RP/IS-7

Installation, Maintenance, & Repair

Series 7 Dual Check Valves

LF7/7, LF7R, LF07S/07S, LF7C/7C, 7B, LFL7/L7, and LFCu7/Cu7

Sizes: 1⁄2"– 2"(15 – 50mm)

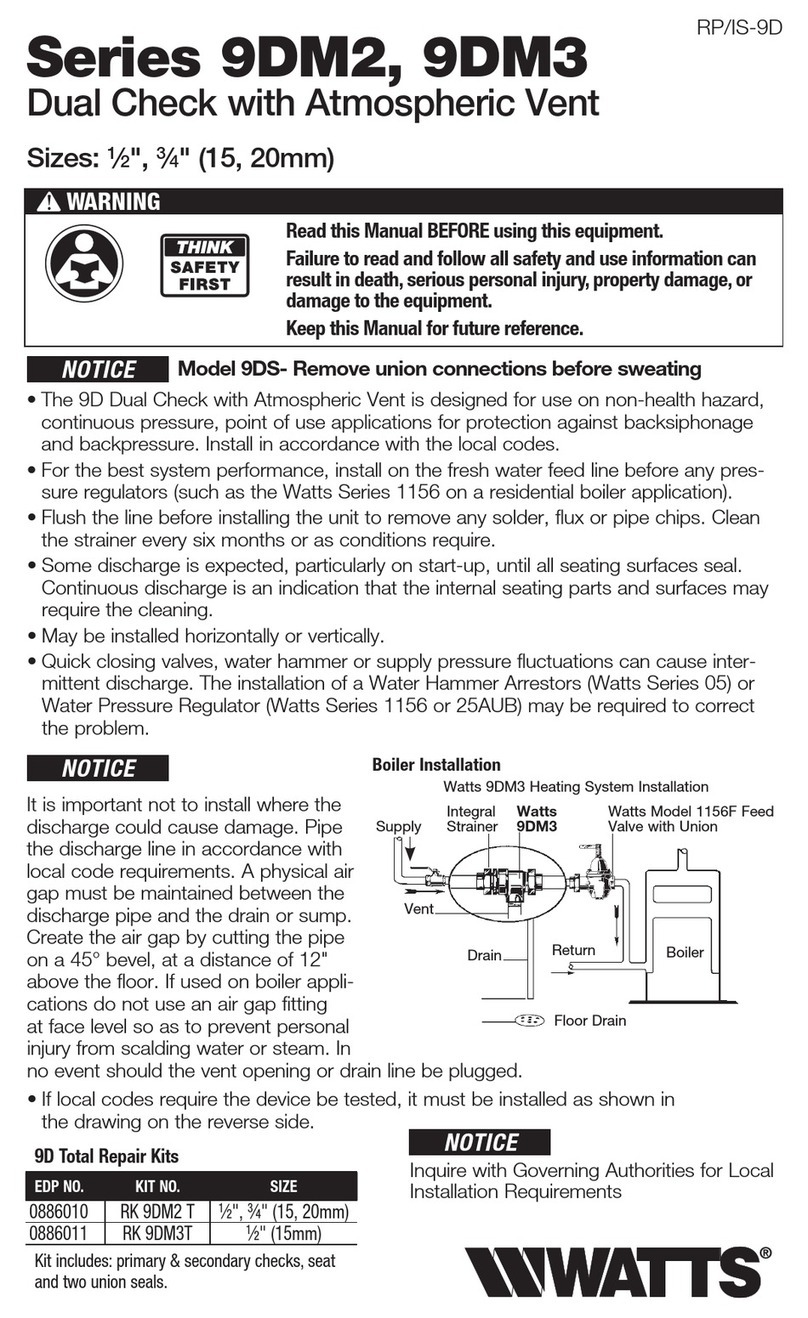

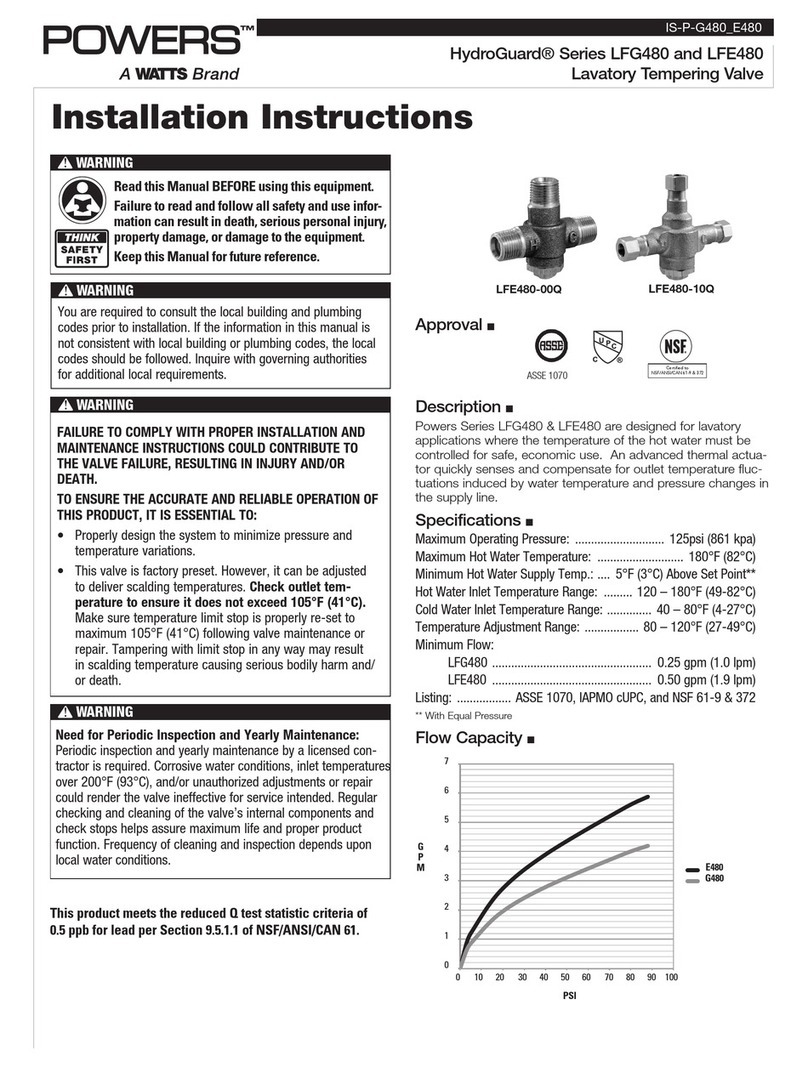

Water Meter

L7

to Sill Cock

Water

Supply

to Fire sprinklers

07S

Main

Supply

Water Pressure

Reducing Valve

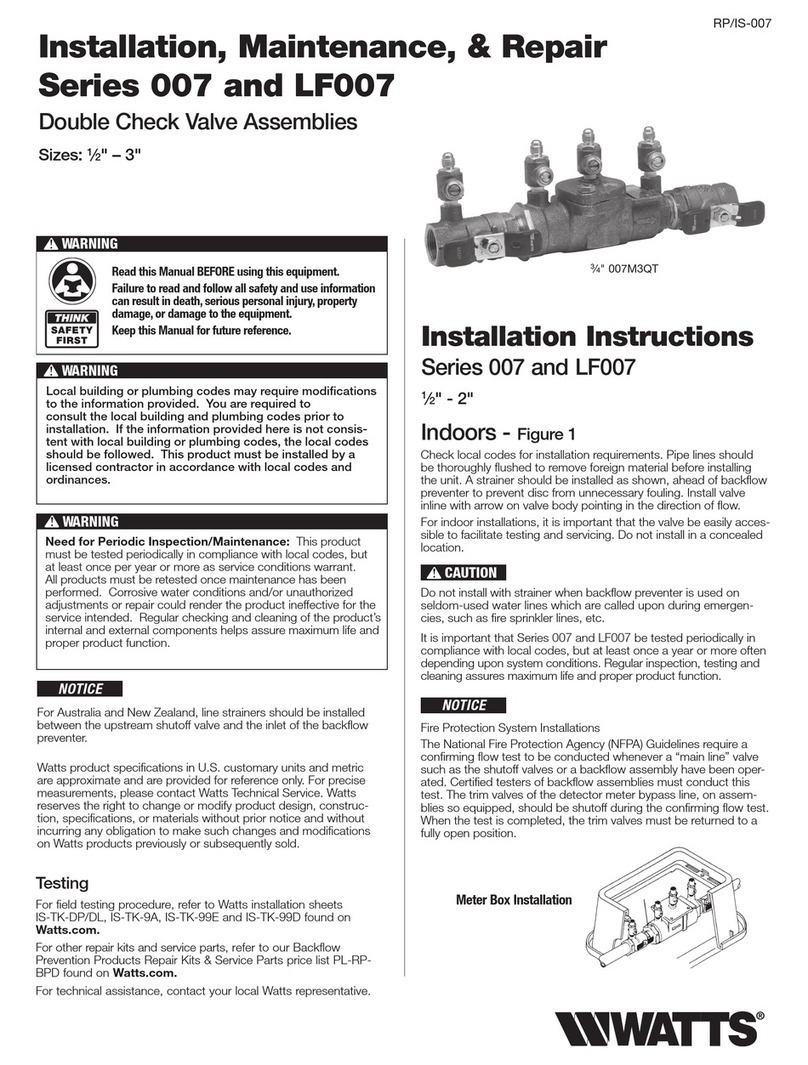

