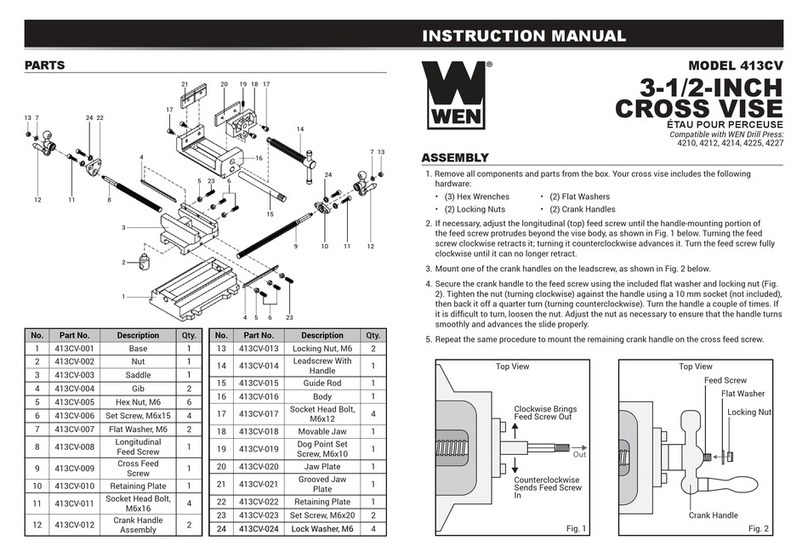

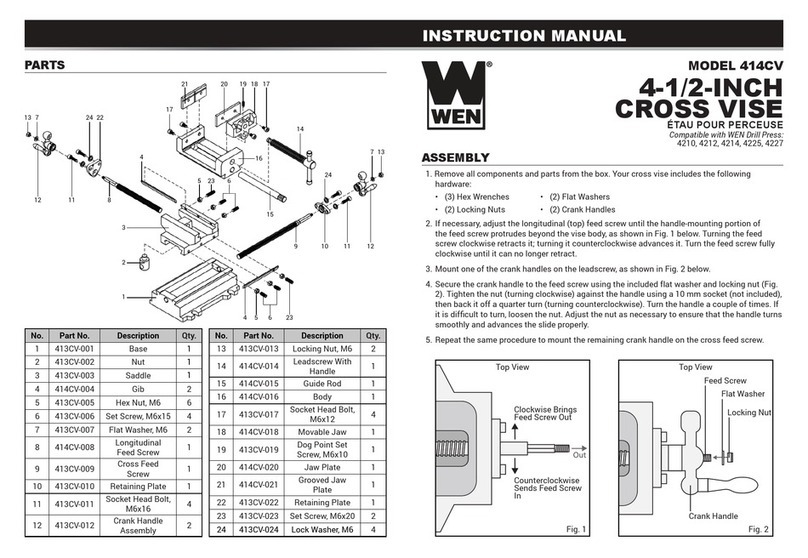

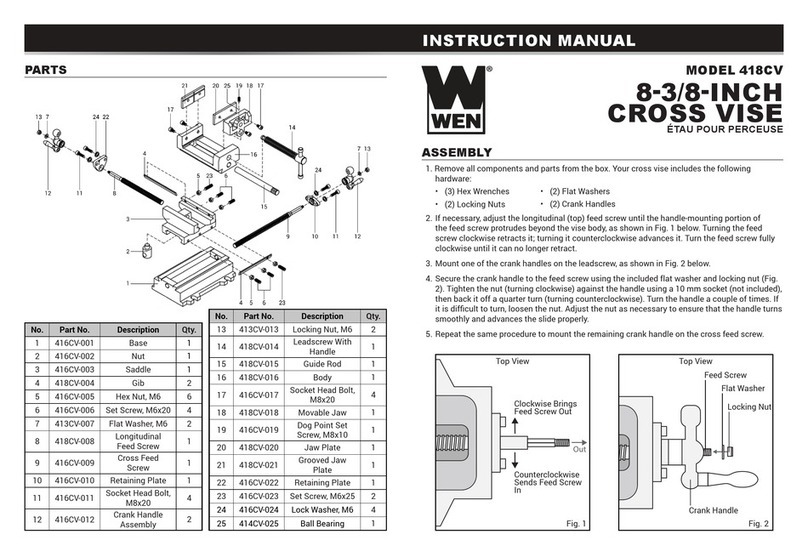

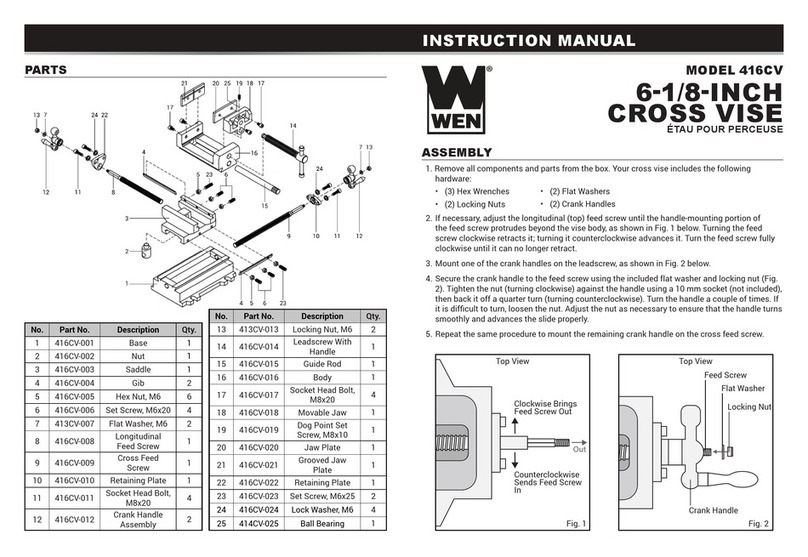

INSTRUCTION MANUAL

ADJUSTMENT GUIDE

Your vise comes pre-adjusted from the factory, and should not require adjustment. However, if

the cross or longitudinal slides (Parts 1 & 16) are too tight or too loose, follow the steps below to

adjust them.

1. Locate the three gib screws on the side of the slide in question (Fig. 3).

2. Loosen the three hex nuts (Part 5), using a 10 mm wrench or socket (not included).

(Fig. 4 - Step 2)

MAINTENANCE

Acetone may irritate the skin. Wear gloves and eye protection when using acetone.

• Your vise comes with a layer of anti-rust protective coating on the machined surfaces. Remove

this coating with a clean cloth moistened with acetone, then protect the machined surfaces by

applying a light coat of good-quality paste wax.

• After using your vise, wipe it off with a cloth to ensure that no chips, shavings, or other debris

get into the way of your vise. Keep your vise clean. Periodically check the ways of the vise to

ensure that they are not blocked or damaged by chips, shavings, or other debris.

Gib Screws

3. IF THE SLIDE IS TOO TIGHT

• Loosen the set screws (Parts 6 & 23) using

the included hex wrench (Fig. 4 - 3A).

IF THE SLIDE IS TOO LOOSE

• Tighten the set screws (Parts 6 & 23) using

the included hex wrench (Fig. 4 - 3B).

4. Using the 10 mm wrench or socket, tighten the hex nuts (Part 5) back down. Make further

adjustments as needed.

Step 2 Step 3

B

A

Step 4

Fig. 3 Fig. 4

Side View

NOTE: To prevent the bolt from

loosening over time, use split

locking washers between at

washers, or use nylon locking

nuts.

MOUNTING INSTRUCTIONS

OPERATION

