Watson McDaniel UTS600 Series Instruction manual

UTS600 Series

Universal Trap Test Valve Station

Installation

Operation &

Maintenance

Manual

428 Jones Boulevard

Limerick Airport Business Center

Pottstown, PA 19464

Phone: (610)495-5131

Fax: (610)495-5134

www.watsonmcdaniel.com

2

Watson McDaniel Company UTS600 Manual 2590000 RevA

UTS600 Specifications

Each Watson McDaniel Company Product is warranted against defects in material and workmanship for one year from date of shipment. This warranty extends to

the first retail purchaser only. All defective material must be returned to the person from whom you purchased the Product, transportation prepaid, free of any

liens or encumbrances, and if found to be defective will be repaired free of charge or replaced, at the warrantor’s or seller’s option. If the material is replaced, any

replacement will be invoiced in the usual manner and after inspection of alleged defective material an adjustment will be made for depreciation caused by

purchaser’s use. In no event will Watson McDaniel Company be liable to do more than refund the original contract price. Incidental and consequential damages

are excluded, whether under this warranty or otherwise. All implied warranties, including warranties of merchantability and fitness for a particular purpose, are

disclaimed and excluded.

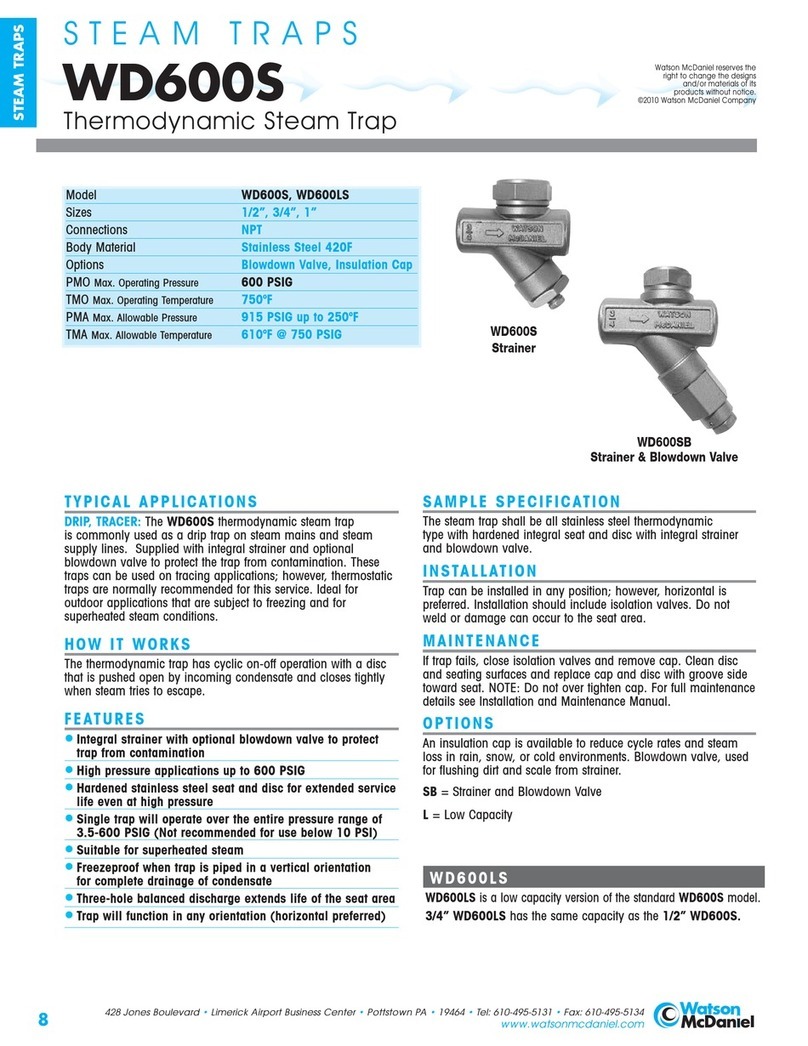

UTS600 Universal Connector Trap Test Station is used with the following Watson McDaniel trap modules:

UTD450

UTD450SM &

UTD600LSM

UT450

UFT450

USIB450

UB450

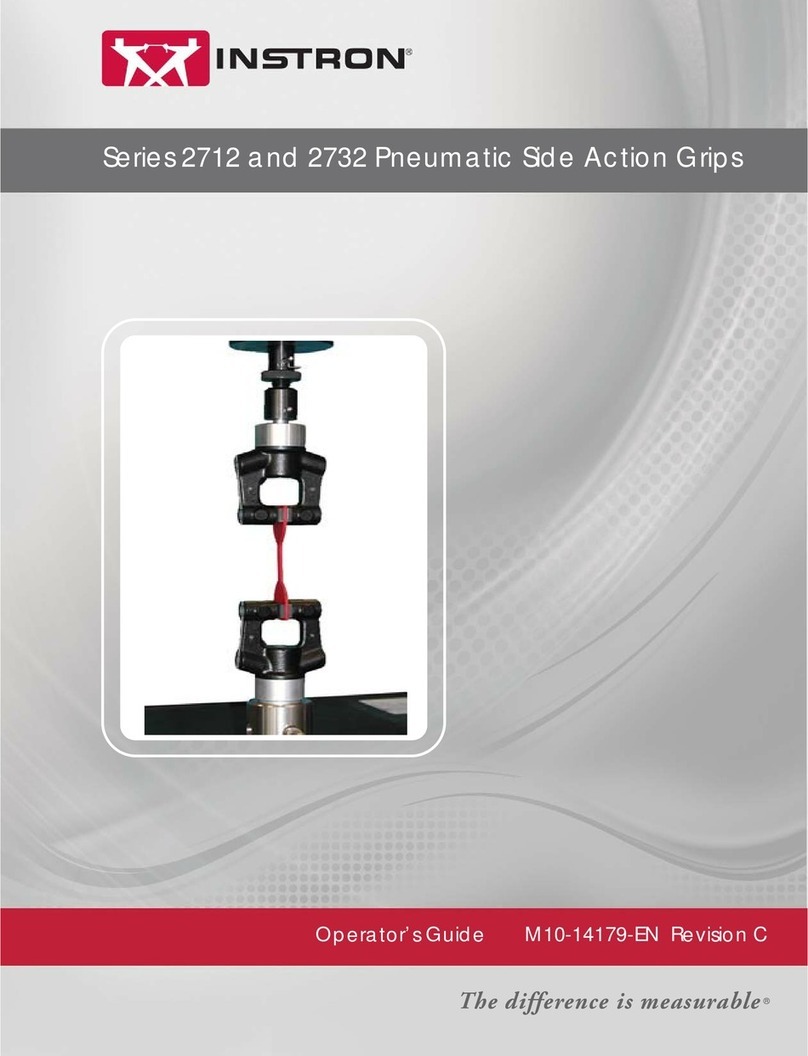

Figure 1: UTS600 Side View

Figure 2: UTS600 Top View

3

Watson McDaniel Company UTS600 Manual 2590000 RevA

Principle of Operation

The UTS600 Series Universal Connector Trap Test Valve Station has a two-bolt 360 degree swivel mount flange

design, integral piston-style isolation valves, test valve, and integral strainer and blowdown valve.

1. Universal Connector Trap Test Station will be in normal operation when both the inlet and outlet isolation valve

are in the open position and the blowdown valve and test valve are in the closed position.

2. To test the trap during normal operation, open the test valve and close the outlet isolation valve. When

opening test valve, hold test valve body in place with wrench while opening valve head.

3. To return Trap Station to normal operation, open the outlet isolation valve and close the test valve.

Caution: Hot condensate and flash steam will be discharged from the test port. Pipe test valve to make sure it

will discharge to a safe area.

Installation

1. Make sure steam supply is safely shut off. Before installing the universal connector trap station, blow out

piping thoroughly to remove loose scale and dirt.