1. Mark pipe as shown.

This is pipe insertion depth.

2. Clean pipe end.

3. If using PEX tubing, insert pipe stiff-

ener (provided) into end of pipe.

4. Push tubing into tailpiece up to mark.

5. Insert collet clip.

PEX tubing only

Pipe Stiffener

Tail Piece

11⁄2in. (38.1mm)

13⁄4in. (44.45mm)

17⁄8in. (47.63mm)

1⁄2in.Pipe (12.7mm)

3⁄4in.Pipe (19.05mm)

1 in.Pipe (25.4mm)

Quick-Connect Installation

To Connect:

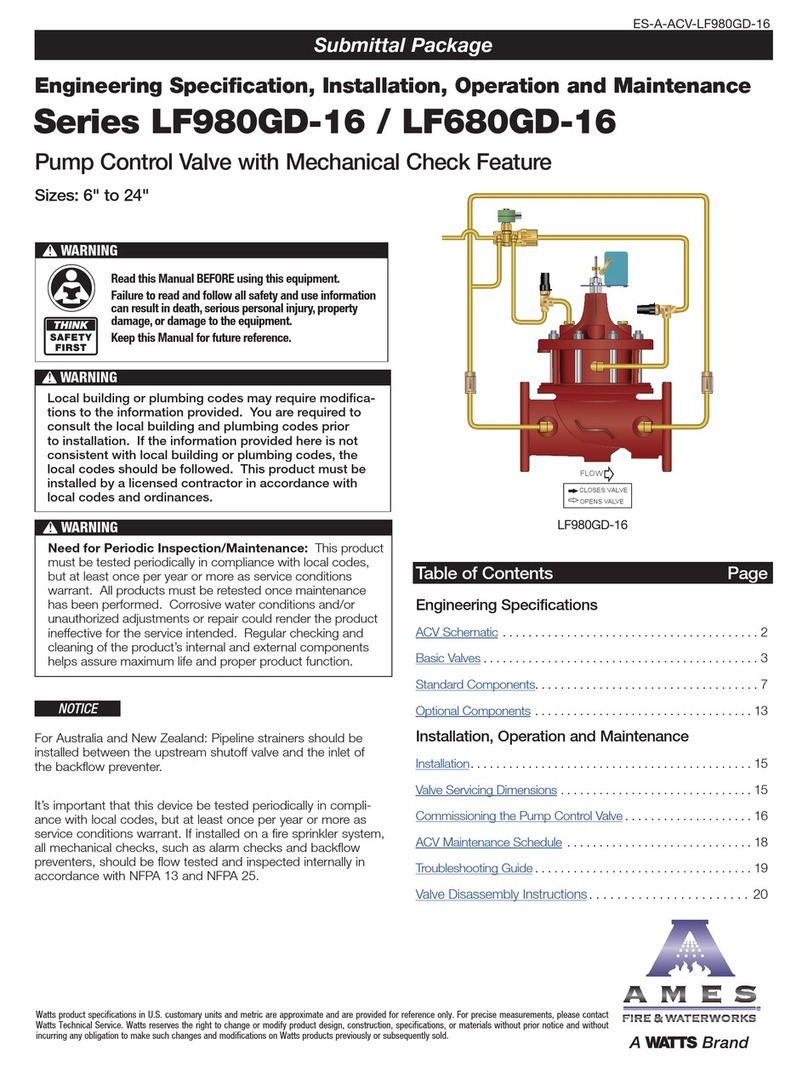

You are required to thoroughly read all installation instructions and product

safety information before beginning the installation of this product. FAILURE

TO COMPLY WITH PROPER INSTALLATION AND MAINTENANCE IN-

STRUCTIONS COULD RESULT IN PRODUCT FAILURE WHICH CAN

CAUSE PROPERTY DAMAGE, PERSONAL INJURY AND/OR DEATH.

