Watts HF scientific SSR-Ex 28037 User manual

Operations and Maintenance Manual

Total Residual Oxidant Monitor for

Use in Hazardous Environments

Model SSR-Ex 28037

IOM-HF-SSR-Ex 28037

WARNING

!

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use information can

result in death, serious personal injury, property damage, or

damage to the equipment.

Keep this Manual for future reference.

IOM-HF-SSR-Ex 28037 Rev 5

2

1.0 Safety........................................................................................... 3

1.1 Understanding Safety Information........................................... 3

2.0 Overview ...................................................................................... 3

2.1 Specifications ......................................................................... 4

2.2 Unpacking and Inspection of the Instrument and Accessories .... 5

2.3 Instrument Labels ................................................................... 5

3.0 Components Listing ..................................................................... 5

3.1 Electronics Compartment ....................................................... 5

3.2 Electrical Enclosure................................................................. 5

3.3 User Connections................................................................... 5

3.4 Wet Section of Enclosure Fittings and Items Listing.................... 6

3.5 The Air Sentinel™ II Controller (Factory Installed).................... 6

3.6 The Air Dryer/Filter.................................................................. 6

4.0 Installation .................................................................................... 6

4.1 Mounting and Site Selection ................................................... 6

4.2 Plumbing and Air Connections ............................................... 7

4.3 Electrical Connections ............................................................ 7

4.3.1 Low Voltage Connections .............................................. 8

4.3.1.1 Relays................................................................ 8

4.3.1.2 4-20 mA Analog Output..................................... 8

4.3.1.3 Modbus ............................................................. 8

4.3.1.4 RMT .................................................................. 8

4.3.1.5 Securing the Glands - Low Voltage.................... 8

4.3.2 Mains Power Connections ............................................. 8

4.3.2.1 Securing the Glands - Mains Power................... 8

4.4 Hardware Control ................................................................... 8

4.5 Modbus Control...................................................................... 9

4.6 Securing the Electrical Enclosure.......................................... 10

5.0 Configuration - General Process................................................. 11

5.1 Instrument Commissioning and Start-Up .............................. 11

5.2 Configuring the SSR-EX ....................................................... 11

5.2.1 Menu Selection Options............................................... 12

5.2.1.1 Main Menu....................................................... 12

5.2.1.2 Config Menu .................................................... 12

5.2.1.3 Analog Output Menu........................................ 13

5.2.1.4 Modbus Menu ................................................. 13

5.2.1.5 Alarms Menu.................................................... 13

5.2.1.6 Units Menu ...................................................... 13

5.2.1.7 Average Menu.................................................. 13

5.2.1.8 Backlight Menu................................................ 13

5.2.1.9 Cycle Time Menu ............................................. 14

5.2.1.10 Contact Period Menu..................................... 14

5.2.1.11 Standby Pulse Menu...................................... 14

5.2.1.12 Restore Defaults Menu................................... 14

5.2.1.13 Restore Factory Cal Menu ............................. 14

5.2.1.14 About Device Menu ....................................... 14

5.3 System Start-Up................................................................... 15

5.3.1 Flush Water Sample Line ............................................. 15

5.3.2 Prepare Reagents ........................................................ 15

5.3.3 Remote Start ............................................................... 15

5.4 Typical Cycle......................................................................... 15

5.5 Observe Operation ............................................................... 15

6.0 Maintenance............................................................................... 15

6.1 Calibration ............................................................................ 15

6.2 Cuvette Replacement ........................................................... 16

6.3 T-Strainer Cleaning ............................................................... 16

6.4 Adjusting the Pressure Regulator.......................................... 16

6.5 Installing New Reagent in the SSR-EX.................................. 16

6.6 Replacing the Peristaltic Sample Pump Head....................... 16

6.7 Instrument Storage ............................................................... 16

7.0 Diagnostic/Troubleshooting Chart............................................... 17

8.0 Error/Alarm Messages and Suggested Actions .......................... 17

9.0 Technical and Customer Assistance ........................................... 17

10.0 Spare Parts Listing ................................................................... 17

11.0 Limited Warranty ...................................................................... 20

Table of Figures

Figure 1 - Instrument Overview........................................................... 3

Figure 2 - Instrument with Electronics Compartment Open ................ 5

Figure 3 - Close-up of Electrical Compartment................................... 5

Figure 4 - Low Voltage Connections................................................... 5

Figure 5 - Wet Chemistry Area of Enclosure ....................................... 6

Figure 6 - Utility Connections.............................................................. 6

Figure 7 - Air/Dryer Filter .................................................................... 6

Figure 8 - Overall Mounting Dimensions of the Instrument.................. 6

Figure 9 - Compression Fitting ........................................................... 7

Figure 10 - Utility Connections............................................................ 7

Figure 11 - Low Voltage Connections................................................. 8

Figure 12 - Main Screen ................................................................... 11

Figure 13 - Pressure regulator and T-strainer.................................... 15

Table of Contents

3

1.1 Understanding Safety Information

This manual contains safety and use instructions that must be

followed during the installation, commissioning, operation, care and

maintenance, and service of the SSR-Ex. All responsible personnel

must read this manual prior to working with this instrument and should

familiarize themselves with the following safety symbols, signals,

and pictorials.

The safety alert symbol is shown alone or used with a signal word

(DANGER, WARNING or CAUTION), a pictorial and/ or a safety

message to alert you to hazards.

When you see this symbol alone or with a signal word on this

instrument or in this manual, be alert to the potential for death or

serious personal injury.

Safety signal words have the following meaning:

Identifies hazards which, if not avoided, could

result in death or serious injury.

Identifies hazards which, if not avoided, will

result in minor or moderate injury.

Identifies practices, actions or failure to act

which will result in property damage or damage

to the equipment.

Pictorials used on the equipment and in this Manual have the following

meanings:

This pictorial alerts you to the need to read the

Manual.

This pictorial alerts you to electricity,

electrocution and shock hazards.

1.0 Safety 2.0 Overview

This instrument has been specifically designed for TRO measurement

and to operate in hazardous atmospheres meeting the IECEx and ATEX

ratings as stated in the specifications. The instrument uses an IECEx

approved purge/ pressurization controller called the Air Sentinel II.

Please refer to the companion manual Cat. No. 100038B for all

information on:

• Operation of the Air Sentinel II

• Electrical Power Connections

• Purge Air Connection

Figure 1 - Instrument Overview

This instrument is sectioned such that all the electrical or powered

devices are in the upper, purged section of the enclosure, while

the lower (wetted parts) section contains no power at all and can

be operated and maintained in a safe condition even with the main

enclosure door open. Refer to Figure 2.

The SSR-Ex has been designed to meet the design criteria specified

by Standard Methods for the Examination of Water and Wastewater

(21th Edition) Method 4500-Cl G. DPD Colorimetric Method.

The SSR-Ex uses a 515nm LED as the measurement light source.

