Waters Pump Control Module II User manual

Waters Pump Control

Module II

Installation Guide

71500078604/Revision B

Copyright © Waters Corporation 2009

All rights reserved

ii

Copyright notice

© 2009 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF

AMERICA AND IRELAND. ALL RIGHTS RESERVED. THIS DOCUMENT

OR PARTS THEREOF MAY NOT BE REPRODUCED IN ANY FORM

WITHOUT THE WRITTEN PERMISSION OF THE PUBLISHER.

The information in this document is subject to change without notice and

should not be construed as a commitment by Waters Corporation. Waters

Corporation assumes no responsibility for any errors that may appear in this

document. This document is believed to be complete and accurate at the time

of publication. In no event shall Waters Corporation be liable for incidental or

consequential damages in connection with, or arising from, its use.

Trademarks

Millennium and Waters are registered trademarks of Waters Corporation,

and Empower, LAC/E, SAT/IN, and “THE SCIENCE OF WHAT’S

POSSIBLE.” are trademarks of Waters Corporation.

Other registered trademarks or trademarks are the sole property of their

owners.

iii

Customer comments

Waters’ Technical Communications department invites you to tell us of any

errors you encounter in this document or to suggest ideas for otherwise

improving it. Please help us better understand what you expect from our

documentation so that we can continuously improve its accuracy and

usability.

We seriously consider every customer comment we receive. You can reach us

at tech_comm@waters.com.

iv

Contacting Waters

Contact Waters®with enhancement requests or technical questions regarding

the use, transportation, removal, or disposal of any Waters product. You can

reach us via the Internet, telephone, or conventional mail.

Safety considerations

Some reagents and samples used with Waters instruments and devices can

pose chemical, biological, and radiological hazards. You must know the

potentially hazardous effects of all substances you work with. Always follow

Good Laboratory Practice, and consult your organization’s safety

representative for guidance.

When you develop methods, follow the “Protocol for the Adoption of Analytical

Methods in the Clinical Chemistry Laboratory,” American Journal of Medical

Technology, 44, 1, pages 30–37 (1978). This protocol addresses good operating

procedures and the techniques necessary to validate system and method

performance.

Waters contact information

Contacting medium Information

Internet The Waters Web site includes contact

information for Waters locations worldwide.

Visit www.waters.com, and click Waters

Division > Contact Waters Online.

Telephone and fax From the USA or Canada, phone 800

252-HPLC, or fax 508 872 1990.

For other locations worldwide, phone and fax

numbers appear in the Waters Web site.

Conventional mail Waters Corporation

34 Maple Street

Milford, MA 01757

USA

v

Safety advisories

Consult Appendix A for a comprehensive list of warning and caution

advisories.

Operating the Waters Pump Control Module II

When operating the Pump Control Module II, follow standard quality-control

(QC) procedures and the guidelines presented in this section.

Applicable symbols

Audience and purpose

This guide is intended for use by individuals whose familiarity with HPLC

ranges from novice to expert. It describes how to install the Pump Control

Module II in a multi-pump gradient system with up to three pumps controlled

by a Waters data control system.

Intended use of the Pump Control Module II

Waters designed the Pump Control Module II to provide programmable

control through a Waters data system of up to three, 500-series high-pressure

pumps.

Calibrating

To calibrate LC systems, follow acceptable calibration methods using at least

five standards to generate a standard curve. The concentration range for

standards should include the entire range of QC samples, typical specimens,

and atypical specimens.

Symbol Definition

Confirms that a manufactured product complies

with all applicable European Community

directives

Australia C-Tick EMC Compliant

ABN 49 065 444 751

vi

To calibrate mass spectrometers, consult the calibration section for the

operator’s guide of the instrument you are calibrating.

Quality-control

Routinely run three QC samples that represent subnormal, normal, and

above-normal levels of a compound. Ensure that QC sample results fall within

an acceptable range, and evaluate precision from day to day and run to run.

Data collected when QC samples are out of range might not be valid. Do not

report these data until you are certain that the instrument performs

satisfactorily.

ISM classification

ISM Classification: ISM Group 1 Class B

This classification has been assigned in accordance with CISPR 11 Industrial

Scientific and Medical, (ISM) instruments requirements. Group 1 products

apply to intentionally generated and/or used conductively coupled

radio-frequency energy that is necessary for the internal functioning of the

equipment. Class B products are suitable for use in both commercial and

residential locations and can be directly connected to a low voltage,

power-supply network.

