7

ANGEL G7

© 2005 WDP LTD.

LCD MENUSDual External LCD Menus in Safe Mode: Basic Menu – Advanced Menu

DUAL EXTERNAL LCD MENUS IN SAFE MODE

– BASIC MENU

FEATURE MENU

ALLOCATION

EXTERNAL

VIEW

EXTERNAL

ADJUST PARAMETER

MENU BASIC YES YES Basic/Adv

FETCH BASIC YES YES ON/OFF

TIMER BASIC YES YES 0.5-30min

A1 BASIC YES YES 0.5-30min

A2 BASIC YES YES 0.5-30min

A3 BASIC YES YES 0.5-30min

ANGEL EYE TEST BASIC NO YES Pass/Fail

VIEWABLE EXTERNAL MENU

The ANGEL has a number of features that may only be adjusted or viewed

on the LCD screen. The menu that is displayed can be split into two main

categories - Basic and Advanced. There is a division between basic and

advanced menus. As default, the menu divisions are factory set.

• This is a basic viewing menu that is designed for speed of use and allows you

to quickly view basic menu items; these are settings for the items you are

most likely to use whilst at a tournament.

• Any menu items that may change the performance of the ANGEL CANNOT be

adjusted externally e.g. Dwell, Trigger Offset and Mode.

FACTORY DEFAULT BASIC MENU SETTINGS

MENU

Allows you to select either Basic or Advanced menu options.

FETCH

Allows you to put your ANGEL in receiver mode so that it will receive data/

settings transmitted from other ANGEL markers or PDA’s.

TIMER, A1, A2, A3 FEATURE

This is a fully interactive game timer with 3 independent alarms and will allow

you and your team members to play in unison. The timer may be set in 30

second increments from 0 to 30 minutes. The 3 independent alarms may also

be set in 30 second increments giving you a very versatile game timer and

alarm system. Once the alarms are set they will be activated by the first trigger

pull after making the ANGEL LIVE.

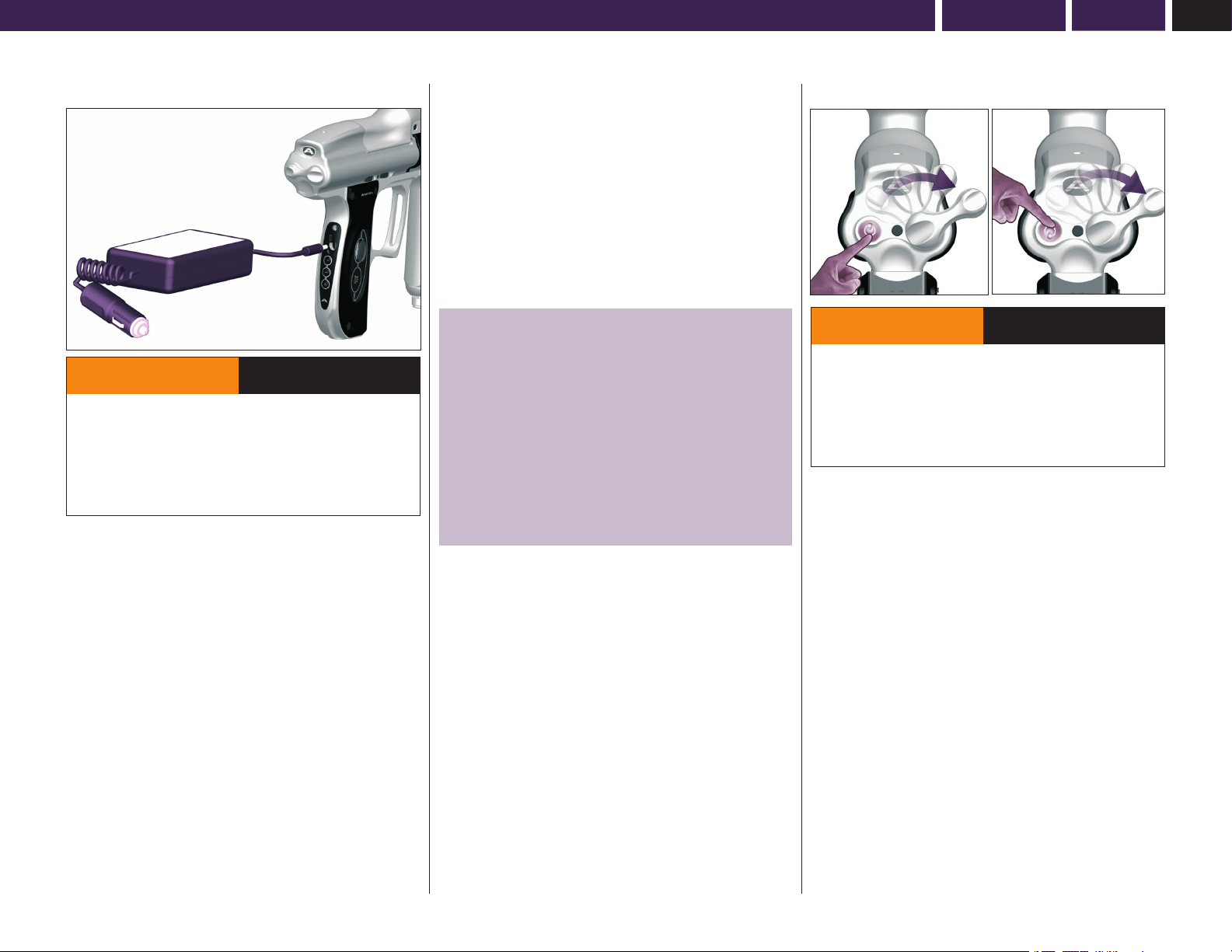

ANGEL EYE TEST FEATURE – Whilst the ANGEL is in SAFE Mode.

