3 of 6

4.Always disconnectthe Die Grinderfrom its compressedair supply source,and squeeze

the trigger torelease all compressedair in thetool before performingany maintenance or

service.

5.The warnings,precautions, and instructionsdiscussed in thismanual cannot coverall

possible conditions andsituations that mayoccur.The operator mustunderstand that

common sense andcaution are factorswhich cannot bebuilt into thisproduct, but must

be supplied bythe operator.

ASSEMBLYAND OPERATING INSTRUCTIONS

TO ATTACHA QUICKCONNECTOR

WARNING!Prior to performingany assembly and/oradjustment procedures,

make sure theair supply hose(not included) isdisconnected from theDie Grinder.

1.Prior touse, the DieGrinder requires theattachment of aquick-connector into itsair

inlet. To do so,wrap approximately 3in.of pipe threadsealer tape (notincluded) around

the male threadsof a quick-connector. Then,firmly tighten thequick-connector into the

air inlet.

TO OPERATE ASA1/4IN. DIEGRINDER:

1.Always wearANSI-approved safetyglasses, a fullface shield, andhearing

protection when operatingthe tool.

2.Use thetwo wrenches providedto loosen thecollet nut.

3.Insert the1/4in. diameter shankof a grindingdrum (not included)fully into thecollet.

Then, firmly re-tightenthe collet nutto lock boththe collet andgrinding drum inplace.

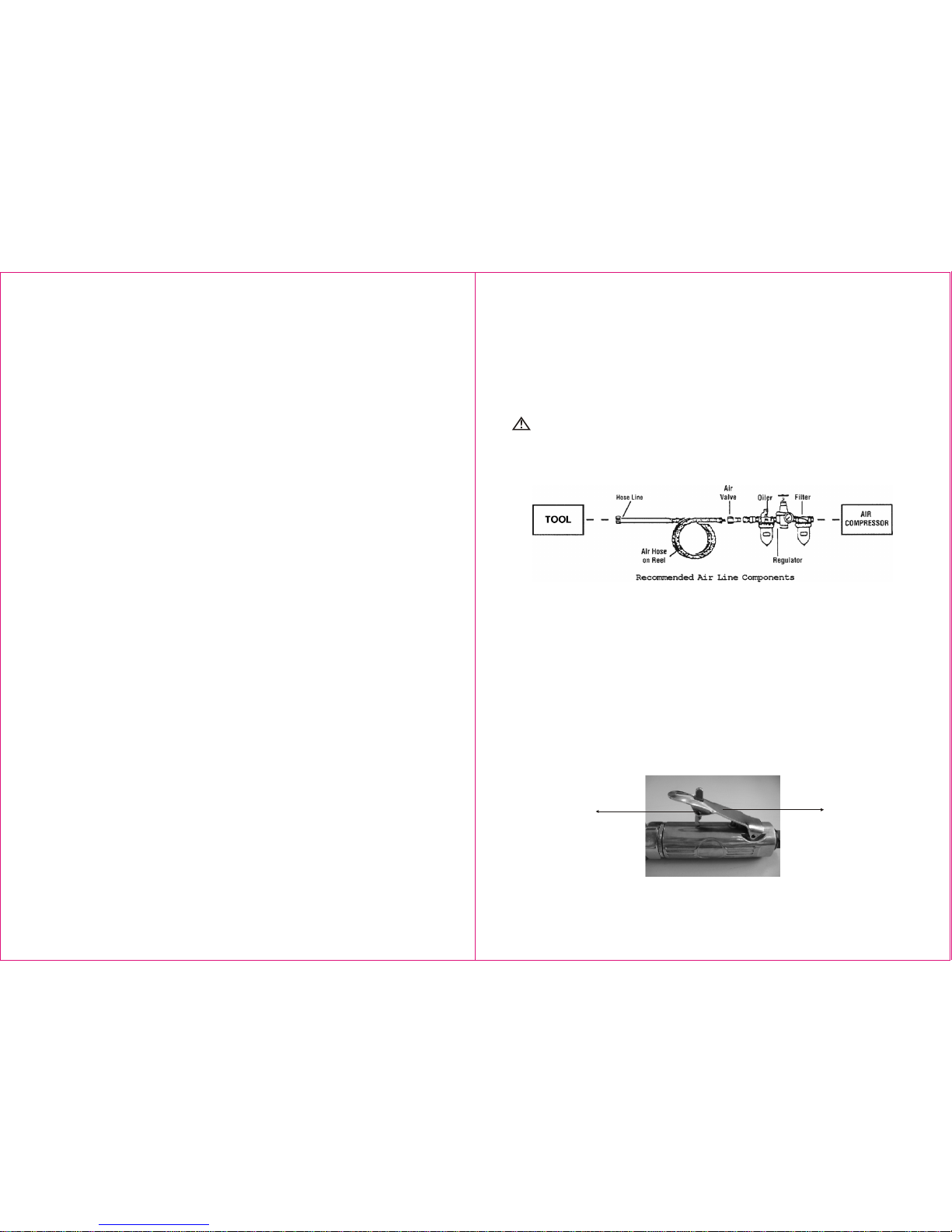

4.Connect theair supply hoseto the quick-connectoron the DieGrinder.Turn onthe air

