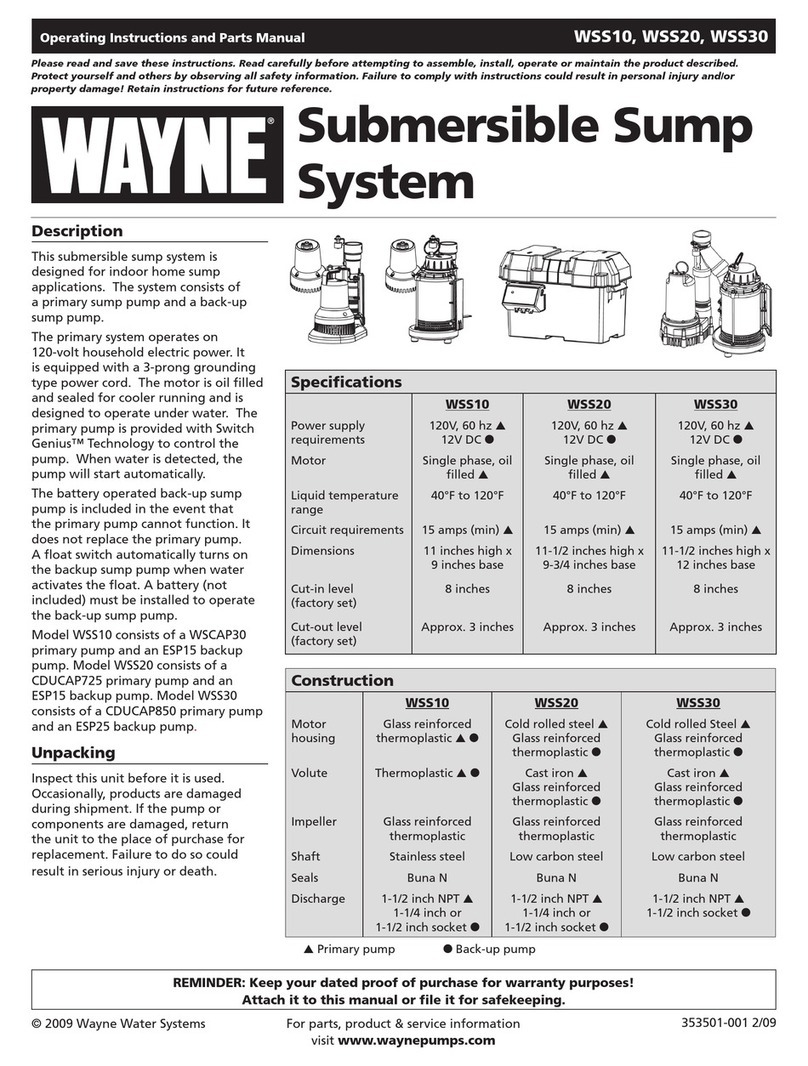

Submersible Utility

Pump

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or prop-

erty damage! Retain instructions for future reference.

© 2000 Wayne Water Systems

Operating Instructions and Parts Manual TSC

Do not pump flammable or

explosive fluids such as gaso-

line, fuel oil, kerosene, etc. Do not use

in a flammable and/or explosive envi-

ronment. Pump only clear water.

Personal injury and/or property dam-

age will result.

Risk of electric shock! This

pump has not been tested for

use in swimming pool areas. Never

place pump in pools while people are

in the water.

Do not handle pump with wet

hands or when standing in

water or on a damp surface.

Risk of electric shock! This

pump is supplied with a

grounding conductor and grounding

type attachment plug. Use a grounded

receptacle to reduce the risk of fatal

electrical shock.

This pump con-

tains dielectric

motor oil for motor heat transfer.

Care should be taken when disposing

of this oil. Do not use this pump in

ponds or fountains because the motor

oil can be harmful to aquatic life.

2. Wear safety glasses at all

times when working with

pumps.

3. It is strongly recommended

that this unit be plugged into a

Ground Fault Circuit Interrupter

(GFCI). Consult a local electrician

for installation and availability.

4. Do not use the power cord or dis-

charge hose to carry or handle the

pump. Damage to the power cord

or discharge hose may occur. Use

the lifting ring supplied on the

pump.

351301-001 1/00

Installation and Operation

Always disconnect

electric supply

before attempting to install, service,

relocate or perform any maintenance.

If the power source is out of sight, lock

and TAG IN OPEN (OFF) POSITION to pre-

vent unexpected power application.

