HIGHGATE

Pressure Balance with Diverter Trim INSTALLATION GUIDELINES

Page 1 of 3

6.6.2012

These guidelines have been prepared for the professional contractor to aid in the installation of:

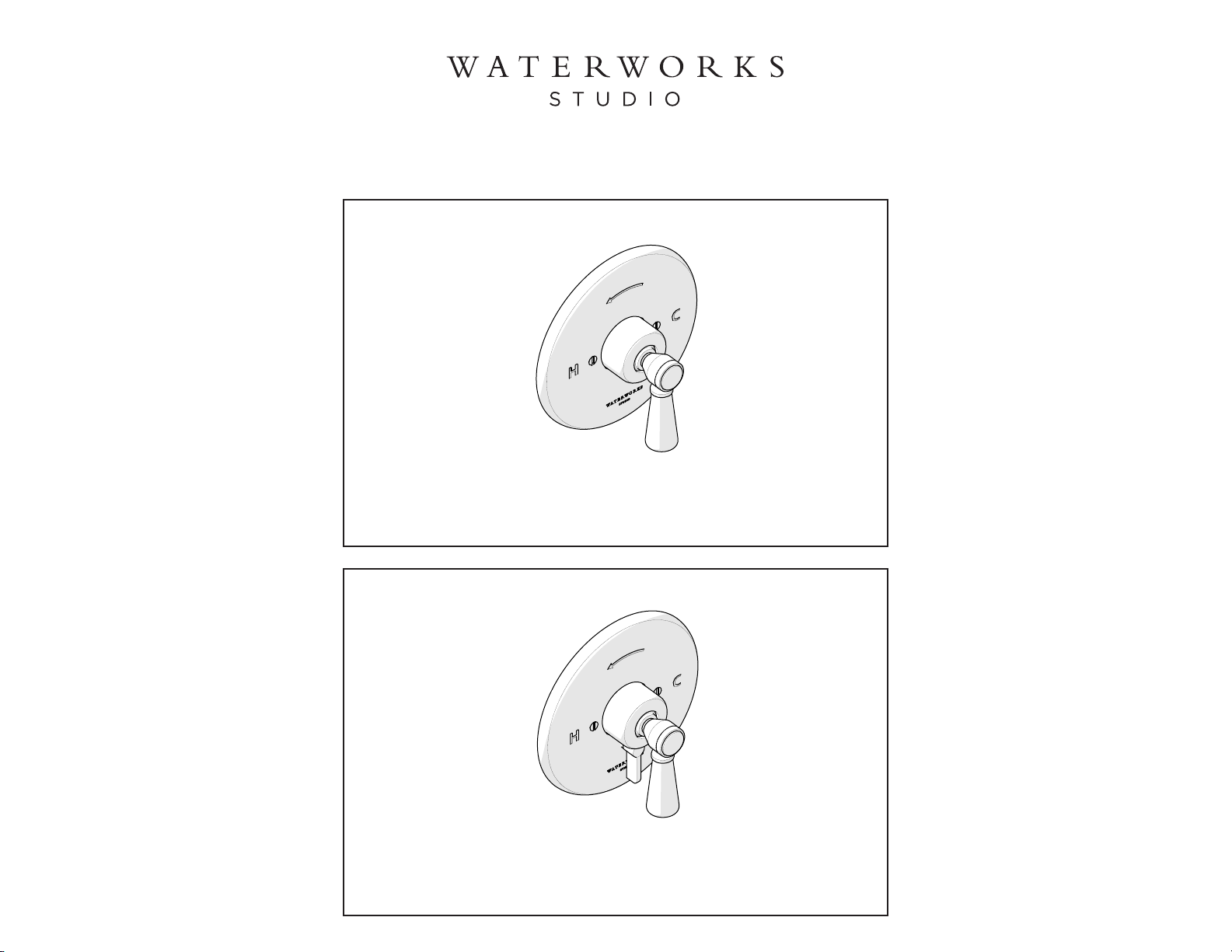