2. The trap station can be installed in horizontal or vertical piping.

3. Use pipe dope or Teflon tape sparingly when attaching the universal connector trap station to the pipe.

Tighten bolts evenly with 35-40 ft-lbs torque.

4. Pipe test port to ensure any condensate and steam will discharge to safe location.

5. Install drip pocket to keep dirt away from the trap station.

6. Mount selected universal trap to the trap station. Ensure that the trap is mounted in the proper orientation for

operation. Refer to trap installation and operation manual for trap installation detail.

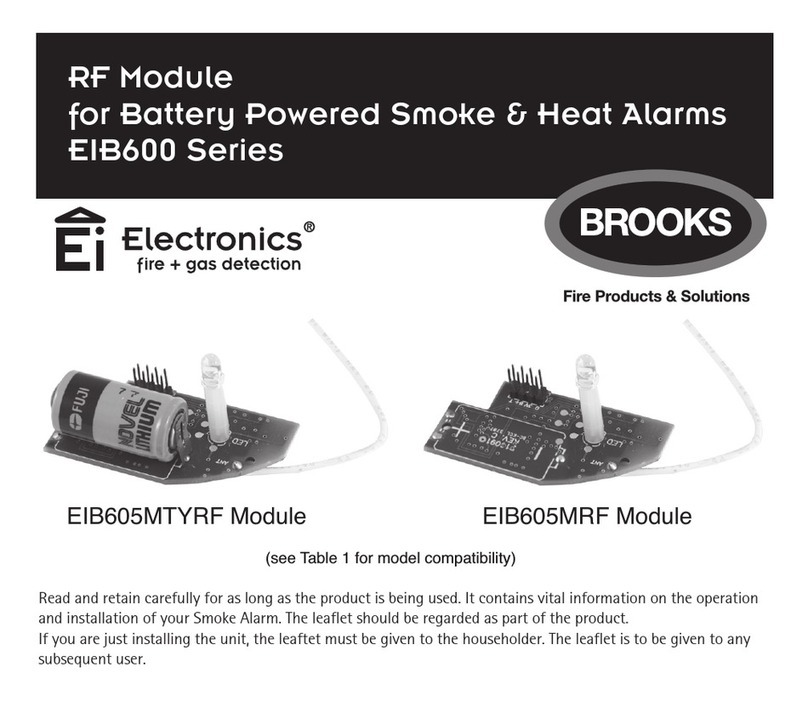

Figure 3: UTS600 with USIB450 Trap Module installed in Drip Leg before PRV.

4

Watson McDaniel Company UTS600 Manual 2590000 RevA

Start-Up

1. Upon start-up, the blowdown valve should be in the open position. Outlet isolation valve and test valve should

be in the closed position. When opening blowdown valve, hold blowdown valve body in place with wrench

while opening valve head.

2. Open the inlet isolation valve to blowdown and purge the trap station.

3. Once the trap station is blown down, close blowdown valve.

4. Open outlet isolation valve. Trap station is now in operation.

Maintenance

1. To clean strainer, open blowdown valve to clear any debris. When opening blowdown valve, hold blowdown

valve body in place with wrench while opening valve head.

2. To test the trap for proper operation, open the test valve during normal operation and close the outlet isolation

valve. Observe the discharge from the test valve. If condensate and flash steam is discharging, trap is working

properly. If live steam is present, trap may be failed open. If no condensate is present, trap may be failed

closed. Replace trap module if necessary. Do not remove trap until pressure is relieved and trap is cool. Refer

to trap installation and operation manual for further trap operation detail.

3. If trap module needs to be removed, isolate the trap by closing the inlet and outlet isolation valves. Open the

blowdown valve and test valve to relieve the pressure and drain any condensate. Once pressure is relieved and

trap is cool, the trap can now be removed and replaced.

Note: When opening blowdown and test valve, hold the valve body in place at the base, with a wrench, while

opening valve head.

5

Watson McDaniel Company UTS600 Manual 2590000 RevA

Troubleshooting and Repair of Trap Test Valve

1. If isolation valve is leaking when valve is closed, make sure the valve is fully closed. If valve is still leaking,

tighten bonnet nuts (4) to compress valve rings (9). If valve continues to leak, replace the valve rings and

bonnet assembly (2, 4).

