INSTALLATION MANUAL

20221594 / B iii

Contents

1INTRODUCTION ................................................................5

2INSTALLATION..................................................................5

2.1 Mechanical installation ........................................................5

2.2 Cabling .............................................................................5

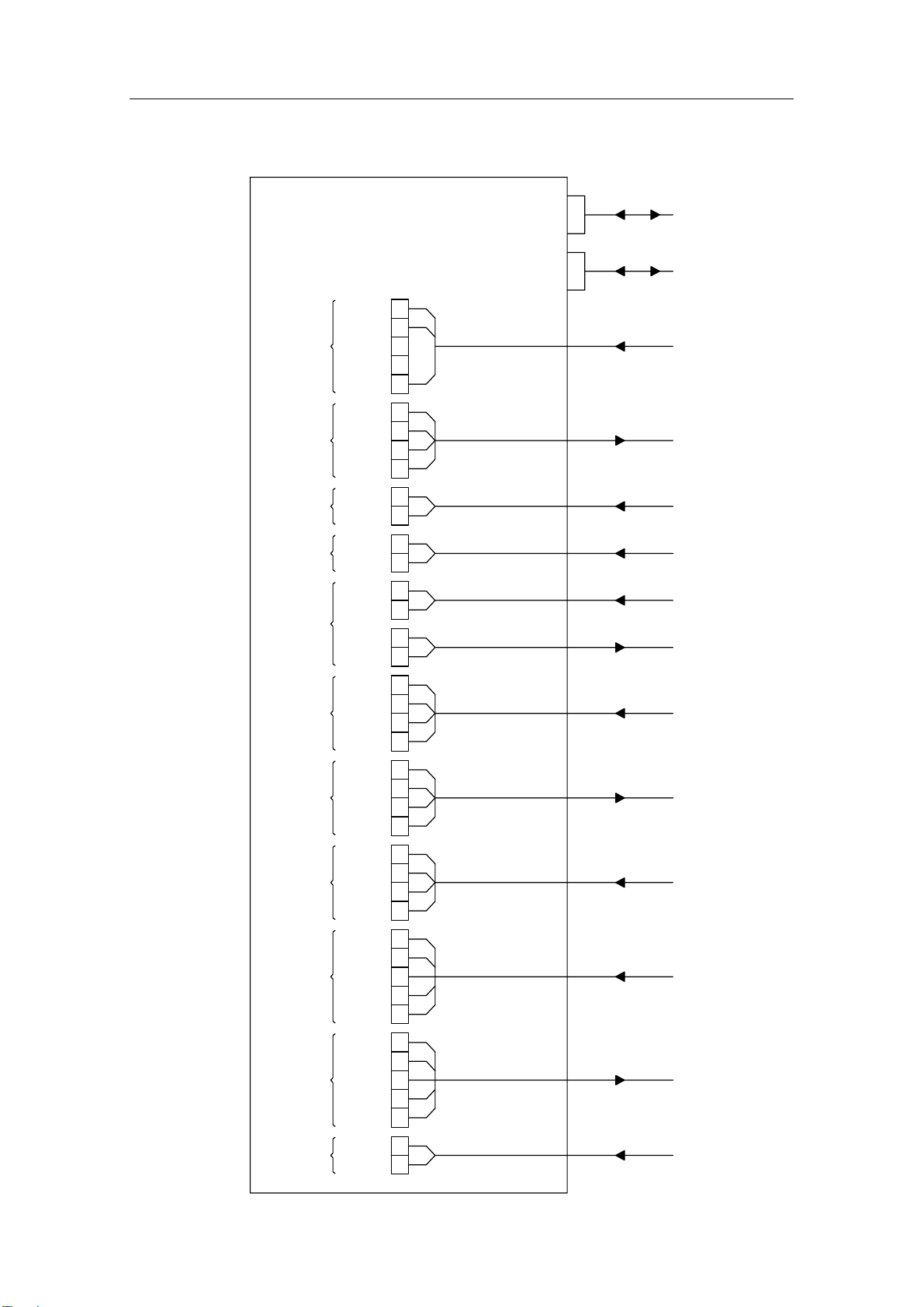

GI51 Block diagram .......................................................6

2.3 Dip switch settings..............................................................7

2.4 Interface setup procedure....................................................8

2.5 Offset adjustment...............................................................8

2.6 Calibration.........................................................................9

2.7 Initial heading and heading change test ............................... 10

2.8 S9 Steering lever.............................................................. 11

3GI51 PCB ........................................................................12

3.1 Component location .......................................................... 12

3.2 Terminal description ......................................................... 13

TB1, Power................................................................. 13

TB2, Sin/Cos Out ........................................................ 13

TB3, Synchro In .......................................................... 13

TB4, NFU ................................................................... 13

TB5, Step Out............................................................. 13

TB6, Step In............................................................... 14

TB7 and TB8, NMEA..................................................... 14

TB9, RGC proprietary................................................... 14

TB10, LOG ................................................................. 14

TB11, Radar ............................................................... 14

TB12, Selector ............................................................ 15

4PENDULUM FUNCTION KEY (OPTION).............................16

5TROUBLE SHOOTING .......................................................17

5.1 LED indicators.................................................................. 18

6SPARE PARTS ..................................................................19

7TECHNICAL SPECIFICATIONS .........................................20

7.1 Hardware ........................................................................ 20

7.2 Supply ............................................................................ 20