Watson McDaniel HSP Series Instruction Manual

Series HSP

Pressure Pilot Regulating Valve

Installation

Operations &

Maintenance

Manual

428 Jones Boulevard

Limerick Airport Business Center

Pottstown, PA 19464

Phone: (610)495-5131

Fax: (610)495-5134

www.watsonmcdaniel.com

2

Watson McDaniel Company HSP Valve Manual Rev3 2415800

HSP Specifications

Figure 1: HS Pressure Regulating Valve

Item Description

I Pilot Assembly

II

Main Valve Assembly

HSP Valve Pressure-Temperature Ratings

150# Flanges 150psi @ 566°F

300# Flanges 450psi @ 650°F

Pressure Adjusting Range for Pilot Spring

Pressure Color

5-40 PSIG Yellow

25-100 PSIG Blue

75-300 PSIG

Red

Note: Y, B, or R is indicated on the pilot at

the adjustment screw to provide the pressure

reducing spring range

Size Flange Face to Face B C* D E** F Weight

(lb)

150PSI 300PSI

1 5 1/2 6 6 11/32 6 11/16 7 1/8 6 23/32 0.12 45

1 1/2 6 7/8 7 3/8 7 9/16 6 13/16 9 7 7/16 0.152 60

2 8 1/2 9 8 1/4 7 10 7/8 7 5/8 0.178 95

3 10 10 3/4 8 7/8 7 13 3/4 8 5/8 0.25 160

4 11 7/8 12 1/2 10 7/8 7 14 3/4 9 3/4 0.299 245

All dimensions are in inches unless noted differently

* With Pilot Screw at max height and applying no load to Spring

** Based on approximate position of plug

Each Watson McDaniel Company Product is warranted against defects in material and workmanship for one year from date of shipment. This warranty extends to

the first retail purchaser only. All defective material must be returned to the person from whom you purchased the Product, transportation prepaid, free of any

liens or encumbrances, and if found to be defective will be repaired free of charge or replaced, at the warrantor’s or seller’s option. If the material is replaced, any

replacement will be invoiced in the usual manner and after inspection of alleged defective material an adjustment will be made for depreciation caused by

purchaser’s use. In no event will Watson McDaniel Company be liable to do more than refund the original contract price. Incidental and consequential damages

are excluded, whether under this warranty or otherwise. All implied warranties, including warranties of merchantability and fitness for a particular purpose, are

disclaimed and excluded.

I

II

Do not insulate

below line

3

Watson McDaniel Company HSP Valve Manual Rev3 2415800

Principle of Operation

The HSP Pilot Operated Pressure Regulating Valve

is designed to maintain a consistent downstream

pressure for steam applications.

1. High pressure steam enters the Main Valve

Body and fills the chamber above the Seat in

the main body.

2. The high pressure steam moves to the Pilot

Base where a stainless steel screen captures

unwanted dirt and particles. This allows

cleaner steam to pass through to the pilot base.

3. Turning the Pilot Adjusting Screw clockwise

compresses the Adjusting Spring. The Adjusting

Spring applies pressure to the Pilot Diaphragm

which opens the Pilot Valve.

4. The steam then travels through the Pilot Valve

to the External Transmission Tubing. This then

fills the area under the Main Valve Diaphragm.

5. The pressure under the Main Valve

Diaphragm pushes the stem upward which

lifts the Main Valve Disc off the Seat, which

allows the upstream steam to flow to the

downstream piping.

6. The Pilot Sensing Line, which is

recommended to be a minimum of 10 pipe

diameters downstream from the valve, also

fills with steam. The steam then builds

pressure under the Pilot Diaphragm to

balance the spring force and allow the Pilot to

throttle to maintain a constant downstream

pressure.

7. When the valve must close, the Bleed Orifice

will allow pressure to exit the area under the

Main Valve Diaphragm and into the

downstream piping

1

2

3

4

5

6

4

Watson McDaniel Company HSP Valve Manual Rev3 2415800

Figure 2: Valve Operations

Installation

ARecommended Notes for System

1. Piping will need to be adequately sized to

handle the flow, velocity, and pressure

requirements for the regulator’s application.

2. Piping upstream should generally be 1-2X

larger and downstream should be 2-3X

larger than the valve to eliminate flow

restrictions.

3. An eccentric reducer at inlets will reduce the

risk of water hammer by removing a

potential condensate collection point.

4. To prevent condensate from possibly

damaging the regulator or pipe, an

adequately sized drip leg with steam trap

should be installed prior to the regulator.

