audience and purpose

This guide is intended for use by individuals who need to install, operate, maintain, or troubleshoot

the Waters Alliance e2695 Separations Module.

This guide sets forth procedures for unpacking, installing, using, maintaining, and troubleshooting

the Waters Alliance e2695 Separations Module. It also includes appendixes for specifications,

spare parts, and solvent considerations.

Intended use of the Waters Alliance e2695 Separations Module

Waters designed the Alliance e2695 Separations Module, an integrated solvent and sample

management platform, to facilitate all critical separations functions. The Waters Alliance e2695

Separations Module is for research use only and is not intended for use in diagnostic applications.

Calibrating

To calibrate LC systems, follow acceptable calibration methods using at least five standards to

generate a standard curve. The concentration range for standards must include the entire range of

QC samples, typical specimens, and atypical specimens.

When calibrating mass spectrometers, consult the calibration section of the operator’s guide for

the instrument you are calibrating. In cases where an overview and maintenance guide, not

operator’s guide, accompanies the instrument, consult the instrument’s online Help system for

calibration instructions.

Quality control

Routinely run three QC samples that represent subnormal, normal, and above-normal levels of a

compound. If sample trays are the same or very similar, vary the location of the QC samples in the

trays. Ensure that QC sample results fall within an acceptable range, and evaluate precision from

day to day and run to run. Data collected when QC samples are out of range might not be valid. Do

not report these data until you are certain that the instrument performs satisfactorily.

EMC considerations

Canada spectrum management emissions notice

This class A digital product apparatus complies with Canadian ICES-001.

Cet appareil numérique de la classe A est conforme à la norme NMB-001.

ISM Classification: ISM Group 1 Class A

This classification has been assigned in accordance with IEC CISPR 11 Industrial Scientific and

Medical (ISM) instrument requirements.

Group 1 products apply to intentionally generated and/or used conductively coupled

radio-frequency energy that is necessary for the internal functioning of the equipment.

February 27, 2018, 715003794 Rev. C

Page ix

Class A products are suitable for use in all establishments other than residential locations and

those directly connected to a low voltage power supply network supplying a building for domestic

purposes.

There may be potential difficulties in ensuring electromagnetic compatibility in other environments

due to conducted as well as radiated disturbances.

EC authorized representative

Waters Corporation

Stamford Avenue

Altrincham Road

Wilmslow SK9 4AX UK

Telephone: +44-161-946-2400

Fax: +44-161-946-2480

Contact: Quality manager

February 27, 2018, 715003794 Rev. C

Page x

February 27, 2018, 715003794 Rev. C

Page xi

General Information ............................................................................................... iii

Copyright notice ......................................................................................................................... iii

Trademarks ................................................................................................................................ iii

Customer comments .................................................................................................................. iv

Contacting Waters ..................................................................................................................... iv

Safety considerations ................................................................................................................ iv

Safety hazard symbol notice........................................................................................ iv

Considerations specific to the Waters Alliance e2695 Separations Module ................. v

FCC radiation emissions notice ................................................................................... vi

Electrical power safety notice ...................................................................................... vi

Equipment misuse notice............................................................................................. vi

Safety advisories ......................................................................................................... vi

Operating this instrument .......................................................................................................... vii

Applicable symbols ..................................................................................................... vii

Audience and purpose................................................................................................ viii

Intended use of the Waters Alliance e2695 Separations Module ............................... viii

Calibrating................................................................................................................... viii

Quality control............................................................................................................. viii

EMC considerations .................................................................................................................. viii

Canada spectrum management emissions notice...................................................... viii

ISM Classification: ISM Group 1 Class A ................................................................... viii

EC authorized representative .................................................................................................... ix

1 Getting started with the Alliance e2695 Separations Module ........................... 19

1.1 Separations module overview ................................................................................................... 19

1.1.1 HPLC system configurations ......................................................................................... 20

1.1.2 Solvent bottle tray kits.................................................................................................... 20