Table of Contents 1

Copyright notice ................................................................................................... ii

Trademarks ............................................................................................................ ii

Customer comments ............................................................................................ iii

Contacting Waters ............................................................................................... iv

Safety considerations .......................................................................................... iv

Safety advisories.................................................................................................. v

Operating the Waters Pump Control Module II ......................................... i-v

Applicable symbols .............................................................................................. v

Audience and purpose.......................................................................................... v

Intended use of the Pump Control Module II..................................................... v

Calibrating ........................................................................................................... v

Quality-control.................................................................................................... vi

ISM classification .............................................................................................. i-vi

ISM Classification: ISM Group 1 Class B ......................................................... vi

1 Overview .................................................................................................. 1-1

Introduction ....................................................................................................... 1-2

System configurations ..................................................................................... 1-3

Ethernet configuration.................................................................................... 1-3

IEEE-488 configuration................................................................................... 1-4

Signal conditions .............................................................................................. 1-5

2 Installing the Pump Control Module II ............................................ 2-1

Selecting the site and unpacking .................................................................. 2-2

Selecting the site.............................................................................................. 2-2

Unpacking and inspecting the module ........................................................... 2-2

Rear-panel signal connections ....................................................................... 2-3

Ethernet signal cable connections .................................................................. 2-4

Table of Contents

2 Table of Contents

IEEE-488 signal cable connections................................................................. 2-5

Connecting the pumps..................................................................................... 2-7

Connecting the event cables............................................................................ 2-8

Powering-on the module ............................................................................... 2-12

Programming the module ............................................................................. 2-14

Maintenance and troubleshooting .............................................................. 2-14

Cleaning the cabinet...................................................................................... 2-14

Replacing the fuse.......................................................................................... 2-14

Troubleshooting ............................................................................................. 2-15

A Safety Advisories .................................................................................. A-1

Warning symbols ............................................................................................... A-2

Task-specific hazard warnings........................................................................ A-2

Warnings that apply to particular instruments, instrument components, and

sample types............................................................................................... A-3

Caution symbol .................................................................................................. A-5

Warnings that apply to all Waters instruments ......................................... A-5

Electrical and handling symbols ................................................................. A-12

Electrical symbols.......................................................................................... A-12

Handling symbols .......................................................................................... A-13

B Specifications ........................................................................................ B-1

Physical and environmental specifications ............................................... B-2

Accuracy and precision .................................................................................. B-2

Electrical specifications ................................................................................. B-3

Protection Class 1 ............................................................................................ B-3

Overvoltage Category II .................................................................................. B-3

Pollution Degree 2 ........................................................................................... B-3

Moisture protection – Normal (IPXO) ............................................................ B-3

AC-to-DC power specifications ..................................................................... B-4

C Spare Parts ............................................................................................ C-1

1-2 Overview

Introduction

The Waters®Pump Control Module II is an HPLC pump controller. Through

the medium of Waters data system software, it offers programmatic control of

high-pressure-mixing pumps in HPLC and MS systems.

Pump Control Module II

Depending on your pump configuration requirements, you can attach as many

as three Waters 510 or 515 HPLC Pumps to the module and regulate the

solvent composition and flow rates by programming instrument method

settings in Empower, Millennium, or MassLynx data control software. (For

the module’s firmware/software requirements, see the Waters Pump Control

Module II release notes.)

A single Waters 510 or 515 Pump in an HPLC system is ideal for

high-throughput isocratic analyses. When you control two or three of these

pumps through a data system and external controller, you can achieve

reproducible, multipump gradient delivery with exceptionally smooth

concurrent-stream blending.

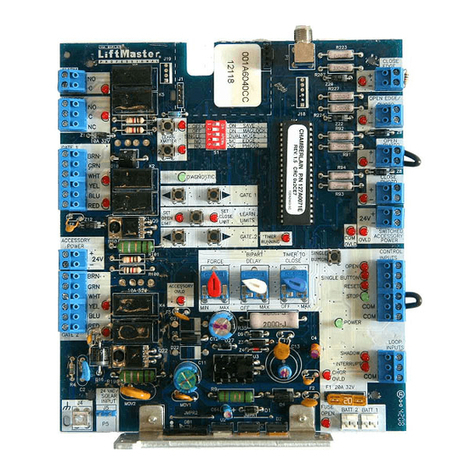

TP02342

System configurations 1-3

System configurations

When the module is under data system control, it can operate in one of these

configurations:

• Where all system modules, including the Pump Control Module II,

communicate with the data system via an IEEE-488 bus interface

• Where all system modules, including the Pump Control Module II,

communicate with the data system via Ethernet communications

Restriction: You cannot use the module’s Ethernet port at the same time you

are using its IEEE-488 bus interface for communications.