5. A strainer with blow down valve is

recommended before all regulator

installations. The strainer should be in the

horizontal position to prevent any collection

of condensate. Pipeline debris and scale

can damage internal valve components,

potentially leading to poor operation and/or

failure.

6. A bypass line may be added with gate

valves before and after the HS Regulating

Valve. A globe valve is recommended to

throttle the bypass line.

7. To ensure proper operation, follow the

recommended guideline of 10 pipe

diameters minimum straight run lengths of

pipe before and after a regulator.

8. Pressure gauges should be installed before

and after the regulator to confirm operation.

A siphon loop and isolation valve should be

installed prior to the gauge.

Figure 3: Recommended Valve Installation

5

Watson McDaniel Company HSP Valve Manual Rev3 2415800

BValve Installation

1. Verify steam supply is safely shut off.

2. Clean out existing pipe to remove scale and

debris buildup. Buildup in the lines could

cause damage to the regulator.

3. The valve shall be installed in the horizontal

position with the diaphragm positioned on

the bottom.

4. Verify the direction of flow is in the correct

orientation. An arrow on the regulator body

will confirm the flow’s direction.

5. When installing the flange bolts, tighten

evenly and in a star pattern.

CPilot Installation

1. Assemble the pilot to the valve body making

sure the gasket is properly seated between

the pilot and main body. Be sure to tighten

the bolts evenly.

2. Install the pilot sensing line, which should

be ¼” stainless steel tubing.

3. The pilot sensing line should be connected

from the pilot valve to the downstream

piping with the following recommendations:

a. A minimum of 10 pipe diameters straight

run length of pipe after the regulator

b. The location should have a minimum

amount of turbulence

c. The sensing line should slope down and

away from the pilot to prevent

condensate from entering the pilot.

d. A needle valve is recommended to be

installed in the sensing line for fine-

tuning purposes.

Start up

1. All valves in the installation need to be

closed.

2. Loosen the locknut on the pilot adjusting

screw and back out until the force has been

released from the adjusting spring.

3. Open the valve ahead of the steam trap or

other drain valve to remove all condensate

from the inlet piping. Follow the same

procedure for a steam trap on the outlet

piping. Note: Serious damage to the piping

system and PRV could occur from the

effects of water hammer.

4. Open the pilot isolation valve in the pilot

sensing line after the condensate has been

removed from the system.

5. Verify that the bypass valve is closed, and

slowly open the outlet gate valve.

6. Slowly open the inlet gate valve for the

main valve and verify there are no

indications of water hammer conditions.

7. Blowdown the main inlet strainer and the

pilot strainer.

8. Turn the pilot adjusting screw slowly

clockwise until the valve begins to open and

pass steam downstream.

9. Adjust the pilot screw until the desired

pressure is reached. Allow time for pressure

changes to occur due to the piping system

volume.

10. After the system has stabilized check the

downstream pressure and readjust the pilot

screw as required.

11. Inspect the piping system and valve for any

leaks and tighten as required. Then tighten

the locknut for the pilot adjusting screw.

6

Watson McDaniel Company HSP Valve Manual Rev3 2415800

Maintenance

Proper maintenance is significant for reliable operation of the valve. Frequency of cleaning and

maintenance performed are dependent on the conditions of the steam system.

AGeneral Service Inspection

1. Inspect all connections for leaks and tighten as required.

2. Blow down or clean the pilot and all pipe line strainers in the system.

3. Verify the pressure is properly set after blow down and readjust if necessary.

Note: At a minimum, these maintenance operations should be performed a few days after the valve

has been initially installed and shortly after the start up during each heating season.

Orifices

There are 2 different orifices located on the Valve. The Tee Bleed orifice is located on the Pilot and

supplies a pressure relief path back to the main valve body. The end of the Tee with the orifice, which

has an indicator mark, should be installed with the orifice side up as shown in Figure 4. The Elbow

Diaphragm orifice is located outside the main valve body opposite of the diaphragm cover.

Figure 4: Orifice Locations

7

Watson McDaniel Company HSP Valve Manual Rev3 2415800

Figure 5: Pilot Assembly

Allow pilot to cool before

disassembly. Condensate trapped

in the system has the potential to

cause burns or serious injury.