1.1.3 Control of chromatographic functions ............................................................................ 22

1.1.4 Spill protection ............................................................................................................... 22

1.1.5 Record-keeping functions .............................................................................................. 23

1.1.6 Power supply ................................................................................................................. 23

1.2 Solvent management system overview ..................................................................................... 23

1.2.1 Solvent blending ............................................................................................................ 24

1.2.2 Prime/vent valve ............................................................................................................ 24

1.2.3 Plunger seal wash system ............................................................................................. 24

1.2.4 Loss of prime protection ................................................................................................ 24

1.2.5 Preferred plunger stroke volume ................................................................................... 25

1.2.6 In-line vacuum degasser................................................................................................ 25

Table of Contents

February 27, 2018, 715003794 Rev. C

Page xii

1.3 Sample management system overview ..................................................................................... 26

1.3.1 Flow path ....................................................................................................................... 26

1.3.2 Normal flow.................................................................................................................... 27

1.3.3 Injection ......................................................................................................................... 27

1.3.4 Carousel configuration................................................................................................... 27

1.3.5 Vial presence ................................................................................................................. 28

1.3.6 Syringe assembly .......................................................................................................... 28

1.4 Operating configurations ........................................................................................................... 29

1.4.1 System Controller mode ................................................................................................ 29

1.4.2 No Interaction mode ...................................................................................................... 30

1.4.3 Remote Control mode.................................................................................................... 31

1.5 Options and accessories ........................................................................................................... 33

1.5.1 Column heater ............................................................................................................... 33

1.5.2 Column heater/cooler .................................................................................................... 33

1.5.3 Column pre-heater......................................................................................................... 33

1.5.4 Sample heater/cooler..................................................................................................... 33

1.5.5 Syringes......................................................................................................................... 33

1.5.6 Sample loops ................................................................................................................. 34

1.5.7 Column selection valve.................................................................................................. 34

2 Install the e2695 Separations Module ................................................................. 37

2.1 Installation overview .................................................................................................................. 37

2.2 Site requirements ...................................................................................................................... 38

2.3 Firmware and software requirements ........................................................................................ 39

2.4 Unpack the instrument ............................................................................................................... 39

2.5 External connections ................................................................................................................. 40

3 Prepare the e2695 Separations Module for Operation ...................................... 41

3.1 Power-on the separations module ............................................................................................. 41

3.1.1 Start-up diagnostic tests ................................................................................................ 41

3.1.2 The Main screen ............................................................................................................ 41

3.2 Operating overview ................................................................................................................... 42

3.2.1 Screen display overview ................................................................................................ 42

3.2.2 Use the keypad.............................................................................................................. 44

3.2.3 Enter values in parameter fields .................................................................................... 45

February 27, 2018, 715003794 Rev. C

Page xiii

3.3 Configure the separations module ............................................................................................. 47

3.3.1 Set configuration parameters......................................................................................... 47

3.3.2 Configure the operating mode ....................................................................................... 52

3.4 Prepare the solvent management system ................................................................................. 56

3.4.1 Prepare solvent reservoirs............................................................................................. 57

3.4.2 Degassing solvents........................................................................................................ 57

3.4.3 Prime the plunger seal wash pump ............................................................................... 58

3.4.4 Prime the solvent management system......................................................................... 58

3.5 Prepare the sample management system for operation ............................................................ 59

3.5.1 Purge the system........................................................................................................... 59

3.5.2 Prime the needle wash pump ........................................................................................ 60

3.5.3 Adjust the seal pack....................................................................................................... 61

3.5.4 Load carousels .............................................................................................................. 62

3.6 Prepare the separations module for operation .......................................................................... 62

3.6.1 Prepare a new or dry separations module for operation................................................ 63

3.6.2 Prepare an idle or powered-off separations module for operation................................. 63

3.6.3 Change from a buffered solvent to an organic solvent .................................................. 64

3.7 Power-off the separations module ............................................................................................. 64