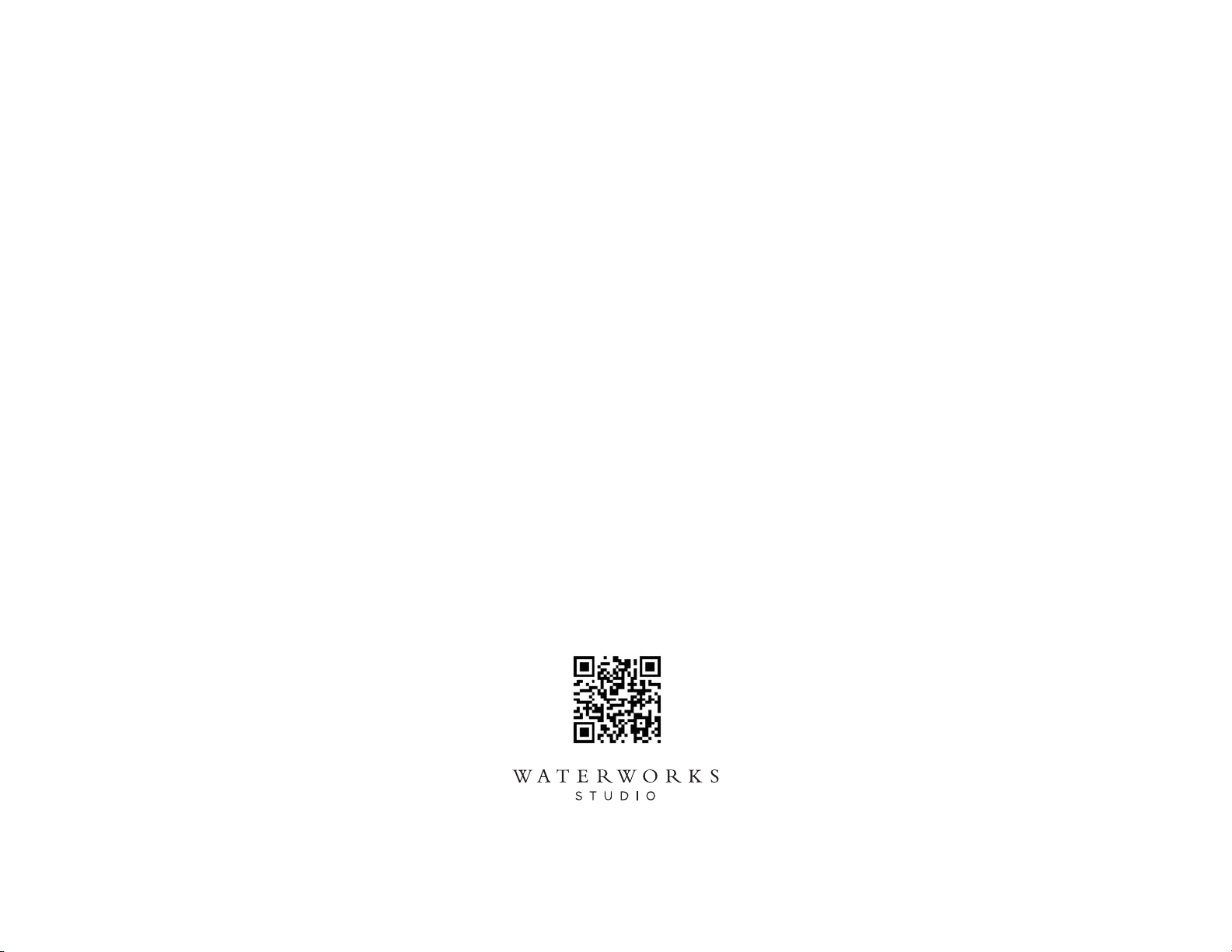

HIGHGATE PRESSURE BALANCE TRIM WITH PORCELAIN LEVER HANDLE WITH DIVERTER

(STYLE# HGPB30)

All dimensions are based on original specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

