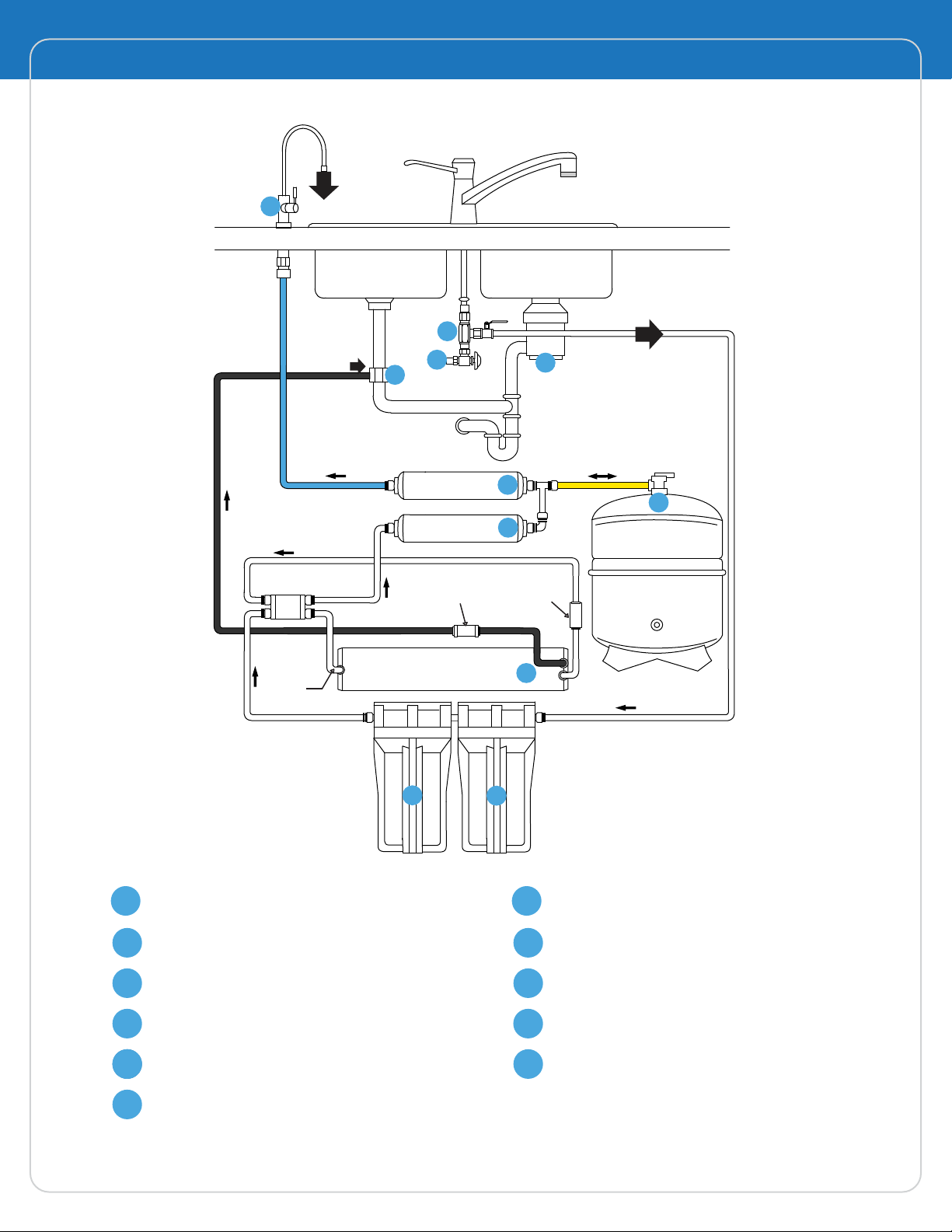

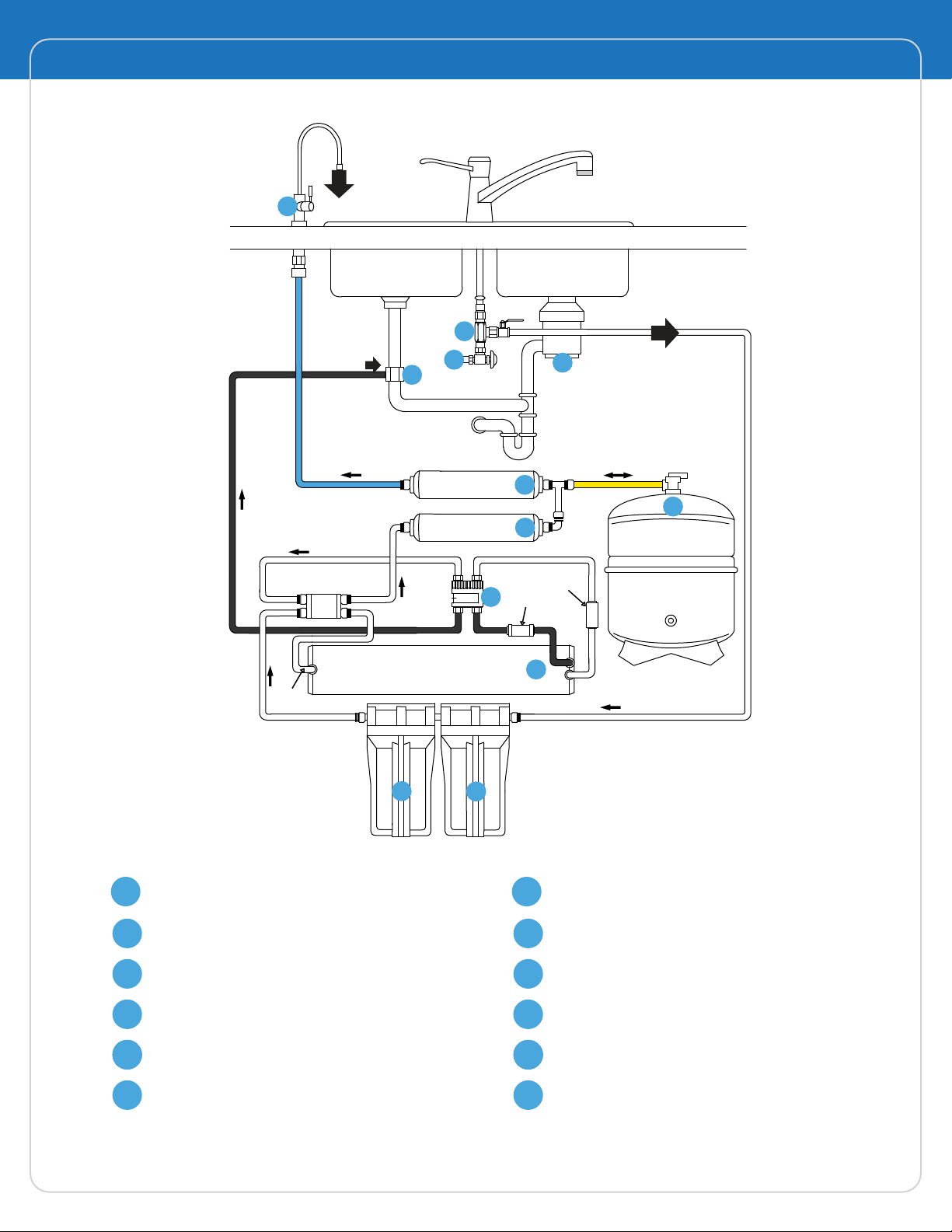

Tapping into the cold water line

(Using the water supply adapter model FW 1)