PILOT ASSEMBLY

ITEM DESCRIPTION MATERIAL

1 Pilot Body Steel

2 Cover Steel

3 Diaphragm Bronze

4

Gasket

Flexicarb / SS

5 Adjusting Spring Stainless Steel

6 Adjusting Screw Steel

7 Stem Stainless Steel

8 Stroke Limiter Stainless Steel

9 Bushing Stainless Steel

10 Blowdown Body Stainless Steel

11 Blowdown Stem Stainless Steel

12 Disc Stainless Steel

13 Main Spring Stainless Steel

14 Gasket Stainless Steel

15 Screen Stainless Steel

16

Seat

Stainless Steel

17 Spring Cup Stainless Steel

18 Pipe Plug, ¼ NPT* Steel

19 Spring Button Stainless Steel

20 Upper Spring Button Stainless Steel

21 Cap Screws Steel

22

Spacer

Steel

BPressure Pilot Service

1. Turn the pilot adjusting screw counter-

clockwise to remove all compression from the

pilot spring.

2. Shut off the inlet gate valve and verify the

downstream pressure is zero.

3. Remove the pilot cover cap screws and cover.

4. Inspect the metal diaphragm for cracks and

wrinkles. Replace as required.

5. Clean any debris from inside the pilot assembly

and diaphragm surfaces.

6. Unscrew the blowdown body assembly from

the pilot.

7. Inspect the seat and disc for wear or damage.

Replace as required.

8. Inspect and clean the pilot screen.

9. Disconnect the tubing lines from the tee on the

pilot and clean the orifice as required.

10. Reassemble the blowdown valve assembly and

tighten back into the pilot body.

11. Reseat the diaphragm and reassemble the pilot

cover making sure to tighten the bolts evenly.

CAUTION

Tee with

Orifice

facing up

*Not shown in drawing view

8

Watson McDaniel Company HSP Valve Manual Rev3 2415800

Figure 6: Main Valve Assembly

Figure 7: F Dimension Detail

Size F

1 0.120

1 1/2 0.152

2 0.178

3 0.250

4 0.299

Note: The F dimension shall be from the diaphragm

step of the main body to the bottom center of the

Diaphragm Plate.

MAIN VALVE ASSEMBLY

ITEM DESCRIPTION MATERIAL

1 Body Steel

2 Cover w/ Bushing Steel

3 Diaphragm Cover Steel

4 Pilot -

5 Seat Stainless Steel

6 Stem & Disc Assembly Stainless Steel

7 Diaphragm Bronze

8 Cover Bolts Steel

9 Cover Nuts Steel

10 Spring Stainless Steel

11 Diaphragm Plate Steel

12 Stem Guide Bronze

13 Control Tubing Stainless Steel

14 Tubing Fittings Stainless Steel

15 Cover Nuts Steel

16 Cover Gasket Grafoil

17 Branch Tee, Bleed Orifice Stainless Steel

18 Diaphragm Orifice Elbow Stainless Steel

19 Dia. Plate Lock Screw Stainless Steel

20 Travel Stop Stainless Steel

9

Watson McDaniel Company HSP Valve Manual Rev3 2415800

CMain Valve Service

Allow valve to cool before disassembly. Condensate trapped in the system has

the potential to cause burns or serious injury. Use caution while disassembling

all components as condensate may leak from within the valve assembly.

1. Close the inlet & outlet gate valves. Bleed the

pressure through the blowdown valve on the

pipe line strainer. Verify that the inlet and

outlet pressure is zero before proceeding.

Note: Outlet gate valve should be closed

when pressure is at zero to prevent any

downstream condensate from entering the

valve.

2. Disconnect the tubing line to the diaphragm

chamber at A.See Figure 8.

3. Inspect the orifice for debris or damage.

Clean or replace as required.

4. Slightly loosen the main valve diaphragm

nuts.

5. Then continue to loosen the nuts opposite the

side of working and pry the cover from the

valve body, if necessary. Allow the

condensate to drain away from where you are

working.

Note: The diaphragm cover may be heavy –

Care should be taken to properly support

it to avoid damage and/or personnel

injury.

6. Gently pry the diaphragm loose from the valve

body and allow any condensate to drain away

from your working position.

7. Once drained, continue to remove all

diaphragm nuts and cover.

8. Inspect the metal diaphragm for small cracks

or wrinkles. Replace as required.

9. Loosen the lock screw for the diaphragm plate

and then remove plate itself. Caution: The

main valve spring is exerting significant force

on the diaphragm plate. Proceed slowly.

10. Remove the top cover nuts and cover plate.

11. Remove the stem and disc assembly from the

valve and inspect the components for wear.

Minor wear can be corrected by lapping disc

and seat together with 400 grit lapping

compound.

12. Inspect the disc and seat for signs or debris

which could have caused leakage.

13. Check for erosion around the valve body of

the seat ring and the seat ring itself. Replace

or clean as required. If replaced, seat and

disc should be lapped.

