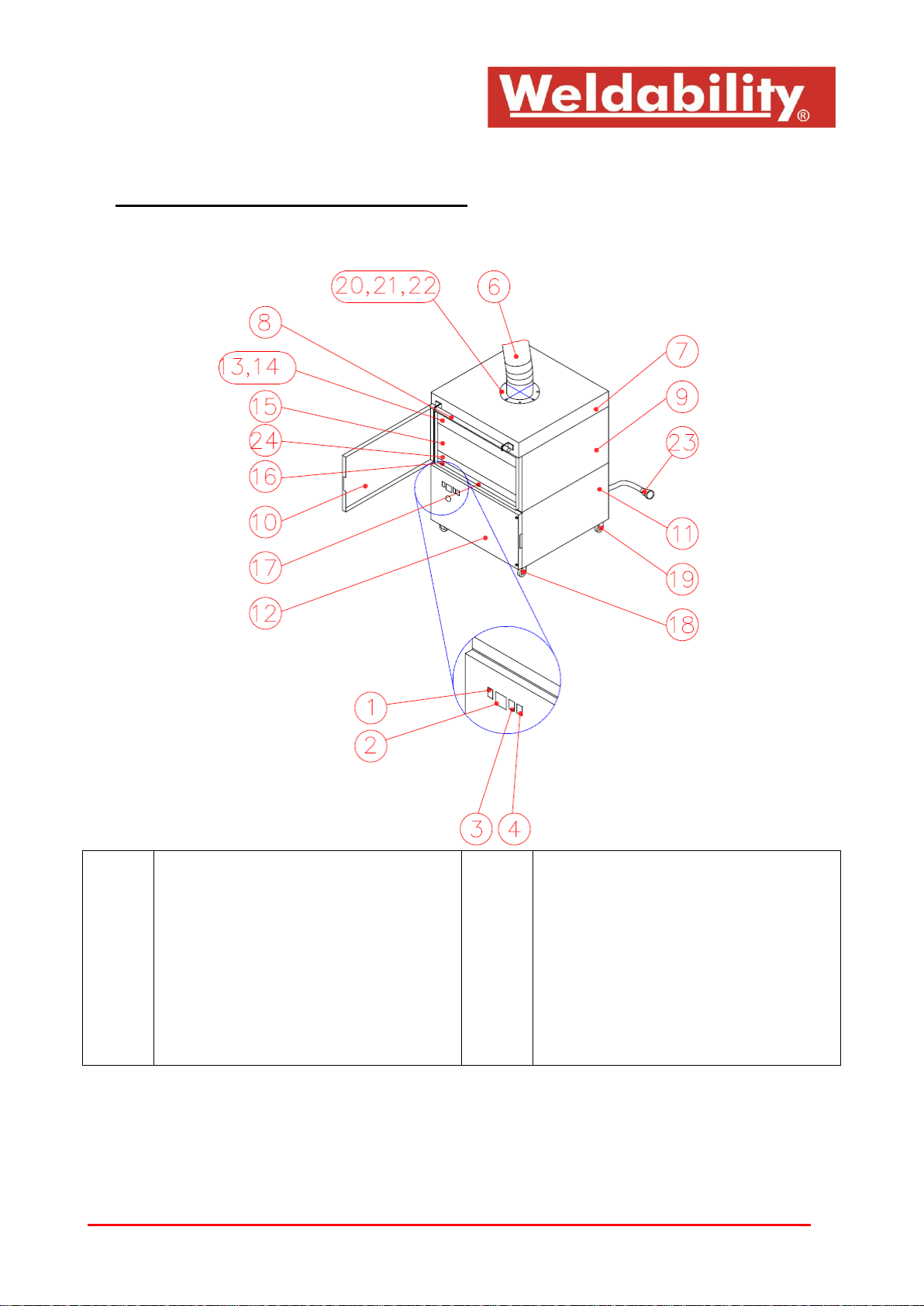

ProtectoSmart - 9 -

7 Maintenance

The accumulation of extracted particles on the filter cartridge will eventually lead to a reduction of the

suction / extraction performance.

The mechanical filter element ensures that more than 99% of the extracted pollutants are retained in the

filter. This also applies to a partially or fully saturated filter. However, the extraction performance of the

filter unit will decrease as the filter elements becomes saturated more and more.

The pre-filter (Pos.14) must be changed at regular intervals. (Refer to chapter 7.1 ‘Changing of pre-filter

element’)

When the internal resistance of the filter element has increased due to the accumulation of the

separated dust particles and the extraction performance of the filter unit decreases as a whole, the

particle filter (Pos. 15) must be changed. (Refer to chapter 7.2 ‘Changing of particle filter element’)

As soon as odours appear the activated-carbon cassette (Pos.24) has to be changed.

Caution :

When changing the filter cartridge, the operation of the filter unit must be interrupted.

Exchange of the filter cartridge and the disposal of the element may be executed only in amply

ventilated environments and when using an appropriate protective respiratory mask.

We recommend to use a respiratory mask to DIN EN 141/143 - Protection class P3.

The job of changing the filter elements should be executed by trained personnel only. Filter disposal

according to pertinent directives on special waste handling.

Manually beating the filter element, washing or air jet blasting will destroy the filter media. As a result

the pollutants will be blown into the room.

7.1 Changing of pre-filter

The pre-filter mat (Pos.14) must be changed after a certain number of operating hours. The time

depends on the amount of accumulated dust. At the latest, the filter mat must be changed when

changing the particle filter.

The procedure is a follows:

•Disconnect the filter unit from the mains power supply.

•Open the air filter access door (Pos.10).

•Lower the lifting mechanism (Pos.16) by turning the lock screw (Pos.17) downward..

•Pull out the pre-filter tray (Pos.13).

•Take out the pre-filter mat (Pos.14).

•Install the new pre-filter mat.

Caution :

Only use original Weldability pre-filter elements.

•Insert the pre-filter tray (Pos.13).

Raise the lifting mechanism (Pos.16) by turning the locking screw (Pos.17) until the pre-filter

tray (Pos.13) sits tight. (At this time check the sealing gasket under the lid (Pos.7) for possible

damage.

•Close the filter access door (Pos.10).

•Connect the filter unit to the mains circuit.