1User notes................................................................................................................... 5

1.1 Target group ............................................................................................................... 5

1.2 Symbols ...................................................................................................................... 5

1.3 Warranty and Liability ................................................................................................. 6

2Safety ......................................................................................................................... 7

2.1 Proper use .................................................................................................................. 7

2.2 Security measures ......................................................................................................7

2.3 Disposal ...................................................................................................................... 7

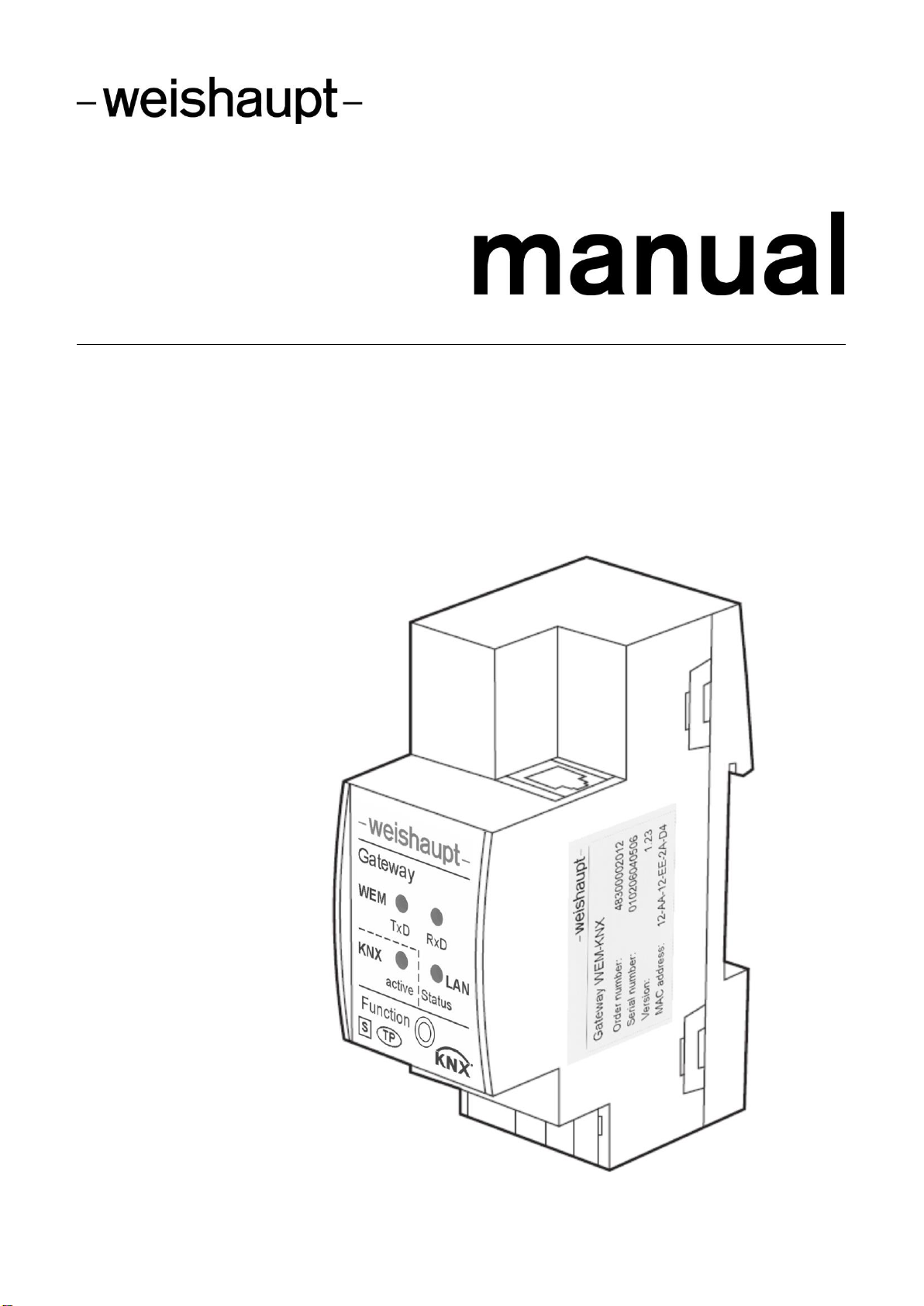

3Product description ...................................................................................................... 8

3.1 WEM Interface ............................................................................................................ 8

3.2 KNX Interface.............................................................................................................. 8

3.3 IP Interface ................................................................................................................. 8

4Technical specifications ............................................................................................... 9

4.1 Supply.........................................................................................................................9

4.2 Housing....................................................................................................................... 9

4.3 Environmental conditions............................................................................................9

4.4 Electrical safety...........................................................................................................9

5Assembly and disassembly ........................................................................................ 10

6Installation................................................................................................................. 11

7Operation .................................................................................................................. 12

7.1 Control elements....................................................................................................... 12

7.2 LED display (normal operation)................................................................................. 12

7.3 Configuring with ETS ................................................................................................ 13

7.4 ETS parameters........................................................................................................ 14

7.4.1 WEM devices...................................................................................................... 14

7.4.1.1 WEM system with numbers of WEM devices ............................................... 14

7.4.1.2 Additional information................................................................................... 14

7.4.2 Automatic WEM device search........................................................................... 15

7.4.3 General settings ................................................................................................. 16

7.4.4 Addresses WEM................................................................................................. 16

7.4.5 Parameters of the individual WEM devices (WTC, SG, etc.).............................. 17

7.4.6 Communication objects for WTC ........................................................................ 18

7.4.7 Communication objects for SG ........................................................................... 20

7.4.8 Communication objects for EM-HK..................................................................... 23

7.4.9 Communication objects for EM-WW................................................................... 25

7.4.10 Communication objects for EM-Sol .................................................................. 26

7.4.11 Communication objects for RF ......................................................................... 26

7.4.12 Communication objects for RG1....................................................................... 26

7.4.13 Communication objects for RG2....................................................................... 26

7.4.14 Communication objects for EM-KA................................................................... 26

7.5 Web frontend ............................................................................................................ 27