Every effort has been made to ensure the accuracy of this manual. Due

to the continuous development and improvement of all instrumentation,

there may be slight differences between this manual and the instrument

received.

4

2.1 Specifications

Measurement Range 0.00 – 15.00 mg/l (PPM)

Accuracy ±10% of reading or ±0.03 mg/l (PPM)

whichever is greater for range of 0 - 15.0 mg/l (PPM)

Resolution 0.01 mg/l (PPM)

Cycle Time Adjustable; 45 seconds to 10 minutes (600 seconds)

Display 3.5" Color Graphic

Alarms Two programmable, 120 - 240 VAC 2A, Form C Relay

Analog Output Powered 4 - 20 mA, 1000Ω drive, isolated

Communications Port Bi-directional RS-485 with Modbus

Water Pressure Integral pressure regulator, maximum pressure 3 bar (45 PSI.)

Flow Rate to Waste Maximum waste flow rate from the drain is 150 ml/min

Operating Temperature 0°C – 55°C (32°F – 131°F)

Wetted Materials Polyethylene, Borosilicate Glass, Generic Viton™* Alternative (FKM), Polypropylene, 316 Stainless Steel, Acetal, EPDM, Silicone, Modified

PPO, Thermoplastic Elastomer

Sample Temperature Range 0°C – 55°C (32°F – 131°F)

Power Supply 100 to 230VAC, 47 - 63 Hz, 240VA

Insulation Rating Double Insulated, Pollution Degree 2, Overvoltage Category II

Enclosure Powder coated steel with windows. IP55 rating

Environmental Conditions Altitude up to 2000 meters

Up to 95% RH (non-condensing)

IECEx Hazloc Rating II 2G Ex pxb IIC T4 Gb 0°C ≤ Ta ≤ 55°C

Compressed Air Requirements Water and oil-free, Particles <5u, ISA Grade Hydrocarbon Free. Full time clean dry air at 5.5 - 7 bar (80 - 101.5 PSI) @ 35 SLPM

(1.2 SCFM) @ 20oC (68oF) Max

Regulatory Compliance And Certifications IECEx, ATEX, DNVGL-CG-0339, tested to USCG 46 CFR Part 162

subsection 162.060-30

Shipping Weight 27.2 kg (60 lbs.)

Shipping Dimensions 93 cm X 62 cm X 32 cm (36½" X 24½" X 12½")

*Viton™ is a trademark of The Chemours Company FC, LLC

5

2.2 Unpacking and Inspection of the

Instrument and Accessories

The table below indicates the items included in the shipment.

Item Quantity

SSR-Ex Monitor Includes - Factory installed Air Sentinel II 1

Owner’s Manual 1

Air/Filter Dryer Assembly 1

*Please note: Reagents are not included and must be purchased

separately. The SSR-Ex will not function without reagent.

Remove the instrument from the shipping crate. Carefully inspect all

items to ensure that no visible damage has occurred during shipment.

If damage is evident contact the delivery company and your supplier. If

the items received do not match the order, please immediately contact

the local distributor or the HF scientific Customer Service Department.

Location Location Label

Serial number,

manufacturer, part

number, power

rating, CE & UL

marking

Side of Unit

Warning and

informational

Inside Front of

Electrical Panel

Enclosure

Warning and

informational

Front of Unit

Informational Front of Unit

2.3 Instrument Labels

The following labels should be applied to the outside of the enclosure.

3.0 Components Listing

3.1 Electronics Compartment

WETTED COMPONENTS COMPARTMENT

ACCESSIBLE ANY TIME

CONTAINS REAGENT BOTTLES

OPTICAL MEASUREMENT COMPONENTS

INLET WATER SAMPLE PUMP (PERISTALTIC)

CONNECTIONS FOR PURGE AIR, DRAIN AND SAMPLE

WATER INLET. ALSO, EMERGENCY DRAIN FITTING

T-STRAINER AND

PRESSURE REGULATOR

ELECTRONICS COMPARTMENT

(AIR PURGED WHEN SCREWED CLOSED)

SHOWN OPEN TO ALLOW CONNECTIONS

AIR SENTINEL II

(FACTORY

INSTALLED)

Figure 2 - Instrument with Electronics Compartment Open

3.2 Electrical Enclosure

3.3 User Connections

Figure 3 - Close-up of Electrical Compartment

Figure 4 - Low Voltage Connection

PURGE AIR PRESSURE REGULATOR

CABLE GLANDS

FOR LOW VOLTAGE

CONNECTIONS

CONNECTORS FOR LOW VOLTAGE

CONNECTIONS (see below for detail)

MAINS

POWER INTO

ENCLOSURE

REAGENT

PUMPS

User Connections for SSR-Ex

RELAYS

4-20 mA

RMT CONNECTIONS

6

3.4 Wet Section of Enclosure Fittings and

Items Listing

Ai r

Dr ai n

Sa mp l e

Optical Assembly Plumbing Connections

Figure 5 - Wet Chemistry Area of Enclosure

EMERGENCY DRAIN (NO CONNECTION

NEEDED)

SAMPLE WATER (6mm connection)

MAIN DRAIN (12 mm connection)

PURGE AIR (AIR ONLY 6mm connection)

DO NOT MIX UP THE AIR and WATER

CONNECTIONS. INSTALLING THE WATER

INTO THE AIR CONNECTION WILL VOID

THE WARRANTY.

Figure 6 - Utility Connections

Reagent Optical

Bottles Assembly

3.5 The Air Sentinel II Controller

(Factory Installed)

The SSR-Ex will not function without proper air purging of the

enclosure. The Air Sentinel II Controller governs the power. Reference

Section 2.1Electronics Compartment, Figure 2 - Instrument with

Electronics Compartment Open.

3.6 The Air Dryer/Filter

For proper operation dry clean air must be supplied to the SSR-Ex at

pressures between 5.5 and 7 bar (80 to 101.5 PSI). The dryer comes

with fittings suitable for use with 6mm tubing, if using the supplied

fittings for installation ensure that a proper thread sealant is used.

Element Replacement

Indicator The red ring

will pop up to show

when the element

needs to be replaced.

Figure 7 - Air/Dryer Filter

4.0 Installation

4.1 Mounting and Site Selection

The instrument is designed for wall mounting. Choose a location that is

easily accessible for operation and service. It is recommended that the

display window is about eye level. Consideration must be made for the

plumbing, air, and electrical conduit connections. The overall mounting

dimensions of the instrument are shown in Figure 8 - Overall Mounting

Dimensions of the Instrument.

Figure 8 - Overall Mounting Dimensions of the Instrument

Be sure that the instrument is mounted as close as possible to the

sampling point to ensure a quick response time (recommended

installation is within 2-3 meters (6-10 ft) of the sampling point).

Mounting bolt size should not exceed the size of provided mounting

bolt location. Mounting hardware must be rated to support the

instrument operation weight of 60 lbs. Mounting hardware provided

by others.