14. Reassemble the valve stem assembly and

secure the top cover. Tighten the nuts

evenly.

15. Clean the diaphragm, diaphragm plate, and

gasket surfaces then reassemble making sure

the travel stop is installed properly.

16. Verify that the diaphragm plate setting is

correct. See dimension F, Figure 7, and

confirm that it is set to the value shown in the

table.

17. Verify that the diaphragm plate is securely

fastened to the stem with the locking screw.

Use High Temp Thread Locking Sealant as

required.

18. Confirm valve stem is operating properly by

pushing up on the diaphragm plate.

Note: Use caution as condensate may be

trapped in the upper portion of the valve

body if valve was not disassembled

completely.

19. Center the diaphragm on the cover. The bolts

will assist with centering.

20. Tighten the bolts evenly on the diaphragm

cover.

21. Reinstall the tubing line to the diaphragm

chamber.

22. After system is started again, recheck all

fasteners for tightness.

CAUTION

10

Watson McDaniel Company HSP Valve Manual Rev3 2415800

Valve Troubleshooting

The most common field problem with the HSP Series regulating valves is that they become saturated

with condensate or water. The valves are designed to operate on steam and may perform erratically

or fail to operate at all if the valve and/or pilot contain significant water. It is imperative to verify all

water is drained from the valve and pilot before attempting to diagnose a malfunctioning valve.

Figure 8: Tubing Location Detail

REGULATOR WILL NOT COME UP TO PRESSURE OR TEMPERATURE

1. Shut off inlet gate valve to regulator and make sure downstream pressure is zero.

2. Check Pilot Strainer for blockage as well as the upstream pipeline strainer.

3. Inspect Elbow Diaphragm Orifice for blockage and Diaphragm for rupture.

4. Check that the Bleed Orifice at the Male Branch Tee is clean and not missing.

PRESSURE OVERRIDES SET POINT: ISOLATE REGULATOR FROM PILOT FOR TESTING

1. Shut off inlet block valve to regulator and make sure downstream pressure is zero.

2. Adjust the pilot to the closed position by backing out the adjustment screw until there is no

compression on the spring.

3. Disconnect the pilot tube at the regulator diaphragm which is indicated as point "A" in the

illustration above. Also disconnect the smaller pilot tube at the side of the regulator body

designated point "B" in the above illustration.

4. Stand clear of the tube connections and open the block valve upstream of the Main Valve only

partially to limit the steam pressure to the regulator. Full line pressure is not necessary for this

test. Note: Do not exceed 10 psi or damage to the main valve diaphragm may result.

5. Regulator seat test - With the long pilot tube disconnected at point 'A' the regulator should be

closed. If there is steam blowing out of the body side connection at point "B", the main valve

and seat are leaking and require inspection for condensate or debris that is holding the valve off

the seat or erosion of the sealing surfaces.

6. Pilot seat test - With the pilot closed there should not be any steam coming out of the long

tubing at point "A". If there is steam flow, the pilot is not closing off and must be inspected for

debris or seat erosion. Try running the adjustment screw in & out a few times to clear the

debris. If that is not successful, the pilot must be cleaned, repaired or replaced.

A

B

11

Watson McDaniel Company HSP Valve Manual Rev3 2415800

System Troubleshooting

PROBLEM POSSIBLE CAUSE CORRECTION

1. Cannot set valve to

give high enough

downstream

pressure

requirements

a) Valve undersized a) Check capacity of valve against load

b) Downstream piping undersize b) Check velocity of steam in piping

system

c) Pilot valve spring not adjusted properly c) Readjust desired reduced pressure

d) Pilot adjusting spring not correct

d) Check color code of spring against

spring range in literature

e) Inlet or outlet gate valve partially closed

e) Open valves

f) Upstream pipeline strainer blocked f) Clean strainer screen

g) Pilot screen clogged

g) Clean screen

h) Inlet pressure too low causing reduced

capacity thru valve h) Check with gage and correct as

required

i) Diaphragm orifice blocked i) Check and clean orifice, Do not

remove clean-out wire

j) Bleed orifice fitting missing, installed

wrong or eroded j) Inspect and check against cut-away

drawing

k) Main valve diaphragms failed k) Replace diaphragms

2. Downstream

pressure over rides

set pressure under

load conditions

a) Valve is extremely oversized a) Check catalog for rated capacities

b) Bypass valve open b) Close valve

c) Pilot valve adjusting spring set too high

c) Readjust to desired reduced

pressure

d) Bleed orifice blocked d) Inspect and clean

e) Dirt in pilot seat or stem guide

e) Clean pilot head and seat assembly

f) Foreign object lodged between main valve

disc and seat f) Check main valve disc and seat.