Watts is not responsible for damages resulting from improper installation

and/or maintenance.

Local building or plumbing codes may require modifications to the informa-

tion provided. You are required to consult the local building and plumbing

codes prior to installation. If this information is not consistent with local

building or plumbing codes, the local codes should be followed.

Need for Periodic Inspection/Maintenance: This product must be test-

ed periodically in compliance with local codes, but at least once per year

or more as service conditions warrant. Corrosive water conditions, and/or

unauthorized adjustments or repair could render the product ineffective for

the service intended. Regular checking and cleaning of the product’s inter-

nal components helps assure maximum life and proper product function.

WARNING

!

When a pressure reducing valve or dual check valve is installed in the

supple line, it creates a closed system which makes plumbing code

compliance imperative for system safety. Special attention must be

given by all concerned to assure pressure relief protection is provided

to protect water heater equipment. It is important to make certain an

approved ANSI Z21.22 temperature and pressure relief valve is installed

on the storage water heater. This device is designed for emergency

safety relief and should not be used as an operating control.

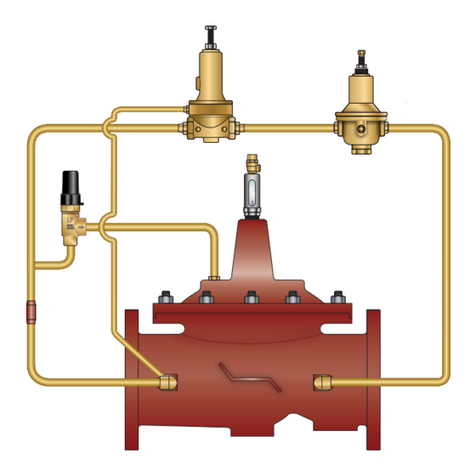

High System Pressure

If the downstream system pressure is higher than the set pressure

under a no flow condition, the cause could be thermal expansion.

Thermal expansion occurs whenever is heated in a closed system.

You must make provisions for thermal expansion protection of your

plumbing system and components when installing a pressure reducing

valve or dual check valve in the supply line.

The use of pressure relief valves such as *Watts 530C, *BRV,

*Governor 80, *3L and or a potable water expansion tank such as the

Watts DETA and PLT may be required.

To determine if this is the result of thermal expansion, try briefly open-

ing the cold water tap. If the increased pressure is caused

by thermal expansion, the pressure will immediately be

relieved and the system will return to the set pressure.

Watts offers a pressure test gauge, model 276H300 to

assist you in determining if you have high water pressure.

The 276H300 when attached to a hose bibb registers the

highest pressure reading over the period of time it is

left on the system.

*NOTE: The Watts 530C, BRV, Governor 80 and 3L

are not ASME approved safety relief valves. Under no

circumstances should these devices be used in place

of an ASME approved valve. Consult your local water

code authority to ensure installation compliance.

Watts product specifications in U.S. customary units and metric are approximate

and are provided for reference only. For precise measurements, please contact

Watts Technical Service. Watts reserves the right to change or modify product

design, construction, specifications, or materials without prior notice and without

incurring any obligation to make such changes and modifications on Watts prod-

ucts previously or subsequently sold.

