____________________________________________________________________________________

Westell

4

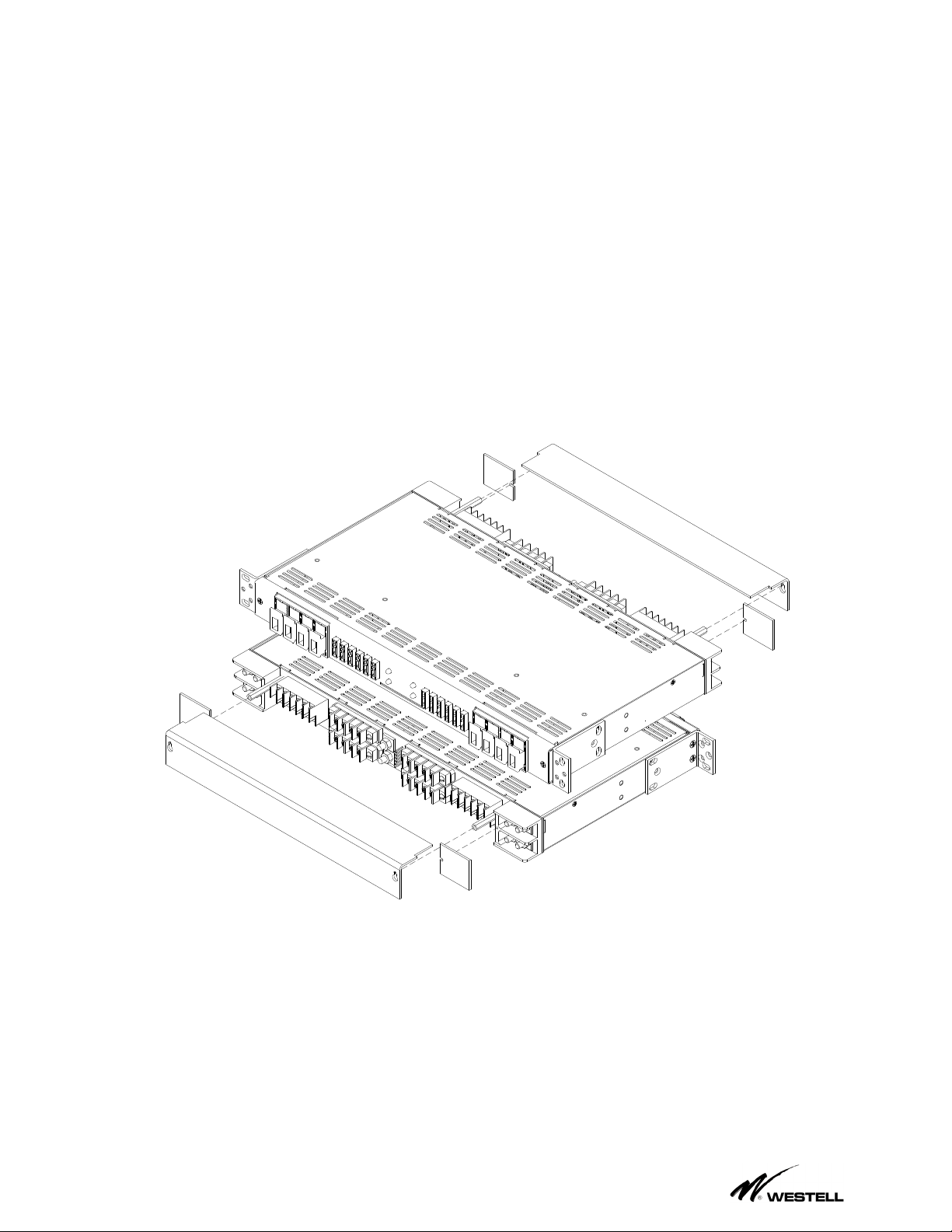

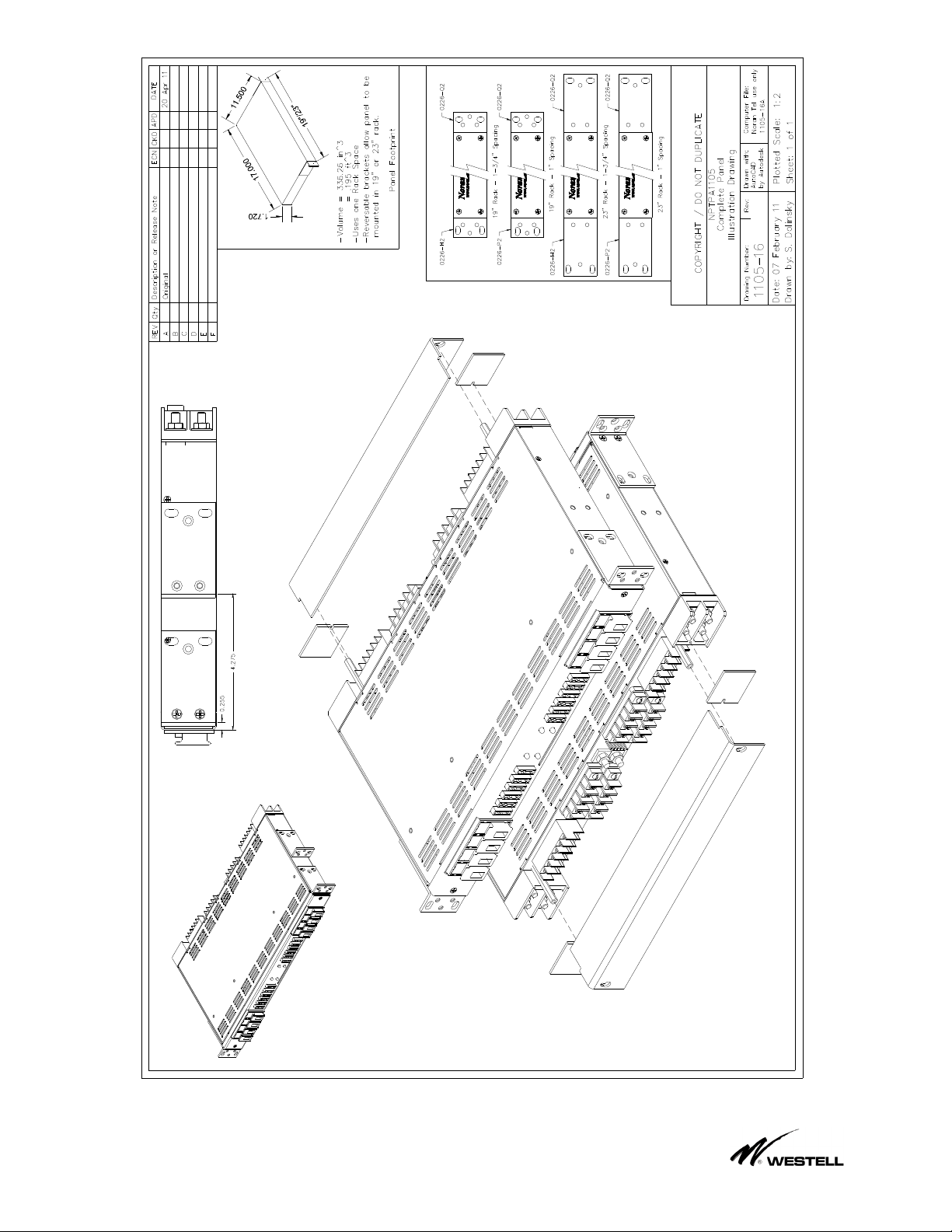

universal for 19” and 23” rack mount spacing

(see figure 4.2.1) and can be mounted so the

panel can be installed for a flush mounting or

5” offset. Adjust the position and orientation of

the correct mounting brackets on the fuse

panel, such that it will fit the rack you wish to

mount the panel in. Please see drawing 1105-

16 on page 8 for mounting bracket

configuration.