Check stem guide bushing for

binding

g) Pilot diaphragms ruptured

g) Replace pilot diaphragms

h) Main valve seat thread leaking

h) Check body in seat ring area for

erosion

3. Valve will not open a) Adjusting spring not set a) Adjust setting

b) Upstream isolation valve closed b) Check and open valve

c) Upstream pipeline strainer blocked c) Clean strainer screen

d) Pilot screen blocked

d) Remove and clean

e) Pilot stem and guide bound with dirt

e) Inspect and clean

f) Bleed orifice missing or installed wrong f) Inspect and check against cut-away

drawing

g) Diaphragm orifice blocked g) Inspect and clean. Do not remove

clean out wire

h) Main valve diaphragms ruptured h) Replace main valve diaphragms

4. Valve will not close

a) Bypass valve open

a) Close bypass valve

b) Pilot sensing line not installed b) Install pilot sensing line

c) Bleed orifice blocked c) Inspect and clean

d) Dirt in pilot seat or guide d) Inspect and clean

e) Inspect and clean

e) Replace pilot diaphragms

f) Foreign object lodged between main valve

disc and seat f) Inspect, clean and repair

12

Watson McDaniel Company HSP Valve Manual Rev3 2415800

HSP Series Valve Capacities

Full Port

Regulating Valve - Capacities

FULL PORT CAPACITIES

- (Steam lbs/hr)

Inlet

Pressure

(PSIG)

Outlet

Pressure

(PSIG) 1" 1-1/2" 2" 3" 4" Inlet

Pressure

(PSIG)

Outlet

Pressure

(PSIG) 1" 1-1/2" 2" 3" 4"

CV Factors 11 21 37 71 113 CV Factors 11 21 37 71 113

5

90 45 1950 3700 6600 12700 20200

0 250 500 800 1600 2600 60 1700 3200 5700 10900 17400

2 230 440 770 1500 2400 75 1200 2300 4100 7900 12600

7 0 325 600 1100 2100 3600 100 50 2100 4100 7300 14000 22200

2 300 575 1000 2000 3100 60 2000 3800 6700 12900 20500

3 275 525 900 1800 2800 80 1400 2700 4800 9200 14700

10 0 425 850 1500 2800 4600 125 60 2700 5200 9100 17500 28000

2 400 800 1400 2700 4300 75 2400 4600 8200 15700 25000

5 300 600 1000 2000 3200 100 1800 3500 6200 11900 19000

12 0 475 900 1600 3100 4900 150 75 3100 6000 10600 20400 32400

4 400 800 1400 2700 4300 100 2700 5100 9000 17400 27700

7 375 700 1200 2400 3800 125 1900 3600 6400 12300 19600

3 550 1000 1800 3500 5600 175 85 3700 7100 12500 24000 38200

15 5 500 900 1700 3200 5200 125 2900 5600 9900 18900 30100

8 400 800 1300 2600 4200 150 2100 4100 7300 14000 22200

5 625 1200 2100 4000 6400 200 100 4200 8000 14100 27100 43100

20 10 550 1000 1800 3500 5600 125 3700 7100 12600 24100 38400

12 500 950 1600 3200 5100 150 3100 6000 10600 20300 32300

7 775 1500 2600 5000 7900 225 120 4600 8700 15400 29500 47000

25 10 700 1300 2400 4600 7300 150 4200 8000 14100 27200 43300

15 600 1100 2000 3900 6200 175 3900 7400 13100 25200 40100

12 800 1500 2700 5200 8300 250 130 5100 9700 17100 32900 53400

30 15 750 1400 2500 4900 7800 150 4700 9100 16000 30800 49000

20 650 1200 2100 4100 6500 200 3500 6700 11900 22800 36200

18 1000 1900 3300 6400 10300 300 160 5920 11310 19220 38230 60840

40 25 850 1600 2800 5400 8700 175 5625 10740 18925 36320 57800

30 700 1400 2500 4700 7600 200 5155 9840 17340 33275 52960

20 1200 2300 4100 7800 12400 350 175 6910 12950 22100 42700 68250

50 30 1100 2000 3600 6900 11000 225 6600 12340 21000 40400 64600

40 800 1500 2700 5200 8300 325 5860 10900 18500 35900 57400

30 1350 2600 4600 8900 14200 400 200 7980 14800 22000 48800 78000

60 35 1250 2400 4300 8200 13100 250 7550 13800 23800 46200 73950

50 850 1600 2900 5600 8900 300 6700 12100 21200 41000 65200

35 1650 3200 5600 10800 17200 450 225 8970 16000 22000 55000 87600

75 50 1350 2600 4600 8900 14100 300 8500 15000 26900 52100 83200

60 1150 2200 3900 7400 11800 350 7540 13300 23900 46200 73900

Note: For inlet pressures in shaded area, use low pressure main valve.