Note: For details on the module’s software and firmware requirements, see

the Waters Pump Control Module II release notes.

Ethernet configuration

To communicate with the Waters data control system via Ethernet, an

Ethernet cable connects the module with the system’s Ethernet network in

one of two ways:

• Directly, through the Ethernet LAN card in the data control system

• Through a network switch

For more information, see “Ethernet signal cable connections” on page 2-4.

1-4 Overview

HPLC system configuration using Ethernet communications

IEEE-488 configuration

To communicate with the Waters data control system via IEEE-488, an

IEEE-488 cable connects the module to an IEEE-488 controller (a busLAC/E™

card in the data control system for Millennium32 or Empower software or an

NI IEEE-488 card for MassLynx software). For more information, see

“IEEE-488 signal cable connections” on page 2-5.

External event-in

(Inj or Stop Flow)

External event-out

(6 available)

Pump

APump

BPump

C

Ethernet

cable

Module-to-pump cable

Pump Control

Module II Event cables

Ethernet LAN card

Data control system

Signal conditions 1-5

HPLC system configuration using IEEE-488 communications

Signal conditions

Terminal strips for two event input (inject-start and stop-flow) and six event

output signal connections are located on the module’s rear panel (see

“Terminal strips” on page 2-8). All external event connections are relay

closures.

The event input signals the module to initiate a run or stop the flow using

event cables (see “Event-in connection” on page 2-10). The event outputs can

trigger external devices when programmed in the pump events table (see

“Event-out connections” on page 2-11).

The IEEE-488 communications interface on the module’s rear panel provides

the means to manually set the IEEE-488 addresses via switch settings (see

“IEEE-488 signal cable connections” on page 2-5).

Data control system

busLAC/E card

External event-in

(Inj or Stop Flow)

External event-out

(6 available)

Pump

APump

BPump

C

IEEE-488

cable

Module-to-pump cable

Pump Control

Module II Event cables

1-6 Overview

2-1

2Installing the Pump Control

Module II

Contents

Topic Page

Selecting the site and unpacking 2-2

Rear-panel signal connections 2-3

Powering-on the module 2-12

Programming the module 2-14

Maintenance and troubleshooting 2-14

Caution: To avoid damaging the module and voiding its warranty,

perform all procedures in the order specified in this guide before you

power-on the module (see “Powering-on the module” on page 2-12).

2-2 Installing the Pump Control Module II

Selecting the site and unpacking

Selecting the site

Follow these requirements:

• When communicating with the data control system via the IEEE-488

interface, install the module within reach of the system. A 2-M

IEEE-488 cable is supplied for this purpose.

Requirement: For IEEE-488 communications, the maximum allowable

distance between the pumps and the module is 2 meters.

• When communicating with the data control system via the Ethernet

interface, install the module within reach of the Ethernet LAN card or

network switch that connects to the system. A 3-M shielded Ethernet

cable is supplied.

• The module is approximately 14 cm wide by 41 cm deep by 20 cm high.

Allow at least 8 cm rear clearance for the cables.

• Operating temperature is 4 to 40 °C.

• Relative humidity is 10 to 90%, noncondensing.

• Vibration and shock are negligible.

• For power requirements, see Appendix B.

Unpacking and inspecting the module

Unpack the shipment, comparing all items received to those specified in the

packing list. Notify Waters immediately if you discover a discrepancy. In the

case of damages items, immediately notify the shipping agency and Waters

Technical Service.

Waters recommends you save the packing materials for future transport or

shipment.

Caution: Do not stack heavy devices or solvent containers atop the

module.

Warning: Always observe Good Laboratory Practices when handling

solvents and performing maintenance.