3.7.1 Flush the flow path......................................................................................................... 64

3.7.2 Power-off the separations module ................................................................................. 65

4 Front Panel Control .............................................................................................. 67

4.1 Routine start-up ......................................................................................................................... 67

4.1.1 Reinitialize the system ................................................................................................... 67

4.2 Load sample vials ...................................................................................................................... 67

4.2.1 Remove the carousel..................................................................................................... 68

4.2.2 Load vials....................................................................................................................... 68

4.2.3 Load the carousel .......................................................................................................... 68

4.2.4 Add new sample vials during a run................................................................................ 68

4.3 Monitor your HPLC system ....................................................................................................... 69

4.4 Perform direct functions ............................................................................................................ 72

4.4.1 Dry prime the system..................................................................................................... 74

4.4.2 Run System Prep........................................................................................................... 75

4.4.3 Wet prime the system .................................................................................................... 76

4.4.4 Purge the 2410 and 410 reference cell.......................................................................... 78

4.4.5 Equilibrate the system ................................................................................................... 78

4.4.6 Condition the column ..................................................................................................... 78

4.4.7 Inject samples................................................................................................................ 79

February 27, 2018, 715003794 Rev. C

Page xiv

5 Automatic Runs .................................................................................................... 81

5.0.1 System Controller or No Interaction mode..................................................................... 81

5.0.2 Controlled by Empower software................................................................................... 81

5.0.3 Controlled by MassLynx software.................................................................................. 82

5.1 Perform automatic runs in a standalone mode .......................................................................... 82

5.1.1 Run a sample set........................................................................................................... 82

5.1.2 View sample sets........................................................................................................... 83

5.1.3 Perform a run from a sample template .......................................................................... 84

5.1.4 Modify a sample set during a run................................................................................... 85

5.1.5 Stop a run ...................................................................................................................... 86

5.2 Perform automatic runs under Empower software control ........................................................ 86

5.2.1 Considerations when performing runs controlled by Empower software....................... 87

5.3 Perform automatic runs under MassLynx control ...................................................................... 87

5.3.1 Perform an automatic run using MassLynx software ..................................................... 88

6 Create Methods, Sample Sets, and Sample Templates ..................................... 89

6.0.1 Separation methods....................................................................................................... 89

6.0.2 Sample sets ................................................................................................................... 89

6.0.3 Sample templates .......................................................................................................... 90

6.1 Create and edit separation methods ......................................................................................... 90

6.1.1 Create a separation method .......................................................................................... 91

6.1.2 Edit a separation method............................................................................................... 92

6.1.3 Copy and edit a separation method............................................................................... 93

6.1.4 Lock and unlock a separation method ........................................................................... 93

6.2 Set separation method parameters ........................................................................................... 94

6.2.1 Set Mobile Phase screen parameter values .................................................................. 94

6.2.2 Set sample parameter values ...................................................................................... 100

6.2.3 Set autosampler parameter values.............................................................................. 101

6.2.4 Set column parameter values ...................................................................................... 103

6.2.5 Set I/O parameter values............................................................................................. 104

6.2.6 Set detector parameters .............................................................................................. 107

6.3 Create and edit a sample set .................................................................................................. 113

6.3.1 Link rows in a sample set ............................................................................................ 116

6.4 Create a sample template ....................................................................................................... 117

February 27, 2018, 715003794 Rev. C

Page xv

7 Maintenance Procedures .................................................................................... 119

7.1 Maintenance considerations .................................................................................................... 119

7.1.1 Proper operating procedures ....................................................................................... 119

7.1.2 Reinitialize the system ................................................................................................. 119

7.2 Spare parts .............................................................................................................................. 119

7.3 Troubleshooting with Connections INSIGHT ........................................................................... 119

7.4 Safety and handling ................................................................................................................. 120

7.5 Maintain the solvent management system .............................................................................. 121