• From the Basic or Advanced menu select Angel Eyes Test option using

the middle button externally or the blue button internally.

• Press the bottom button externally and the display will show ‘dropB’.

• Drop a paintball into the breech.

• When the paintball is detected the display will show ‘PASS’.

• Failure to obtain the ‘PASS’ message is an indication that the Angel

Eyes need cleaning or servicing.

DUAL EXTERNAL LCD MENUS IN SAFE MODE

– ADVANCED MENU

FEATURE MENU

ALLOCATION

EXTERNAL

VIEW

EXTERNAL

ADJUST PARAMETER

MENU ADV & BASIC YES YES Basic/Adv

FETCH ADV & BASIC YES YES ON/OFF

TIMER ADV & BASIC YES YES 0.5-30min

A1 ADV & BASIC YES YES 0.5-30min

A2 ADV & BASIC YES YES 0.5-30min

A3 ADV & BASIC YES YES 0.5-30min

ANGEL EYE TEST ADV & BASIC NO YES Pass/Fail

MROF ADVANCED YES YES 8-25bps

Hopper T Time ADVANCED YES YES 0.01-1.0 Secs

Hopper A Time ADVANCED YES YES 1-4 Shots

Hopper Type ADVANCED YES YES 1-16 Levels

TEMP ADVANCED YES YES °C / °F

VIBRATOR ADVANCED YES YES ON/OFF

TRIP ADVANCED YES YES Re-Zero

BACKLIGHT ADVANCED YES YES ON/OFF

SEND ADVANCED YES YES ON/OFF

ROF ADVANCED YES YES Re-Zero

MODE ADVANCED YES NO Where Applicable

DWELL ADVANCED YES NO 9-20m/s

TRIGGER OFFSET ADVANCED YES NO 1-20 Levels

CYCLES ADVANCED YES NO Non-Resetable

ID ADVANCED YES NO Non-Resetable

VIEWABLE EXTERNAL MENU

• This is an advanced viewing menu that allows you to view the full menu for the

items you are most likely to use whilst setting up your ANGEL.

• Any menu items that may change the performance of the ANGEL CANNOT be

adjusted externally e.g. Dwell, Trigger Offset and Mode.

FACTORY DEFAULT ADVANCED MENU SETTINGS

In addition to the seven items in the Basic menu, the Advanced menu contains

the following:

MROF

This allows you to tune your maximum rate of fire whilst the Angel Eyes modes

are OFF. The MROF should not be set greater than your loader is capable of

delivering. When the Angel Eyes are switched OFF the MROF is capped at 15.

HOPPER (LOADER) T TIME FEATURE

This allows the user to set the hopper (loader) activation time and is settable

from 0.1 to 2.0 seconds. This is the time period that the intellifeed will supply a

signal output for the hopper (loader).

HOPPER (LOADER) A ACTIVATION FEATURE

This allows the user to set the hopper (loader) activation point and can be set to

activate on the following;

A1 = Activates on every shot

A2 = Activates of a ROF of 2 shots or greater

A3 = Activates of a ROF of 3 shots or greater

A4 = Activates of a ROF of 4 shots or greater

HOPPER (LOADER) TYPE

This allows you to select the correct Angel Eye settings for the type of loader

that you are using. Once you have selected the correct setting the Angel Eyes

program will intelligently adjust itself to the variable speeds of your loader.

1-4 = 9v Agitator type loaders

5-8 = 12-18v Agitator type loaders

9-12 = Force-fed type loaders

13-16 = Only Very Fast force-fed type loaders (Ensure that your loader is at

maximum performance and reliability otherwise you may encounter problems

related to the loader)

TEMP FEATURE

This allows you to select Fahrenheit or Centigrade and monitors the

environmental temperature that the marker is exposed to.

VIBRATOR FEATURE

Should the game timer vibrator alarm function not be required this feature

allows you to disable the vibrator. The game timer will still function with the

vibrator disabled but no interactive alarms will activate.

TRIP FEATURE

This is a resettable shot counter that allows you to view the total number of

shots you have fired, and can be referred to at any stage, eg. per game, per day

or per event.

BACKLIGHT FEATURE

This allows you to switch the display backlight on/off.

SEND IR FEATURE

This allows you to switch on the infra red transmitter and be capable of

transmitting infra red data to other ANGELs. SEND IR will transmit the Game

Timer and its alarms information and will also switch on the vibrator and reset

the trip meter.

ROF FEATURE

This will record your highest rate of fire achieved shooting your ANGEL. The data

is constantly updated with the highest reading achieved should it exceed the

previous readings to ensure that you record the latest data. You can reset this

when necessary.

• Ensure a barrel blocking device is fitted to the ANGEL.

• Ensure the hopper is removed from the ANGEL.

• Ensure that there are no paintballs in the ANGEL.

WARNING ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES

• Ensure a barrel blocking device is fitted to the ANGEL.

• Ensure the hopper is removed from the ANGEL.

• Ensure that there are no paintballs in the ANGEL.

WARNING ADHERE STRICTLY TO THESE

AND ALL OTHER SAFETY

INSTRUCTIONS AND GUIDELINES