CF-2 5

Table of Contents

Paragr. Title ........................................................ Page

Preface....................................... 3

General Safety Instructions ..... 4

Table of Contents ..................... 5

1 Technical Description .............. 6

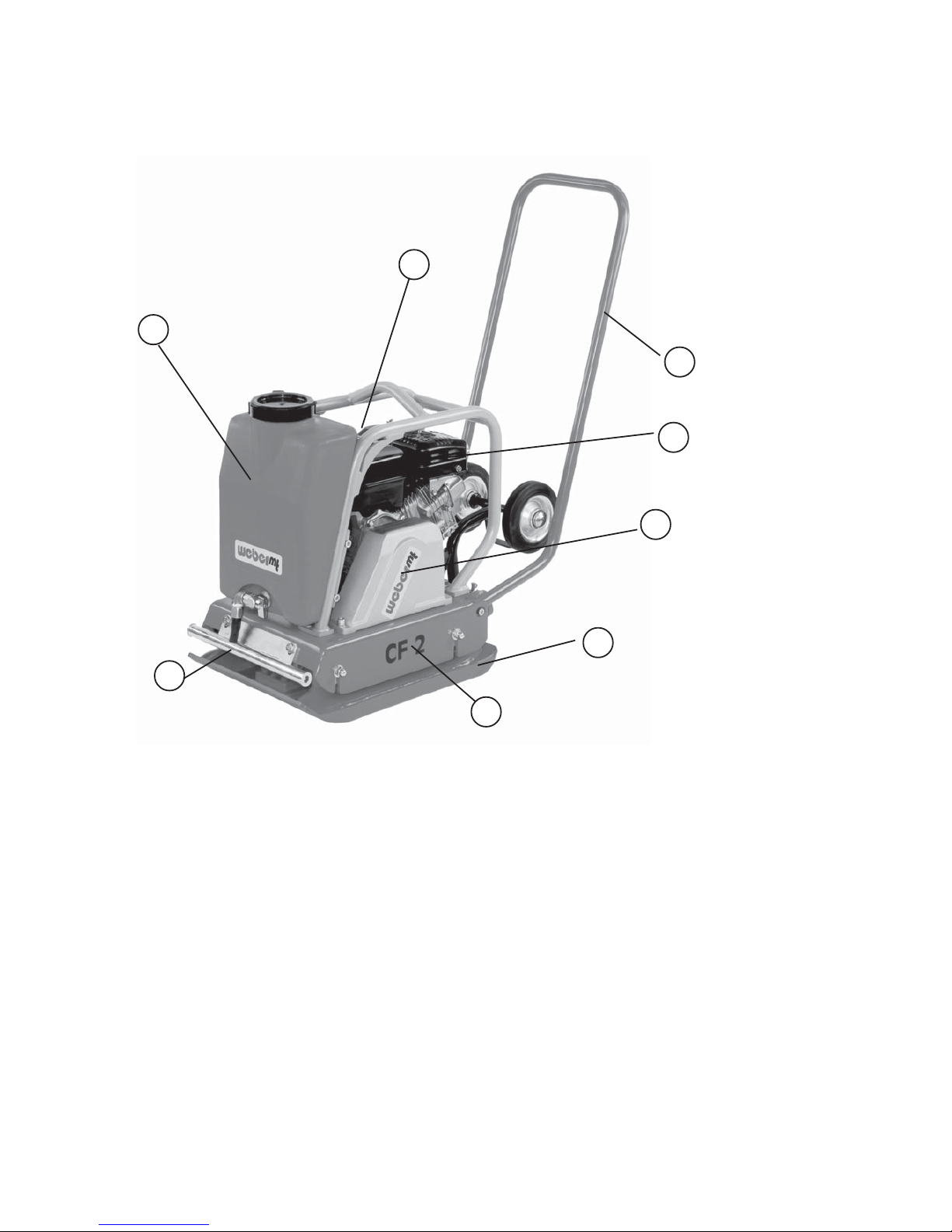

1.1 Illustration ............................................ 6

1.2 Machine Description ........................... 7

1.3 Specifications ................................... 8/9

2 Operation.................................. 10

2.1 Safety Precautions for the

Operation ........................................... 10

2.2 Transport ........................................... 11

2.2.1 Loading by Crane ................................ 11

2.2.2 Manual Loading ................................... 11

2.3 Commissioning ................................. 11

2.4 Pres-Start Work ................................. 11

2.4.1 Checking the Fuel Level ...................... 12

2.4.2 Checking the Engine Oil Level............. 12

2.4.3 Fitting the Damper Plate ...................... 13

2.4.4 Fitting the Undercarriage ..................... 13

2.4.5 Fitting the Water Sprinkler System ...... 14

2.5 Starting the Engine ........................... 15

2.5.1 Starting the Robin Engine .................... 15

2.5.2 Starting the Honda Engine................... 16

2.6 Compaction Work ............................. 17

2.7 Putting the Compactor out of

Operation ........................................... 18

2.7.1 Stopping the Robin Engine .................. 18

2.7.2 Stopping the Honda Engine ................. 19

3 Maintenance .............................20

3.1 Safety Precautions for

Maintenance Work ............................ 20

3.2 Maintenance Survey .......................... 21

3.2.1 Initial Maintenance............................... 21

3.2.2 Routine Maintenance .......................... 22

3.3 Description of the

Maintenance Work ............................ 23

3.3.1 Changing/Adding Engine Oil................ 23

3.3.2 Cleaning/Replacing the Air Filter

Cartridge ............................................. 24

3.3.2.1 CF-2 Robin .......................................... 24

3.3.2.2 CF-2 Honda ........................................ 25

3.3.3 Cleaning/Replacing the Fuel

Filter .................................................... 26

3.3.3.1 CF-2 Robin

3.3.4 Checking the Condition and Tension

of the Vibrator V-Belt .......................... 27

3.3.5 Replacing the V-Belt ............................ 27

3.3.6 Changing the Vibrator Oil ................... 28

3.4 Consumables and Quantities ........... 29

4 Malfunctions During

Operation ..................................30

4.1 General ............................................... 30

4.2 Trouble Shooting .............................. 31

5Preserving the Machine..........32

5.1 Preservation Measures ..................... 32

5.2 Removing Machine

Preservatives ..................................... 32

6

Weber

Maschinentechnik GmbH ............33

Paragr. Title Page