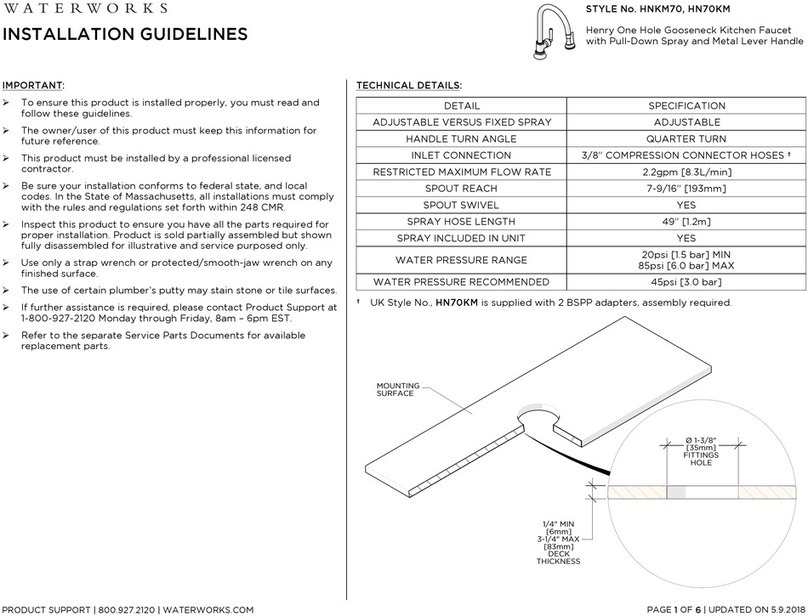

White Porcelain Lever Handle

Style No. HGPB30

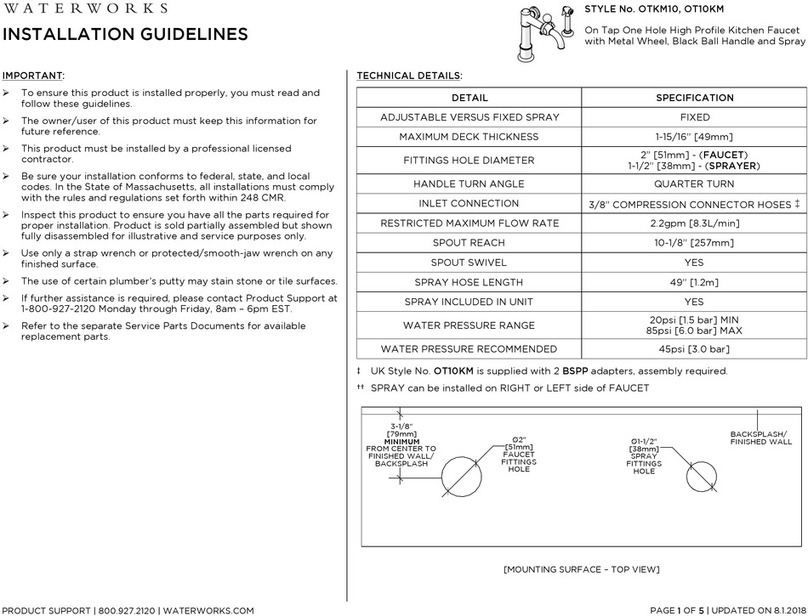

SPECIFICATIONS:

Rough-in Depth Minimum: 1-7/8"

Rough-in Depth Maximum: 2-7/8"

Integrated Diverter: Yes

REQUIRED PLUMBING DETAILS:

Universal Pressure Balance with Diverter Valve

STYLE # GUPB87R

CODE # GUSV87R

IMPORTANT:

¾To ensure this product is installed properly, you

must read and follow these guidelines.

¾The owner/user of this product must keep this

information for future reference.

¾This product is intended to work with the

Waterworks Universal Pressure Balance with

Diverter Valve (Style # GUPB87R). The risk of

scalding exists until the installer has properly

calibrated/adjusted the temperature setting during

final trim installation.

¾The bottom outlet of the GUPB87R is intended for

use with a tub spout only. The use of any fitting with

a restricted flow, such as a handshower, will cause

the diverter to not function properly.

¾Do not use Pex piping from the valve to the tub

spout. This will cause too much back pressure for

the valve to function properly.

¾Be sure your installation conforms to federal state,

and local codes. In the State of Massachusetts, all

installations must comply with the rules and

regulations set forth within 248 CMR.

¾This product must be installed by a professional

licensed contractor.

