5

Po w e r T r a n s m i s s i o n

ROTOMEC USe and Maintenance handbook

0.4 MANUAL LAYOUT AND SYMBOLS

Part 0 - reference docUMentS

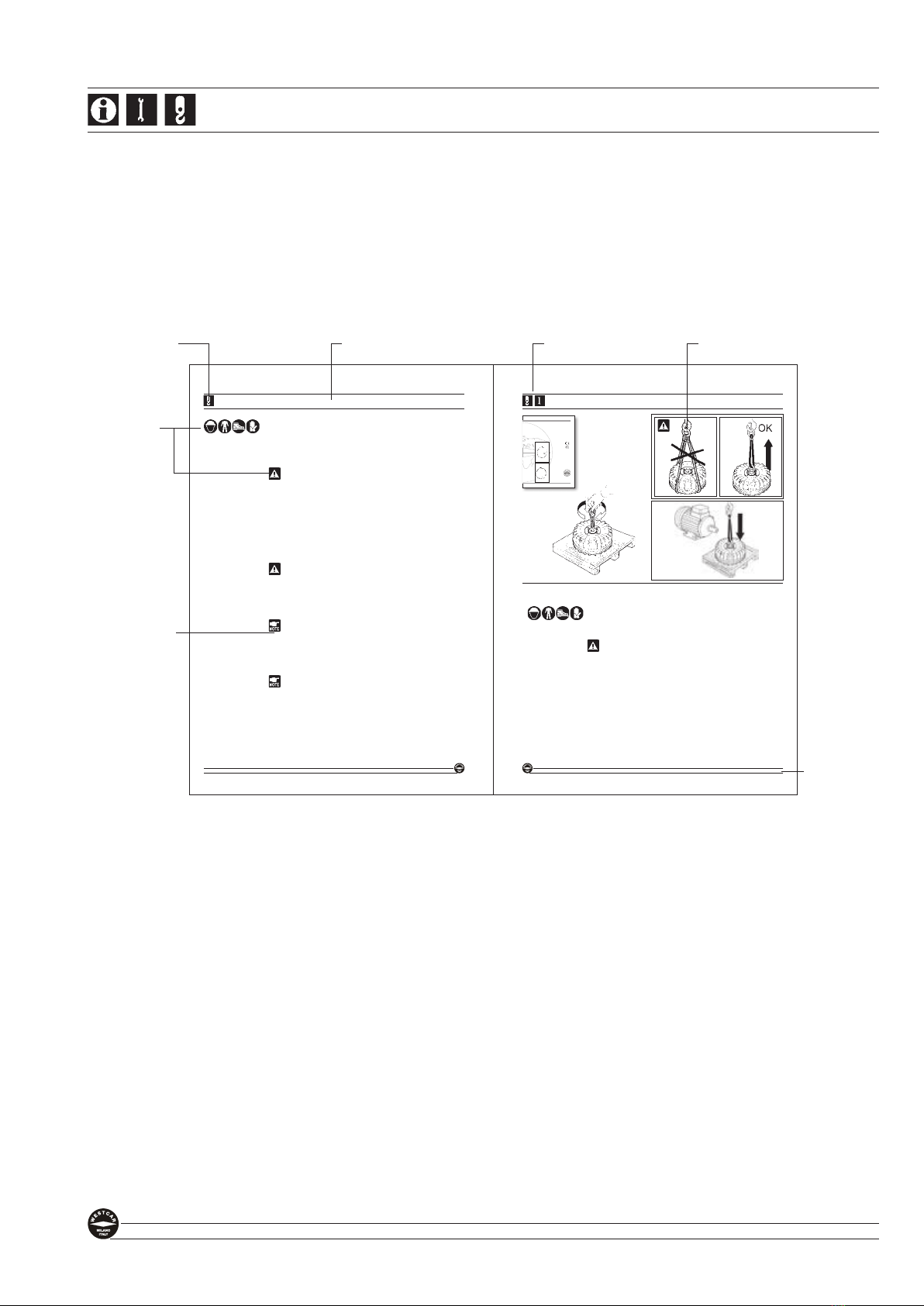

This handbook has been subdivided into topics in order to classify information and operators’ activity.

This handbook is composed of several PARTS (chapters) and sections dealing with operational topics to

enable correct installation, use and maintenance of the ROTOMEC hydromechanic couplings.