7

4.2 Plumbing and Air Connections

To avoid injury, death, fire, explosion, leak, or property damage:

• The fluid waste from the drain connection MUST NEVER

BE reintroduced into the incoming water stream. HF

scientific recommends that operators review with local

authorities concerning the proper disposal of waste

diluted fluids.

• All plumbing connections MUST BE made through the

provided stainless steel connections. Fittings should not

be modified or substituted.

• The air line and the water line MUST NOT BE reversed

in connecting the supplies. Connecting the water source

to the air line will damage the electronics and void

the warranty.

• All connections MUST BE properly installed and sealed

to ensure water tightness and preserve the ratings of

the instrument.

• The drain MUST BE open to the atmosphere for proper

operation. Ensure the vent drain remains open and is not

subject to fouling.

All wet and air connections are made with user supplied tubing using

the compression fittings attached to the SSR-Ex. When using the

compression fittings, follow these steps:

Step 1: Unscrew the nut from the applicable connection point.

Step 2: Remove the nut, front sleeve, and back sleeve from the

SSR-Ex.

Step 3: Place the nut, then the back sleeve, and then the front sleeve

onto the applicable tubing.

Step 4: Slide the tubing into the open connection point and

tighten the nut to secure the tubing. Refer to Figure 9.

Fitting Connections for assistance to assemble the tubing

connection. Refer to Figure 10 - Utility Connections for

assistance locating the proper fitting connection on the

enclosure for the sample to be connected.

Figure 9 - Compression Fitting

When making the plumbing connections, be advised that:

• The maximum pressure for proper operation is 3 bar (45 PSI).

• The maximum sample water intake and drainage flow is

150 ml/minute.

• The maximum allowable fluid temperature is 55°C (131°F).

• The sample water supply does not need to be pressurized.

The SSR-Ex incorporates a pressure regulator at the water

supply inlet.

• In order to ensure that the sample measured is representative of

the ballast water, keep sample pipe runs as short as possible.

• A water shut off valve should be located close to the instrument

to allow for periodic maintenance.

• An air shut off valve should be located close to the instrument to

allow for periodic maintenance.

EMERGENCY DRAIN (NO CONNECTION

NEEDED)

SAMPLE WATER (6mm connection)

MAIN DRAIN (12 mm connection)

PURGE AIR (AIR ONLY 6mm

connection)

NOTE: IMAGE DEPICTS BOTTOM OF

THE ENCLOSURE.

DO NOT MIX UP THE AIR and WATER

CONNECTIONS. INSTALLING THE

WATER INTO THE AIR CONNECTION

WILL VOID THE WARRANTY.

Figure 10 - Utility Connections

All wet and air connections are made with user supplied OD tubing

using the compression fittings attached to the SSR-Ex. All air and water

tubing connected to the instrument is to be supplied by others. When

using the compression fittings, see Figure 9 - Compression Fitting and

then follow these steps:

Do not connect sample water line to the purge air connection.

Plumbing Connections

Step 1: Connect the sample water line to the SSR-Ex using the 6 mm

OD fitting on the bottom of the enclosure. Reference Figure

10 - Utility Connections.

Step 2: Connect the main drain line to the SSR-Ex using the 12 mm

OD fitting on the bottom of the enclosure.

Reference Figure 10 - Utility Connections. There is no tubing

connection for the emergency drain.

Air Connection

Step 1: Install the air/filter dryer assembly by mounting it in

a convenient location near the SSR-Ex between the

compressed air supply and the SSR-Ex.

Step 2: Connect the compressed air supply to the air/filter dryer

assembly intake.

Step 3: Connect the air supply tubing from the air/filter dryer

assembly output to the SSR-Ex using the 6 mm OD fitting

on the bottom of the enclosure. Reference Figure 10 - Utility

Connections.

4.3 Electrical Connections

The power must be provided by a safe remote location. All

power must be removed from a safe location while the electrical

compartment access is open. Do not reconnect power until the

electrical compartment access is closed and all captive Philips

screws have been replaced and tightened appropriately.

All electrical connections are located in the upper electrical

compartment. The electrical compartment access at the front

can and should only be opened during installation. No power

should be applied until the electrical compartment access is

closed and sealed.

The SSR-Ex has two types of electrical connections. First, the mains

power connection, which connects to the Air Sentinel II through the

cable gland on the left side of the SSR-Ex. Second, the low voltage

connections, which are made through the cable glands on the right

side of the SSR-Ex.

8

All low voltage connections should be completed before the

main power is connected to system.

All electrical connections must pass through a compression

gland. The glands can accept cabling from 11 to 21 mm in

diameter. After installation, the glands must be tightened to

ensure that the SSR-Ex maintains cabinet air pressure.

Mains power connects only to the Air Sentinel II.

No mains power should be connected directly to the main PCB.

Figure 11 - Low Voltage Connections

User Connections for SSR-Ex

RELAYS

4-20 mA

RMT CONNECTIONS

4.3.1 Low Voltage Connections

All of the low voltage electrical communication connections to the

instrument are made at the termination area located on the right side

of the main PCB. To access the connections, lower the access flap by

loosening the captive Phillips screws. The connections are labeled and

are self-descriptive. Please follow all government recommendations and

requirements for installation of electrical connections to and between

the instrument and other peripheral devices. All terminals are designed

to accept wires in the range of 14 - 28 AWG.

4.3.1.1 Relays

Two relay alarm connections labeled COM1, NC1 & NO1 and COM2,

NC2 & NO2 are provided. The relays are rated 240VAC 2A. Operation

of this alarm is covered in section 4.2.1.5 Alarms Menu.

4.3.1.2 4 - 20 mA Analog Output

These connections are located on the mid right side of the Main PCB.

The 4 - 20 mA output is driven by a 24 VDC power source and can

drive recorder loads up to 1000 ohms. Transformer isolation is provided

on the SSR-Ex. Operation of this output is covered in section 4.2.1.3 -

Analog Output Menu.

Polarities of the connections are labeled beside this termination on the

PC board.

The recommended cable is 22 AWG shielded twisted pair. To prevent

ground loops, connect the shield at its destination. The terminal block

is removable to assist in making connections.

The 4 - 20mA is factory calibrated. An adjustment is available on the

4 - 20mA in section 4.2.1.3 Analog Output Menu. In addition to making

adjustments, these menus output continuous 4 mA or 20 mA and

can be used as a signal test. The configuration mode will timeout

after 15 minutes.

4.3.1.3 Modbus

The RS-485 half-duplex (2-wire) digital interface operates with

differential levels that are not susceptible to electrical interferences.

Therefore, cable lengths up to 3000 ft can be implemented. The last

device on every bus may require a 120-ohm termination resistor to

eliminate the possibilities of signal reflection on the line. Do not run RS-

485 cables in the same conduit as power.

Ensure each instrument is not powered when connecting the RS-

485 line. To prevent damage to the instrument, ensure that power is

disconnected prior to making connections. The Modbus connection is

located on the lower right portion the main PCB as seen on Figure 11.

