Dear music lover,

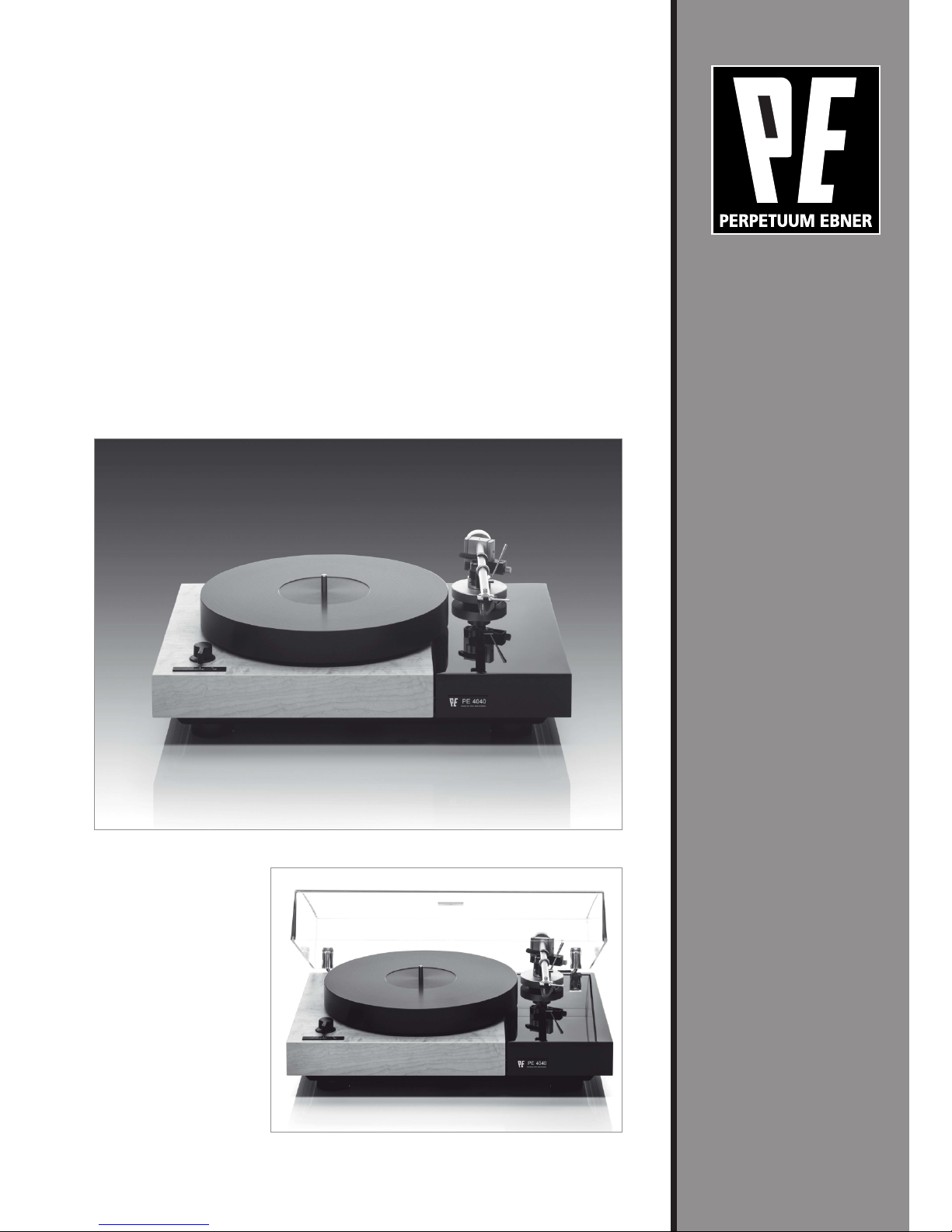

Congratulations on the purchase of your new Perpetuum

Ebner (PE) turntable.

This product has been designed and manufactured with the

greatest care.

Please, take note of the enclosed safety information and read

the operating instructions carefully before you set up and

operate the device.

SAFETY INFORMATION:

PLEASE READ CAREFULLY BEFORE OPERATING YOUR

UNIT !

CAUTION:

To reduce risk of electric shock, do not remove the cover.

There are no user-serviceable parts inside.

This symbol on the product or on its packaging indicates that this product

must not be disposed of with your other household waste. Instead, it is

your responsibility to dispose of your waste equipment by handing it over

to a designated collection point for the recycling of waste electrical and

electronic equipment. The separate collection and recycling of your waste

equipment at the time of disposal will help to conserve natural resources

and ensure that it is recycled in a manner that protects human health and

the environment.

For more information about where you can drop off your waste equipment

for recycling, please contact your local city office, your household waste

disposal service or the shop where you purchased the product.

This product was tested and complies with all the requirements

for the CE Mark.

IMPORTANT: Disposal of waste equipment by users in private

households in the European Union.

Tradition verpflichtet

3