Pages have the following layout and contents:

This document is the property of WESTCAR srl. All copyrights reserved.

This handbook is an integral part to this partly completed machine and it has to be considered as a SAFETY

DEVICE; it provides both the purchaser and the personnel (operators and qualied technicians) with the

necessary installation, use and maintenance instructions in order to keep the product safe and in good working

order for its whole life-cycle.

We recommend to read and to fully understand the content of this manual.

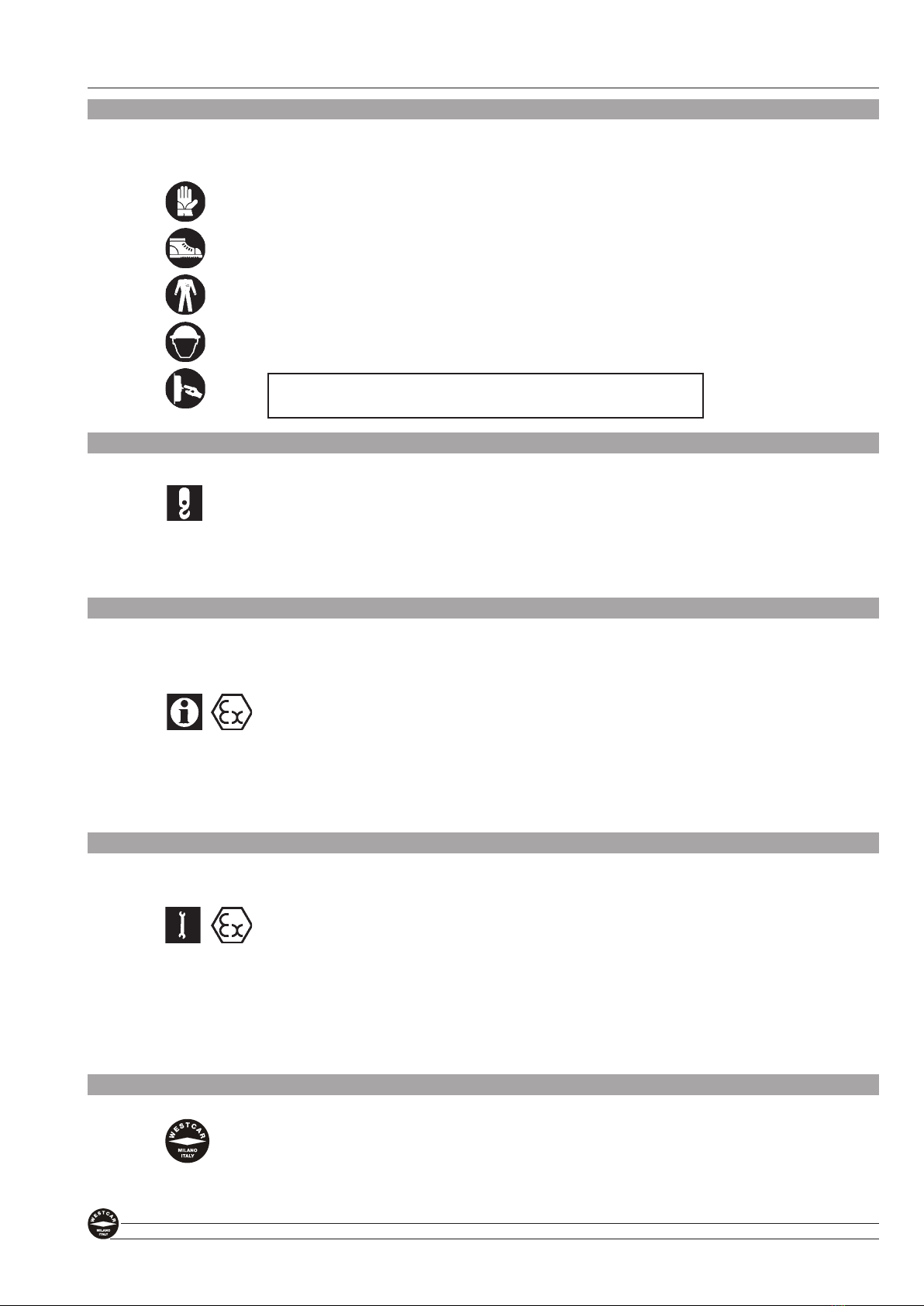

Topics are dealt with in chapters and sections, so that each stage is clearly illustrated in a numbered step-

by-step sequence. At the beginning of each section a bar shows the symbols associated with the personnel

qualied for the task.