4.3.1.4 RMT

By design the SSR-Ex will only be actuated for measurement by a

remote command. The system can be set up to either be actuated

through MODBUS or by means of a remote actuation provided by the

end user.

These connections are located in the lower right corner of the main

PCB. See Figure 4 - Low Voltage Connections.

The instrument operates on user control software, where an external

control initiates each cycle. The SSR-Ex will indicate the current status

of connections using a relay contact that is closed when busy and

open when in standby mode.

4.3.1.5 Securing the Glands - Low Voltage

Low voltage connections to the instrument are made through electrical

glands located on the right side of the enclosure. Once the appropriate

low voltage wiring is inserted through the electrical gland and wiring

is secured at the terminals on the main circuit board glands on the

right side of the enclosure must be tightened to ensure wiring is

safely installed.

4.3.2 Mains Power Connections

Once all low voltage connections are made, the mains power should be

connected through the Air Sentinel II. Reference Figure 3 – Close-up of

Electrical Compartment.

4.3.2.1 Securing the Glands - Mains Power

Mains power connection to the instrument is made through an electrical

gland located on the left side of the enclosure. Once the mains power

wiring is inserted through the electrical gland and wiring is secured at

the mains power terminals of the Air Sentinel II electrical gland on the

left side of the enclosure must be tightened to ensure mains power

wiring is safely installed.

4.4 Hardware Control

The connections are labeled RMT Stby. The input has + and – polarity

connections and requires an external 24VDC control signal.

The output is simply a relay contact and is not polarized. After the

SSR-Ex completes a cycle of measurement, the unit will return to

standby awaiting another pulsed signal to measure. Alternately, 24VDC

can be continuously applied and the SSR-Ex will take readings until

the 24VDC is removed. When power is removed it will complete the

current cycle. The measured value will remain displayed until the

next measurement.

9

4.5 Modbus Control

In addition to the above mentioned Remote Standby Connections,

control can also be achieved using Modbus control. Two special

Modbus addresses are provided. The reading cycle is initiated using

the Coil Address 00005 with the default at False (0). Setting this

Address to True (1) initiates the reading cycle.

At any time the standby status can be checked at Modbus Coil

Address 00005 or Modbus Input Address 10005. False (0) indicates

standby and True (1) indicates the measurement cycle is taking place.

Control is only available from the Coil Address 00005 for more setting

information refer to Section 4.2.1.4. - Modbus Menu.

The default communication parameters are 8 bits, no parity and 1 stop

bit. Please note that all Modbus communication is via RS-485. The

instruments can support a two wire multidrop network of 255 units. If

the connection is to the master on USB, an RS-485 to USB converter

is required.

4.5.1 Coils

These single-bit values are readable and changeable from the master.

The data will be returned with the lowest addressed coil in the least

significant bit (LSB) of the data. Unused bits in the data will be set to 0.

True is a 1 and False is 0.

4.5.1.1 Valid Command(s)

Code Name Broadcast

0x01 Read Coil Status No

0X05 Force Single Coil Yes

MSB LSB

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

4.5.1.2 Format

16-bit word format

4.5.1.3 Valid Addresses

00001 – 00XXX

4.5.1.4 Definitions

Address Function Default

00001 NOT USED False

00002 NOT USED False

00003 NOT USED False

00004 Service mode (Go into service mode if true) False

00005 FDI (flag data in)

False means waiting for a command. Standby mode. True means

start a cycle.

False

00006 Zero Flag – Zero the reading if True False

00007 Prime mode – Start a prime if True False

4.5.2 Input Status

These single-bit values are readable from the master. The data will be

returned with the lowest addressed input status in the least significant

bit (LSB) of the data. Unused bits in the data will be set to 0.

4.5.2.1 Valid Command(s)

Code Name Broadcast

0x02 Read Input Status No

4.5.2.2 Format

16-bit word format

MSB LSB

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

4.5.2.3 Valid Addresses

10001 – 10XXX

4.5.2.4 Definitions

Address Function Default

10001 Instrument error False

10002 Instrument error with alarm False

10003 Alarm 1 active False

10004 Alarm 2 active False

10005 FDO (flag for data out)

False means waiting for a command to start. True means

going through a cycle (busy).

False

4.5.3 Holding Registers

These 16-bit values are readable and changeable from the master. The

data is stored and transmitted with the most significant bit (MSB) first

and then the least significant bit (LSB).

4.5.3.1 Valid Command(s)

Code Name Broadcast

0x03 Read Holding Registers No

0x06 Preset Single Register Yes

0X16 Preset Multiple Registers Yes

4.5.3.2 Format

Float – stored in two consecutive addresses, with the first address

containing the least significant word (lower part of mantissa) and the

second address containing the most significant word (sign, exponent,

and upper part of mantissa).

4.5.3.3 Valid Addresses

40001 – 40XXX

4.5.3.4 Definitions

Address Type Register Min Default Max Function

40001 Int NOT USED 0 0 0

40002 Int Units (scaling) 0 0 1 0 – PPM

1 – MG/L

40003 Int Readings Per Average 1 2 5 Number of readings

used for averaging

40004 Int LCD backlight 10 80 100 Percent. Higher is

brighter

40005, 40006 Float 4-20 mA minimum

value

0.0 0.00 15.0 Scaling value

40007, 40008 Float 4-20 mA maximum

value

0.0 15.00 15.0 Scaling value

40009 Int 4-20 mA error alarm

output

0 2 3 0 – Off

1 – 0 mA

2 – 2 mA

3 – 4 mA

10

Address Type Register Min Default Max Function

40010 Int RS-485 baud 0 3 4 0 – 1,200

1 – 2,400

2 – 4,800

3 – 9,600

4 – 19,200

40011 Int NOT USED 0 0 0

40012 Int RS-485 parity 0 0 2 0 – None

1 – Even

2 – Odd

40013 Int RS-485 stop bits 0 1 1 0 – One

1 – Two

40014 Int Instrument

address

1 1 255 Slave address

40015 Int Modbus serial

mode

0 0 1 0 – RTU

1 – ASCII

40016 Int Alarm 1 type 0 0 3 0 – Off

1 – Low alarm

2 – High alarm

3 – Error alarm

40017,

40018

Float Alarm 1 set point 0.0 0.0 15.0

40019 Int Alarm 2 type 0 0 3 0 – Off

1 – Low alarm

2 – High alarm

3 – Error alarm

40020,

40021

Float Alarm 2 set point 0.0 0.0 15.0

40022 Int Not used 0 0 0 Not used

40023 Int Contact time 0 0 600 Seconds before starting

measurements (steps of

15sec.)

40024 Int Measurement

period

45 45 600 Seconds for measurements

to complete

40025 Int Standby purge 0 24 100 Hours between pulsing of

reagent pumps (0 = OFF,

no pulsing)

4.5.4 Input Registers

These 16-bit values are readable by the master. The data is stored

with the most significant bit (MSB) first and then the least significant

bit (LSB).

