3

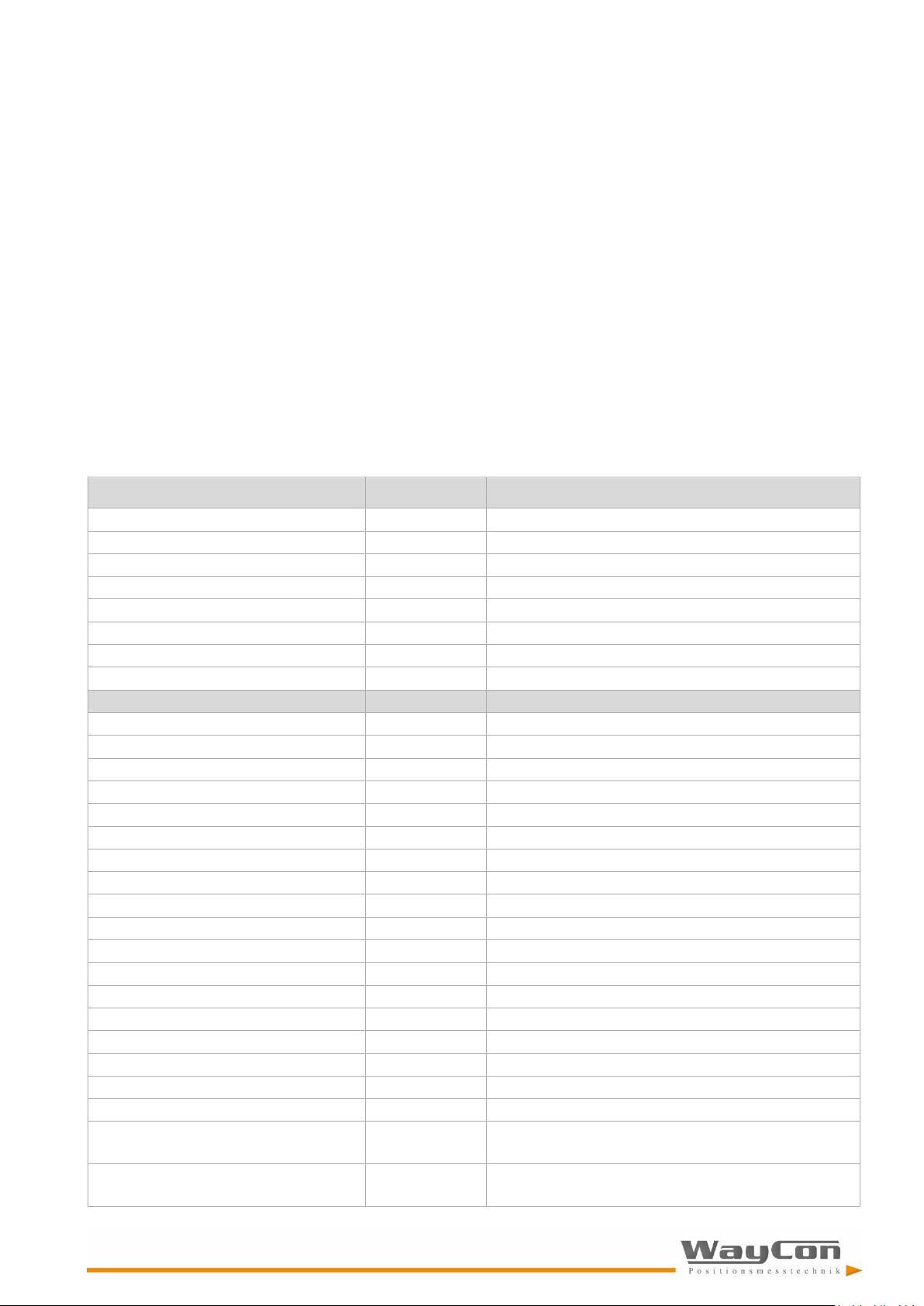

6.4.6 MW – Measurement window................................................................................................................24

6.4.7 MUN – Unit of the measured value......................................................................................................25

6.4.8 SF – Scale factor..................................................................................................................................25

6.4.9 OF – Offset...........................................................................................................................................25

6.4.10 SO-Set Offset.....................................................................................................................................26

6.4.11 SD – Data format of the serial interface output..................................................................................26

6.4.12 BR – Baudrate....................................................................................................................................27

6.4.13 SB – Stop bit of the serial output .......................................................................................................28

6.4.14 RS – Serial Port .................................................................................................................................28

6.4.15 AS – Autostart ....................................................................................................................................28

6.4.16 TE - Terminator ..................................................................................................................................30

6.4.18 SP-Separator for parameters.............................................................................................................31

6.4.19 HE – Heating adjustment...................................................................................................................31

6.4.20 MCT – Output/ Modification of the operating mode when starting a measurement using the display

......................................................................................................................................................................31

6.4.21 PB – Setting the Profibus parameters.................................................................................................32

6.4.22 SSA – Profibus slave address ............................................................................................................32

6.4.23 SSI – Setting the SSI parameters.......................................................................................................32

6.4.24 Additional commands.........................................................................................................................33

6.5 Operating modes.........................................................................................................................................33

6.5.1 DM – Individual distance measurement ...............................................................................................33

6.5.2 DT – Continuous distance measurement (distance tracking)...............................................................33

6.5.3 CT – Continuous tracking.....................................................................................................................35

2values for maximum accuracy for the lower and upper limit of measuring range ......Fehler! Textmarke nicht

definiert.

6.6 Q1/Q2/Q3 – Switching output......................................................................................................................36

6.7 QA – Analog output .....................................................................................................................................38

6.8 TRI + TRO Trigger .......................................................................................................................................40

6.8.1 Trigger function ....................................................................................................................................40

6.8.2 TRI – Trigger-Input ...............................................................................................................................40

6.8.3 TRO – Trigger-output ...........................................................................................................................41

6.9 Direct controlling of the LLD-500.................................................................................................................42

7. Serial interface and communication software..............................................................................................44

7.1 Transmission protocol .................................................................................................................................44

7.2 Installation of the communication program .................................................................................................44

8. Profibus ............................................................................................................................................................46

8.1 ID-Number...................................................................................................................................................46

8.2 Connecting conditions .................................................................................................................................46

8.3 GSD-File......................................................................................................................................................46

8.4 Slave address..............................................................................................................................................47

8.5 Profibus termination ....................................................................................................................................47

8.6 Baudrate ......................................................................................................................................................47

8.7 Length of segment.......................................................................................................................................47

8.9 Configuration data .......................................................................................................................................48

8.10 Cyclical data exchange – input (slave -> master) ......................................................................................49

8.11 Cyclical data exchange – output (master -> slave) ....................................................................................49