Contents

Operation Manual LVSF600T-ATEX 3

Contents

1Important Information.......................................................................................5

1.1 Note for the user / personnel..........................................................................................................5

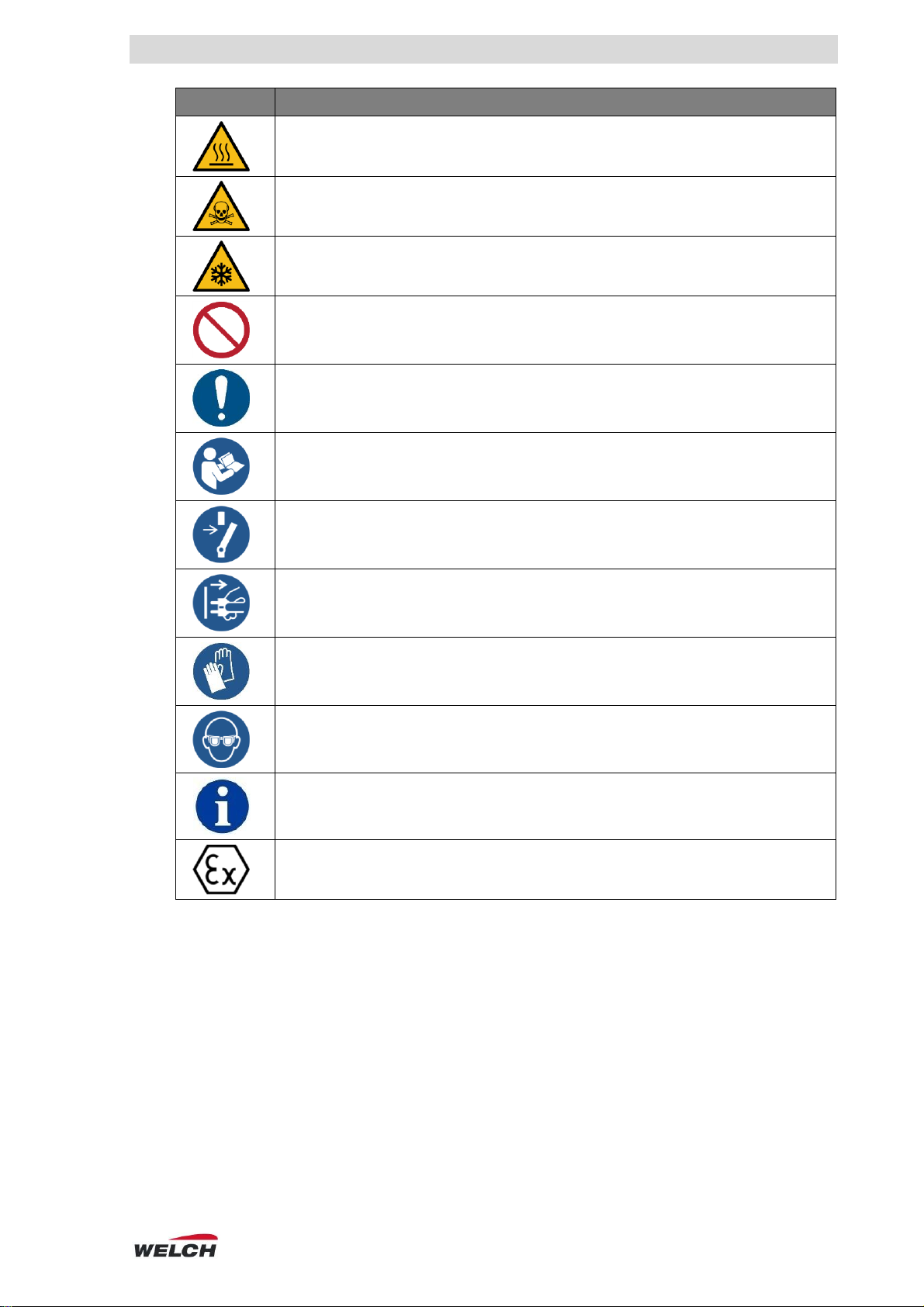

1.2 Depiction of safety and warning notices ........................................................................................6

1.3 Explanations of symbols ................................................................................................................6

1.4 Legend for the abbreviations .........................................................................................................8

2Safety.................................................................................................................9

2.1 General...........................................................................................................................................9

2.1.1 Proper use..................................................................................................................................... 9

2.1.2 Improper use................................................................................................................................. 9

2.1.3 Foreseeable misuse.................................................................................................................... 10

2.2 Target groups...............................................................................................................................10

2.2.1 Personnel qualification................................................................................................................ 10

2.2.2 Overview of the responsibilities .................................................................................................. 11

2.3 Protective measures ....................................................................................................................11

2.3.1 General protective measures...................................................................................................... 11

2.3.2 Reliable operation ....................................................................................................................... 12

2.4 Special hazards............................................................................................................................12

2.4.1 Hazardous materials................................................................................................................... 13

2.4.2 Electricity..................................................................................................................................... 13

2.4.3 Mechanics................................................................................................................................... 14

2.4.4 Temperatures.............................................................................................................................. 14

2.4.5 Vacuum....................................................................................................................................... 15

2.5 ATEX application..........................................................................................................................15

2.5.1 ATEX classification ..................................................................................................................... 16

2.5.2 Special conditions ....................................................................................................................... 16

3Technical data.................................................................................................18

3.1 Dimensions...................................................................................................................................18

3.2 Characteristic values....................................................................................................................18

3.2.1 Pumping speed ........................................................................................................................... 18

3.2.2 Parameter.................................................................................................................................... 19

3.3 General information on connections ............................................................................................19

3.4 Parts in contact with medium.......................................................................................................20

4Description......................................................................................................21

4.1 Field of application .......................................................................................................................21

4.1.1 General description..................................................................................................................... 21

4.1.2Specific description ..................................................................................................................... 21

4.2 Set-up...........................................................................................................................................22

4.2.1 Front of device ............................................................................................................................ 22

4.2.2 Back of device............................................................................................................................. 23

4.2.3 Drive chamber flushing ............................................................................................................... 24

4.2.4 Gas ballast .................................................................................................................................. 24

4.2.5 Equipotential bonding.................................................................................................................. 24

4.2.6 Material........................................................................................................................................ 24

4.2.7 Motor temperature protection...................................................................................................... 25

4.3 Attachments .................................................................................................................................25