Failure to do so could result in fatal

electrical shock!

This unit is not designed for

use in septic tanks or under-

ground vaults to pump raw sewage or

effluents. Never use in hazardous or

explosive locations.

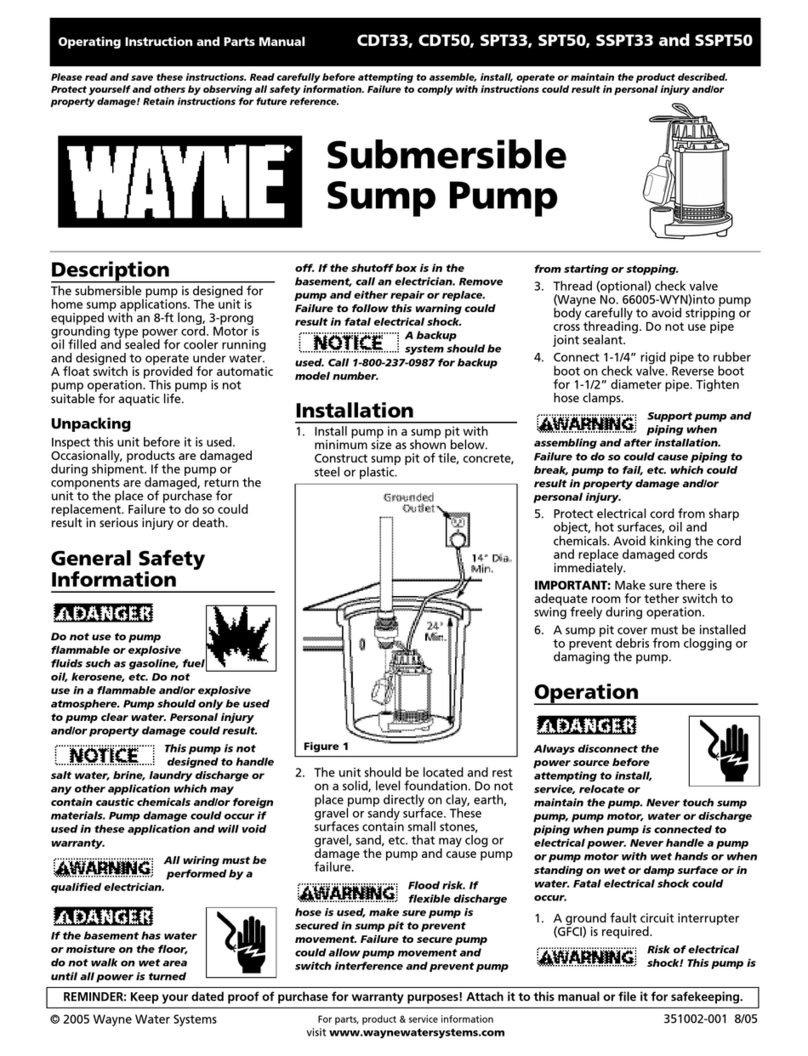

1. This pump has been designed to

attach to a standard garden hose.

Thread the female end of the gar-

den hose to the male discharge on

the pump.

2. To reduce leakage between the

pump and the hose, place a hose

washer (not included) on the gar-

den hose before installing to the

pump.

3. For best pump performance,

unwind the hose before starting the

pump. This will help remove any

kinks or binds in the hose and allow

the unit to pump with less

restriction.

4. Set the pump on a hard surface in

the water. Do not set the pump

directly on mud or sand surfaces.

This will cause the inlet screen to

clog.

5. The water level must be at least 1/2

inches for the pump to operate.

Water levels less than 1/2 inches will

not allow the impeller to contact

water and no water will be

pumped.

