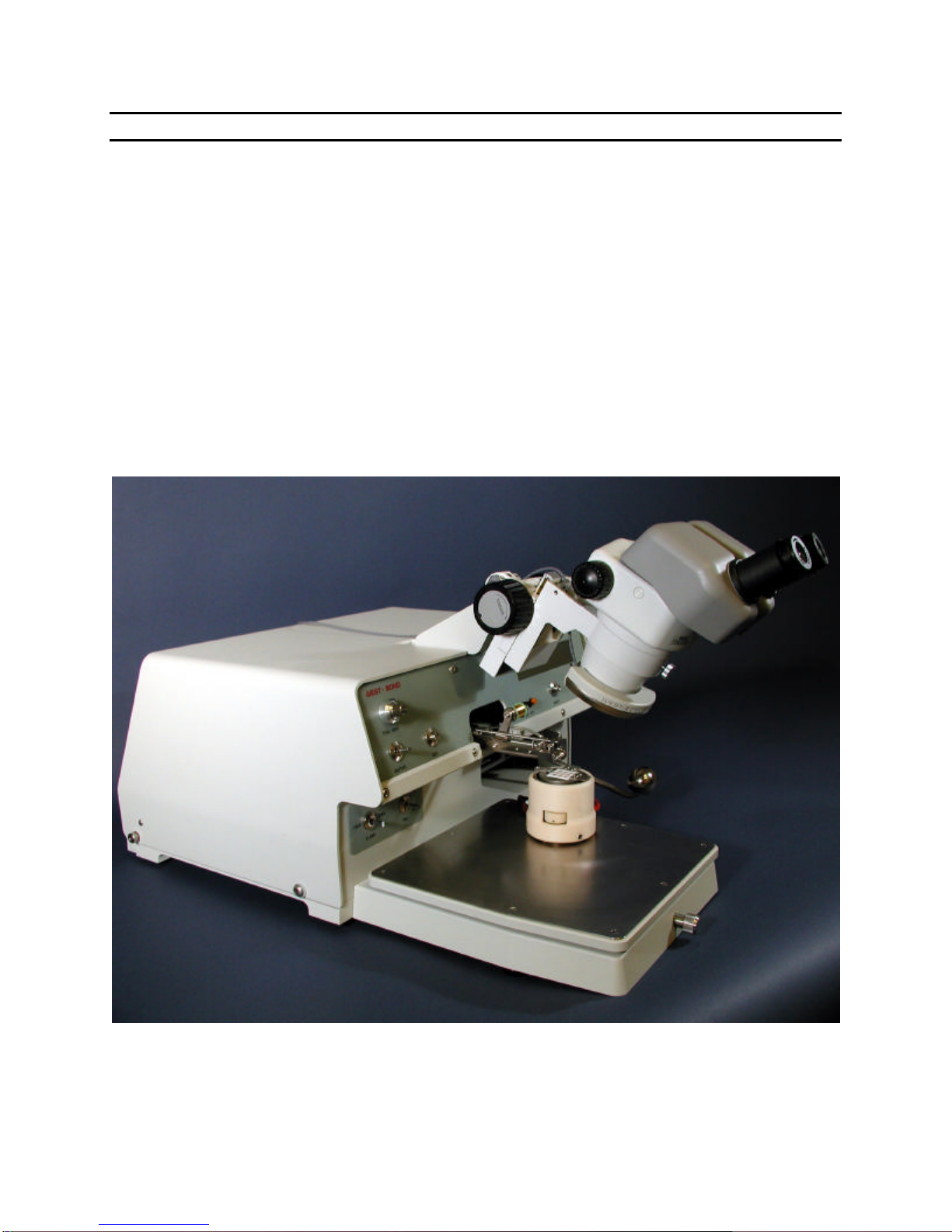

WEST•BOND MODEL 7476D SERIES INSTRUCTION MANUAL

Page 7

CAUTIONS

Contained in this section are continuous to be observed during 7476D / 7600C Installation and Operation.

Wiring

All machine wiring has common ground connected to machine chassis and continuous through the power

supply, cord and cord plug. Make sure the receptacle for this plug has a good ground connection.

Safety and Comfort

Some ergonomic studies suggest that long periods of repetitive motion may be traced to certain types of

physical discomfort leading to possible injury. We have compiled specific instructions herewith to minimize

your chances of experiencing carpal tunnel syndrome (CTS), tendonitis, and tenosynovitis.

It is recommended that your work environment be comfortable for your work situation. A carefully planned

work environment can actually increase productivity. WEST?BOND recommends that you adopt the

following steps for a healthy physical and mental approach to your work.

Exercises

Many motor oil-manufacturing companies that your car engine is most subject to wear and tear when you

first start up in the morning often claim it. This is due to the lack of oil on the metal bearing surfaces to

offer protection when the car is first started. To a great extent, the same can be said for the tendons and

bones and joints they form in your body. In the early morning hours, your body tends to retain fluid from its

over night rest, and the first time these tendons and joints are put to usage, there is often a feeling of

stiffness and tightness, and when utilized in an abrupt fashion, can often lead to inflammation and at times

injury.

Therefore, it is considered appropriate if not mandatory for most people engaged in physical activities

such as sports or heavy labor such as construction, to perform a variety of warm-up exercises before

beginning their job. We have found the same philosophies and many of these same exercises just as

beneficial for those individuals who are placed in a seated position for long periods of time where they

utilize primarily their upper extremities, and most importantly, their hands and wrists.

We are therefore, suggesting the following gentle warm-up program to be done by you before leaving for

work. Begin by gently tilting your head both to the right and left side, to the point of comfortable tension.

Next, tilt your head forward and backward, and lastly, turn your head both to the left and to the right. Each

of these positions is taken to the end of their natural range of motion and held for a brief period of time. Do

not take any of these movements beyond the point of comfort.

Next, for the shoulders, perform a series of simple, slow, shoulder circles in both a forward and backward

direction. Five to ten repetitions in each direction should be enough to warm up the shoulder musculature.

Next, while standing, lift your arms laterally out to the side, away from your body and over your head.

Repeat this motion five times. For added benefit, make large, wrist circles with your hands while your arms

are overhead.

Lastly, and possibly most importantly, it is important that you carefully flex and extend your wrist prior to

beginning your workday. Using the opposite hand to bend the wrist downward does this. This is best done

with the arm in a forward position with the elbow straight. To assist in wrist extension, lift your wrist up,

using the palm of the opposite hand, pressing against the fingers to assist in lifting the wrist. These

stretches are done only to the point of comfortable tension and are repeated with both hands.

These basic exercises will get you off to a good start in the morning and allow your drive to work to be

more comfortable and less likely to increase the tension and tightness in your upper back, shoulders and

hands.