8

STEAM TRAPS

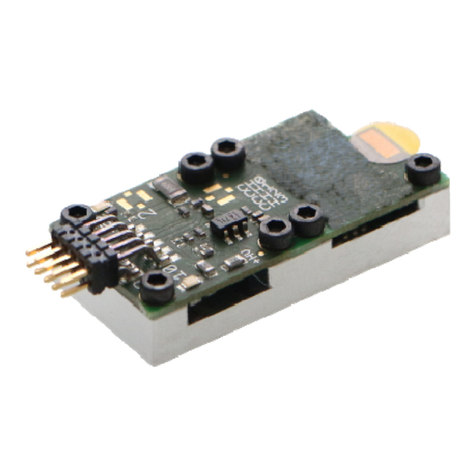

WD600LS

WD600LS is a low capacity version of the standard WD600S model.

3/4” WD600LS has the same capacity as the 1/2” WD600S.

Model WD600S, WD600LS

Sizes 1/2”, 3/4”, 1”

Connections NPT

Body Material Stainless Steel 420F

Options Blowdown Valve, Insulation Cap

PMO Max. Operating Pressure 600 PSIG

TMO Max. Operating Temperature 750ºF

PMA Max. Allowable Pressure 915 PSIG up to 250ºF

TMA Max. Allowable Temperature 610ºF @ 750 PSIG

TYPICAL APPLICATIONS

DRIP, TRACER: The WD600S thermodynamic steam trap

is commonly used as a drip trap on steam mains and steam

supply lines. Supplied with integral strainer and optional

blowdown valve to protect the trap from contamination. These

traps can be used on tracing applications; however, thermostatic

traps are normally recommended for this service. Ideal for

outdoor applications that are subject to freezing and for

superheated steam conditions.

HOW IT WORKS

The thermodynamic trap has cyclic on-off operation with a disc

that is pushed open by incoming condensate and closes tightly

when steam tries to escape.

FEATURES

•Integral strainer with optional blowdown valve to protect

trap from contamination

•High pressure applications up to 600 PSIG

•Hardened stainless steel seat and disc for extended service

life even at high pressure

•Single trap will operate over the entire pressure range of

3.5-600 PSIG (Not recommended for use below 10 PSI)

•Suitable for superheated steam

•Freezeproof when trap is piped in a vertical orientation

for complete drainage of condensate

•Three-hole balanced discharge extends life of the seat area

•Trap will function in any orientation (horizontal preferred)

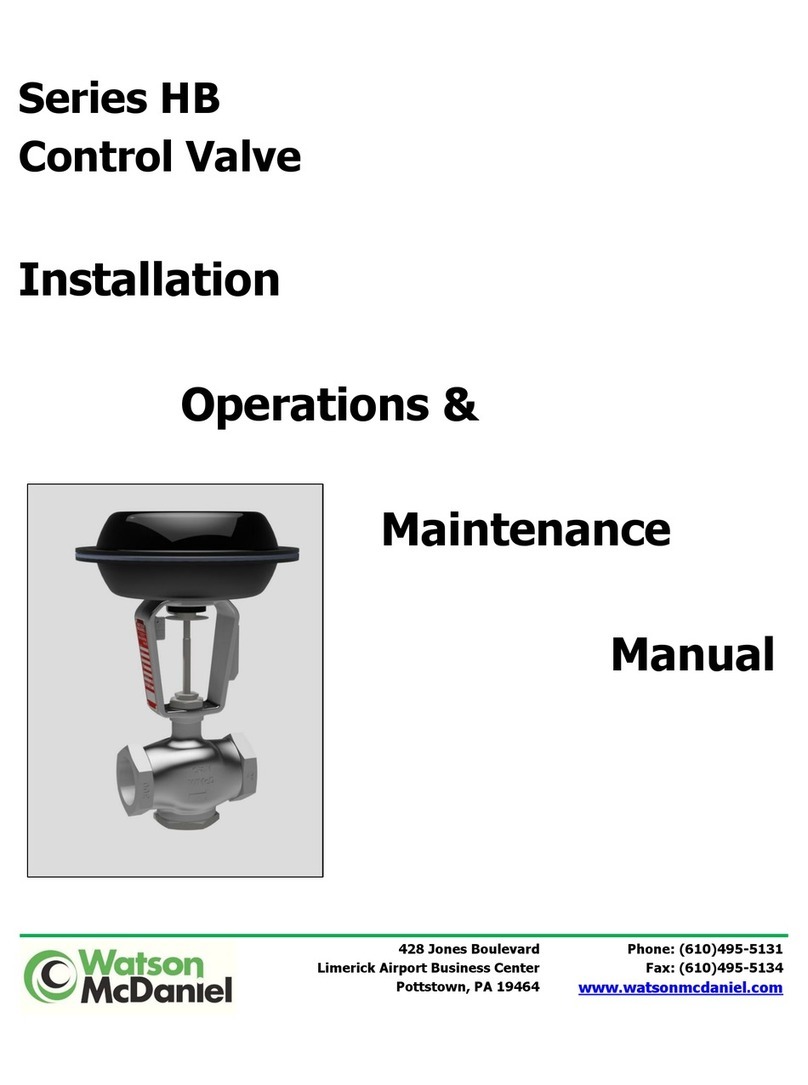

Thermodynamic Steam Trap

WD600S

WD600S

Strainer

WD600SB

Strainer & Blowdown Valve

SAMPLE SPECIFICATION

The steam trap shall be all stainless steel thermodynamic

type with hardened integral seat and disc with integral strainer

and blowdown valve.

INSTALLATION

Trap can be installed in any position; however, horizontal is

preferred. Installation should include isolation valves. Do not

weld or damage can occur to the seat area.

MAINTENANCE

If trap fails, close isolation valves and remove cap. Clean disc

and seating surfaces and replace cap and disc with groove side

toward seat. NOTE: Do not over tighten cap. For full maintenance

details see Installation and Maintenance Manual.

OPTIONS

An insulation cap is available to reduce cycle rates and steam

loss in rain, snow, or cold environments. Blowdown valve, used

for flushing dirt and scale from strainer.

SB = Strainer and Blowdown Valve

L= Low Capacity

428 Jones Boulevard •Limerick Airport Business Center •Pottstown PA •19464 •Tel: 610-495-5131 •Fax: 610-495-5134

www.watsonmcdaniel.com

Watson McDaniel reserves the

right to change the designs

and/or materials of its

products without notice.

©2010 Watson McDaniel Company

STEAM TRAPS