L12 – User manual – English (EU) – 29/10/2019 - ISSUE 1

10

If weeds go brown immediately after treatment, this could

indicate that treatment speed is too slow and excessive

heat is being applied.

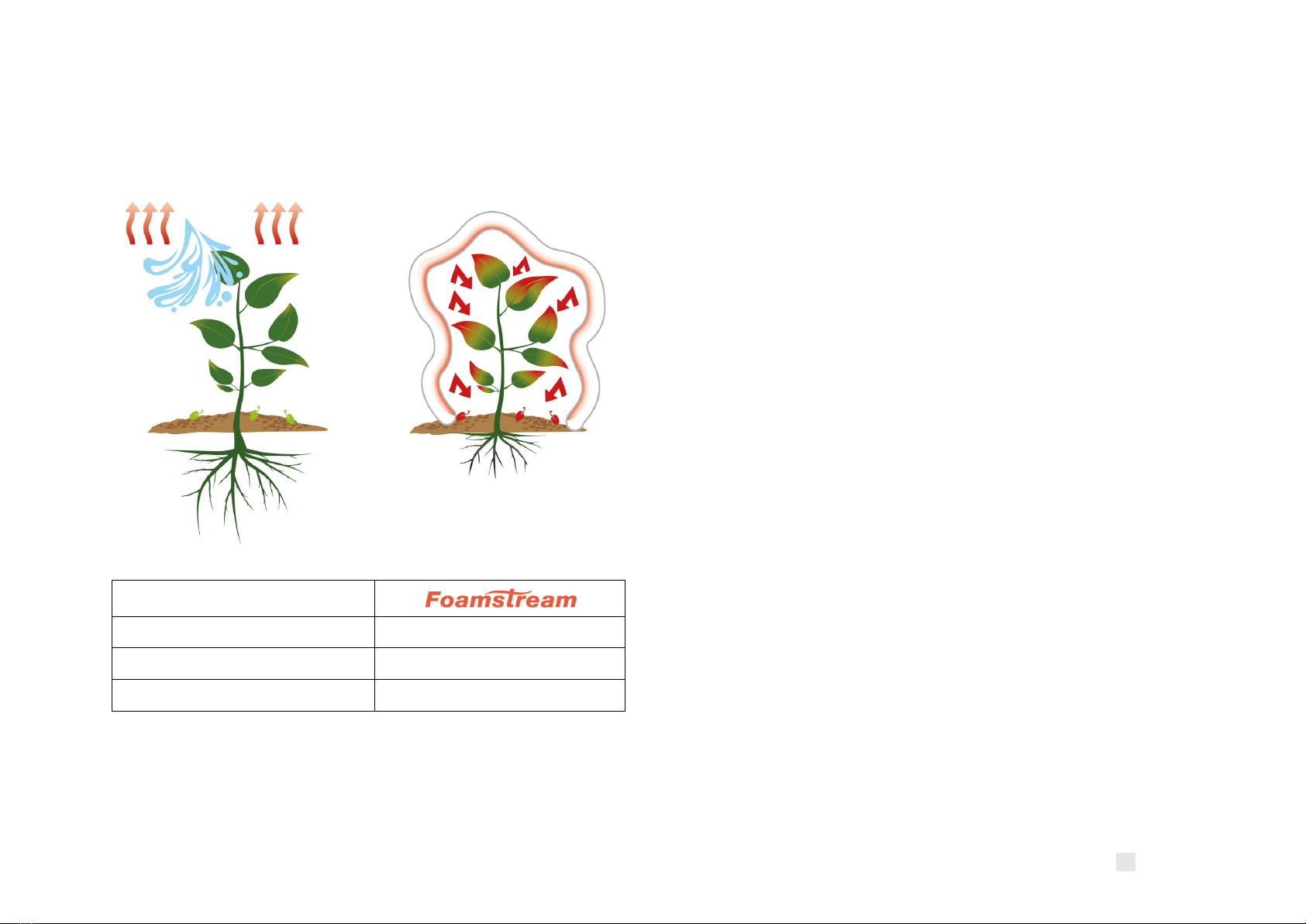

Figure 6 - Foamstream's triple action

Steam / Hot Water

Kills the leaves Kills weeds

No effects on seeds Sterilises seeds

Very weak effect on roots Damages the root

In general, annual weeds are easier to kill than biennial or

perennial ones. Weed species that originate from desert or

semi-arid regions are more heat tolerant and will need a

slightly prolonged treatment period compared to other

species.

Biennial or perennial weeds usually have parts protected

against heat (especially regenerative parts under the soil,

the Rhizome). Foamstream is a contact application, it will

kill foliage, but many perennial and biennial plants will

regenerate. The number of repeat treatments required to

completely kill weeds depends on the species and their size.

5.3 Caution – poisonous weeds

Some poisonous weeds, such as common ragweed (Senecio

jacobaea) may still be attractive to animals after treatment

with Foamstream. When treating any area where animals

are likely to graze after treatment with Foamstream, check

for the presence of such potentially toxic weeds and remove

them or keep out of reach of animals that are at risk.

5.4 The effect of the system on plants

The L12 has been designed to operate in an urban

environment and control weed growth on both hard surfaces

and cultivated land. These weeds may be in, at, or around

kerbs and channels, footpath edges, driveways, boundaries,

obstacles etc.

Within these environments there are various plant species

that need to be controlled. These species may vary in type

and growth patterns depending on the specific geographic

location.

The system, through its unique operation, delivers a plant

kill based on thermal activity penetrating and breaking down

the cell structure of the plant.

With varying plants in the target area, it is important for the

operator have some knowledge of the weed types, sizes and