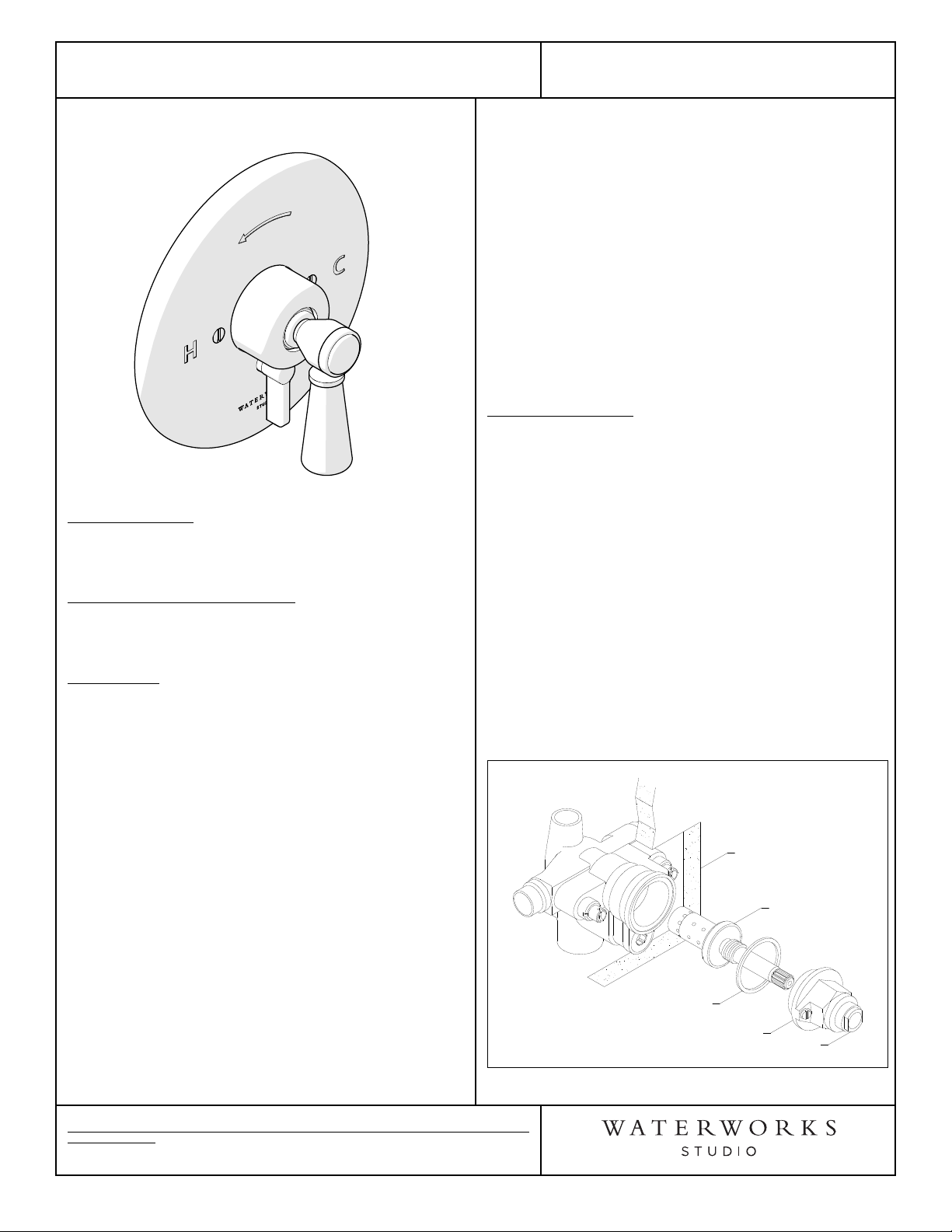

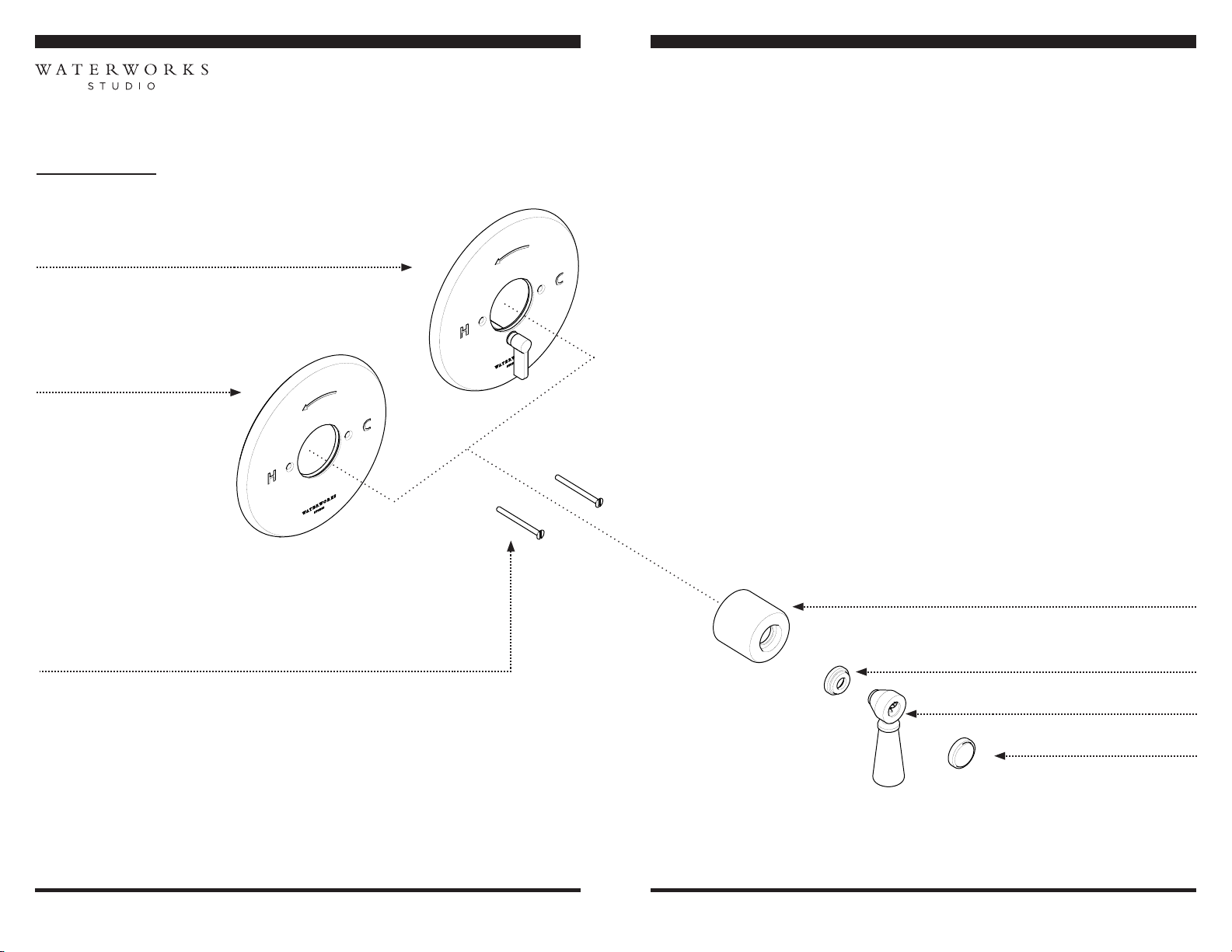

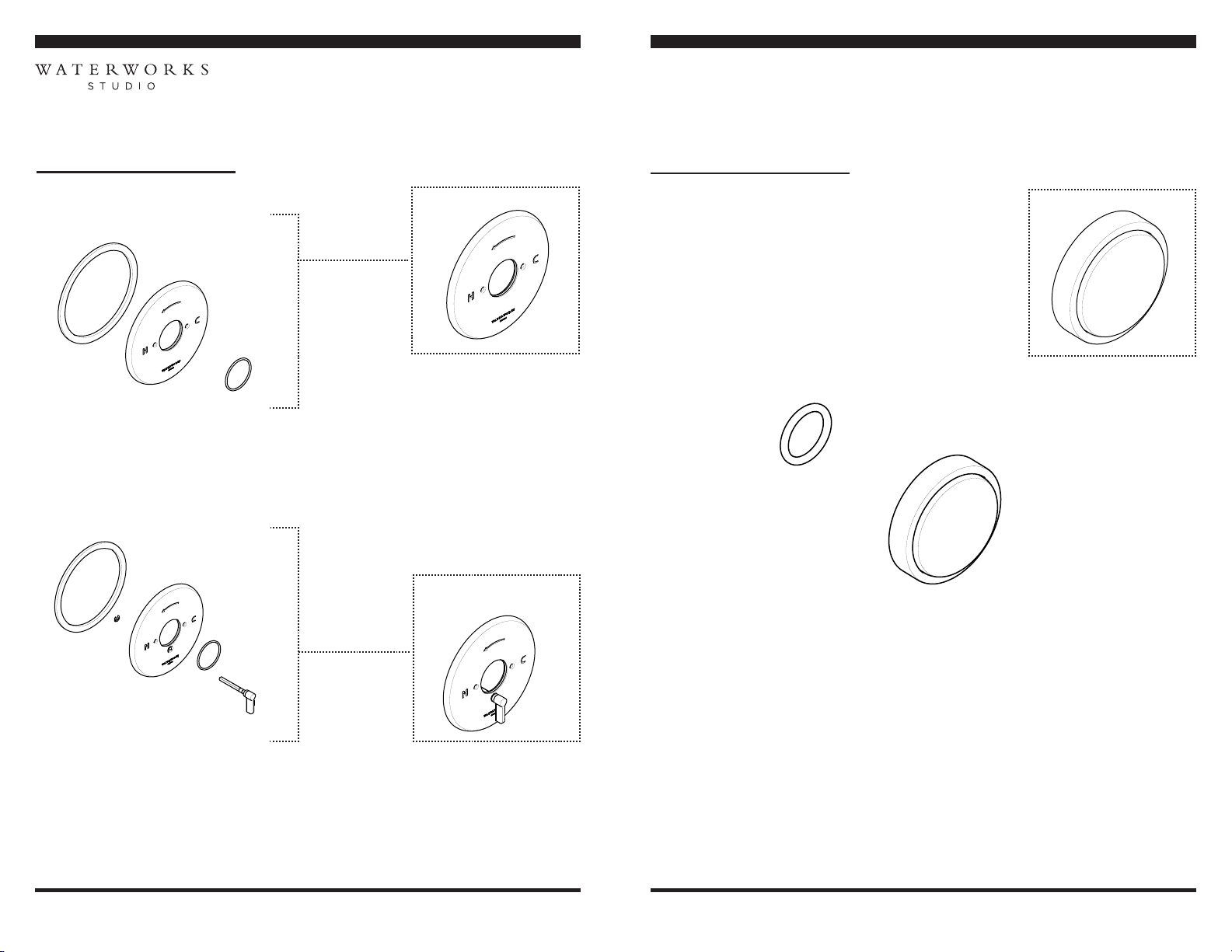

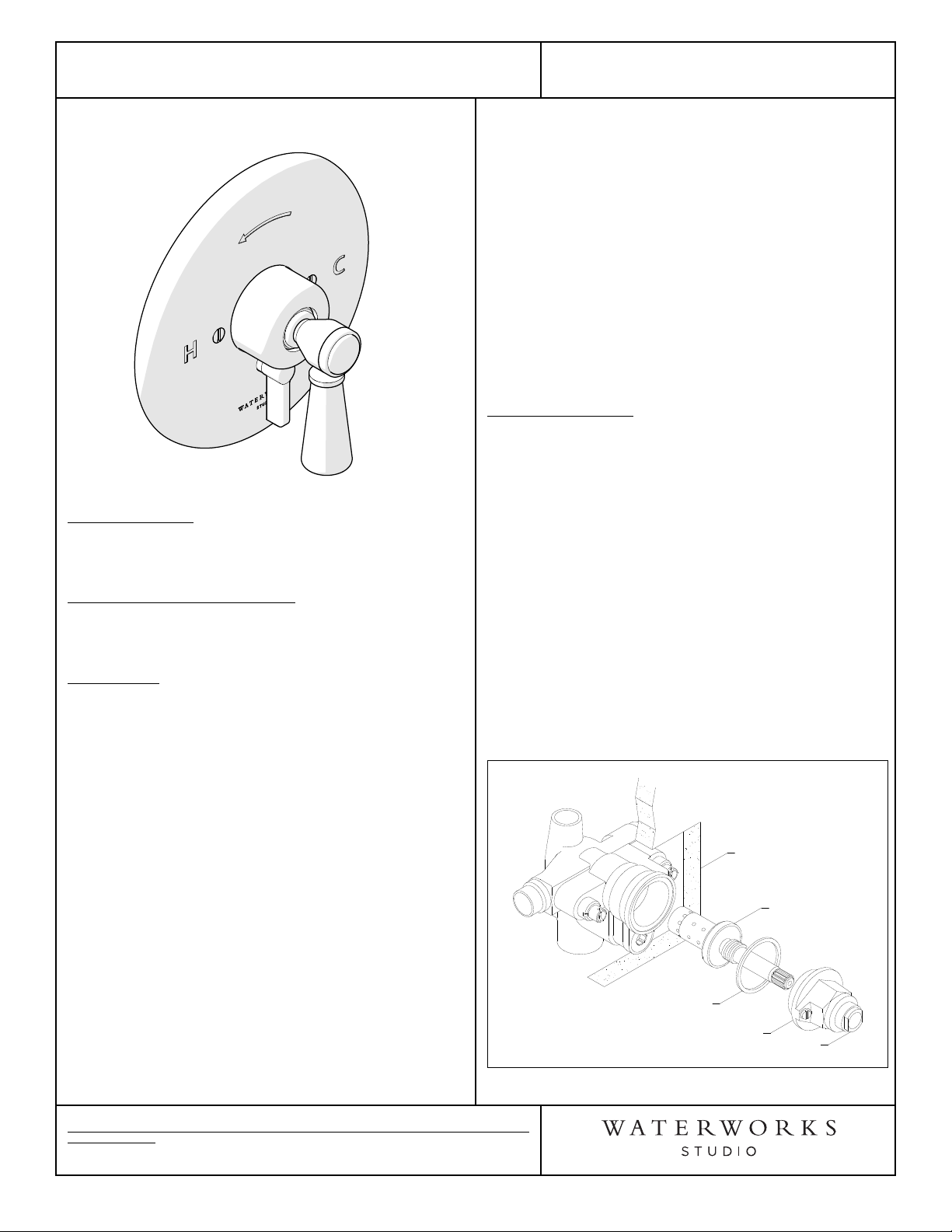

¾Refer to the specifications and assembly drawings

attached. Product is sold partially assembled but

shown fully disassembled for illustrative and service

purposes only.

¾Inspect this product to ensure you have all the parts

required for proper installation.

¾This product must be on-site prior to rough-in which

allows the installer to visualize the installation.

¾Use only a strap wrench or protected/smooth-jaw

wrench on any finished surface.

VALVE OPERATION:

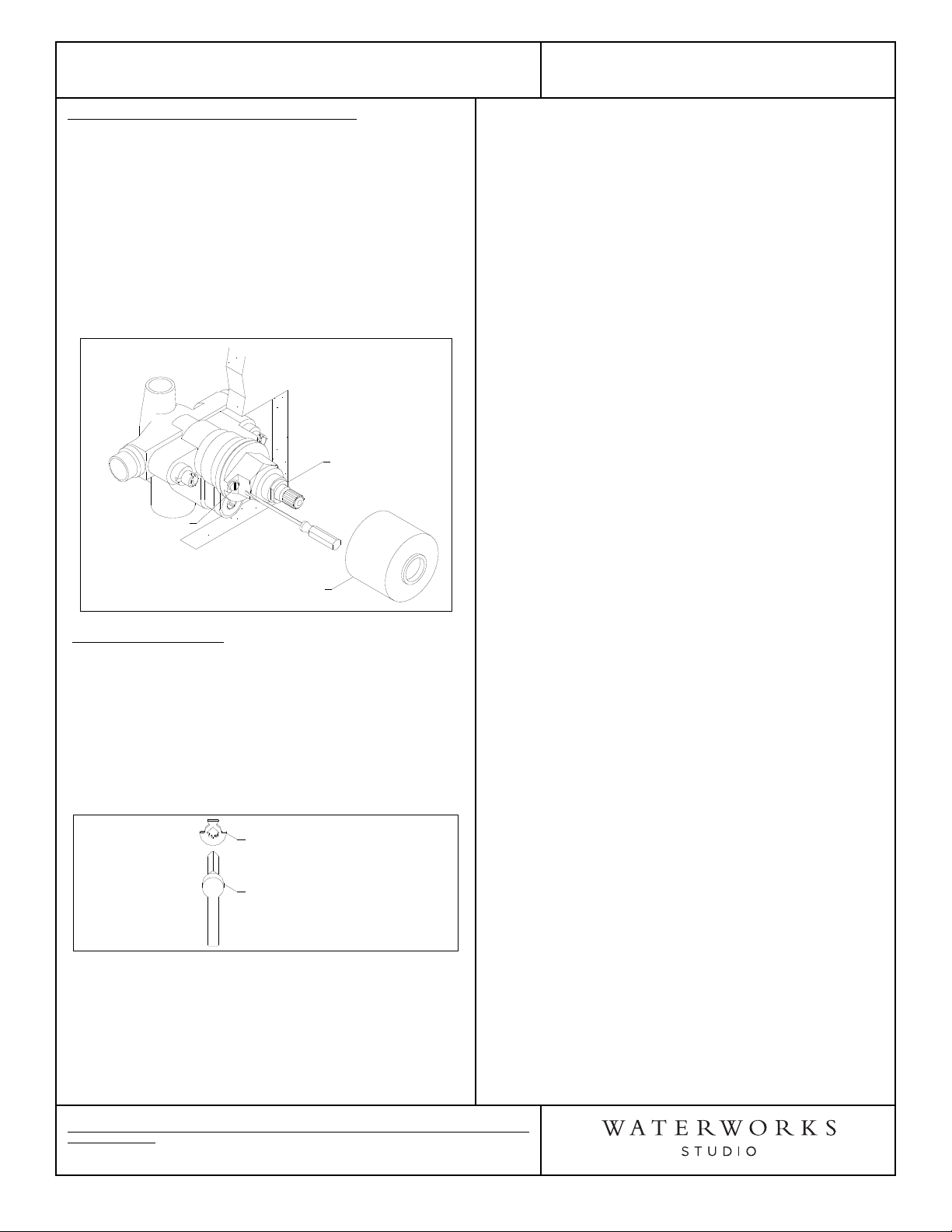

1. When the finished wall is complete, turn on the hot

and cold supplies and pull off the tile guard. Valve

will not operate unless BOTH supplies are turned on.

