Page 2

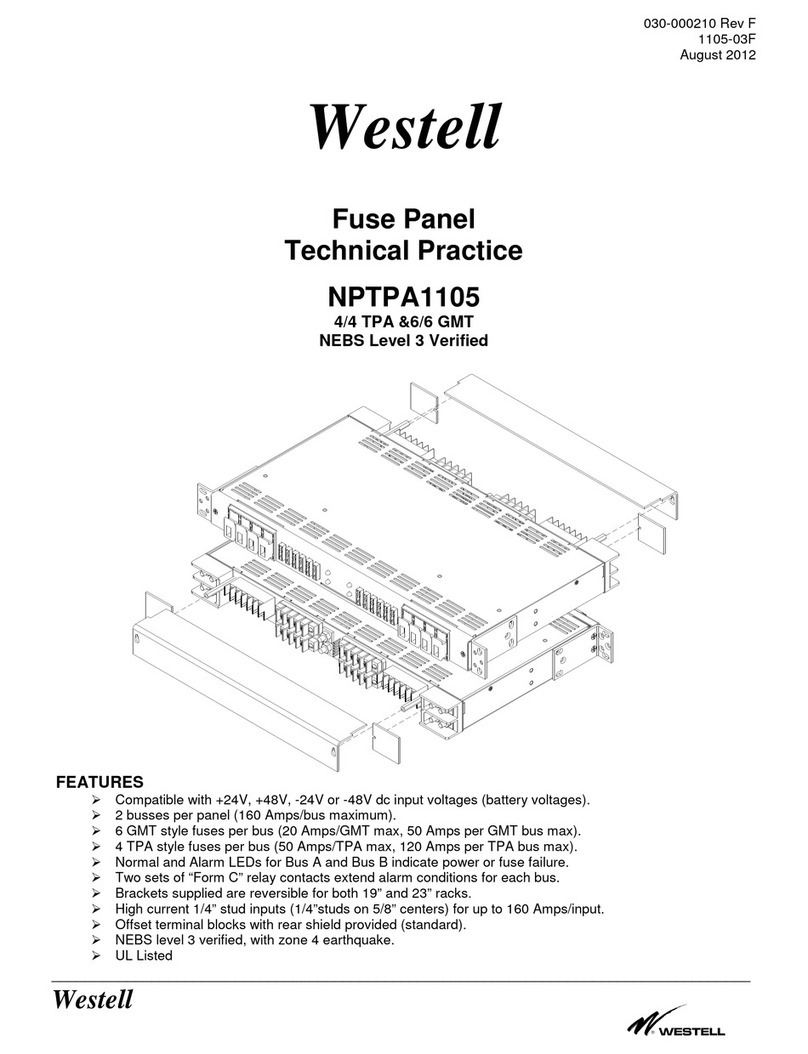

1. GENERAL DESCRIPTION

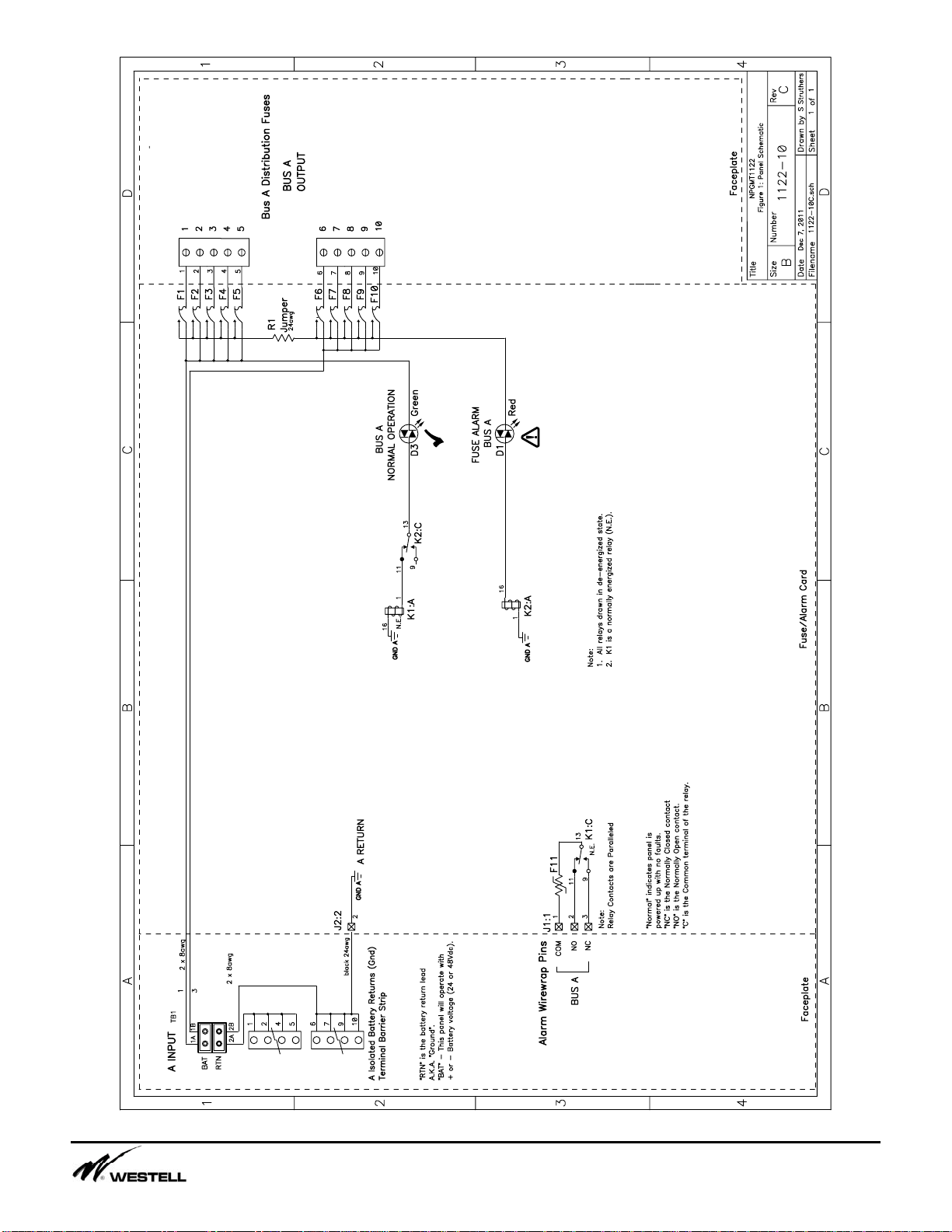

1.1. The NPGMT1122 Fuse Panel provides up

to 10 circuits for the distribution of DC power to

equipment. Each of the 10 circuits is

individually protected by a GMT style

telecommunication fuse located on the panel's

faceplate. Alarm circuits are provided to

indicate and extend alarm conditions when

faults occur. Normal Operation LEDs are

provided to indicate the status of each bus in

the panel.

1.2. Input wiring is connected to a high current,

2-hole lug input block located on the front of the

panel.

