- 3 -

TECHNICAL DATA MECHANIC

Measurement range [m] 10 / 15

Linearity [%] ±0.05 (depending on the used encoder)

Sheave circumference [mm] 568.9

Operating temperature [°C] -20...+70

Hydraulic uid only non-hazardous uids (non-ammable, non-toxic), no gaseous media

Operating pressure [bar] 300 (30 MPa)

Testing pressure [bar] 400 (40 MPa)

Pressure port Minimess 1620

Piston travel speed [m/s] max. 2 (in air)

Rope tension [N] start of measurement range: 10...11.5 (13...16.5)

end of measurement range: 29...31.5 (37...43)

Wire sag (calculated) [mm] <30

Connector orientation adjustable in 90° steps

Weight [kg] 61

Housing 42CRMo4 (1.7228)

Draw wire stainless steel 1.4301, Ø 0.69 mm

Encoder requirements

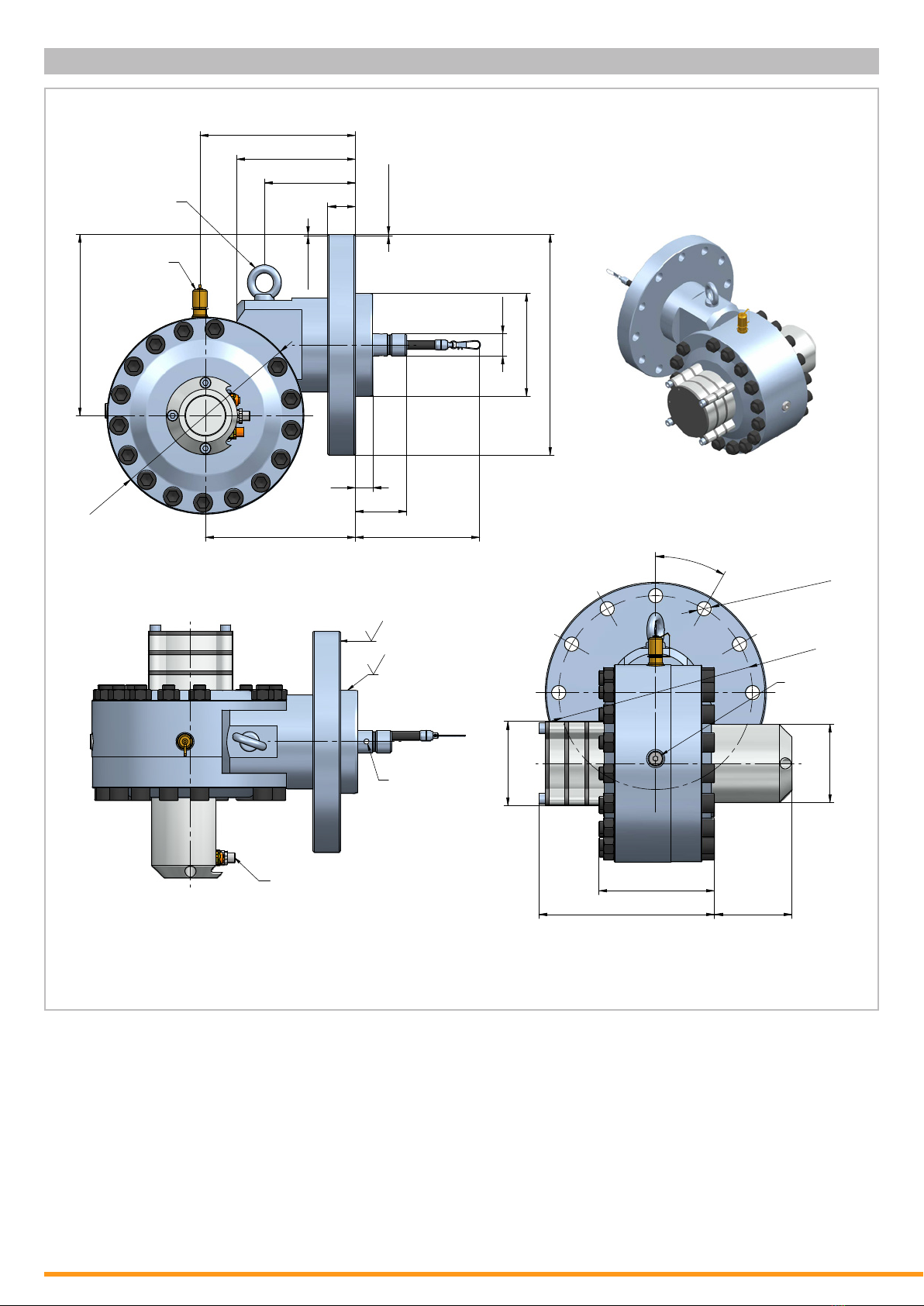

[mm]

ange with stator coupling Ø 58

pitch circle diameter for xing screws 63

hollow shaft Ø 15

identified laboratory value without hydraulic fluid

TECHNICAL DATA ENCODER

SSI CANopen Probus-DP EtherCAT Pronet

Linearity [%] ±0.05 (independent of the measurement range))

Resolution scalable (via Software) no yes

Resolution standard [Pulses/mm]

[Bit]

7.2

12

14.4

13

Resolution maximal [Pulses/mm]

[Bit] -115.2

16

Sensor element Multiturn-Absolute-Encoder with optical disc

Connection connector M23,

radial, 12 pins

2 x cable gland,

radial

3 x cable gland,

radial

3 x connector M12, radial, 4 pins

Power supply [VDC] 10...30, reverse polarity protection of the power supply

Current consumption (no load, 24 VDC) [mA] max. 50 max. 100 max. 120 max. 200

Protection class IP65, optional IP67

Humidity max. 90 % relative, no condensation

Temperature [°C] -20...+80

Special cables needed yes