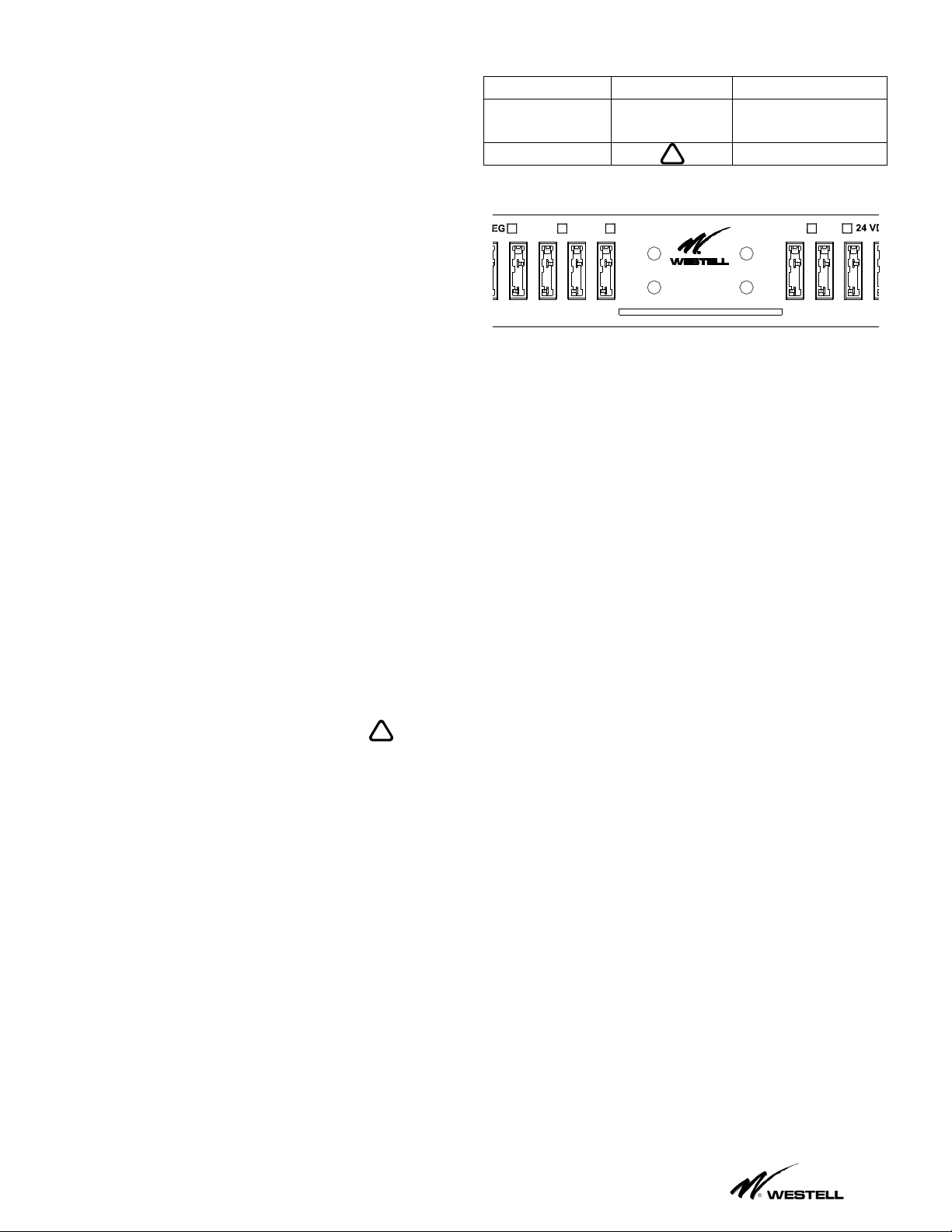

19" Mounting Position

23" Mounting Position

Figure 4.2.1

4.3. Mount the fuse panel in the required

position on the rack using the thread forming

rack screws and tooth lock washers provided.

WARNING:For safety reasons, all wiring

should be performed with the power source

removed, and performed by a trained Installer

experienced with DC power systems.

Note: A readily accessible disconnect device

shall be incorporated in the building

installation wiring.

