Safety notes Model 4500H

4Weed

1 Safety notes

Safe and secure operation of the head transmitter can only be guaranteed if the

operating instructions and all safety notes are read, understood and followed.

1.1 Designated use

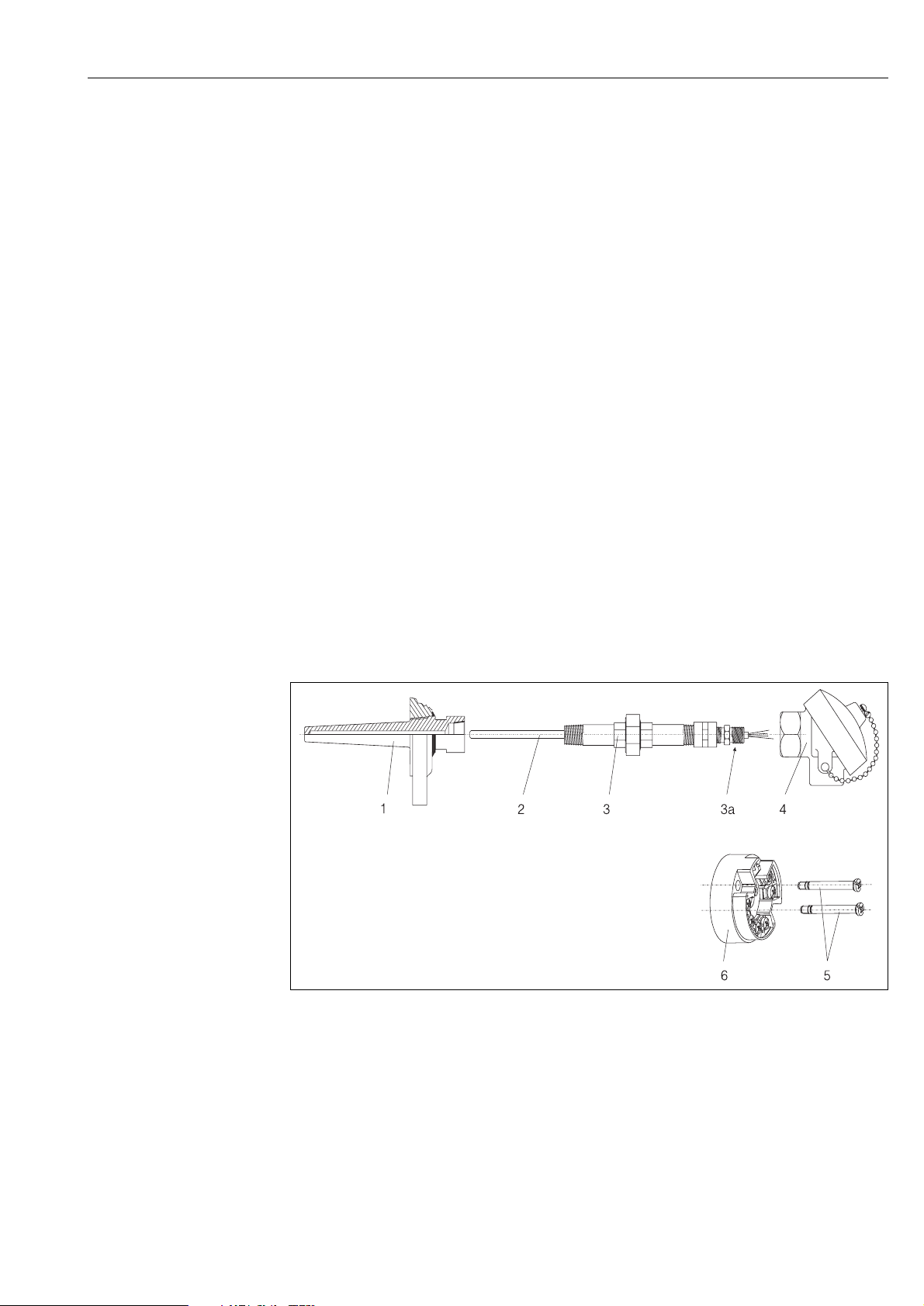

•The unit is a presettable temperature head transmitter for resistance temperature

detectors (RTD). The unit is constructed for mounting in a connection head (DIN form

B) or field housing.

•The manufacturer cannot be held responsible for damage caused by misuse of the

unit.

1.2 Installation, commissioning and operation

The unit is constructed using the most up-to-date production equipment and complies

to the safety requirements of the local guidelines. The temperature transmitter is fully

factory tested according to the specifications indicated on the order. However, if it is

installed incorrectly or is misused, certain application dangers can occur. Installation,

wiring and maintenance of the unit must only be done by trained, skilled personnel who

are authorized to do so by the plant operator. This skilled staff must have read and

understood these instructions and must follow them to the letter. The plant operator

must make sure that the measurement system has been correctly wired to the

connection schematics.