2. Before replacing isolation valve and components, the Trap Test Station must be separately isolated upstream

and downstream.

3. Open the inlet and outlet isolation valves on the Trap Test Station. Open the blowdown valve to remove any

pressure in the piping.

4. Loosen and remove bonnet nuts (4) and washers (5). Pull the bonnet assembly (2) off the valve body.

5. Remove the valve rings (9) and lantern bushing (8). Inspect and clean and dirt and debris on valve body.

A. Replacing valve rings

6. Remove bonnet nuts (4) using ½” wrench. Loosen nuts evenly until fully removed. Remove washers (5).

7. Remove valve rings (9) and lantern bushing (8).

8. Clean metal seating surface on valve body and underside of bonnet of any dirt debris. Clean inside of valve

body where valve rings and lantern bushing sit.

9. Insert 1 set of new valve rings into connector body (1).

10. Insert new lantern bushing on top of valve rings.

11. Insert 1 set of new valve rings on top of lantern bushing.

12. Reinstall bonnet assembly onto connector body. Place washer (5) and nuts (4) and tighten evenly until bonnet

seats against the valve body.

13. Close inlet valve before bring back into operation. Refer to start up section when bringing trap back into

operation.

6

Watson McDaniel Company UTS600 Manual 2590000 RevA

B. Replacing valve stem

1. Remove hand wheel nut (11), washer (12) and nametag (13). Remove hand wheel (10).

2. Remove bonnet nuts (4) using ½” wrench. Loosen nuts evenly until fully removed. Remove washers (5).

3. Valve rings and lantern bushing may stay in place in valve body.

4. Clean metal seating surface on valve body and underside of bonnet of any dirt debris.

5. Unthread valve stem from the underside of the bonnet.

6. Apply anti seize compound onto valve stem threads and thread stem into bonnet from the underside. The

smooth end of valve stem will be on the bottom of the bonnet. (underside of bonnet will have a raised face)

7. Place bonnet (2) onto bonnet studs (3) on valve body. Install washers (5) and bonnet nuts (4) and tighten

evenly until bonnet seats on the valve body.

8. Place hand wheel onto valve stem making sure hand wheel is engaged with the valve stem.

9. Place name tag (13) then washer (12) then locknut (11) and fully tighten to secure hand wheel to valve stem.

10. Close inlet valve before bring back into operation. Refer to start up section when bringing trap back into

operation.

C. Replacing Blowdown and Test valves

1. Remove blowdown valve body (16) using 7/8” wrench, gasket (15) and internal strainer screen (14).

2. Apply anti-seize to new blowdown valve body threads as well as the surface where the gasket will sit.

3. Place gasket (15) onto blowdown valve body and apply anti-seize to top of gasket.

4. Insert strainer screen and thread blowdown valve body into connector body. For left to right flow trap station,

blowdown valve is located on the left side of the connector body.

5. Close blowdown valve before bringing back into operation. Refer to start up section when bringing trap back

into operation.

6. Remove test valve body (18) using 7/8” wrench and gasket (15).

7. Apply anti-seize to new test valve body threads as well as the surface where the gasket will sit.

8. Place gasket (15) onto test valve body and apply anti-seize to top of gasket.

9. Thread test valve body into connector body. For left to right flow trap station, test valve is located on the right

side of the connector body.

10. Close test valve before bringing back into operation. Refer to start up section when bringing trap back into

operation.

Table of contents

Other Watson McDaniel Control Unit manuals

Popular Control Unit manuals by other brands

National Instruments

National Instruments 9755 user manual

Texas Instruments

Texas Instruments bq25505 user guide

GEM

GEM 616 operating instructions

Genebre

Genebre 2105 Installation, operation and maintenance manual

Helmholz

Helmholz CAN 300 PRO Startup guide

Pfeiffer Vacuum

Pfeiffer Vacuum TVV 001 operating instructions