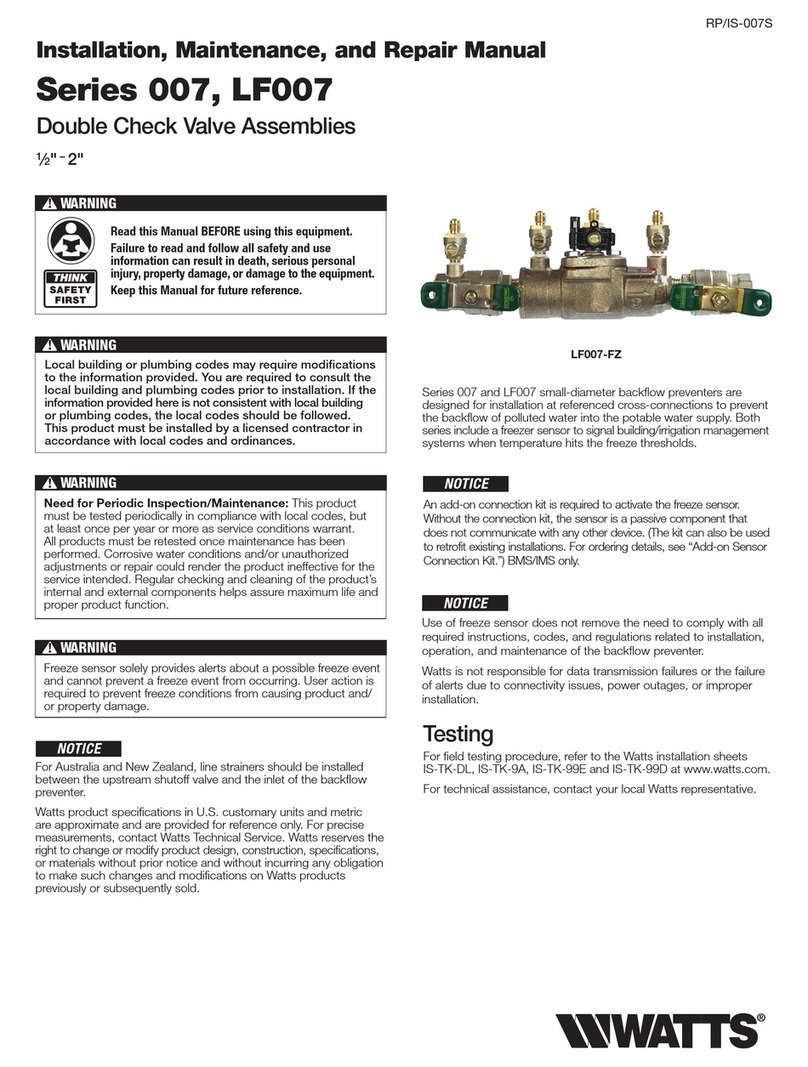

2

Guidelines

Most field problems occur because dirt and debris present in

the system at the time of installation becomes trapped in the

#1 check. The system should be flushed before the backflow

valve is installed. If the system is not flushed until after the

backflow valve is installed, remove both check modules from

the valve and open the inlet shutoff to allow water to flow for a

sufficient time to flush debris from the water line. If debris in the

water system continues to cause fouling, a strainer can be

installed upstream of the backflow assembly.

Watts models 757a and 757aDCDA may be installed in either

horizontal or vertical position as long as the backflow assembly

is installed in accordance with the direction of the flow arrow

on the assembly and the local water authority approves the

installation. The assembly should be installed with adequate

clearance around the valve to allow for inspection, testing and

servicing. 12" should be the minimum clearance between the

lower portion of the assembly and the floor or grade.

Horizontal Installation

Vertical Installation

Figure D Figure E Figure F

Figure A Figure B Figure C

Prior to servicing any Watts valve, it is mandatory to shut down

the water system by closing both the inlet and outlet shutoff

valves. After shutoff valves are closed, open test cock #2, #3

and #4 to relieve pressure within the backflow assembly.

1. After #3 test cock has been opened to relieve pressure,

remove #3 test cock from housing. (Figure A)

2. Slowly slide the cover sleeve to the downstream side of the

housing. (Figure B)

3. Remove the stainless steel check retainer from the housing.

(Figure B)

4. Remove the #1 check module (Figure C) by inserting two

flat blade screwdrivers into the slots on either side of the

check module and gently pry to check module toward the

open zone.

5. Remove #2 check module with the same instructions as in

#4 above.

6. To clean or inspect either check module, insert a #3 screw-

driver through the downstream side of the check module as

shown in Figure D and E. When the screwdriver is in place,

remove the E-clip (Figure F) and pin connecting the structur-

al members and the check clapper will open with no tension.

7. Thoroughly clean the seating area. The sealing disk may be

removed, if necessary, by removing the screws connecting

the keeper plate to the clapper. The sealing disc may be

reversed and reinstalled if the elastomer is cut or damaged.

8. Wash check module and O-ring and inspect for any dam-

age. If damaged, reinstall new parts.

9. After thorough cleaning, lubricate O-ring w/FDA approved

lubricant, replace pin and E-clip in structural members,

remove screw driver and reinstall check modules and

assemble housing in reverse order of these instructions.

Maintenance Instructions

Basic Installation Instructions