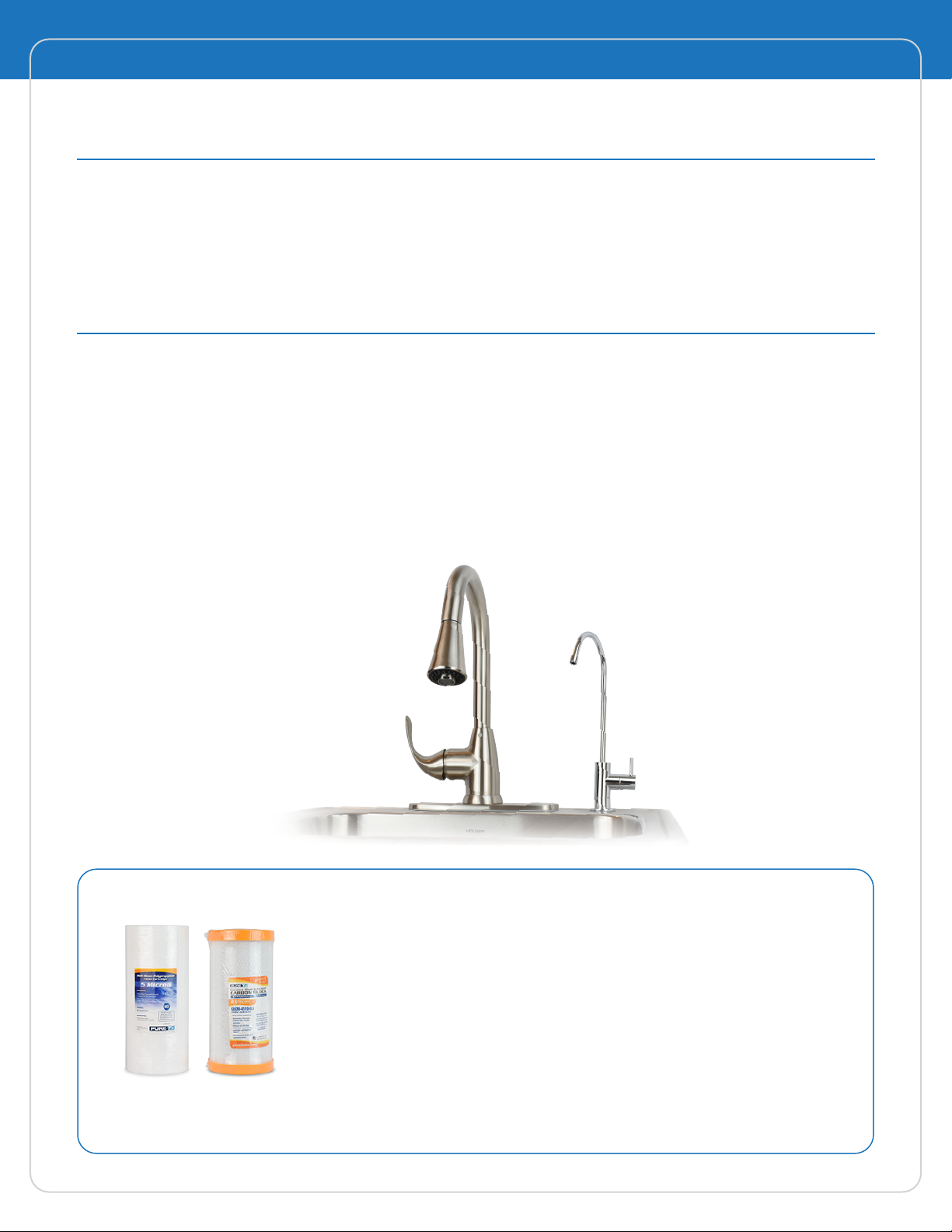

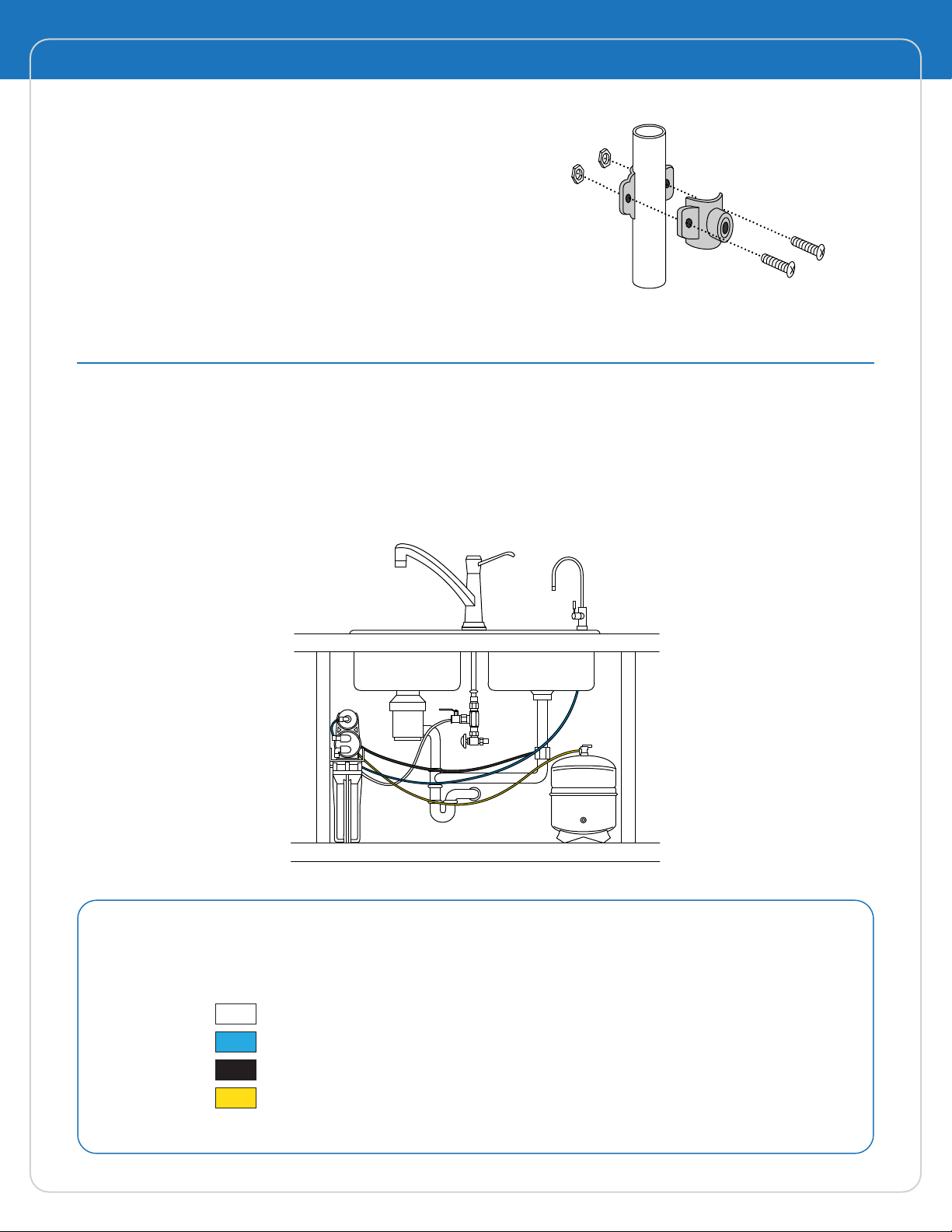

Drilling the hole for the faucet

1. For best results, a ½” carbide-tipped drill bit should be used to drill a hole into your sink for the

auxiliary faucet.

2. Carefully select the faucet location making sure it will have a neat water fall pattern and that

the faucet stud will be accessible from below once the hole is completed.

3. For Porcelain Sink: Before starting the drill motor, apply firm downward pressure on the bit until

a crunching occurs. This will help keep the drill bit from moving.

4. For Stainless Steel Sink: Before using a ½” carbide drill bit, an indent should be made with a

center punch to keep the drill bit from moving. A small pilot hole will also aid the ½” drill bit.

5. For best results, keep steady firm pressure during the start of the hole will cause excess wear

on the bit and progress will be slow.

6. Once the hole is complete, clean the area of metal chips and roughness around the hole.

Metal chips will stain Porcelain.

5

NOTE: The drinking water system must be connected to the COLD

water supply only.

1. Turn off the cold water supply to the sink faucet

by locating the Round or oblong handle on the

right side of the sink cabinet and Turning clockwise

until the water supply is off.

NOTE: If the cold water shut-off valve fails to turn off the water, the

house water supply can be turned off at the main water supply.

2. The water supply adapter can be installed at the faucet Connection (A of Fig. #5) of the cold

water line or at the shut-off Valve connection (B of Fig. #5).

3. Disconnect the threaded nut at the connection and thread the water supply adapter, with

the flat washer in place, onto the connection and tighten. Connect the white tubing to the

water supply adapter with the treaded nut and tighten.

