2

Table of Contents

1. General......................................................................................................................................3

1.1 Information Concerning these Instructions .............................................................................................3

1.2 Explanation of Symbols ..........................................................................................................................3

1.3 Limitation of Liability ...............................................................................................................................4

1.4 Copyrights...............................................................................................................................................4

2. For Your Safety ........................................................................................................................5

2.1 Use for Intended Purpose.......................................................................................................................5

2.2 Use for Other than the Intended Purpose...............................................................................................5

2.3 Personnel Qualifications .........................................................................................................................6

2.4 Modification of Products ........................................................................................................................6

2.5 General Safety Precautions....................................................................................................................6

2.6 Approvals and Protection Class.............................................................................................................6

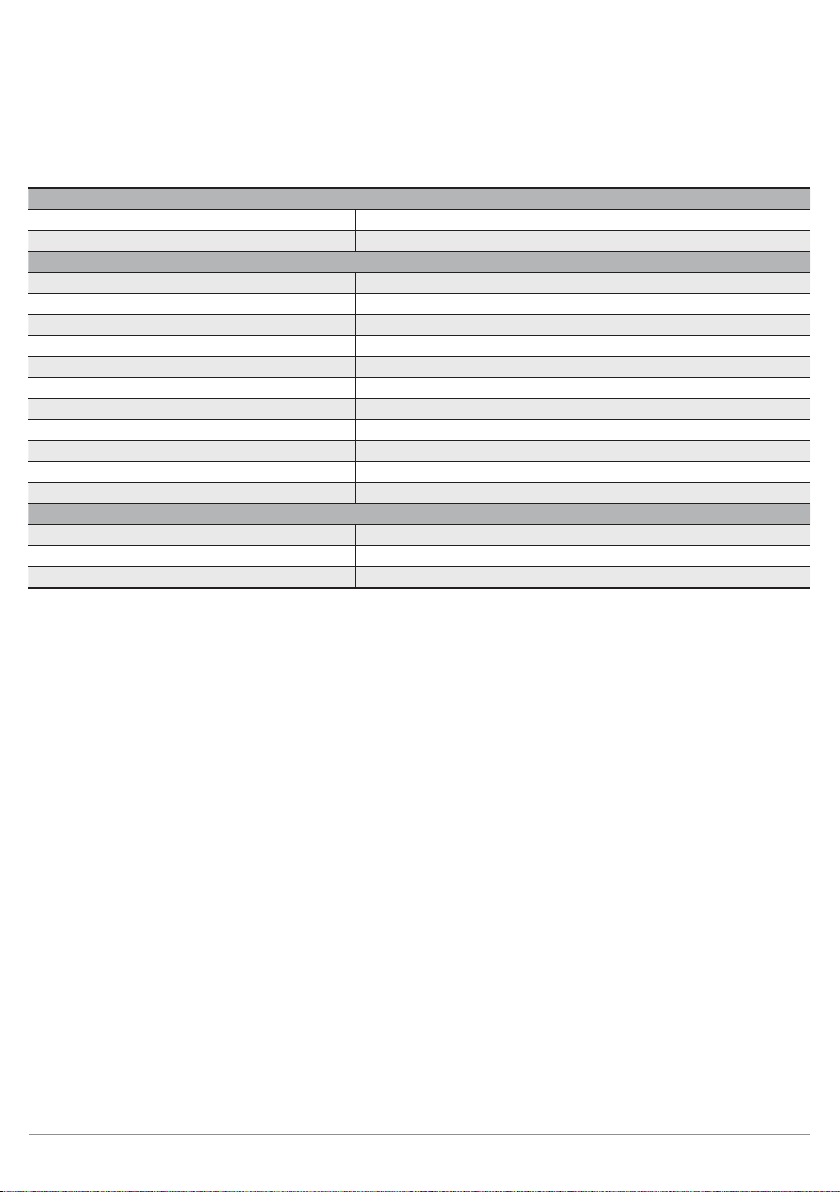

3. Technical Data.......................................................................................................................... 7

3.1 Technical Data........................................................................................................................................7

3.1.1 Light spot diameter.......................................................................................................................8

3.2 Complementary Products .......................................................................................................................9