Any operation-related residual risk is highlighted through suitable symbols in the text. In the handbook some

symbols are used to highlight and differentiate particular instructions or recommendations, which are of crucial

importance for safe operation and/or correct use and maintenance.

These measures allow WESTCAR to draw operators’ and qualied technicians’ attention to the CAUTIONS,

WARNINGS OR NOTES concerning them.

For any further clarication on the content of this handbook, do not hesitate to contact your WESTCAR

Customer Support Service.

fax (+39) 02 76110041 web site: www.westcar.it

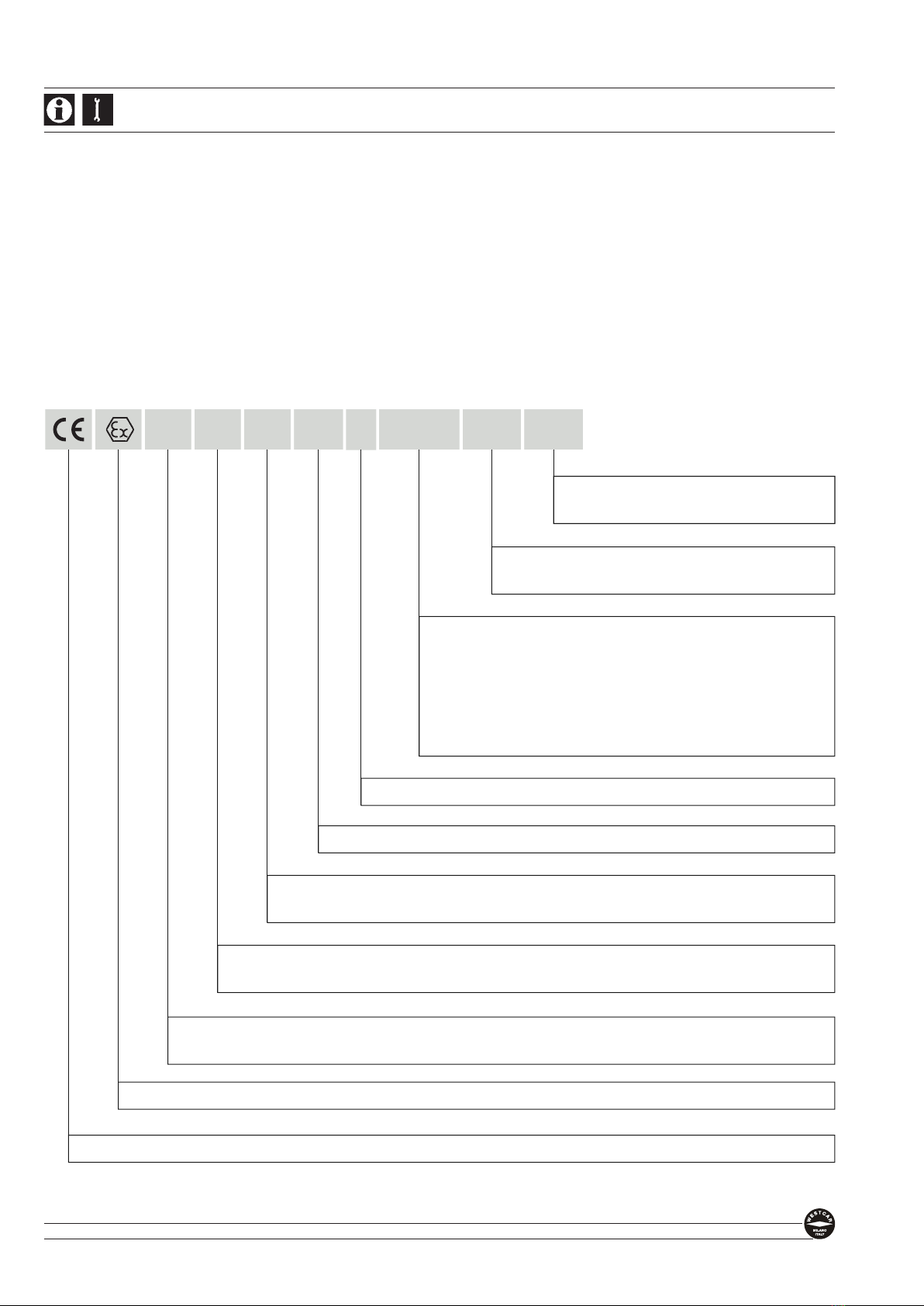

GRAPHIC DESIGN AND

OPERATION SEQUENCES

PRECAUTIONS,

WARNINGS OR

NOTES

for safety and

operation

SYMBOLS

-

hazard

- prohibition

- obligation

PAGE

NUMBERS

HEADING OF

CHAPTER

OR PART

AUTHORIZED

PERSONNEL

HEADING OF

SECTION OR

TOPIC

24

P

ow e r

T

ra n s m i s s i o n

3.1 TRANSPORT OF COUPLING WITH PACKAGE

The handling and transport operations are reserved to the handling

technicians equipped with suitable personal protective equipment

(protection gloves, safety shoes). DANGER OF CRUSHING, CRASHING

AND/OR INJECTION

3.1.1

Upon reception of the supply, check the weight reported on the label.

CAUTION

DANGER OF TILTING AND CRUSHING:

The load within the packaging could be unbalanced; therefore abide by

the procedures set out. Do not roll or damage the packaging. RISK OF

OVERTURNING.

3.1.2

Spread the forks of the fork-lift truck (with capacity suitable for the weight to be

trasported) as much as possible. Lift the coupling with its packaging slowly and

transport it (keeping it as much close to the soil as possible, about 30 cm) and

put it under a shelter in a dry place; then get the fork-lift out of the way.

3.1.3

Open the upper part and remove the packaging.

CAUTION

DANGER OF ENVIRONMENTAL POLLUTION:

Do not dump packaging material in the environment, but keep it for any future

re-use or shipping to the manufacturer or dispose of it properly as industrial waste.

3.1.4

Remove any stiffening rib, plastic lm for internal protection and brackets that x

the hydromechanic coupling to the pallet.

NOTE

Should the product be sent to the factory for repair works or maintenance,