4. Thread the needle valve into the adapter tightly and turn the handle clockwise all the way in.

Turn on cold water supply to the sink faucet and check for leaks.

NOTE: Safety glasses should be worn to protect your eyes while drilling the faucet hole.

INSTALLATION INSTRUCTIONS

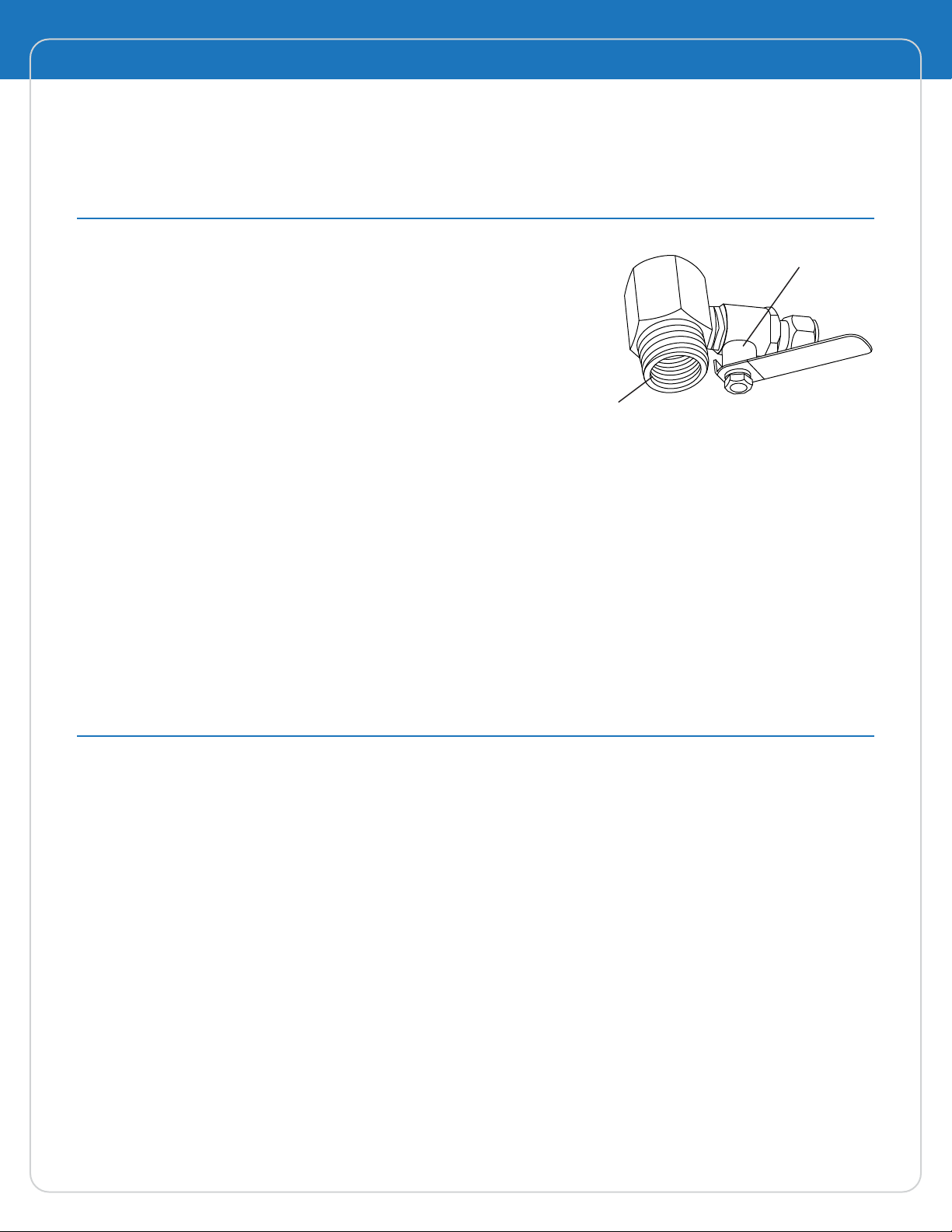

NEEDLE VALVE

WATER SUPPLY

ADAPTER

Fig. #5

MX Manual

© 2017 Water Engineering Corporation