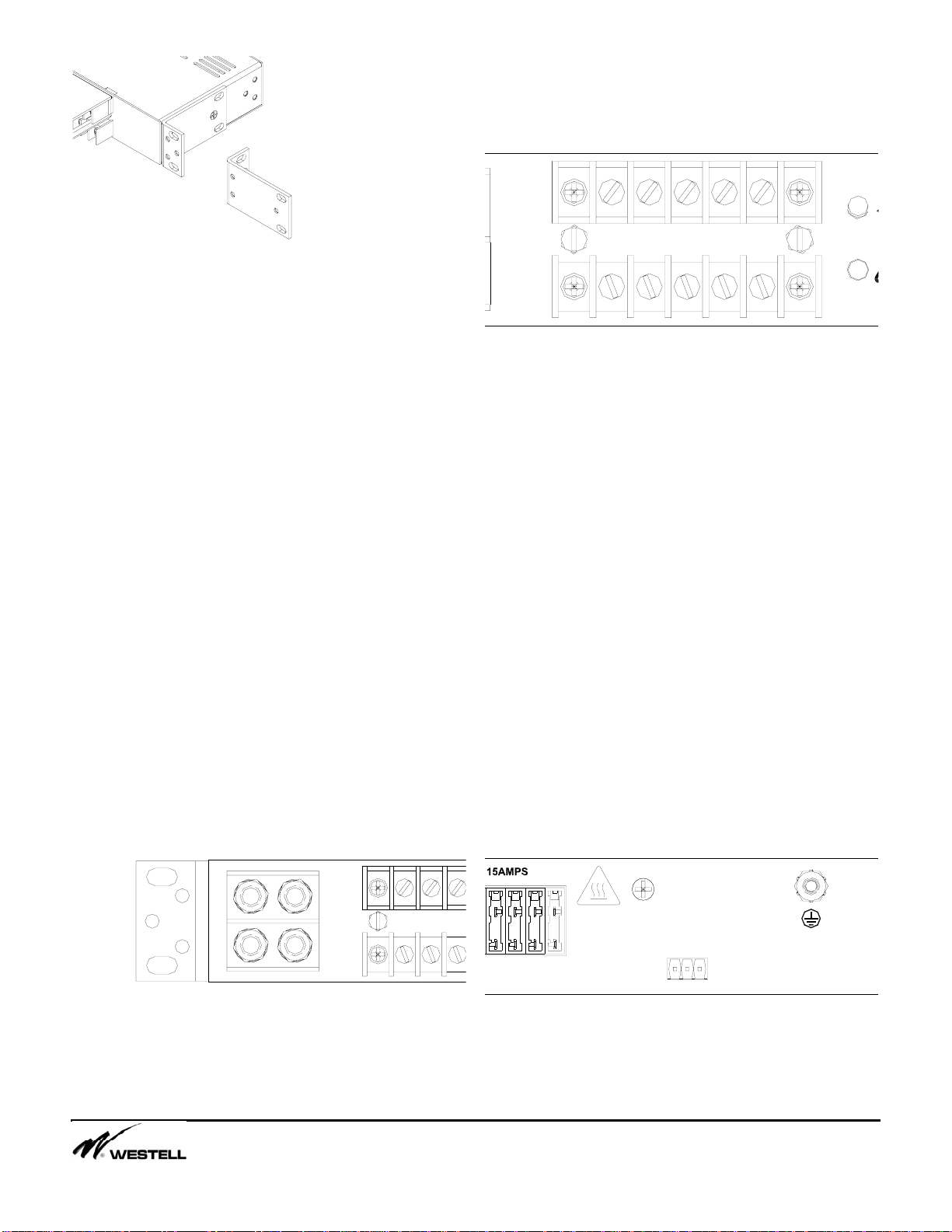

1.3. The power is distributed to the load side

equipment through GMT style fuses. There are

a total of 10 fuses per panel. (See Figure 3.2.1)

Each fuse position is available for installer

connection on the front of the panel. (See

Figure 4.5.1) A designation card is provided for

keeping records of which position is connected

to which equipment and what amperage is to

be used.

1.4. Alarm circuits are provided to alert service

personnel of fault conditions. A fuse alarm is

caused when any of the GMT distribution fuses

opens. A red fuse alarm !LED on the

faceplate will illuminate and the green Normal

Operation 9 LED will extinguish to signal a

fuse alarm and also the appropriate relay

contacts will change states. (See Figure 3.2.1)

The fuse panel has common (C), normally

open (NO) and normally closed (NC) terminals

for alarms. Note, the use of the alarm

contacts is optional, if you do not wish to

extend the alarms, you don’t have to do

anything with the alarm pins. (See Figure

4.7.1)

The “Normal” condition of the relay exists when

the panel is powered up without any blown

fuses.

If input power is lost the 9 LED will extinguish

and the alarm relay will indicate an alarm.