4.5.4.1 Valid Command(s)

Code Name Broadcast

0x04 Read Input Registers No

4.5.4.2 Format

Float – stored in two consecutive addresses, with the first address

containing the least significant word (lower part of mantissa) and the

second address containing the most significant word (sign, exponent,

and upper part of mantissa).

4.5.4.3 Valid Addresses

30001 – 30XXX

Address Type Register Function

30001,

30002

Float Sensor read-

ing

The meter reading

30003,

30004

Float ABS The absorbance

30005 Int Main version Main board software version

30006 Int Display

version

Display board software version

30007 Int NOT USED

30008 Int Model number 28037

30009 Int Model suffix

number

Options – model dependent 0

30010 Int Reading

status

0 – unknown

1 – normal

2 – over range

3 – under range

4 – need standard

5 – need sample

6 – reading problem (Reading error)

Above will display last reading twice

then 0.00 is displayed.

30011 Int NOT USED

30012 Int Instrument

error summary

(bit-mapped)

0x00000 – normal

0x00001 – Error

0x00002 – Alarm 1 is active

0x00004 – Alarm 2 is active

0x00008 – Calibration error

0x00010 – Optical error

0x00020 – 12-volt power supply

(Fatal error) 0x00040 – Purge solenoid

0x00080 – Reagent solenoid

(Halting error)

0x00100 – STM32 internal A/D

converter (Fatal error)

0x00200 – STM32 flash data read

(Fatal error)

0x00400 – STM32 flash data write

(Fatal error) 0x00800 – LTC2400 A/D

problem (Fatal error)

4.5.5 Exception Responses Implemented

Code Name Meaning

00 -- No error

01 ILLEGAL FUNCTION The function code is not allowed in

the device.

02 ILLEGAL DATA

ADDRESS

The data address is not allowed in

the device

03 ILLEGAL DATA

VALUE

A value contained in the query field is

wrong for the device

4.6 Securing the Electrical Enclosure

Once all electrical connections are made, the electrical enclosure must

be secured by closing the compartment and tightening the captive

Phillips screws.

4.5.4.4 Definitions

11

4.5.5 Exception Responses Implemented

5.0 Configuration - General

Process

5.1 Instrument Commissioning and

Start-up

After all water, air, and electrical connections have been made, the

SSR-Ex can be powered on by turning on the power to the Air Sentinel

II. Once power is supplied to the Air Sentinel II, it will run through an

automatic three-minute purge cycle and then supply power to the

SSR-Ex. If at any time there is a loss of pressurization in the electrical

enclosure, the Air Sentinel II will remove power to the SSR-Ex.

The condition of the Air Sentinel II can be determined based on the

color of the LED lamps on its body as explained by this chart:

Lamp Color Matrix Meaning Power to

Attached

Device

Alarm Relay

Response

Both Lamps

GREEN

Safe

Operation

ON Normally Open

Contacts OPEN

TIMER Lamp RED Instrument

is Purging

OFF Normally Open

Contacts

CLOSE

PRESSURE Lamp

RED

Unsafe

Operation

OFF Normally Open

Contacts

CLOSE

NO Lamps No power

out applied

No power

applied;

everything

off

The SSR-Ex is ready for operation when the Air Sentinel II displays two

green LED lamps.

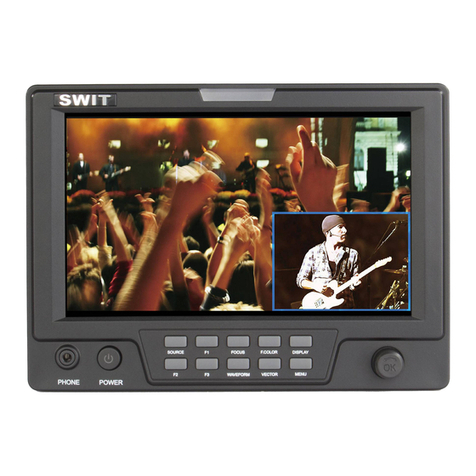

5.2 Configuring the SSR-Ex

The SSR-Ex is configured using the buttons located on the outside of

the electrical enclosure. The Mainscreen is shown below in Figure 12 -

Main Screen.

Using the UP and DOWN buttons, navigate to the desired function

shown on the screen. Once you have highlighted the desired function

press

SELECT to display the next menu.

The Service and Config menus permit access to the processes listed in

the charts below. Use the EXIT button to return to the previous screen.

Figure 12 - Main Screen

Service Menu Options

Config Menu Options

Title Function/Description

PRIME Prime DPD and Buffer Reagents.

CALIBRATE Initiate Calibration Procedure. Follow

prompts to complete.

WATER PRIME Actuate the sample pump to flush the

water lines.

Title Function/Description

ANALOG OUTPUT Configure 4 - 20 mA Output

MODBUS Configure MODBUS

ALARMS Configure Alarms

UNITS Select PPM or mg/l

AVERAGE Select Signal Averaging 1 - 5 cycles

BACKLIGHT Adjust Display Backlighting

CYCLE TIME Reading Update Rate

CONTACT PERIOD Permits Chlorine Contact time before

measuring

STANDBY PULSE Pulses reagent to reduce clogging

while in standby

RESTORE DEFAULTS Restores factory default settings

RESTORE FACTORY CAL. Restore factory calibrations

ABOUT DEVICE Displays the DISPLAY and MAIN

software version numbers

12

5.2.1 Menu Selection Options

5.2.1.1 Main Menu

SERVICE MENU By design the SSR-Ex will only be actuated for

measurement by a remote command. The system can be set up

to either be actuated through MODBUS or by means of a remote

actuation provided by the end user.

PRIME function pulses the reagent pumps to ensure the reagent lines

are filled with reagent.

CALIBRATE function allows you to calibrate the SSR-Ex in the field.

Please refer to Section 5.1 - Calibration for the calibration procedure.

WATER PRIME function allows the sample pump to be actuated to

flush the water line to the SSR-Ex in order to expedite delivery of

representative sample to the SSR-Ex.

Every time SERVICE mode is exited, all faults are cleared. If the original

fault or a new fault occurs, it will be posted to the display. Faults will not

stay cleared until the fault condition is no longer detected.

(Select using UP & DOWN buttons)

HOME No Change

PRIME

CALIBRATE

WATER PRIME

(SEE BELOW)

CONFIG

ANALOG OUTPUT (see 4.2.1.3)

CONFIG

MODBUS (see 4.2.1.4)

ALARMS (see 4.2.1.5)

UNITS (see 4.2.1.6)

AVERAGE (see 4.2.1.7)

BACKLIGHT (see 4.2.1.8)

CYCLE TIME (see 4.2.1.9)

CONTACT PERIOD (see 4.2.1.10)

STANDBY PULSE (see 4.2.1.11)

RESTORE DEFAULTS (see 4.2.1.12)

RESTORE FACTORY CAL

ABOUT DEVICE

(see 4.2.1.13)

(see 4.2.1.14)

SERVICE

PRESS SELECT TO

ACCESS

Once changes have been made to the settings, the SSR-Ex will display

the prompt “Are you sure?” To save the changed settings, press the

SELECT button.