7.5.1 Overview ..................................................................................................................... 121

7.5.2 Remove the head, seal wash assembly, and plunger ................................................ 123

7.5.3 Notes on replacing the plunger seals ......................................................................... 124

7.5.4 Replace the seal wash assembly seals ....................................................................... 126

7.5.5 Clean and replace the plunger .................................................................................... 128

7.5.6 Replace an inlet check valve cartridge ........................................................................ 129

7.5.7 Replace the in-line filter .............................................................................................. 131

7.6 Maintain the sample management system .............................................................................. 133

7.6.1 Remove side panel of separations module.................................................................. 135

7.6.2 Replace the lower needle wash frit (if so equipped) .................................................... 136

7.6.3 Replace the injector needle and seal pack .................................................................. 141

7.6.4 Clean the sample compartment................................................................................... 147

8 Diagnostic Testing and Troubleshooting ......................................................... 149

8.0.1 Proper operation .......................................................................................................... 149

8.1 Safety and handling ................................................................................................................. 149

8.2 Use the error log ..................................................................................................................... 150

8.3 Perform main diagnostic tests ................................................................................................. 150

8.3.1 Exit the Diagnostics screens........................................................................................ 151

8.3.2 Prime the plunger seal wash pump ............................................................................. 152

8.3.3 Perform the compression check ................................................................................. 152

8.3.4 Prime the needle wash pump ..................................................................................... 154

8.3.5 Adjust the seals ........................................................................................................... 154

8.3.6 Service utilities diagnostic tests ................................................................................... 156

8.4 Perform other diagnostic tests and functions .......................................................................... 156

8.4.1 Perform the motors and valves diagnostic test............................................................ 157

8.4.2 Sensors diagnostic function......................................................................................... 159

8.4.3 Static leak test ............................................................................................................. 161

8.4.4 Valve leak test.............................................................................................................. 162

8.4.5 Head removal and replacement function .................................................................... 163

February 27, 2018, 715003794 Rev. C

Page xvi

8.4.6 Inputs and outputs test ................................................................................................ 164

8.4.7 Keypad test ................................................................................................................. 165

8.4.8 Display test .................................................................................................................. 165

8.4.9 Carousel test ............................................................................................................... 165

8.4.10 Sample heater/cooler test ......................................................................................... 166

8.4.11 Defrost sample heater/cooler function ...................................................................... 166

8.4.12 Column heater or column heater/cooler test ............................................................. 167

8.4.13 Rebuild injector valves function ................................................................................. 168

8.4.14 Create a GPV Test Method........................................................................................ 168

8.4.15 Verify the firmware checksum.................................................................................... 168

8.5 Troubleshoot ............................................................................................................................ 169

8.5.1 General troubleshooting hints...................................................................................... 169

8.5.2 When to call Waters Technical Service ....................................................................... 170

8.5.3 Troubleshoot chromatography problems .................................................................... 171

8.5.4 Troubleshooting hardware problems .......................................................................... 175

A Safety Advisories ............................................................................................... 181

A.1 Warning symbols ..................................................................................................................... 181

A.1.1 Specific warnings......................................................................................................... 182

A.2 Notices .................................................................................................................................... 183

A.3 Bottles Prohibited symbol ....................................................................................................... 183

A.4 Required protection ................................................................................................................. 184

A.5 Warnings that apply to all Waters instruments and devices .................................................... 184

A.6 Warnings that address the replacing of fuses ......................................................................... 187

A.7 Electrical and handling symbols .............................................................................................. 189

A.7.1 Electrical symbols........................................................................................................ 189

A.7.2 Handling symbols ........................................................................................................ 190

B External Connections ........................................................................................ 191

B.1 Connect to the electrical power supply ................................................................................... 191

B.2 Connect tubing and attachments ............................................................................................ 193

B.2.1 Install the B-series drip tray......................................................................................... 193

B.2.2 Install A- and C-series drip tray and support bracket .................................................. 195