Follow the instructions below to safely and securely mount your

cross vise to a stable workbench. Mounting your vise eliminates

the risk of your vise moving or falling, allowing for more accuracy

and user safety.

1. Select a secure worktop to which your vise will be mounted,

such as a workbench. The workbench should be sturdy and

xed to the oor.

2. Find the best location on your worktop to mount your vise.

It is good to select a spot that allows access to both crank

handles, as well as the vise clamping handle (Part 14).

3. Once you have selected where you want to mount your vise,

use a pencil to mark the holes where the vise will be bolted

(four mounting anges are located on the base). You must

use at least two bolts that are diagonal from each other. Use

four bolts for optimum stability.

4. Move the vise to the side and use a drill to drill out the

marked spots for the bolts.

5. Line up the vise with the drilled holes. Insert bolts and

fasten. If the bolts extend through the bench, place a

washer and nut onto the end. Tighten nuts onto the bolts

using a wrench. (These bolts, washers and nuts are not

included).

Before operation, mount your vise and follow the assembly instructions on page 1 to attach the

handles.

1. Mark your workpiece for your specic job.

2. Rotate the leadscrew with handle counterclockwise to open the jaws. Place workpiece inside

of jaws in desired position. Rotate the handle clockwise to tighten the jaws and rmly secure

your workpiece.

3. To move the secured workpiece back and forth or side to side, rotate the lower and upper

handles.

SPECIFICATIONS

Jaw Capacity

5-1/8 in.

Cross Slide Travel 6.5 in.

Longitudinal Slide Travel 5 in.

Clamping Strength 2500 LBF

Dimensions 14-1/2 in. x 14-1/8 in. x 6-3/4 in.

Weight

39.4 lbs

0.58"

5.15"

7.25"

10.5"

5.93"