13

Watson McDaniel Company HSP Valve Manual Rev3 2415800

Reduced Port

Regulating Valve - Capacities

REDUCED PORT CAPACITIES - (Steam lbs/hr)

Inlet

Pressure

(PSIG)

Outlet

Pressure

(PSIG) 1" 1-1/2" 2" 3" 4" Inlet

Pressure

(PSIG)

Outlet

Pressure

(PSIG) 1" 1-1/2" 2" 3" 4"

CV Factors

5.6

13.3

18.8

41.7

74

CV Factors

5.6

13.3

18.8

41.7

74

5 90 45 916 2177 3077 6825 12112

0 59 140 197 438 777 60 789 1874 2648 5874 10425

2 53 128 181 401 712 75 585 1389 1964 4357 7731

7 0 82 195 276 613 1088 100 50 1018 2419 3419 7584 13458

2

79

187

265

587

1042

60

940

2234

3158

7006

12432

3 74 177 250 554 983 80 706 1676 2367 5254 9324

10 0 117 279 395 876 1554 125 60 1290 3063 4329 9603 17041

2

115

274

387

858

1523

75

1176

2793

3948

8757

15540

5 102 242 342 758 1346 100 882 2095 2961 6568 11655

12 0 141 335 473 1051 1865 150 75 1527 3628 5128 11376 20187

4 133 316 446 990 1758 100 1315 3123 4414 9791 17374

7 115 272 385 854 1515 125 975 2316 3274 7261 12885

3 173 410 580 1287 2284 175 85 1800 4272 6939 13396 23771

15

5

166

395

558

1238

2198

125

1440

3421

4835

10725

19032

8 149 354 500 1111 1972 150 1060 2518 3558 7893 14008

5 227 541 764 1696 3009 200 100 2037 4838 6838 15168 26916

20

10

204

483

684

1517

2692

125

1836

4360

6164

13672

24262

12 188 447 632 1401 2486 150 1556 3695 5223 11584 20557

7 282 670 948 2102 3730 225 120 2238 5360 7514 16667 29577

25 10 269 640 905 2006 3561 150 1972 4684 6621 14686 26061

15 235 559 790 1751 3108 175 1663 3950 5583 12384 21976

12 323 768 1085 2408 4273 250 130 2511 5964 8431 18700 33184

30

15

305

726

1025

2275

4037

150

2352

5586

7896

17514

31080

20 263 625 883 1958 3475 200 1764 4190 5922 13136 23310

18 420 998 1410 3128 5551 300 160 3015 7160 10120 22450 39840

40

25

367

872

1232

2734

4852

175

2865

6800

9615

21330

37850

30 311 739 1044 2317 4111 200 2625 6235 8810 19545 34680

20 539 1280 1809 4013 7121 350 175 3560 8280 2450 25360 45020

50 30 470 1117 1579 3502 6216 225 3370 7850 10830 24020 42650

40 353 838 1184 2627 4662 325 3000 6970 9630 21360 37910

30 611 1451 2051 4550 8074 400 200 4070 9460 2450 28980 51450

60

35

573

1361

1924

4268

7573

250

3860

8970

12380

27460

48750

50 390 926 1309 2904 5154 300 3430 7970 11010 24410 43330

35 780 1853 2619 5809 10308 450 225 4580 10650 2450 32600 57890

75

50

657

1561

2207

4895

8687

300

4340

10090

13930

30890

54840

60

529

1257

1777

3941

6993

350

3860

8970

12380

27460

48750

Note: For inlet pressures in shaded area, use low pressure main valve.