5.2.1.2 Config Menu

13

5.2.1.3 Analog Output Menu

Select using UP & DOWN buttons)

SSR-Ex allows the user to determine how an error message will affect

the analog outputs. Settings include driving the analog output either

to 0 mA, 2 mA, or 4 mA or the setting can be OFF to not affect the

output.

Default value is OFF.

SSR-Ex allows the analog output to be scaled to the desired range

using the 4 mA and 20 mA adjustments. Select either 4 mA or 20 mA

and using the UP & DOWN buttons adjust to the desired value.

Default values are 4 mA = 0 ppm and 20 mA = 15 ppm

The 4 and 20 mA outputs can be offset to account for signal loss

between the SSR-Ex and the SCADA system using the 4 mA and 20

mA CALIBRATE options.

ERROR LEVEL

MODE

ALARM 1 TYPE

4 mA

BAUD RATE

ALARM 1 SETPOINT

20 mA

ADDRESS

ALARM 2 TYPE

4 mA CALIBRATE

PARITY

ALARM 2 SETPOINT

20 mA CALIBRATE

STOP BITS

ANALOG OUTPUT

MODBUS

ALARMS

5.2.1.4 Modbus Menu

5.2.1.5 Alarms Menu

The factory default setting is 9600, 8 bit, no parity, 1 stop bit, RTU. All

parameters are adjustable. Make sure the parameters on the Host and

the SSR-Ex are configured identically.

(Select using UP & DOWN buttons)

These settings allow the user to configure the SSR-Ex MODBUS.

Settings include the MODE, BAUD RATE, ADDRESS, PARITY and

BITS.

(Select using UP & DOWN buttons)

SSR-Ex allows the alarms to be configured to be either HI, LO, OFF or

ERROR and the set points can be configured to actuate the relays at

the desired values.

ppm

mg/l

UNITS

(Select using UP & DOWN buttons)

SSR-Ex will display units in either ppm or mg/l. Default value is ppm.

(Select using UP & DOWN buttons)

SSR-Ex averages the selected number of readings and displays the

average on the display MODBUS and on the analog output.

Default value is 2.

(Select using UP & DOWN buttons) Change is in increments of 10.

Default value is 80%.

5.2.1.8 Backlight Menu

5.2.1.7 Average Menu

5.2.1.6 Units Menu

AVERAGE 1 - 5

% RANGE 10% - 100%

14

(Select using UP & DOWN buttons) Values are in seconds.

Default value is 45 seconds.

The SSR-Ex will perform a test based on the cycle time interval

selected and actuation by means of MODBUS or RST.

(Select using UP & DOWN buttons)

The range 0:00 to 10:00 in minutes and seconds. The default is 00:00

This setting enables the user to allow contact time with the ballast

water and selected oxidant.

5.2.1.10 Contact Period Men

5.2.1.9 Cycle Time Menu

45 - 600CYCLE TIME

0:00

CONTACT PERIOD

OFF - 100

STANDBY PULSE

(Select using UP & DOWN buttons)

This setting will energize the reagent pumps to ensure the lines remain

free of clogs. Range of settings is 1 - 100 hours. Setting below 1 turns

the function OFF.

Default setting is ON and default time is 24 Hr.

This option will restore the factory default settings. Screen displays

“RESET DEFAULTS?” Pressing the SELECT button will restore factory

default settings. Before performing a Restore Defaults it is advised to

make a listing of any user changed menu options prior to the reset.

5.2.1.12 Restore Defaults Menu

5.2.1.11 Standby Pulse Menu

RESTORE DEFAULTS RESET DEFAULTS?

This option will restore the factory default calibration. Screen displays

“RESTORE FACTORY CAL?” Pressing the SELECT button will restore

the factory calibration. This will restore the factory reading, 4 and 20mA

calibrations.

5.2.1.13 Restore Factory Cal Menu

RESTORE FACTORY CAL RESTORE FACTORY CAL?

(Select using UP & DOWN buttons)

This option will display the DISPLAY and MAIN software version

numbers.

5.2.1.14 About Devise Menu

DISPLAY: VERSION XX MAIN: VERSION:

XX

ABOUT DEVICE

15

5.2.1.13 Restore Factory Cal Menu 5.3 System Start-up

Once the SSR-Ex is powered on, air has been purged, and all

configurations have been completed, it is ready for use.

5.3.1 Flush Water Sample Line

Before sampling any sample water, the water line from the source

water to the enclosure must be flushed to ensure that the sample line

has a representative sample and is not impacted by any debris or other

foulants. Flush the sample line by using the WATER PRIME feature

found under the SERVICE menu. When this feature is selected, the

connect- ed water sample line will automatically flush water to drain.

Reference section 4.2.1.1 main menu.

5.3.2 Prepare Reagents

Prepare and install the reagents according to the instructions provided

on the reagent bottles. In the SERVICE menu, select PRIME to prime

the reagents. You can access the bottom of the enclosure to service

these items, if needed.

5.3.3 Remote Start

Once the line is flushed and the reagents primed, initiate a cycle

remotely through RMT or MODBUS.

The SSR-Ex will only operate using a remote start signal.

5.4 Typical Cycle

During normal operation, the SSR-Ex will run through a timed cycle. A

simplified cycle will consist of the following sequences:

Flushing – sample flow Purging – PURGE valve opens

Zeroing – no flow with cuvette full

Adding Reagents – one pulse of the reagent pumps

Sample Reaction – reaction of reagents with oxidant sample Reading

resulting sample – no flow with cuvette full

Purging – PURGE valve opens to remove the reacted sample and water

The cycle above is simplified and does not describe all the actions

and testing that occurs. The CPU continuously diagnoses the entire

system for correct operation and sample water flow. If an error occurs,

a message is posted on the LCD screen and is indicated on a Modbus

address. Alarm contact closure can be user configured to provide an

alarm in the event of an error message.

5.5 Observe Operation

Observe the process in the optical assembly, you should see a vortex

of water form as the SSR-Ex flushes water through the cuvette, then

the unit will stop water flow and “zero” on the source water, flush again

and then actuate the reagent pumps and take

6.0 Maintenance

Under normal operating conditions, it is recommended that the

main enclosure door is closed. If the electrical or power devices in

the purged (upper) section of the enclosure needs to be accessed

for service, ensure all power has been removed from a safe location

before accessing the electrical or powered devices in the electrical

enclosure.