the hydromechanic coupling will have to be shipped in a new package.

The shipping procedure shall be previously agreed upon with WESTCAR.

3.1.5

Take the Original Instruction Handbook and check that the product is not dam-

aged, no parts are missing and the content complies with the order.

NOTE

Non-compliance must be reported to Westcar and it’s distributor within

eight days from the receipt date.

3.1.6

To store the coupling, observe what set out in section 3.3. STORAGE OF THE

COUPLING.

The transport the of coupling with packaging has thus ended; now it is

possible to follow the steps described in the next section.

Part 3 - tranSPort and inStallationROTOMEC USe and Maintenance handbook

25

P

ow e r

T

ra n s m i s s i o n

To handle the hydromechanic coupling without its package, it is necessary to follow

this procedure:

The handling and transport operations are reserved to handling technicians

equipped with suitable personal protective equipment (protection gloves,

safety shoes). DANGER OF CRUSHING.

3.2.1

Take the instructions and follow the description.

CAUTION

RISK OF CUSHING. In order to hoist and handle the hydromechanic

coupling, use the suitable lugs and devices recommended by the manufac-

turer, available on request; do not use any other reference than the equip-

ment and lifting points recommended by the manufacturer.

3.2.2 - For couplings with more than 30 kg of weight:

The hydromechanic coupling is located inside its packaging with its axis in verti-

cal position. Screw in the threaded pin equipped with hoisting ring in the extrac-

tion hole of the coupling.

3.2.3

Sling the coupling through the hoisting ring with hoist lines of suitable load

capacity for the coupling weight (see Identication Plate).

3.2.4

By slow movements, lift the coupling and transfer it to a dry, sheltered place and lay it

on a wooden plane next to motor and drive end, where the coupling will be installed.

The transport of the coupling without packaging has thus ended; now it is

possible to follow the procedure as set out in the next section.

3.2 HANDLING OF THE COUPLING WITHOUT PACKAGE

3.2.2

3.2.3

3.2.4

3.2.1

Part 2 - WarningS and PreScriPtionS ROTOMEC USe and Maintenance handbook

Original Instructions

WESTCAR s.r.l.