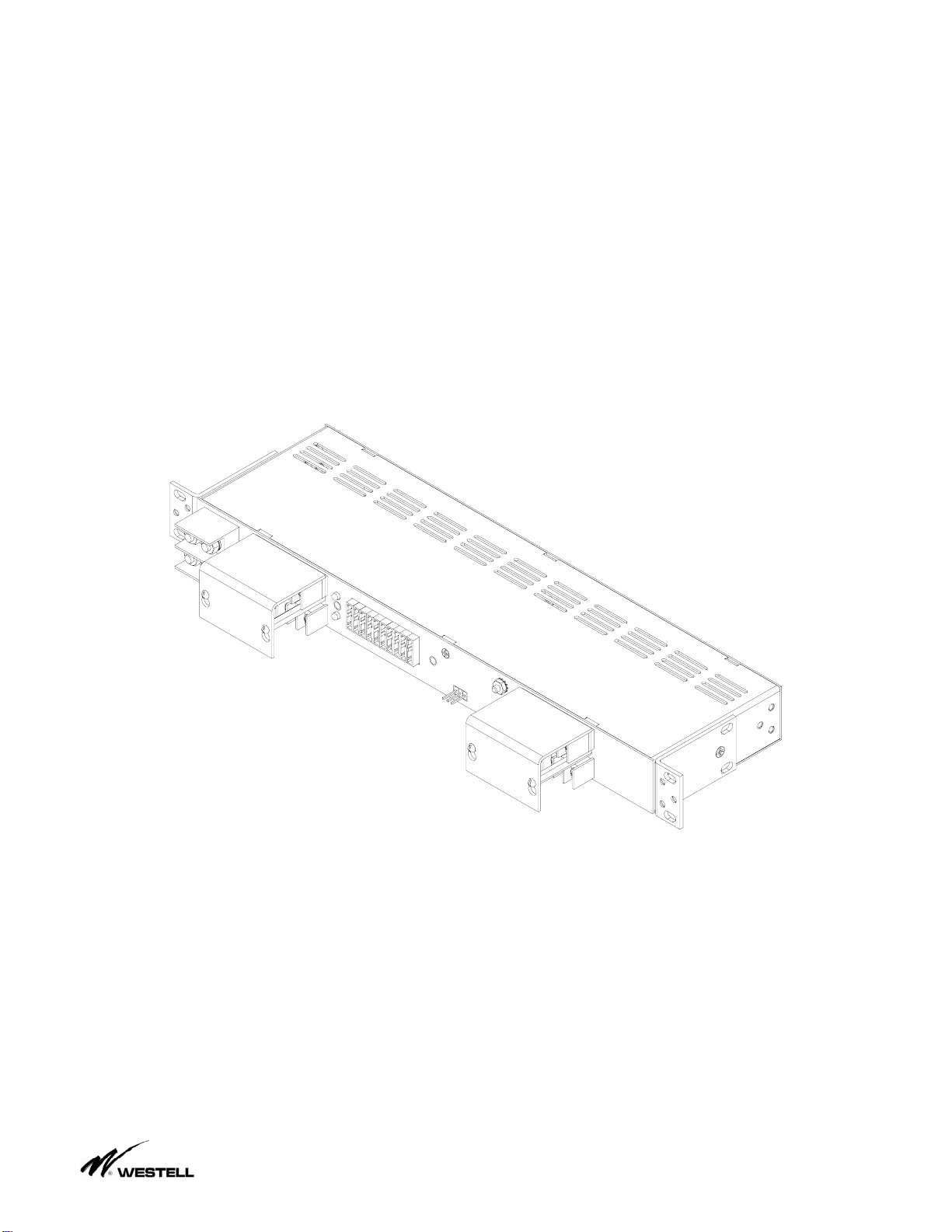

1.5. The NPGMT1122 fuse panel is made from

0.050" steel and painted off white. This panel is

shipped universal brackets that will fit both 19"

and 23" wide racks and uses only one 1.75"

panel spaces. The panel has two clear L

shaped shields to protect the wiring

connections on the front of the panel. (See

Figure 1.6.1)

Figure 1.6.1

2. APPLICATION

2.1. The NPGMT1122 Fuse Panel is designed

to be used in the distribution of DC power.

They are rack mount panels that can provide

fused DC power to up to 10 individual circuits.