The SSR-Ex instrument is sectioned such that all the electrical or powered

devices are in the upper, purged section of the enclosure, while the lower

(wetted parts) section contains no power at all and can be operated and

maintained in a safe condition even with the main enclosure door open. In

the interest of safety, if the electrical or power devices in the purged (upper)

section of the enclosure needs to be accessed for service, ensure all power

has been removed from a safe location prior to accessing the electrical or

powered devices in the electrical enclosure. All components in the lower

(wetted parts) section of the enclosure can be accessed for service or routine Figure 13 - Pressure regulator and T-strainer

6.1 Calibration

Calibration kit (Cat. No. 28144S) includes:

125 ml of zero solution (solution #1)

125 ml of calibration solution (solution #2) 1 each replacement cuvette

The SSR-Ex instrument was tested and calibrated prior to leaving the

factory. The instrument operates from a pre-determined calibration

curve for high accuracy of residual oxidant concentration. It is not

necessary to recalibrate to maintain stated accuracy specifications. If

re-calibration is required by a regulatory authority, calibration can easily

be accomplished in the field using the procedure below.

Step 1: Ensure the supply water is shut off. From the control buttons,

enter the calibration screen. Follow the on-screen instructions.

Step 2: Disconnect the black tubing from the pressure regulator to

the pump. Some water may drain from the regulator, this is

normal and it may be appropriate to use a container to catch

the small volume of water.

Step 3: Insert the black tube into solution #1. This is used to set a

zero reference. Follow the instructions on the display.

Step 4: When the SSR-Ex has completed the zero procedure you

will be instructed to move the tube to solution #2. Follow the

instructions on the display.

Step 5: The SSR-Ex will take a reading of the solution. If this reads

from 9-11 mg/l (PPM), the instrument is operating within

the stated specifications and no further action is required.

If the reading is outside of this range the SSR-Ex will allow

you to make an adjustment to bring it into range. Follow the

instructions displayed on the SSR-Ex.

Step 6: Restore the black tube to the pressure regulator and turn

the water supply back on. Check for leaks before closing the

enclosure door.

maintenance, while the SSR-Ex instrument is powered, air supplied, and

while the main enclosure door is open. Under normal operating conditions,

it is recommended that the main enclosure door is closed. In cases where

the SSR-Ex instrument is in an environment considered to be Zone 0 for a

period of time, power and air to the instrument must be removed.

General Condition Check - Once a month check the general condition

of the instrument in operation by opening the enclosure door and

visually inspecting the instruments wet chemistry section components to

confirm proper operation and to also check for any leaking components

or other concerns. The wet section components can be accessed for

maintenance, reagent replacement and visual inspection during voyages.

Specific condition of use: Parts of the enclosure are non-conducting

and exceed the maximum permissible resistance according to

the IEC 60079-0. Therefore, to avoid electrostatic charge build-

up, it must not be rubbed or cleaned with solvents or a dry cloth

when installed/used within a potentially explosive atmosphere.

16

6.2 Cuvette Replacement

HF scientific recommends that the cuvette be replaced annually or if it

appears badly soiled or discolored at any time. It is suggested to place

a covering over a floor grate if the instrument is installed over a grate.

To replace the cuvette:

Step 1: Press SERVICE to stop the flow of sample water and drain

the cuvette.

Step 2: Ensure the source water is turned off.

Step 3: Turn counterclockwise, but do not completely remove, the

knurled fitting on top of the optics system to loosen the

cuvette. Occasionally it is necessary to very gently rotate the

cuvette on the O-rings to facilitate removal. Once the cuvette

rotates easily on the O-rings carefully remove the cuvette.

There is a spring installed in the optical block to facilitate

removal of the cuvette.

Step 5: Reverse the procedure to install a new or cleaned cuvette.

Step 6: Retain the removed cuvette for future use if it can be cleaned.

Refer to Figure 5 - Wet Chemistry Area of Enclosure

Install the new cuvette by pushing it firmly but gently to seat it on the

O-rings, carefully turn the knurled top clockwise until the cuvette is held

level and securely against both the top and bottom O-rings, do not

overtighten. Return to normal operation.

6.3 T-Strainer Cleaning

The T-strainer is integral to the instrument and must be checked when

changing the reagent. When necessary the T-strainer screen and bowl

must be cleaned. The T-strainer is clamped to the door and does not

require removal to be cleaned. You may want to place a container

under the instrument to catch the water and debris during cleaning.

Step 1: Press SERVICE to stop the flow of sample water and drain

the cuvette.

Step 2: Ensure the source water is turned off.

Step 3: Disconnect the top (bowl) of the T-strainer by turning

counterclockwise.

Step 4: Remove and clean the screen and the bowl and then

reassemble.

Step 5: Be sure to tighten the bowl of the strainer.

Step 6: Turn source water back on.

Step 7: Return to normal operation.

Step 8: Check for any leaks.

The T-strainer screen (Cat. No. 28625) may require replacement after a

period of time or as needed.

6.4 Adjusting the Pressure Regulator

The pressure regulator is factory set and it should not be necessary to

adjust it in the field.

6.5 Installing New Reagent in the SSR-Ex

Use caution when changing the reagents, as they are corrosive. These

reagents may stain clothing. After changing the reagents, operators

should wash their hands.

Step 1: Press SERVICE to stop the flow of sample water and drain

the cuvette.

Step 2: Ensure the source water is turned off.

Step 3: Remove both reagent bottles by unscrewing cap assembly.

Step 4: The buffer is installed on the right and the indicator is installed

on the left.

Step 5: Once bottles are secure in the bracket, wrap the Velcro

around both bottles to ensure they do not move.

Step 6: Screw cap on the bottle and ensure a tight fit. Ensure tubing

is fully submerged at the bottom of the bottle.

Step 7: Follow the PRIME procedure under the SERVICE menu.

This will draw enough of each reagent to completely prime

the tubes and replace any old solution. The system will

automatically return to normal operation after it completes the

prime.

6.6 Replacing the Peristaltic Sample

Pump Head

The pump head assembly can be replaced. Recommended replacement

for the pump head assembly is annually. It is replaced as a complete

assembly, not just the pump tube. The pump is located in the upper

right of the wet enclosure.

Step 1: Press SERVICE to stop the flow of sample water and drain

the cuvette.

Step 2: Ensure the source water is turned off.

Step 3: Squeeze the right side of the pump housing, this will release

the pump head from the bracket and a new pump head can

be installed.

Step 4: Disconnect the inlet and outlet sample tubes from the pump

once it has been removed from the pump base taking care to

note which tube connects to which side of the pump head.

Step 5: Connect the inlet and outlet sample tubing to the new pump.

Step 6: Carefully replace the pump head in the enclosure.

6.7 Instrument Storage

If the SSR-Ex is relocated or will be inactive for long periods of time

(several months).

Step 1: Press SERVICE to stop the flow of sample water and drain

the cuvette.

Step 2: Ensure the source water is turned off.

Step 3: Remove the reagents.

Step 4: Flush the reagent sample lines with distilled water. Flush the

reagent system.

Step 5: Remove power by disconnecting the mains power.

Step 6: It is usually a good idea to disconnect or shut off the source

water for the duration of storage.

To order any accessory or replacement part, please contact the HF

scientific Customer Service Department. If for any reason technical

assistance is needed regarding this instrument, please do not hesitate

to contact the HF scientific Technical Services Department.