Rear-panel signal connections 2-3

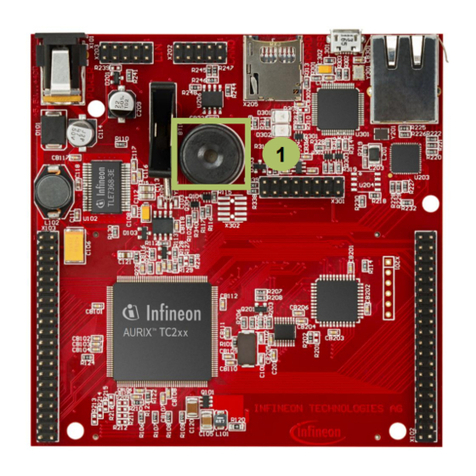

Rear-panel signal connections

Use the signal connectors on the module’s rear panel to connect the module to

other HPLC system components. The following table summarizes these signal

connections.

The following figure shows the rear panel locations of the signal connectors

used to operate the module with external devices.

Component connector types

Connector type Component

Ethernet Waters data control system, such as an

Empower 2 system, connected via the

Ethernet network

Tip: The Ethernet port also supports the

Waters PC-based Autoloader utility for

installing firmware (for details, see the

Waters Pump Control Module II release

notes).

IEEE-488 Waters data control system, such as

Empower, Millennium32, or MassLynx

system connected via the IEEE-488 bus

Analog Event inputs/outputs

terminal strips Peripheral devices, such as column

select valves, column-switching valves,

and manual injectors

Pump (A, B, and C) Up to three, Waters 510 or 515 HPLC

Pumps

RS-232 For firmware upgrades only

2-4 Installing the Pump Control Module II

Rear panel of the Pump Control Module II

Ethernet signal cable connections

The module is equipped with a RJ-45 connector for Ethernet port

communications (see the figure, above). The Ethernet port—a 10/100 Base-T

networking interface—is used only for remote control, the case when

Empower 2 controls its operation, and for firmware upgrades via the Waters

Autoloader utility. Appendix C lists the supplied Ethernet cable.

Requirements:

• In an Ethernet configuration, all Waters HPLC system components,

including the module, must communicate with the data system via

Ethernet communications.

• As with IEEE-488 control, when using an autoinjector, triggering of the

inject-start signal occurs over the Ethernet cable, so no external I/O

cable is needed. For more information, see “Connecting the event cables”

on page 2-8.

RS-232

IEEE

488

PUMP A PUMP B

PUMP C

ETHERNET

!

V - 100-240

Hz 50-60

VA 60

F 3.15A / 250V

ETL LISTED

CONFORMS TO

UL STD 3101-1

CERTIFIED TO

CA/CSA C22.2 NO. 1010.1-92

IEEE

ADDRESS

16

8

4

2

1

10

Event input and

output

connectors

Pump

connectors

Fuse

Power

Ground stud

IEEE-488

address

IEEE-488

connector

RS-232

connector

Ethernet

connector

Rear-panel signal connections 2-5

Restriction: You cannot use the module’s Ethernet port at the same time you

are using its IEEE-488 bus interface for communications.

To make the Ethernet connections

1. Connect one end of the Ethernet cable to the Ethernet port on the

module’s rear panel (see the figure on page 2-4).

2. Connect the other end of the Ethernet cable to the Ethernet LAN

network card in the data control system or an Ethernet switch connected

to the data control system. For additional Ethernet configuration

information, see the Waters Ethernet Instrument Getting Started Guide

(P/N: 7150074403).

IEEE-488 signal cable connections

The IEEE-488 cable transmits digital data between the module and the

busLAC/E card. Observe the IEEE cabling and connection requirements, and

follow the IEEE specifications when adding the module to the existing

IEEE-488 connections. Appendix C lists the IEEE-488 cables.

Requirements:

• In an IEEE-488 configuration, all of the Waters HPLC system

components, including the module, must communicate with the data

system via IEEE-488 communications.

• When using an autoinjector, triggering of the inject-start signal occurs

over the IEEE-488 cable, so no external I/O cable is needed. For more

information, see “Connecting the event cables” on page 2-8.

Restriction: You cannot use the module’s Ethernet port at the same time you

are using its IEEE-488 bus interface for communications.

To make the IEEE-488 connections

1. Place the module on a level surface.

2. Insert one end of the IEEE-488 cable into the IEEE-488 port on the

module’s rear panel, and tighten both thumbscrews.

3. Insert and secure the other end of the cable to the IEEE-488 connection

on the busLAC/E card in the data control system.