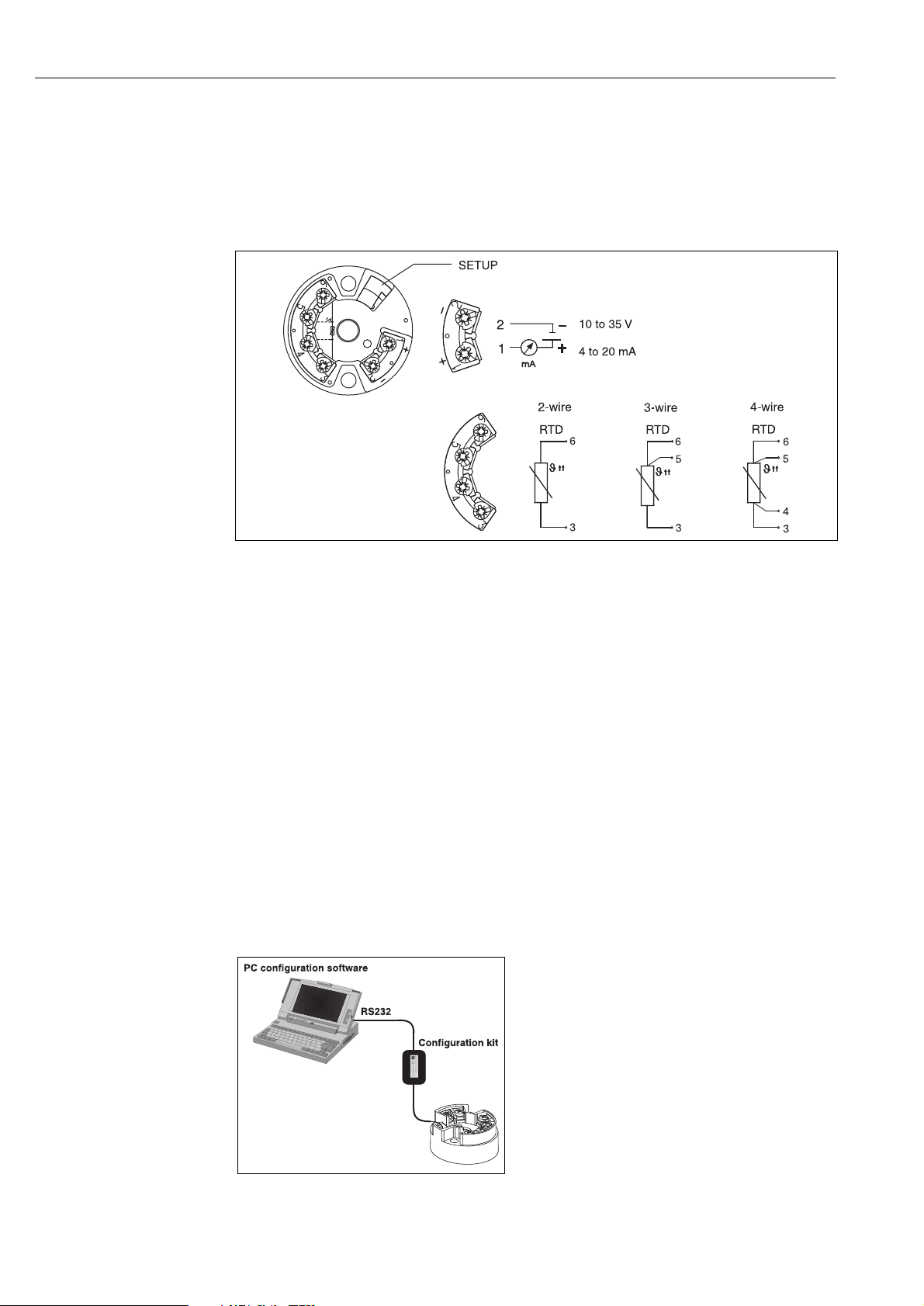

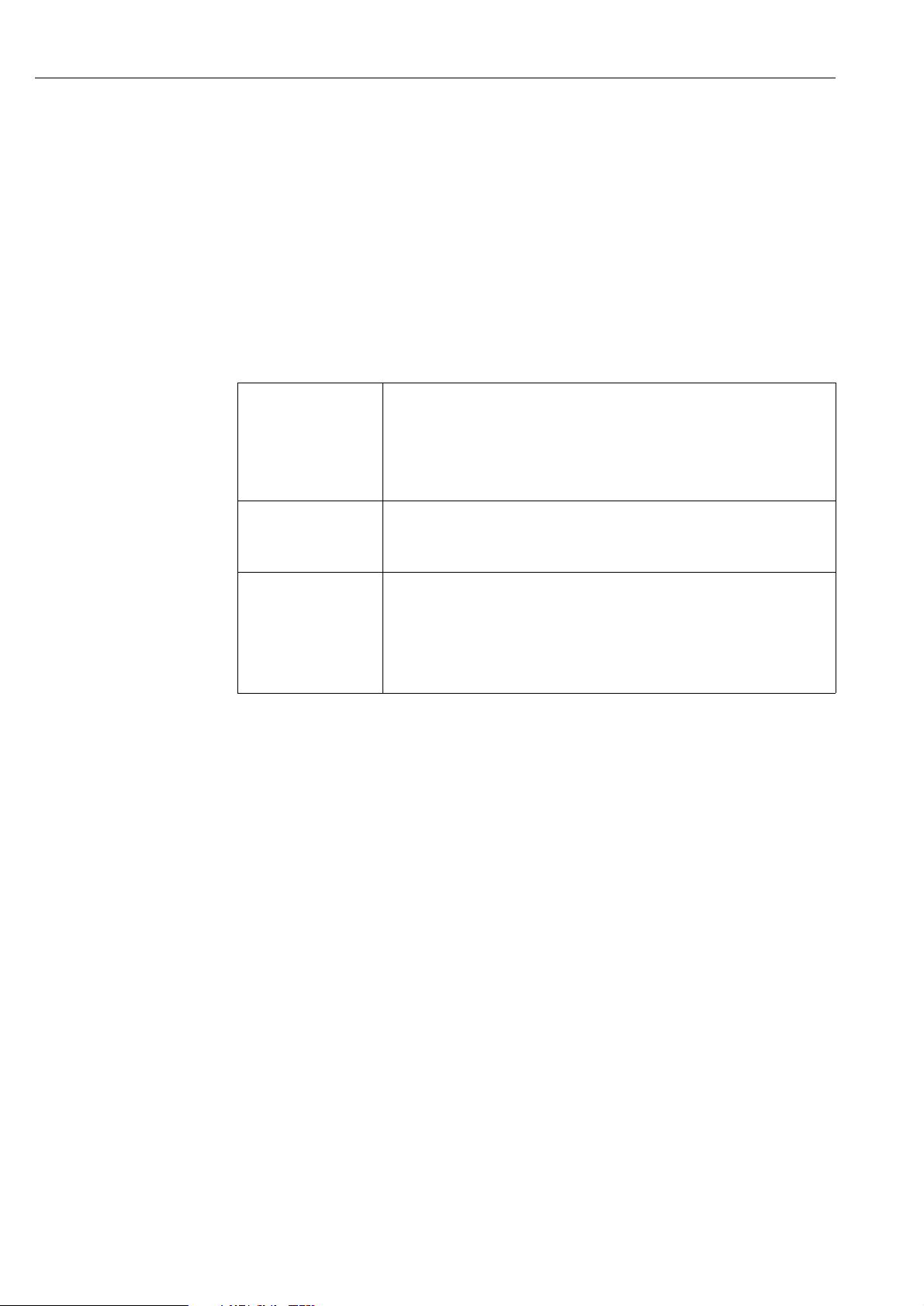

Electrical temperature sensors such as RTD's produce low-level signals proportional to

their sensed temperature. The temperature transmitter converts the low-level sensor

signal to a standard 4 to 20 mA DC signal that is relatively insensitive to lead length and

electrical noise. This current signal is then transmitted to the control room via two wires.

The transmitter electronics module is permanently sealed within the housing, resisting

moisture and corrosive damage. Verify that the operating atmosphere of the transmitter

is consistent with the appropriate hazardous locations certifications.

#Warning!

Electrical shock could cause death or serious injury. If the sensor is installed in a high

voltage environment and a fault or installation error occurs, high voltage may be present

on the transmitter leads and terminals.

Temperature Effects

The transmitter will operate within specifications for ambient temperatures between -40

and 185 °F (-40 and 85 °C). Heat from the process is transferred from the thermowell to

the transmitter housing. If the expected process temperature is near or beyond

specification limits, consider the use of additional thermowell lagging, and extension

nipple, or a remote mounting configuration to isolate the transmitter from the process.

1.3 Operational safety

The measuring device complies with the general safety requirements in accordance

with IEC61010, the EMC requirements of IEC61326 and NAMUR recommendation NE21

and NE43.

Technical advancement

The manufacturer reserves the right to modify technical data without prior notice. Your

distributor can supply you with current information and updates to these Operating

Instructions.