17

7.0 Diagnostic/Troubleshooting

Chart

8.0 Error/Alarm Messages and

Suggested Actions

9.0 Technical and Customer

Assistance

If for any reason assistance is needed regarding this instrument please

do not hesitate to contact either the HF scientific Technical Service

Department or the HF scientific Customer Service Department:

Symptom Cause Cure

Display shows MA 4 - 20 mA loop open Check wiring

Display shows FAIL Major system fault Contact HF scientific Technical

Support

Readings are erratic (1) Bubbles in solution

(2) Debris in water sample

(1) Check for air leaks

(2) Clean T-strainer at inlet

Readings are lower

than expected

(1) Leaky measurement

cuvette

(2) Measurement cuvette dirty

(3) Reagents bad or expired

(4) Buffer reagent not

(1) Check seating of cuvette on the

O-rings

(2) Replace or clean cuvette

(3) Replace reagents

(4) Attempt a prime procedure, check

the status of reagent pump(s)

Display flashes Sample Over-Range Check sample. Sample may be too

high to read.

Display shows none

while attempting to

calibrate

No current reading displayed Wait for SSR-Ex to post a reading

No display on

SSR-Ex

Air Sentinel II issue with air

supply

Troubleshoot air supply system and

Air Sentinel II

ERROR DISPLAYED Definition Suggested Action

Solenoid 1 Reagent solenoid 1 problem Test solenoid, try factory reset

Solenoid 2 Reagent solenoid 2 problem Test solenoid, try factory reset

Drain Valve Error Problem with the drain valve (1) Flush the SSR-Ex

(2) Clean the drain solenoid

(3) Clean the optical assembly drain

orifice

4 - 20 mA Output

Error

Analog output problem Check for open loop

12 V Monitor Error Power supply Issue On board power supply problem, try

factory reset

Optical Sensor Error Measurement error Wait for SSR-Ex to post a reading, try

factory reset

EEPROM Error Non-volatile error Try factory reset

Main Board Lost Internal communication loss Check cable connections, try factory

reset

Low Setpoint Alarm Reading below set point Check source water oxidant level

High Setpoint Alarm Reading above set point Check source water oxidant level

10.0 Spare Parts Listing

Part/Kit Name Description Frequency of part or kit

change

Calibration Kit - 28144S Description - Includes 125 ml

solution #1, 125 ml solution #2,

and a spare cuvette

Frequency – As required by

regulatory authority

Air/Filter Dryer Assembly

- 28139

Description - Includes air prep

assembly and appropriate fittings

Annual or when red indicator

is shown. See kit below.

Air Filter/Dryer Element

Replacement Kit -

28140S

Description - Qty. 1 AMG-EL150,

Qty. 1 AF20P-060S, and Qty. 1

AMH-EL150

As needed

TOTAL Chlorine SSR-Ex

DRY REAGENT KIT (30

Day Supply) - 110186

Description - Includes DPD

tube, Indicator, Buffer in reagent

bottles, MSDS documents

As needed

TOTAL Chlorine SSR-Ex

Liquid REAGENT KIT (30

Day Supply) - 110187

Description - Includes DPD

tube, Indicator, Buffer in reagent

bottles, MSDS documents

As needed

T-Strainer/ Pressure

Regulator Assy - 28143S

Description - Includes both the

T-strainer and pressure regulator

assembly.

As needed

Replacement T-Strainer

Screen - 28145S

Description - Includes Qty. of 1,

replacement T-strainer screen

As needed

Replacement Peristaltic

Pump Head - 28141S

Description - Includes

replacement pump head

As needed

Reagent Tubing Kit -

28142S

Description - Includes Injectors,

O-rings, Idex nuts, Ferrules,

Coupling nuts and C-Flex tubing.

As needed

Pressure Regulator (Inlet

Water) - 24320S

Description - Includes Qty. of 1,

Watts®Pressure Regulator

As needed

To order any accessory or replacement part, please contact the HF

scientific Customer Service Department. If for any reason technical

assistance is needed regarding this instrument, please do not hesitate

to contact the HF scientific Technical Services Department. Each spare

part will include appropriate instructions of proper use.

18

Notes

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

19

Notes

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________________________________

11.0 Limited Warranty

Watts Regulator Co. (the “Company”) warrants each ballast water market instrument product to be free from defects in material and workmanship

under normal usage for a period of two (2) years from first use or three (3) years from date of the Company’s invoice from the original sale of the

product, whichever occurs first. In the event of such defects within the warranty period, the Company will, at its option, replace or recondition

the product without charge. Parts which by their nature are normally required to be replaced periodically, consistent with normal maintenance,

specifically reagents, desiccant, sensors, electrodes and fuses, are excluded. Also excluded are accessories and supply-type items.

Proof of purchase from the Company (Company invoice or paid order confirmation) and/or first use (commissioning) must be provided when making

a product warranty claim.

THE WARRANTY SET FORTH HEREIN IS GIVEN EXPRESSLY AND IS THE ONLY WARRANTY GIVEN BY THE COMPANY WITH

RESPECT TO THE PRODUCT. THE COMPANY MAKES NO OTHER WARRANTIES, EXPRESSED OR IMPLIED. THE COMPANY HEREBY

SPECIFICALLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

The remedy described in the first paragraph of this warranty shall constitute the sole and exclusive remedy for breach of warranty, and the Company

shall not be responsible for any incidental, special or consequential damages, including without limitation, lost profits or the cost of repairing or

replacing other property which is damaged if this product does not work properly, other costs resulting from labor charges, delays, vandalism,

negligence, fouling caused by foreign material, damage from adverse water conditions, chemical, or any other circumstances over which the

Company has no control. In addition, the Company shall not be responsible for any costs incidental to the Company’s warranty response efforts,

including, without limitation, costs associated with the removal and replacement of systems, structures or other parts of facilities, de-installation,

decontamination and re-installation of products, or transportation of products to and from the Company. This warranty shall be invalidated by any

abuse, misuse, misapplication, improper installation or improper maintenance, alteration of the product, or use of any parts or accessories (including

but not limited to reagents) not provided by the company.

Some states do not allow limitations on how long an implied warranty lasts, and some states do not allow the exclusion or limitation of incidental or

consequential damages. Therefore the above limitations may not apply to you. This Limited Warranty gives you specific legal rights, and you may

have other rights that vary from State to State. You should consult applicable state laws to determine your rights. SO FAR AS IS CONSISTENT

WITH APPLICABLE STATE LAW, ANY IMPLIED WARRANTIES THAT MAY NOT BE DISCLAIMED, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO ONE YEAR

FROM THE DATE OF ORIGINAL SHIPMENT.

IOM-HF-SSR-Ex 28037 2225 28037 © 2022 HF scientific

USA: T: (239) 337-2116 • Toll-Free (888) 203-7248 • F: (239) 454-0694 • HFscientific.com

Latin America: T: (52) 55-4122-0138 • HFscientific.com

Table of contents

Other Watts Monitor manuals