Operating instructions, Piercing press, Weidmann Type MV5 Version: May 2019 Page 2

The purpose of these operating instructions

These operating instructions must be retained for the entire service life of the piercing press and must be

observed whenever any activities are undertaken in connection with the piercing press.

If you sell the piercing press on to a third party, you must hand these operating instructions over to the

purchaser concerned.

General safety information and general safety instructions

You may be exposed to the risks set out below whenever you use the piercing press, and you must therefore

take the following protective measures:

The spindle dropping down: Always be sure to apply the brake on the spindle ……………….

Parts falling off: Wear safety shoes in line with EN20345

Parts flying off: Wear safety goggles in line with EN166 and protective gloves

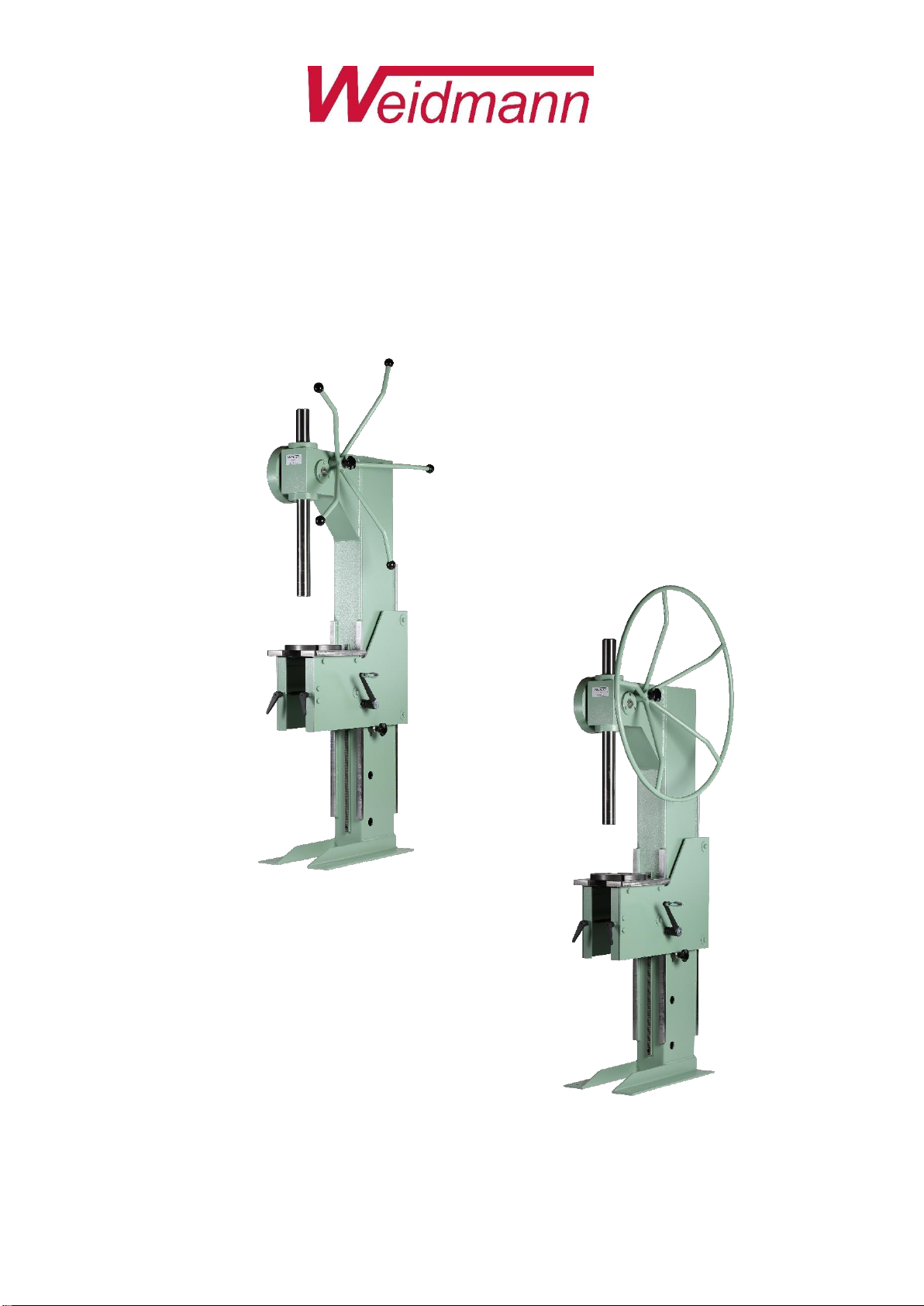

Description of the piercing press

Mechanical piercing press, manually operated, with an adjustable table.

The manufacturer rejects all liabilities for any defects that may arise as a result of any modification that may

have been made to the piercing press without the written approval of the manufacturer.

Intended use

This press is intended for use by adults within indoor spaces in trading and industrial premises.

These presses can be used for all pressing-in and pressing-out operations, at pressure forces of up to 5 tonnes.

The press is also suitable for the following tasks: broaching, straightening, pressing, bending, riveting,

embossing, stamping and assembly tasks.

The following are examples of improper use: splitting wood and the simultaneous operation of the hand wheel

by more than one person.

Only those people who have read the necessary information within the operating instructions may work with

the press,or interfere with the press or its operation.

Important information about the piercing press

The piercing press is constructed in line with the current status of technology and meets the requirements of

the Swiss Federal Law on Product Safety, as well as the Swiss Ordinance on Product Safety.

Dimension Diagram (Layout/Plan view), see Page 10

Drawing of Punch Insert, see Page 11

Illustration of All Parts /Replacement Parts, see Page 12

Datasheet for HSA Stud Anchors by Hilti, see Pages 13/14