Table of contents

Other Watson McDaniel Control Unit manuals

Popular Control Unit manuals by other brands

Congatec

Congatec COM Express conga-TR4 user guide

Siemens

Siemens IP-Module user manual

ViscoTec

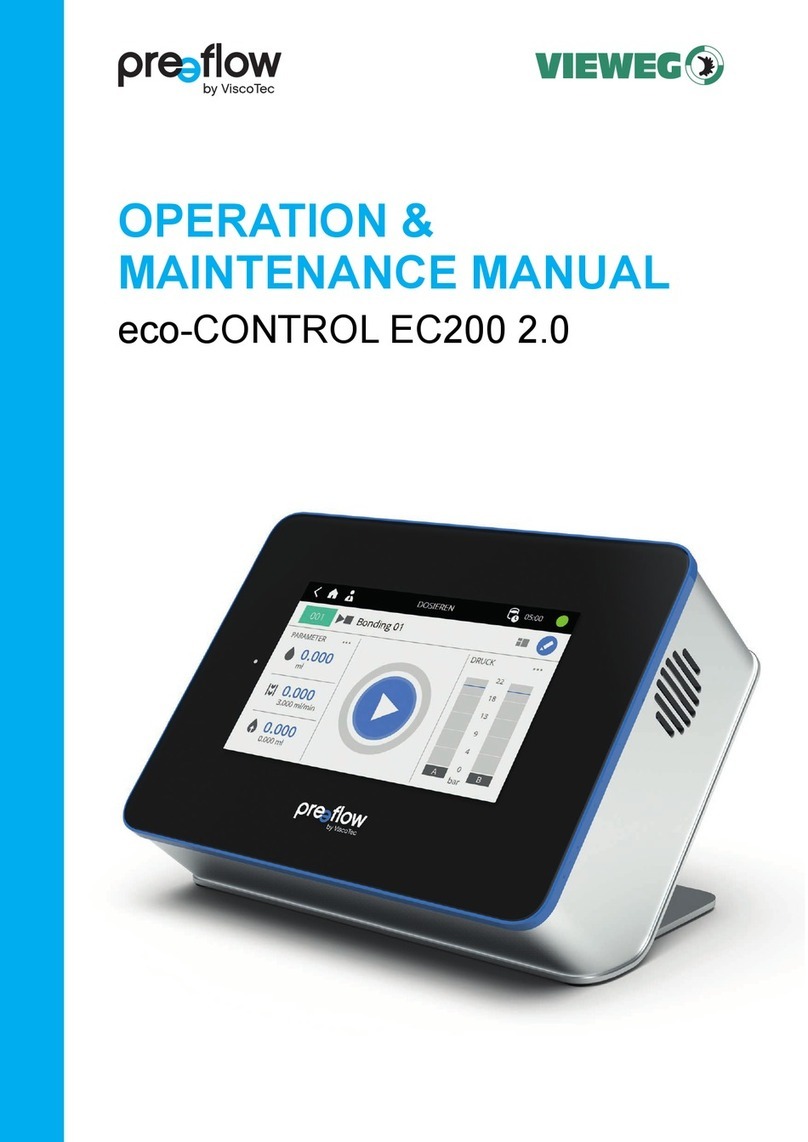

ViscoTec preeflow eco-CONTROL EC200 2.0 Operation & maintenance manual

AMS

AMS AFDAU T-1 installation manual

Emerson

Emerson Alco Controls 110RB Operating instruction

ECTIVE