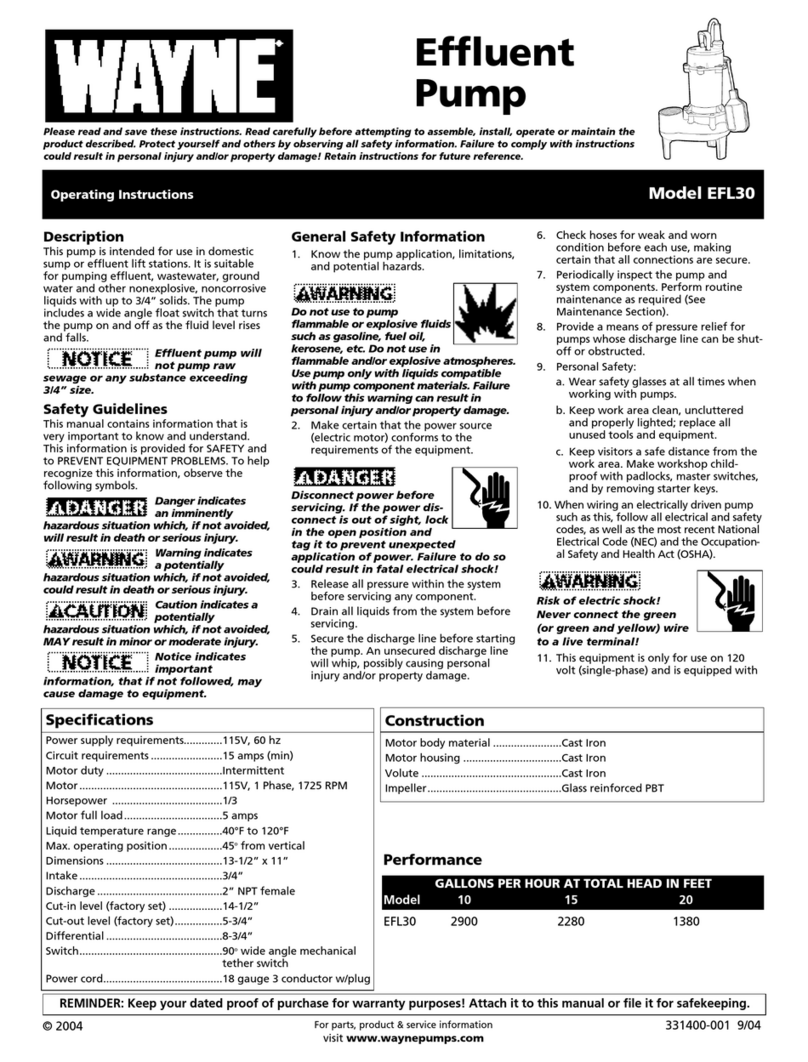

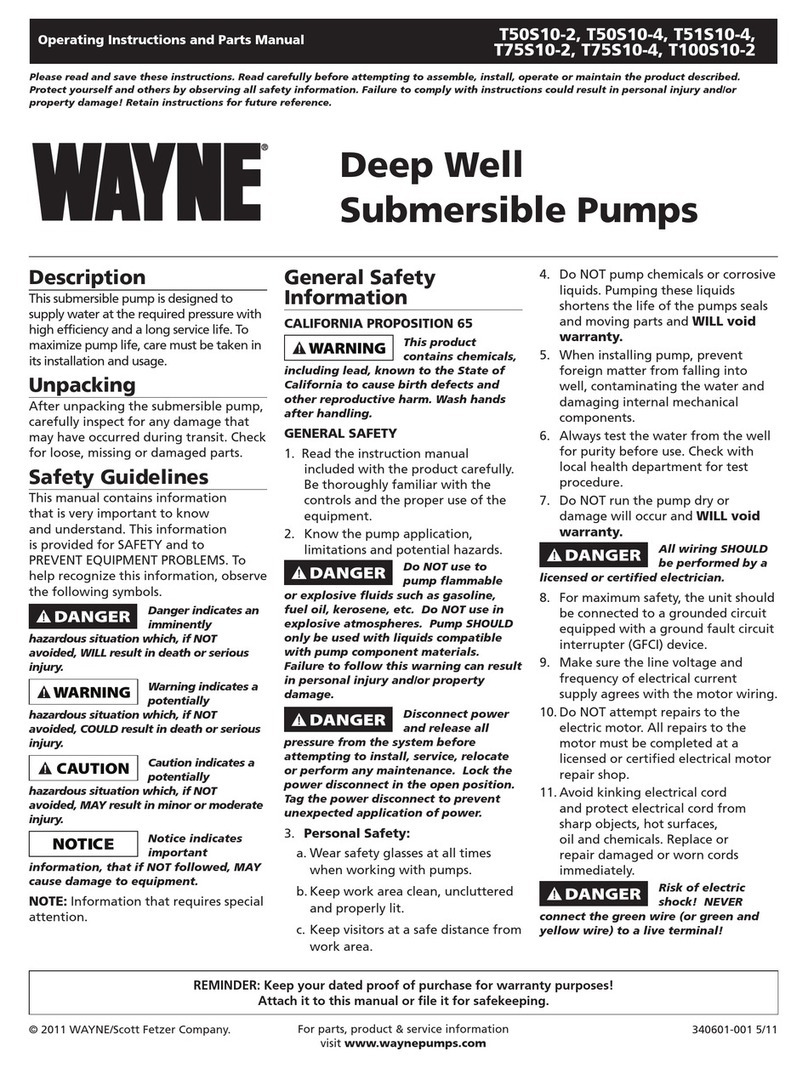

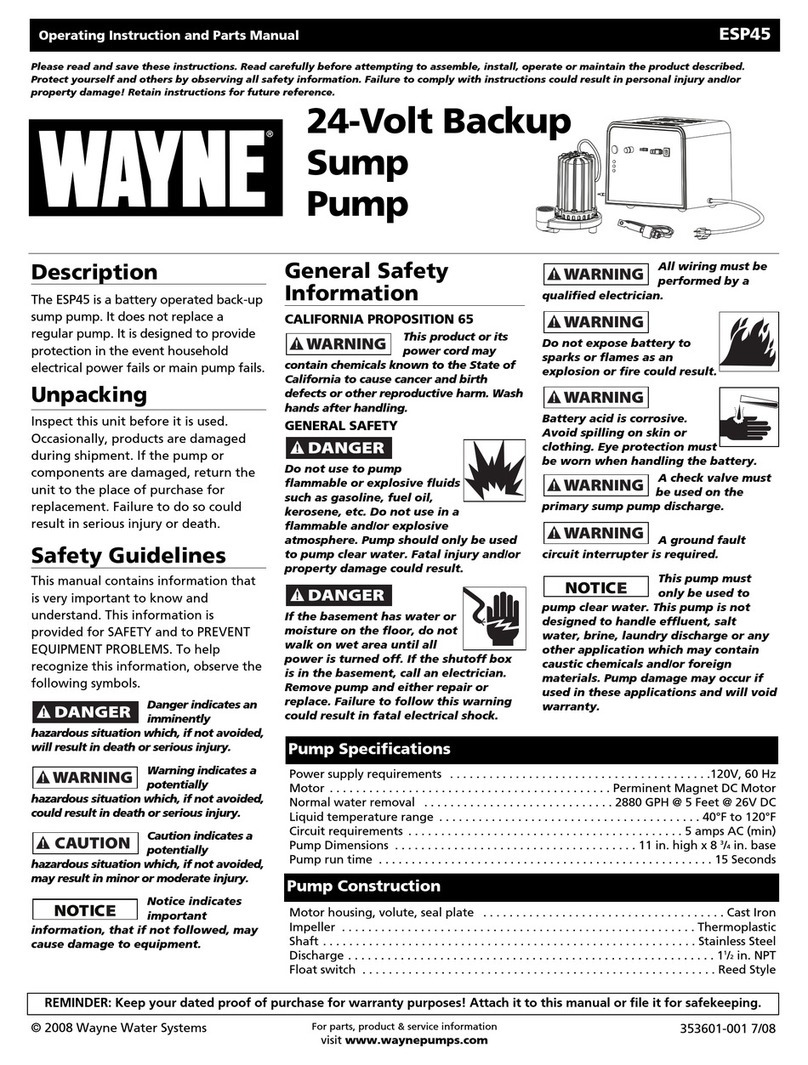

Description

This portable, submersible utility pump

is designed for non-automatic use in

water. The units are equipped with an

8 ft. 3-prong grounding type power

cord. The motor is oil filled and sealed

for cooler operation. The discharge fit-

ting is designed for convenient attach-

ment to a garden hose.

IMPORTANT: THIS PUMP IS NOT

SUITABLE FOR AQUATIC LIFE!

Unpacking

After unpacking the unit, carefully

inspect for any damage that may have

occurred during transit. Check for

loose, missing or damaged parts.

Danger indicates

an imminently haz-

ardous situation which, if not avoided,

WILL result in death or serious injury.

Warning indicates

a potentially haz-

ardous situation which, if not avoided,

COULD result in death or serious injury.

Caution indicates a

potentially haz-

ardous situation which, if not avoided,

MAY result in minor or moderate

injury.

Notice indicates

important informa-

tion, that if not followed, MAY cause

damage to equipment.

This manual contains information that

is very important to know and under-

stand. This information is provided for

SAFETY and to PREVENT EQUIPMENT

PROBLEMS. To help recognize this

information, observe the following:

1. Read these rules and

instructions carefully.

Failure to follow these

instructions could cause

serious bodily injury and/or proper-

ty damage.

Very Important Safety

Information