B.2.3 Install solvent supply tubing ........................................................................................ 199

B.2.4 Make waste line connections ...................................................................................... 200

B.2.5 Install needle wash and plunger seal wash reservoirs ................................................ 201

B.2.6 Connect the column .................................................................................................... 202

February 27, 2018, 715003794 Rev. C

Page xvii

B.2.7 Connect the column selection valve............................................................................ 203

B.2.8 Connect the detector ................................................................................................... 206

B.3 Signal connections .................................................................................................................. 207

B.3.1 I/O signal connections ................................................................................................. 208

B.3.2 Digital signal connections............................................................................................ 211

B.4 Add hardware options ............................................................................................................. 213

B.4.1 Install an optional sample loop .................................................................................... 214

B.4.2 Install the column heater and column heater/cooler.................................................... 216

B.4.3 Install a syringe ........................................................................................................... 216

C Specifications ..................................................................................................... 217

C.1 Physical specifications ............................................................................................................ 217

C.2 Environmental specifications .................................................................................................. 218

C.3 Electrical specifications ........................................................................................................... 218

C.4 Solvent management specifications ....................................................................................... 220

C.5 Sample management specifications ....................................................................................... 221

D Solvent Considerations ..................................................................................... 223

D.1 Introduction ............................................................................................................................. 223

D.1.1 Clean solvents............................................................................................................. 223

D.1.2 Solvent quality............................................................................................................. 223

D.1.3 Solvent reservoirs ....................................................................................................... 223

D.1.4 Preparation checklist................................................................................................... 224

D.1.5 Water........................................................................................................................... 224

D.1.6 Buffers......................................................................................................................... 224

D.1.7 Tetrahydrofuran (THF)................................................................................................. 224

D.1.8 GPC solvents and seal choices .................................................................................. 224

D.2 Solvent compatibility ............................................................................................................... 225

D.2.1 Solvents to avoid......................................................................................................... 225

D.2.2 Solvents to use............................................................................................................ 226

D.3 Solvent miscibility ................................................................................................................... 228

D.3.1 How to use miscibility numbers (M-numbers) ............................................................. 229

D.4 Buffered solvents .................................................................................................................... 230

D.5 Head height ............................................................................................................................ 230

D.6 Solvent viscosity ..................................................................................................................... 230

February 27, 2018, 715003794 Rev. C

Page xviii

D.7 Mobile phase solvent degassing ............................................................................................. 230

D.7.1 Gas solubility............................................................................................................... 231

D.7.2 Vacuum degassing...................................................................................................... 231

D.8 Wavelength selection .............................................................................................................. 232

D.8.1 UV cut-offs for common solvents ................................................................................ 232

D.8.2 Mixed mobile phases .................................................................................................. 233

D.8.3 Refractive indices of common solvents....................................................................... 234

February 27, 2018, 715003794 Rev. C

Page 19

1Getting started with the Alliance

e2695 Separations Module

1.1 Separations module overview

The Alliance e2695 Separations Module is an integrated solvent and sample management

platform. Integrating the two, traditional high performance liquid chromatography (HPLC)

components—a solvent management system and a sample management system—facilitates all

critical separations functions.