ECTIVE SUNDOCK MSP operating instructions

Siemens

Siemens Simatic S7-1500 manual

American Standard

American Standard R110 installation instructions

Bryant

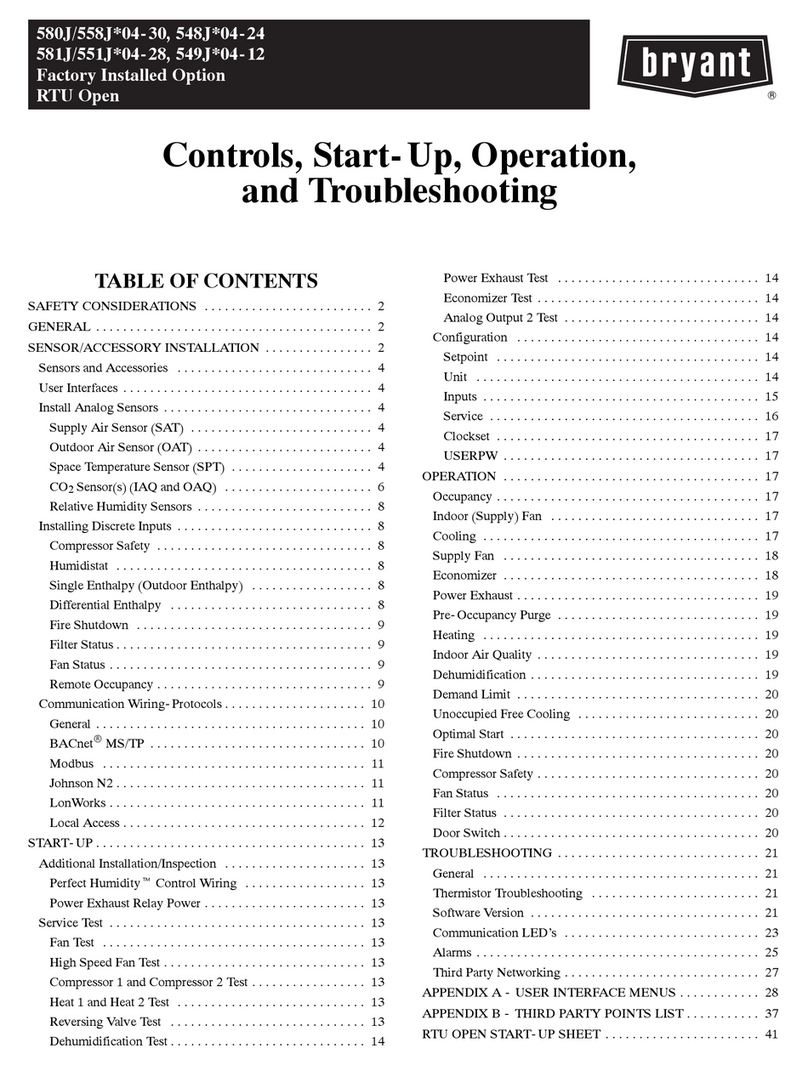

Bryant 580J 04-30 Controls, Start-Up, Operation and Troubleshooting

Indumicro

Indumicro IMM-M10 S Series user manual

Siemens

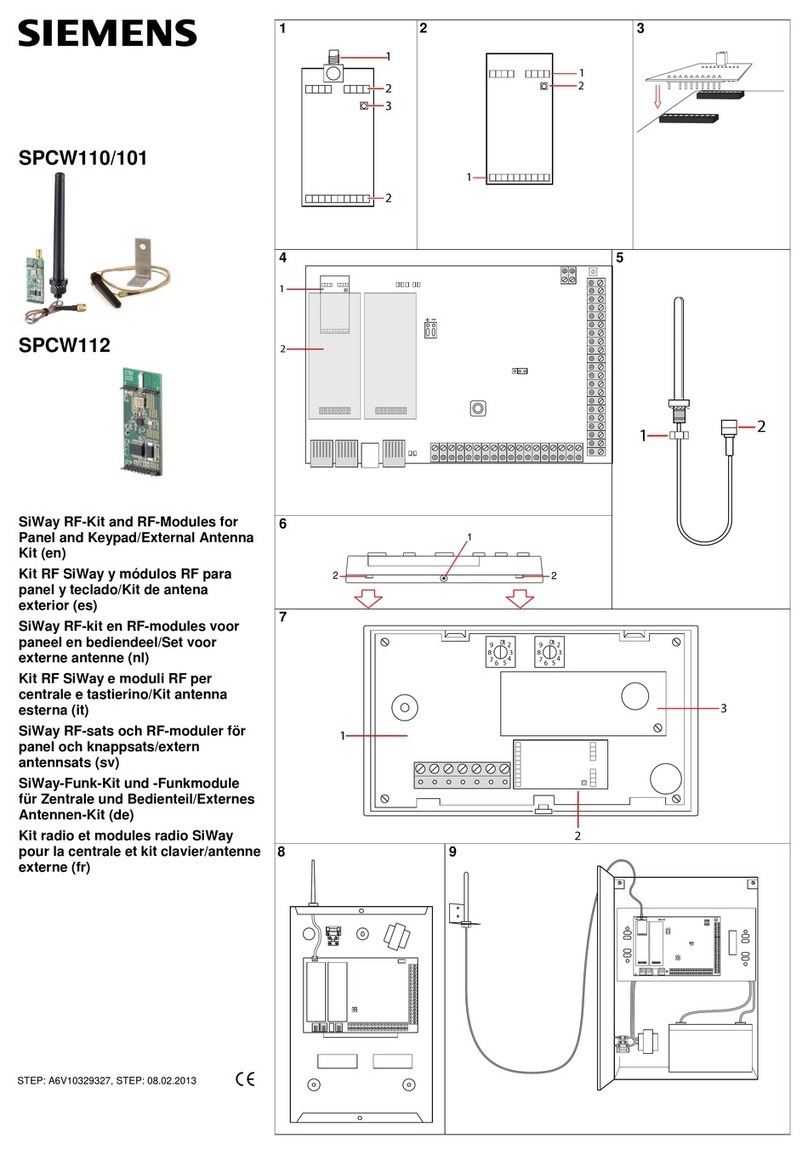

Siemens SPCW110 Installation instruction

Centralite

Centralite AZELA ZIGBEE HA quick start guide