ViaMonte Rosa 14

20149- MILANO

Tel.+39-02-76110319

Fax+39-02-76110041

www.westcar.it

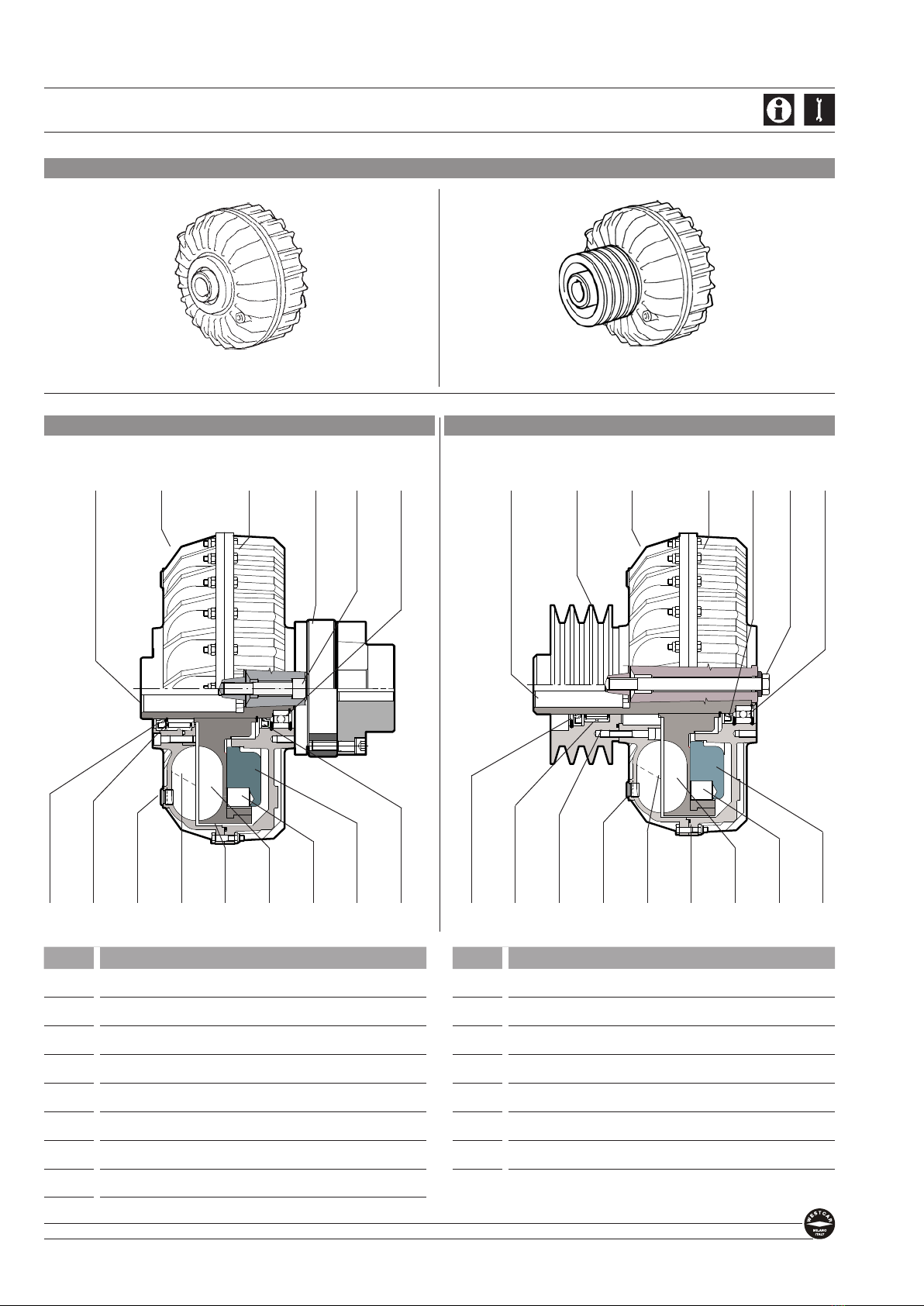

Constant-fill

HYDRO

MECHANIC

COUPLINGS

ROTOMEC

®

ROTOMECALFA

ROTOMECBETA

M2021-ENG- ed. 2021-02