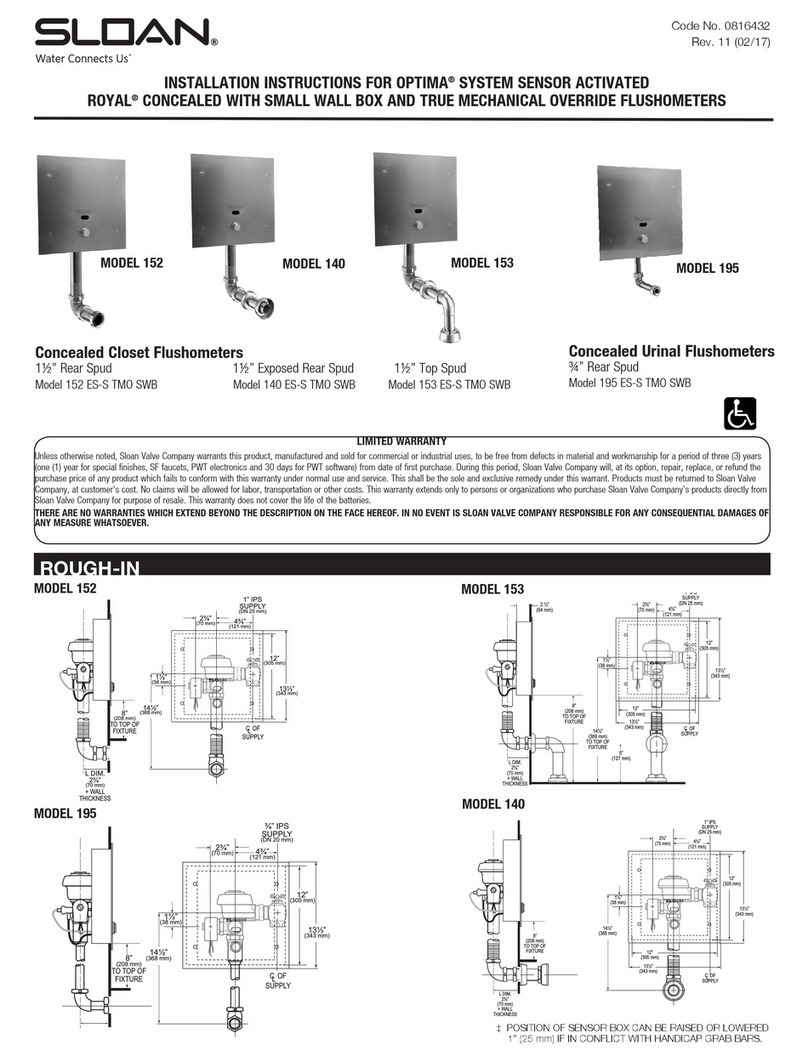

Figure 1–1: Alliance e2695 Separations Module (front view)

TP03527

Syringe

access door

Solvent

conditioning

tray access door

Solvent

delivery tray

access door

Sample

compartment

access door

Front panel

display and

keypad

February 27, 2018, 715003794 Rev. C

Page 20

1.1.1 HPLC system configurations

The separations module supports RS-232, IEEE-488, Ethernet, and I/O connections for

compatibility with a variety of HPLC system configurations. It can function in these ways:

• As the source of Input/Output and timing signals in a simple, standalone HPLC system

• As the IEEE-488 system controller in an HPLC standalone system that includes these

Waters detectors:

– 2414 or 2410* refractive index (RI), or 410* differential refractive index (dRI)

– 2414 RI, 2410 RI, or 410 dRI and the 2487* dual wavelength or 486* tunable

absorbance

– 2487 dual wavelength or 486 tunable absorbance

*A legacy product that is no longer available for purchase from Waters.

• As a component of an HPLC system controlled by Empower or MassLynx software that

uses IEEE-488 communications

• As a component of an HPLC system controlled by Empower software and that uses

Ethernet communications

• As a component of an HPLC system controlled by a non-Waters data system that uses

RS-232 communications

1.1.2 Solvent bottle tray kits

There are several solvent bottle tray kits available for use with Alliance HPLC system

configurations.

Table 1–1: Solvent bottle tray kit options

System configuration Kit part number Where used Description

A series:

Bottle organizer

176003103 Systems with a

separations module

only

Bottle tray comes with a

removable drip tray and is

stacked atop the detector.

Accommodates up to two

4-liter bottles and nine

1-liter bottles.

B series:

Bottle tray and

detector base

176003104 Systems with a

separations module

and a column heater or

column heater/cooler

installed

Bottle tray comes with a

removable drip tray and

adjacent detector base.