compressor, andset its regulatorto the recommended90 PSI forthe Die Grinder.

5.IMPORTANT! Grip the appliancefirmly with BOTHhands.

6.Tripthe safety withyour finger.Then slowlyapply hand pressureto the triggeruntil the

desired speed isobtained. NOTE: The toolalways turns theGrinding Drum/Drill

Chuck clockwise. (Seefig. 2)

Fig. 1

Fig. 2

SAFETY TRIGGER

2 of 6

PERSONAL SAFETY

1.Stay alert.Watch whatyou are doing,and use commonsense when operatinga

pneumatic tool. Donot use apneumatic tool whiletired or underthe influence ofdrugs,

alcohol, or medication.Amoment of inattentionwhile operating pneumatictools may

result in seriouspersonal injury.

2.Dress properly. Do not wearloose clothing orjewelry.Keep your hair, clothing, and

gloves away frommoving parts. Looseclothes, jewelry, or longhair can becaught in

moving parts.

3.Avoidaccidental starting.Be sure thetrigger is off before connectingto the airsupply.

Carrying pneumatic toolswith your fingeron the trigger, or connectingpneumatic tools to

the air supplywith the triggeron, invites accidents.

4.Remove adjustingkeys or wrenchesbefore turning onthe tool.Awrench or akey

that is leftattached to arotating part ofthe tool mayresult in personalinjury.

5.Do notoverreach. Keep proper footingand balance atall times. Properfooting and

balance enables bettercontrol of thetool in unexpectedsituations.

6.Use safetyequipment. Always wearANSI-approved safetyglasses underneath afull

face shield, andhearing protection.

USE ANDCARE

1.Use clampsor other practicalways to secureand support theworkpiece to astable

platform. Holding thework by handis unstable andmay lead toloss of control.Only work

on a workpiecethat is properlysecured.

2.Do notforce the tool.Use the correcttool for yourapplication. Thecorrect tool willdo

the job betterand safer atthe rate forwhich it isdesigned.

3.Do notuse the powertool if thetrigger does notturn it onor off.Any toolthat cannot be

controlled with thetrigger is dangerousand must bereplaced.

4.Disconnect theair hose fromthe tool beforemaking any adjustments,changing

accessories, or storingthe tool. Suchpreventive safety measuresreduce the riskof

starting the toolaccidentally.

5.Store idletools out ofreach of childrenand other untrainedpersons. Tools are

dangerous in thehands of untrainedusers.

6.Maintain toolswith care. Donot use adamaged tool.Tagdamaged tools "Donot use"

until repaired.

7.Check formisalignment or bindingof moving parts,breakages of parts,damaged air

hose (not included),and any othercondition that mayaffect thetool's operation. If

damaged, have thetool serviced beforeusing. Many accidentsare caused bypoorly

maintained tools.

8.Use onlyaccessories that arerecommended by themanufacturer for yourmodel.

Accessories that maybe suitable forone tool maybecome hazardous whenused on

another tool.

SERVICE

1.Tool service mustbe performed onlyby qualified repairpersonnel. Service or

maintenance performed byunqualified personnel couldresult in arisk of injury.

2.When servicinga tool, useonly identical replacementparts. Follow instructionsin the

"Inspection, Maintenance andCleaning" section ofthis manual. Useof unauthorized

parts or failureto follow maintenanceinstructions may createa risk ofinjury.

SPECIFIC SAFETYRULES

1.To avoid accidentalinjury,always wearANSI-approved safety glasses,a full faceshield,

and hearing protectionwhen operating theDie Grinder.

2.Use clean,dry,regulated compressed airat 90 PSI.Do not exceedthe recommended

90 PSI. Neveruse oxygen, carbondioxide, combustible gases,or any otherbottled gas

as a powersource for thistool.

3.When connectingto the airsupply: Prior toeach use, ifan automatic oileris not used,

add two dropsof air tooloil (not included)into the airinlet fitting ofthe Die Grinder.