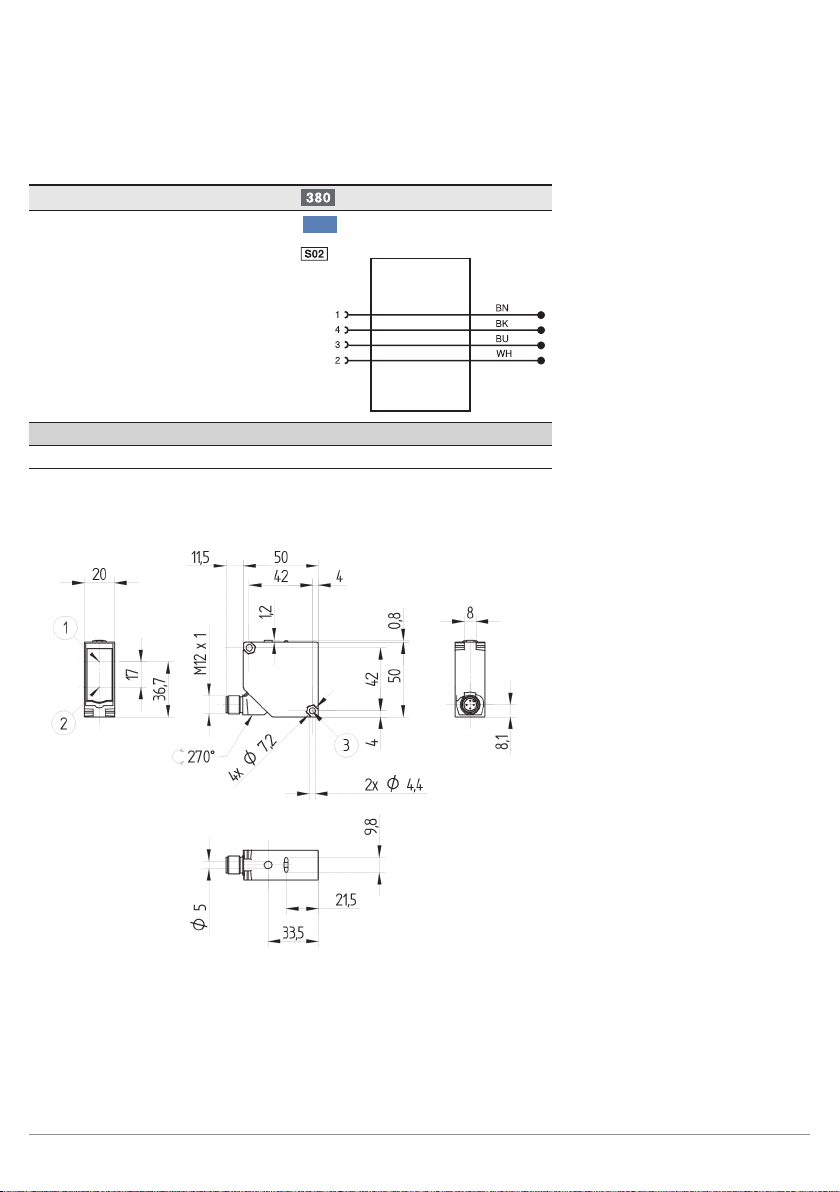

3.3 Layout .....................................................................................................................................................9

3.4 Control Panel ........................................................................................................................................10

3.5 Scope of Delivery..................................................................................................................................10

4. Transport and Storage...........................................................................................................10

4.1 Transport ..............................................................................................................................................10

4.2 Storage .................................................................................................................................................10

5. Installation and Electrical Connection.................................................................................11

5.1 Installation.............................................................................................................................................11

5.2 Electrical Connection ............................................................................................................................13

5.3 Diagnosis ..............................................................................................................................................14

6. Settings...................................................................................................................................15

6.1 Teach-in on a static background (default P1PM101/P1PM102)...........................................................15

6.2 Teach-in on a moving background (default P1PM103/P1PM104) .......................................................16

7. Functions Overview...............................................................................................................17

7.1 Teach-In Mode......................................................................................................................................17

7.2 Pin E/A2 Function .................................................................................................................................19

7.2.1 External Teach-in Input ..............................................................................................................19

7.2.2 Error Output ...............................................................................................................................19

7.3 Additional Functions and Settings ........................................................................................................20

8. IO-Link.....................................................................................................................................20

9. Maintenance Instructions......................................................................................................20

10. Proper Disposal......................................................................................................................20

11. Appendix.................................................................................................................................21

11.1 List of Abbreviations ...........................................................................................................................21

11.2 Change Index for the Operating Instructions ......................................................................................21

11.3 Declarations of Conformity .................................................................................................................21

Table of Contents