Enables placement of

detector atop column

heater. Accommodates up

to two 4-liter bottles and

four 1-liter bottles.

C series:

Bottle bucket

176003105 Any Alliance HPLC

system

Free-standing bottle tray.

Accommodates a

combination of 1 to 4-liter

bottles.

Other manuals for Alliance e2695

1

Table of contents

Other Waters Control Unit manuals

Popular Control Unit manuals by other brands

Mirion Technologies

Mirion Technologies Neutron Hp 10 user guide

Phoenix Contact

Phoenix Contact FL WLAN 1100 user manual

Ublox

Ublox ZED-F9K Integration manual

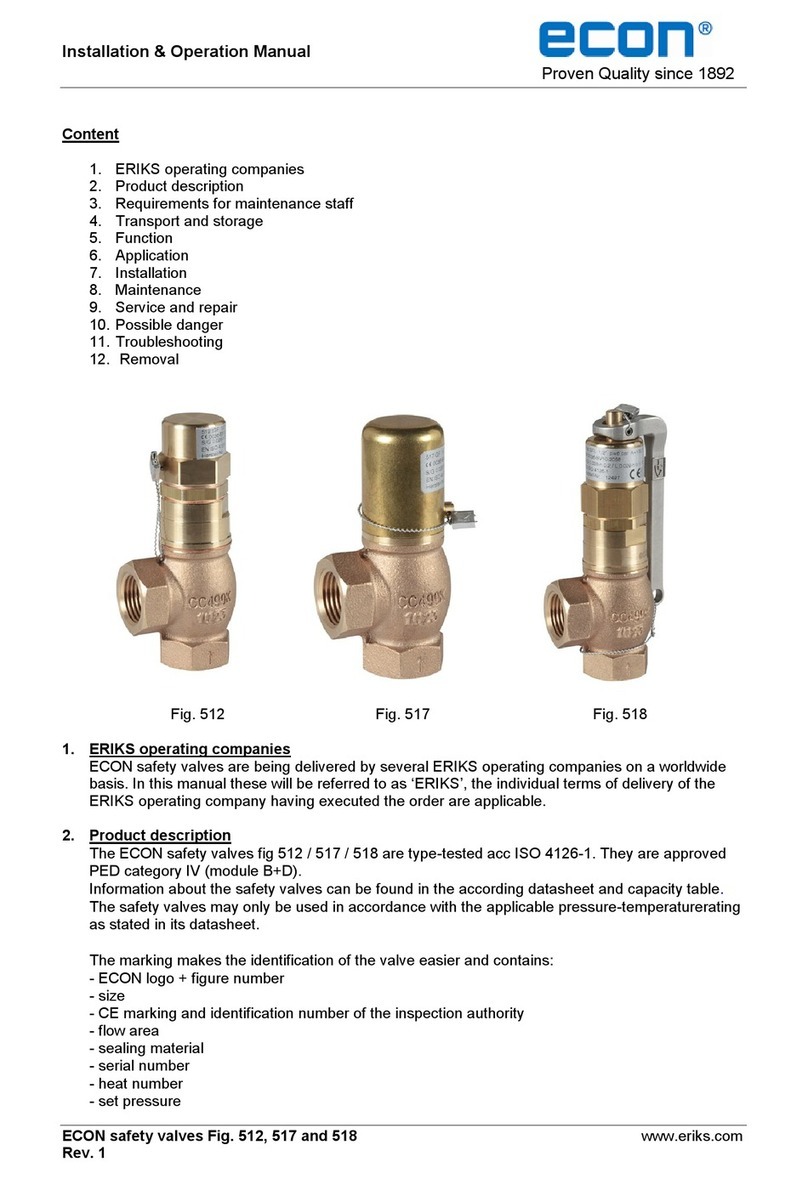

Econ

Econ Fig. 517 Installation & operation manual

General Photonics

General Photonics FPS-002 Instruction Notes

Helios

Helios AIR1-ULM Installation and operating instructions