4.4. Remove the distribution fuse feeding the

input cables that are to be connected to the

new panel. Attach the input cables to the

input terminal block in accordance to the

National Electrical Code, ANSI/NFPA, and

Canadian Electrical code. Hook up the input

cables to the input terminal block on the fuse

panel (“BAT” & “RTN” for each bus). Each

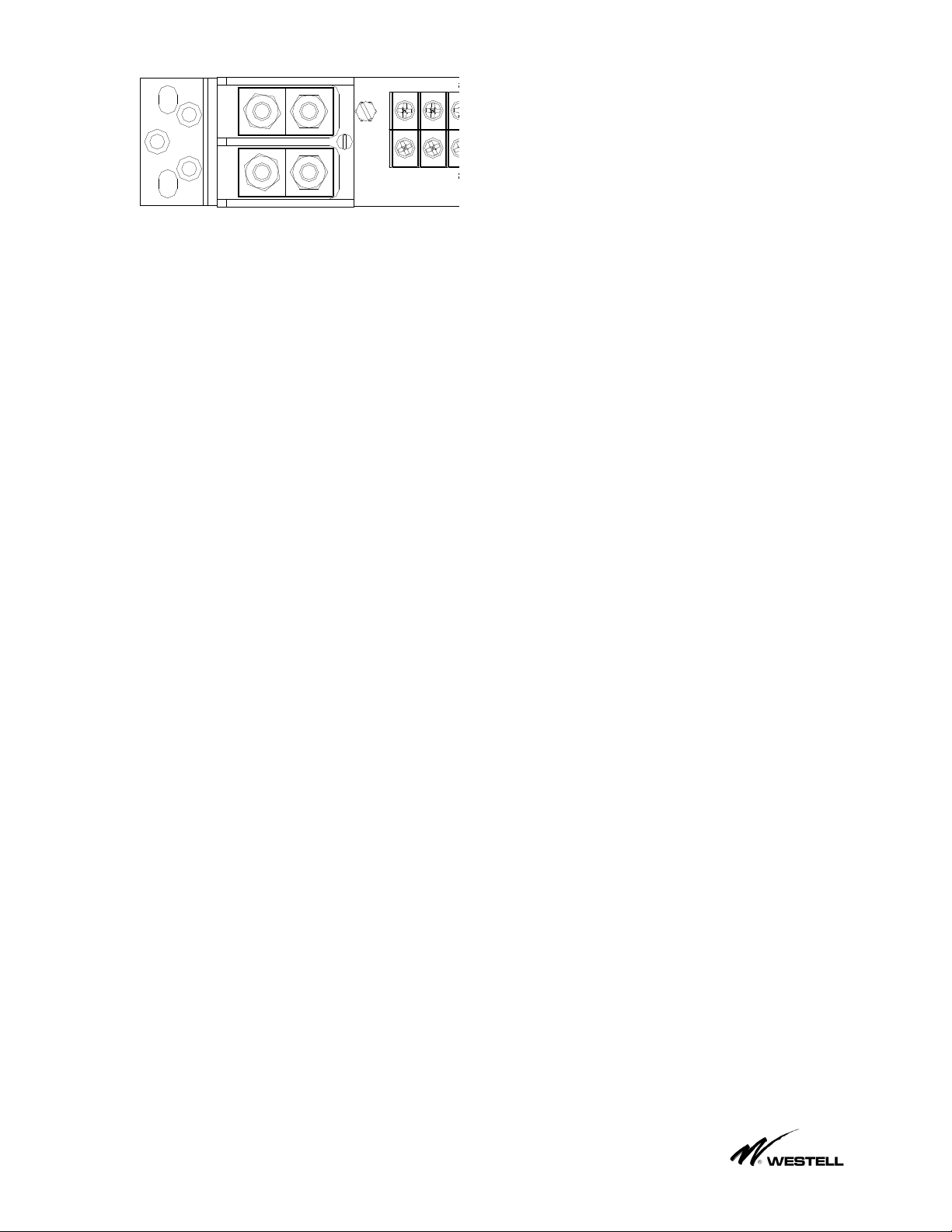

high current input terminal uses a two hole

compression lug (1/4” on 5/8”, torque to 5.5 ft-

lbs). A two hole lug must be used for proper

operation

4.5. The fused battery outputs (BAT) and

ground returns (RTN) are also located on the

back of the panel. Each fuse holder and

terminal position is individually numbered.

Connect your load side equipment to the fuse

panel, and record which equipment is

connected to which input on the designation

card (supplied).

4.6. Alarms; There are three connections for

each of the alarm relays; common (C),

normally open (NO), and normally closed

(NC). Connect the alarm extension wires as

per your alarming scheme (22 or 24awg

typical). Example; Connect the signal that you

want extended in an alarm condition to the “C”

pin. When there’s an alarm, “C” will become

shorted to “NO”. Typically a ground is

connected to the “C”, and the “N.O.” signal is

extended to the alarm monitoring system,

providing a “Ground Alarm”. A “Bus Alarm” is

caused by a fuse failure or an input power

failure on that bus. “Normal” indicates the

state when the panel is powered up with no

blown fuses. The three relay contacts are dry,

so you can parallel the contacts, etc. Please

limit the current thru the relays to 1Amp or less

(Alarm Battery Supply fuse should be 1 Amp

max). Alarm extensions discussed above, are

optional; only use them if you wish (see 3.4 for

details).

4.7. Chassis Ground; for safety reasons, the

chassis should be electrically connected to the

rack ground. From step 4.3, the panel should

already be bonded to the rack via the #12-24

thread forming rack screws and outside tooth

lock washers. In addition to grounding via the

mounting brackets, an appropriate cable size

as outlined in section 5 (typically 10awg or

larger) and the ¼” bolt and locks on rear of

chassis (1/4” bolt torque;5.5ft-lbs or 7.5Nm)

should also be used. Consult the National

Electric Code, ANSI/NFPA, and Canadian

Electrical code for AWG sizes.

4.8. The input wiring feeding this panel should

be protected by a Listed fuse/breaker rated for