Tip: You can daisy-chain IEEE-488 cables.

2-6 Installing the Pump Control Module II

Note: Each device on the IEEE communications bus requires a unique

IEEE-488 address. The module’s address must be a unique number from

2 to 29.

4. Set a unique IEEE-488 address on the module’s rear panel by moving

the appropriate switches from 0 to 1 (see the table on page 2-6 ).

Example: For an address of 7, add the numbers of the switches in the 1

position.

Setting the address switches

The following table shows the switch positions for addresses 2 to 29.

IEEE-488 switch settings

IEEE-488

address Switch settings

124816

2 0 1 0 0 0

3 1 1 0 0 0

4 0 0 1 0 0

5 1 0 1 0 0

6 0 1 1 0 0

7 1 1 1 0 0

8 0 0 0 1 0

9 1 0 0 1 0

10 01010

11 11010

12 00110

13 10110

IEEE

address

10

16

8

4

2

1

These settings have a

value of 0

Add 1 + 2 + 4 = 7

Table of contents

Other Waters Control Unit manuals

Popular Control Unit manuals by other brands

MEIG

MEIG SLM758 Hardware Design Guide

PA

PA VB 200 quick start guide

Pentair

Pentair E-Box INTELLIPOOL Installation and operation guide

Brainchild

Brainchild PR Series user guide

Pentair

Pentair HI FLOW SIX-WAY 1-1/2 INCH TOP MOUNT VALVE Installation and user guide

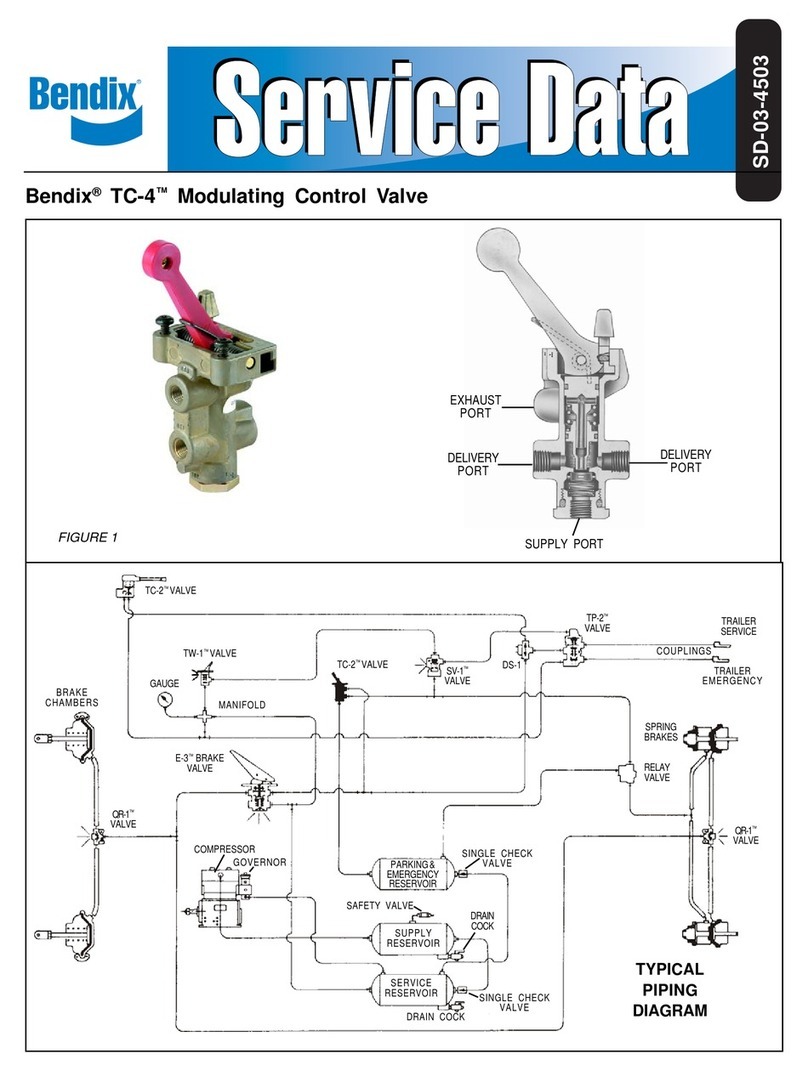

BENDIX

BENDIX TC-4 MODULATING CONTROL VALVE manual