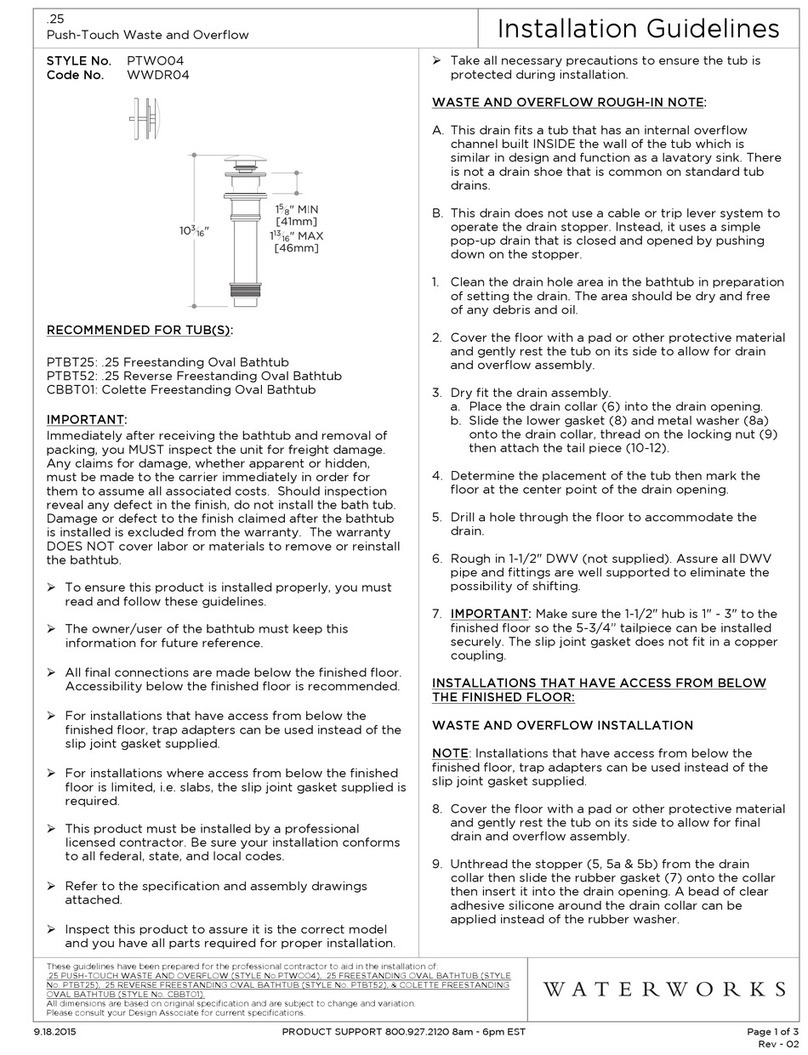

2. The lever handle (5) is for controlling the

temperature only, not volume. Place the handle on

the valve stem so it rests at 6 o'clock in the OFF

position and then turn the handle counter clockwise

through the cold, then warm and stopping at the hot

position. If additional rotational friction is required to

maintain the handle position, tighten the packing

nut. See Figure-01.

3. Allow the valve to run in the warm position for a few

minutes to completely flush the system. If system is

quite dirty, remove valve spindle to ensure proper

flushing. Refer to the Installation Guidelines for the

Pressure Balance Valve which contains a complete

parts breakdown and related information.

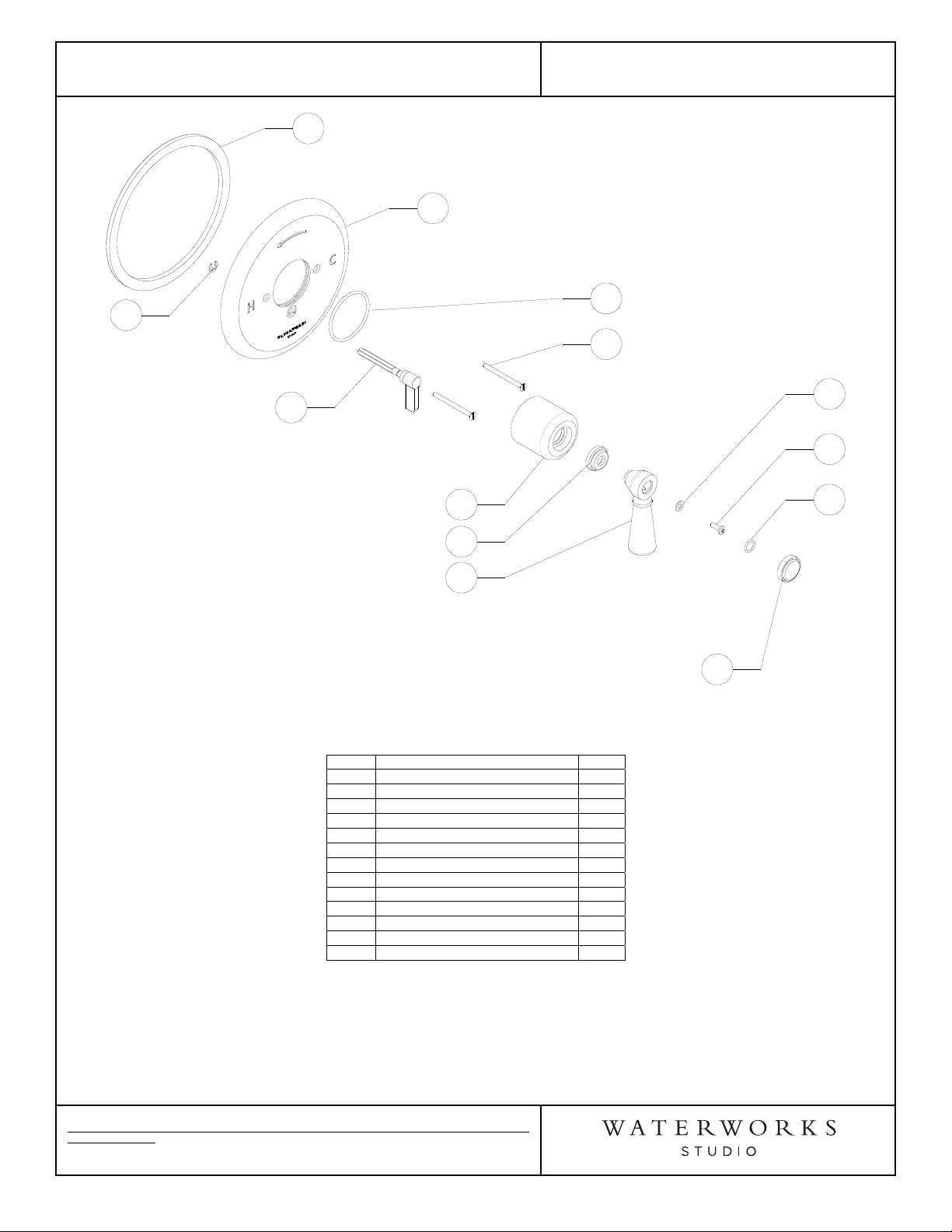

Figure - 01

Valve Spindle

Plastic Washer

Bonnet

Finished Wall

Packing Nut