Basic Installation Instructions

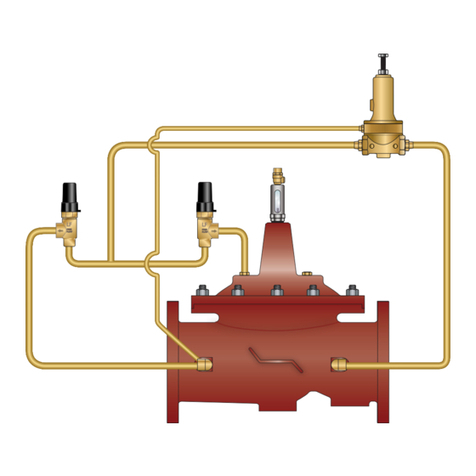

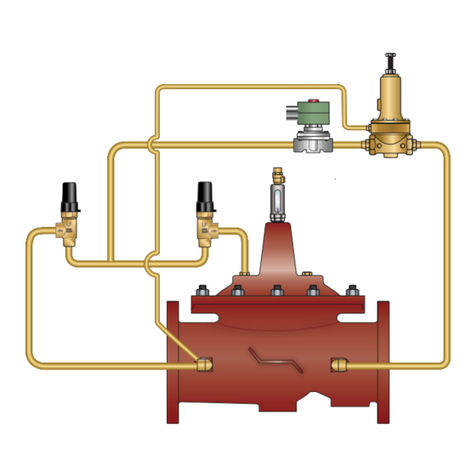

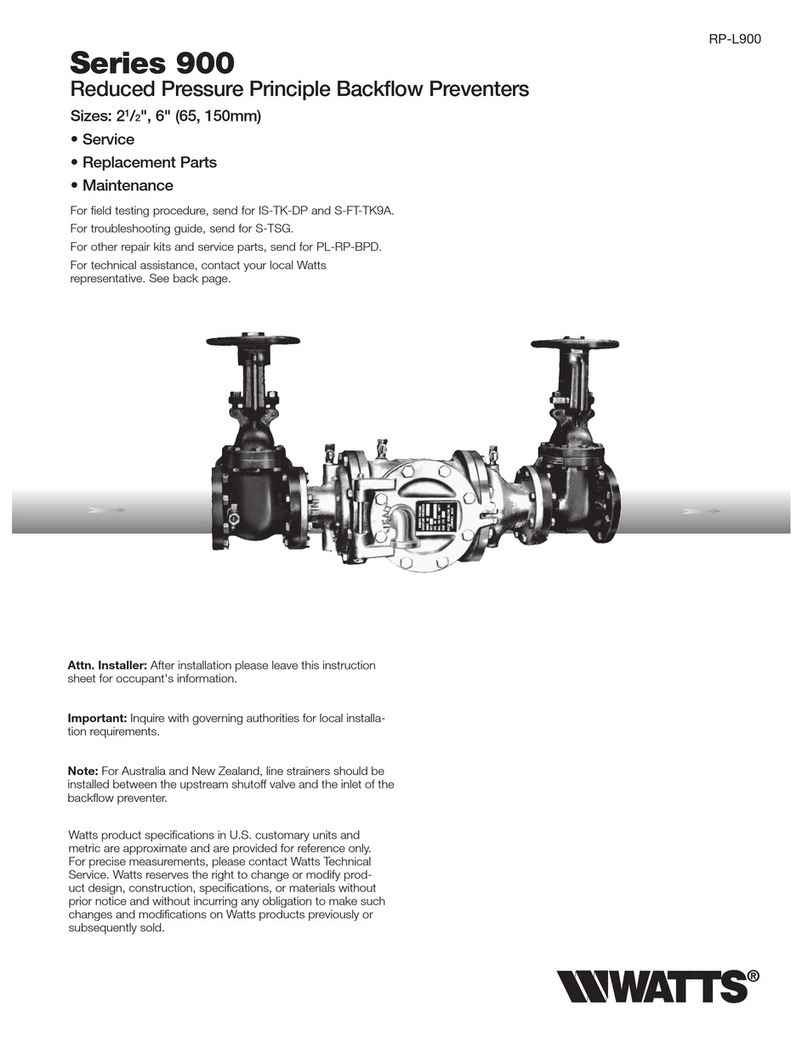

A. Watts dual check valves may be installed in either a vertical or a horizon-

tal position. Series 7 & LF7 should be installed downstream of the water

meter and of the water pressure regulator. All outlets including sill cocks

must be downstream of the Series 7. Model 07S & LF07S should be

installed at the fire sprinkler service connection to the main line.

B. They should always be installed in an accessible location to facilitate

the removal for servicing and testing.

C. Pipe lines should be thoroughly flushed to remove foreign material

before installing the unit.

D. Protect from freezing

E. Ensure that valve is installed in proper flow direction. Refer to flow

direction arrow on valve nameplate or body.

F. When installing valve in pipe line, only use wrenching flats provided.

Do not apply wrench to body of valve. This will prevent distorting the

valve body and component parts.

G. These valves incorporate an O-ring union seal that requires minimum

tightening of union nut. Do not overtighten.

H. These valves contain plastic check modules and should never be

directly sweated into the line. Sweat fit adapters should be sweated

into the line prior to valve installation.

I. Avoid improper application and excessive pipe sealants such as tef-

lon®tape and pipe dope.

1. Remove collet clip.

2. Depress collet.

3. Pull tubing from tailpiece.

To Disconnect:

Watts 276H300

WARNING

!