Document Number:

Revision: 0

CONTROLLED DOCUMENT

Copyright © 2015, Weir Minerals Australia Ltd. All rights reserved

.

Page 1-4

Issue Date: 23 February 2015

3.5.2 Anchoring Pilot Lines .............................................................................................................................3-21

3.5.3 Vertical Float Extensions .......................................................................................................................3-22

3.5.4 Lever Float (Fixed) Connections............................................................................................................3-23

3.5.5 Hydrau-Flo®Applications.......................................................................................................................3-24

3.6 Hydrau-Flo®Valves Dimensions....................................................................................................................3-24

4Installation..........................................................................................................................................................4-25

4.1 Pre-Installation...............................................................................................................................................4-25

4.2 Installation Tool Kit.........................................................................................................................................4-25

4.3 Installation Procedure –To suit General Installation.....................................................................................4-26

4.4 Installation Procedure –To suit CAT D10R/D11R Dozers............................................................................4-27

4.5 Installation Procedure - To suit CAT 16H Grader..........................................................................................4-28

4.6 Additional Information on Installation.............................................................................................................4-29

4.6.1 General Arrangement ............................................................................................................................4-29

4.6.2 Multiple Filling Valves with Single Lever Float Valve.............................................................................4-30

4.6.3 Multiple Filling Valves with Single Vertical Float Valve..........................................................................4-31

4.6.4 Check Valve Arrangement.....................................................................................................................4-32

4.6.5 Lever Float Height Adjustment...............................................................................................................4-32

5Commissioning..................................................................................................................................................5-33

6Operation............................................................................................................................................................6-34

6.1 Fuel Filling......................................................................................................................................................6-34

6.2 Flow Specification..........................................................................................................................................6-34

6.3 Fuel Filling of Dual Tanks ..............................................................................................................................6-34

6.4 Multiple Filling Valves Flow Rating ................................................................................................................6-34

6.5 Suitable Mediums ..........................................................................................................................................6-35

6.6 Fuel Consumption..........................................................................................................................................6-35

6.7 Fuel Reticulation ............................................................................................................................................6-35

6.8 Float Control...................................................................................................................................................6-35

7Maintenance.......................................................................................................................................................7-36

7.1 Maintenance Instructions...............................................................................................................................7-36

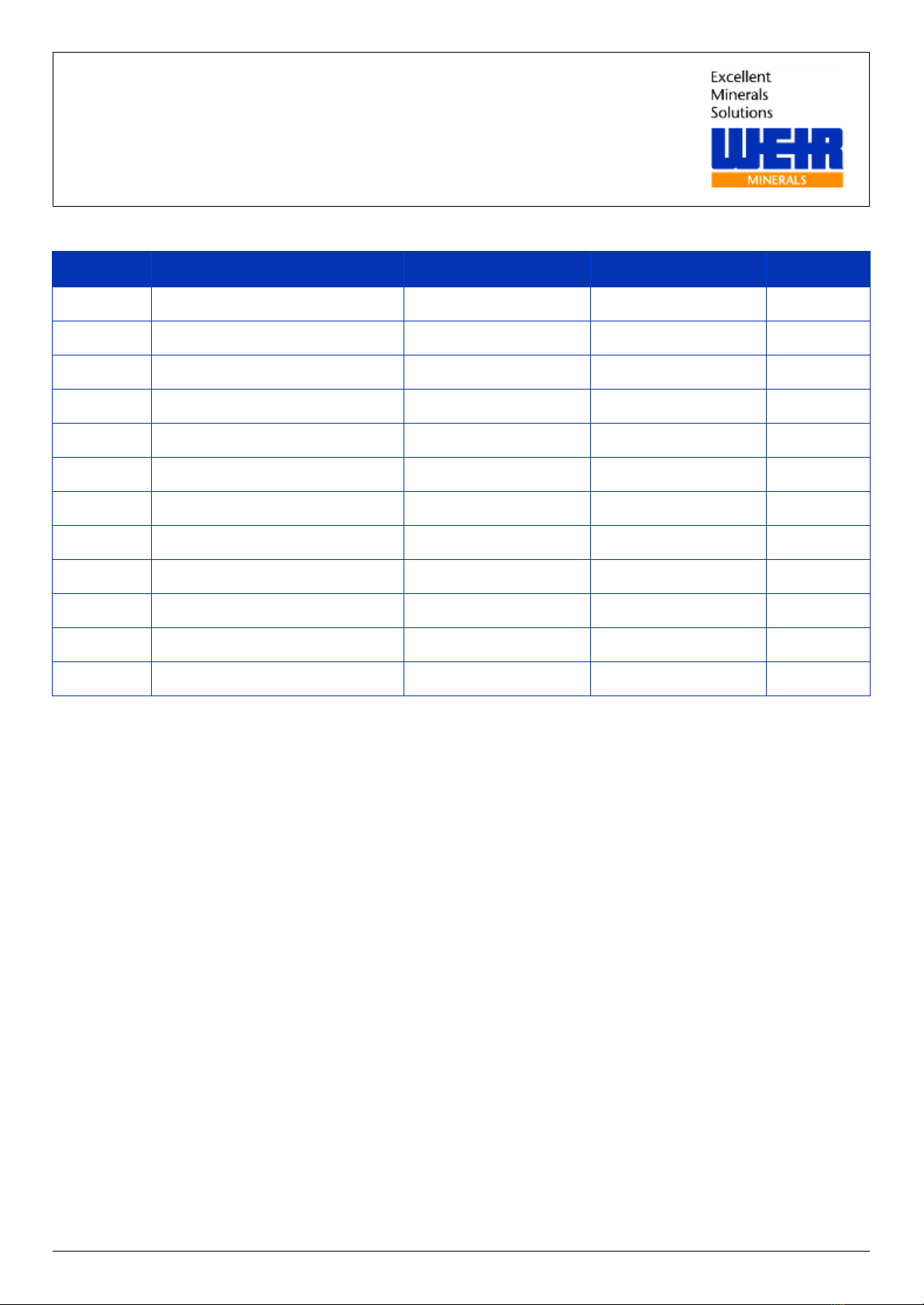

7.2 Troubleshooting Guide...................................................................................................................................7-37

8Appendices ........................................................................................................................................................8-38

8.1 Commissioning Checklist...............................................................................................................................8-38

8.2 Maintenance Checklist...................................................................................................................................8-39

8.3 Black Valve with Hydrau Flo®Receiver.........................................................................................................8-40

8.4 Red Valve in Adapter with Hydrau Flo®Receiver..........................................................................................8-41

8.5 Blue Valve with Hydrau Flo®Receiver...........................................................................................................8-42

8.6 Single Receiver and Single Vertical Float (Mobile) General Arrangement....................................................8-43

8.7 Single Receiver and Single Lever Float (Stationary) General Arrangement.................................................8-44

8.8 Lever Float Dimension Drawing.....................................................................................................................8-45

8.9 Fuel Lever Float Settings...............................................................................................................................8-46

8.10 Vertical Float Drawing....................................................................................................................................8-47

8.11 Float Control Valve Drawing (Catch Tank Option).........................................................................................8-48