3. CIRCUIT DESCRIPTION

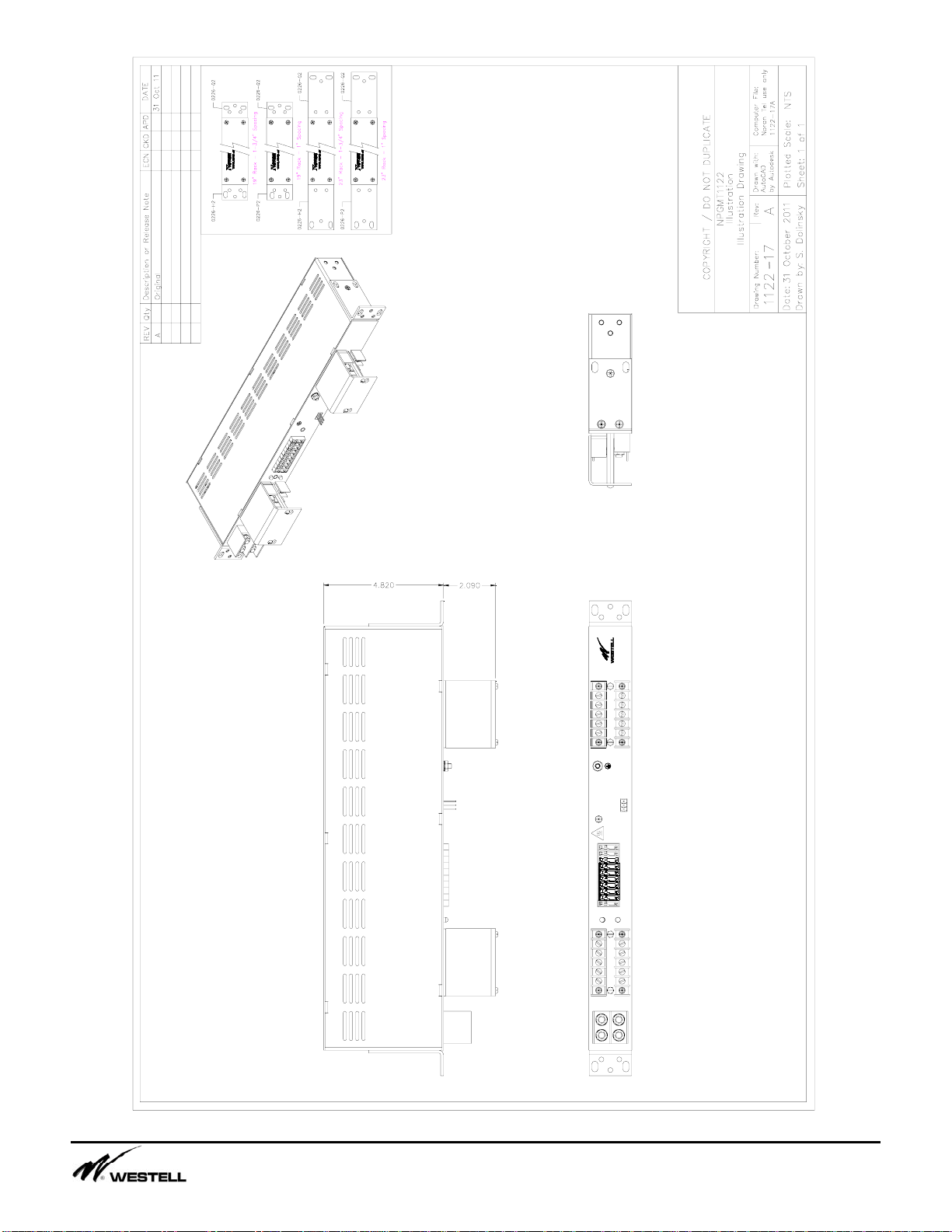

3.1. Power is connected to the fuse panel via

¼” studs on 5/8” centers located on the front of

the panel (Torque 36 in-lbs). This input is a

high current stud block that supplies current to

the fuse panel. Connect the battery return

cable to the stud input that is labeled “RTN”

and the Battery supply cable is connected to

the terminals labeled “BAT”.

3.2. Distribution of current is provided by GMT

style fuses. Each panel has 10 fuse holders for

distribution, the fuses are labeled 1 to 10.

(See Figure 3.2.1) Each fuse position is made

available on the front of the fuse panel.

Maximum output current of each fused position

is 10.5 Amps for a 15 Amp fuse. The input

must be fused at the BDFB at 100Amps max.

Load current should not exceed 70% of the

fuse capacity. Fuses should be sized at at

least 1.5 times the maximum current draw of

the equipment.